When it comes to the maintenance and efficiency of lawn care equipment, having a clear understanding of the essential components is crucial. This segment delves into the intricate elements that make up the mowing apparatus, offering insights into their functions and interrelationships. By familiarizing yourself with these details, you can enhance your ability to troubleshoot and perform maintenance effectively.

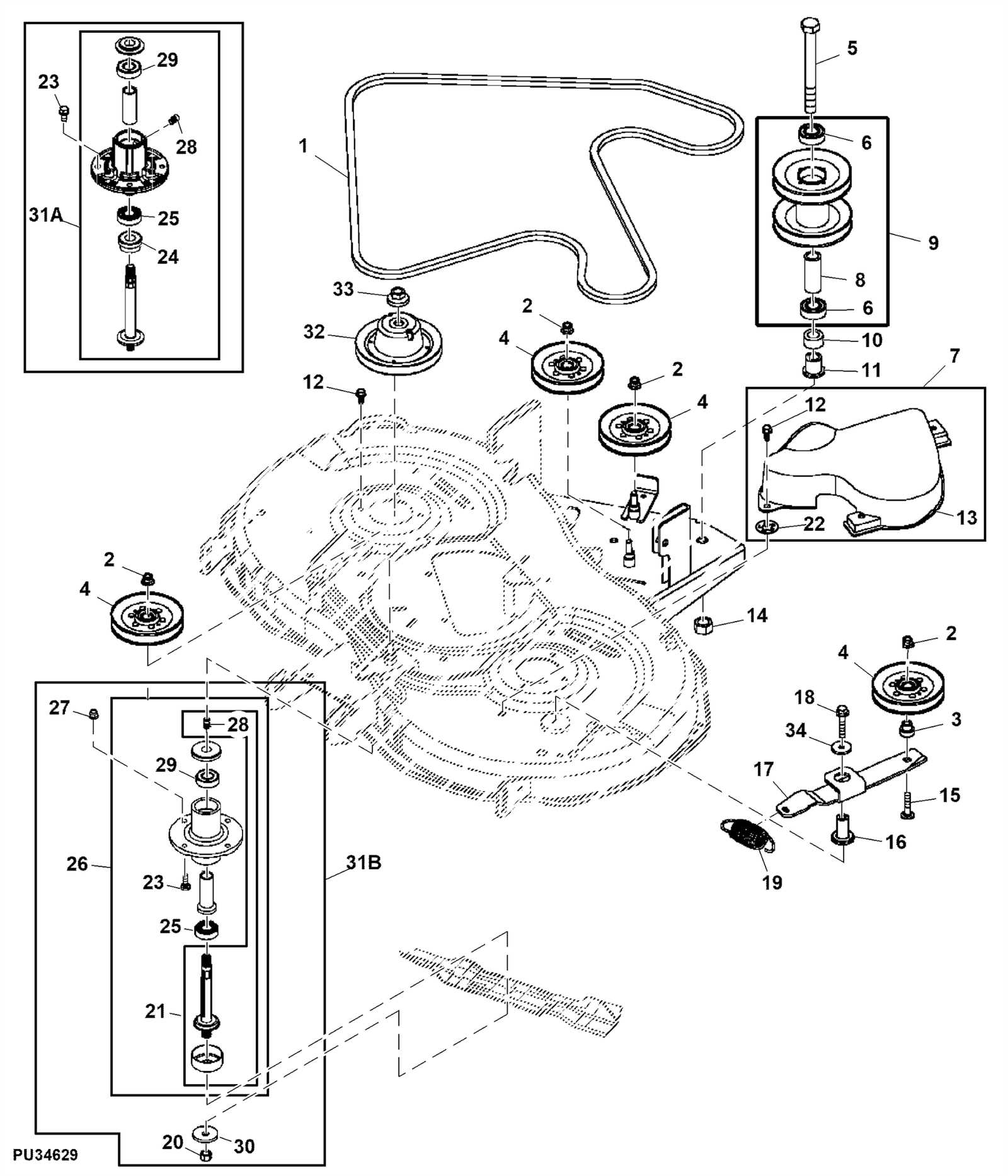

Each segment of the mowing machinery plays a pivotal role in its overall performance. From the cutting blades to the housing structure, every component is designed to work in harmony, ensuring a smooth operation. A comprehensive overview of these elements not only aids in proper care but also empowers users to make informed decisions regarding repairs and upgrades.

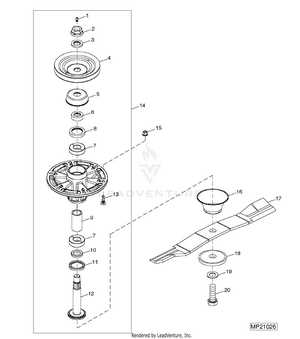

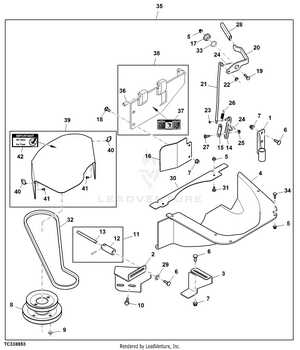

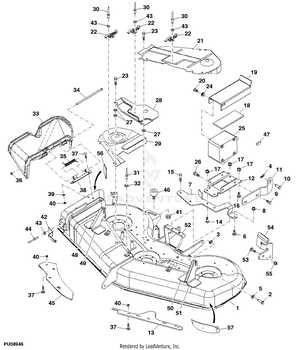

In this exploration, we will break down the various components, providing a visual representation that highlights their arrangement and connection. This guide aims to serve as a valuable resource for enthusiasts and professionals alike, equipping them with the knowledge needed to optimize their lawn care experience.

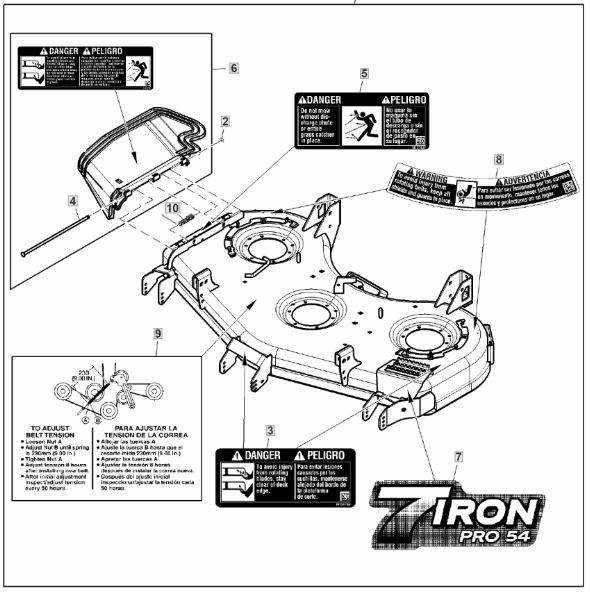

Understanding John Deere 7 Iron Deck

This section explores the intricate structure and components of a well-known mowing system, highlighting its efficiency and durability. The focus is on how the design elements contribute to optimal performance and longevity in various mowing conditions.

Key Features

- Robust construction that withstands wear and tear.

- Innovative design for improved cutting efficiency.

- Easy maintenance access for quick servicing.

Benefits of the System

- Consistent grass cutting for a pristine lawn appearance.

- Enhanced performance in diverse terrains.

- Reduction in downtime due to reliable engineering.

Understanding these elements can aid in making informed decisions regarding maintenance and upgrades, ensuring that users get the most out of their mowing experience.

Key Features of the 7 Iron Deck

The innovative cutting platform offers a blend of efficiency and performance, ensuring a superior mowing experience. Designed for durability, this system enhances overall functionality while maintaining ease of use.

Enhanced Cutting Performance: The design promotes a consistent cut, allowing for even grass height and a polished appearance.

Robust Construction: Built with high-quality materials, this setup withstands rigorous conditions, providing longevity and reliability.

Ease of Maintenance: Features allow for straightforward cleaning and servicing, ensuring optimal performance without significant effort.

Adjustable Height Settings: The flexibility in cutting heights enables users to customize their mowing experience based on specific lawn needs.

In conclusion, this platform stands out for its unique combination of durability, efficiency, and user-friendly design.

Importance of Proper Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of any equipment. Neglecting maintenance can lead to diminished efficiency, increased wear, and costly repairs. Establishing a routine care schedule not only safeguards your investment but also enhances safety and functionality.

One of the key aspects of maintenance is the inspection of moving components. By identifying wear and tear early, you can prevent more severe issues down the line. Below is a summary of maintenance tasks that should be prioritized:

| Task | Frequency | Benefits |

|---|---|---|

| Lubrication of moving parts | Every 20 hours | Reduces friction, extends life |

| Blade sharpening | Every 25 hours | Improves cutting efficiency |

| Check belt tension | Monthly | Ensures proper operation |

| Fuel and oil changes | Every season | Maintains engine performance |

Investing time in proper maintenance routines not only prolongs the life of your machinery but also enhances its performance and reliability, providing a better overall experience.

Common Issues with Deck Parts

Maintenance and performance of outdoor machinery often hinge on the efficiency of various components. These elements can face a range of challenges that affect overall functionality. Identifying and addressing these issues promptly can lead to smoother operation and increased longevity.

Typical Problems Encountered

- Wear and Tear: Continuous use can lead to degradation, affecting cutting efficiency and overall performance.

- Misalignment: Components may become misaligned over time, resulting in uneven cuts and increased strain on the machinery.

- Corrosion: Exposure to moisture and harsh conditions can lead to rust, which compromises integrity and performance.

Signs of Trouble

- Inconsistent cutting height.

- Unusual noises during operation.

- Vibrations that were not previously present.

Monitoring these common issues can help maintain optimal performance and prevent costly repairs. Regular inspection and timely maintenance are key to ensuring that everything operates as intended.

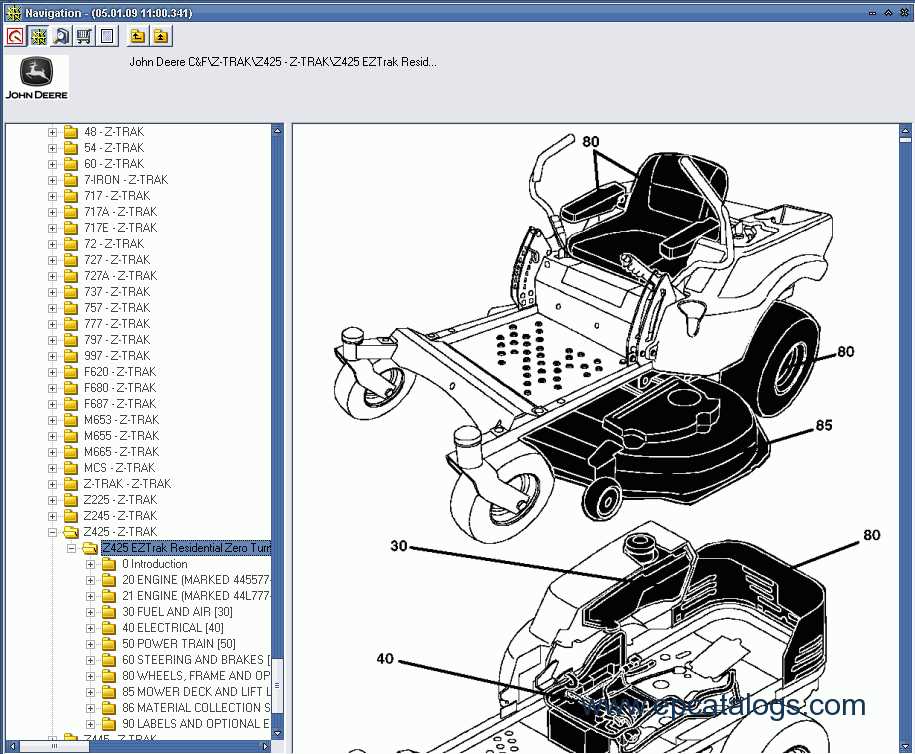

How to Identify Replacement Parts

Finding the right components for your machinery can be crucial for maintaining optimal performance. Knowing how to accurately identify and source the necessary elements ensures that your equipment runs smoothly and efficiently. Here are some effective strategies to help you pinpoint the correct replacements.

Check the Model Number

The first step in identifying suitable replacements is to locate the model number of your equipment. This number typically appears on a label or plate, often found in a visible area. Recording this information will aid in searching for compatible components and streamline the replacement process.

Utilize Online Resources

There are numerous online platforms and databases dedicated to machinery and equipment. These resources often provide comprehensive catalogs, allowing users to search by model number or specific needs. Additionally, community forums can offer insights from experienced users who may have encountered similar issues.

| Identification Method | Description |

|---|---|

| Model Number | Locate the model number on the equipment for accurate matching. |

| Online Catalogs | Use digital databases to find specifications and compatible items. |

| Community Forums | Engage with other users for advice and shared experiences. |

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that contribute to optimal performance and longevity. These elements are specifically designed to meet the precise specifications of the equipment, ensuring a perfect fit and reliable operation. By opting for genuine items, users can experience enhanced efficiency and reduced risk of failure.

Quality Assurance

- Manufactured to strict standards

- Thorough testing for durability

- Consistent performance under various conditions

Long-Term Cost Savings

- Minimized need for replacements

- Reduced likelihood of repairs

- Improved resale value of equipment

Investing in authentic components is not just about immediate needs; it ensures the equipment remains in optimal condition for years to come, ultimately providing peace of mind to the user.

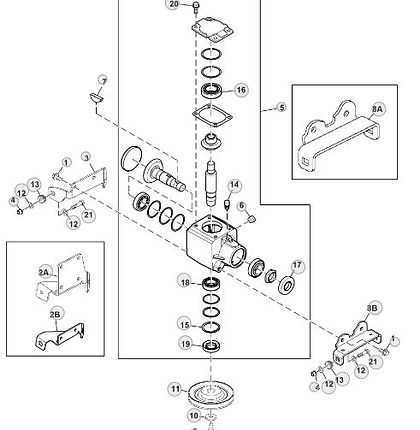

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing essential components of your lawn maintenance equipment. By following these detailed steps, you can ensure optimal performance and longevity of your machinery.

Tools and Materials Needed

- Wrenches

- Screwdrivers

- Replacement components

- Lubricating oil

- Cleaning supplies

Repair Steps

- Preparation: Begin by ensuring the equipment is turned off and disconnected from any power source.

- Inspection: Examine all visible components for signs of wear or damage. Take note of any parts that need replacement.

- Disassembly: Carefully remove any screws or bolts securing the affected parts. Keep track of all fasteners for reassembly.

- Replacement: Install the new components, ensuring they fit securely and are aligned properly.

- Lubrication: Apply lubricating oil to moving parts to minimize friction and wear.

- Reassembly: Reattach all components and fasteners in the reverse order of disassembly.

- Testing: Once reassembled, conduct a test run to ensure everything is functioning correctly.

By adhering to this guide, you can maintain the efficiency and reliability of your lawn equipment, minimizing downtime and maximizing performance.

Tools Needed for Deck Maintenance

Proper upkeep of your mowing equipment requires a selection of essential tools to ensure optimal performance and longevity. Regular maintenance helps prevent breakdowns and enhances the efficiency of your machinery, making it crucial to have the right instruments at your disposal.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To adjust and secure various components. |

| Socket Set | Useful for more efficient fastener management. |

| Cleaning Brush | To remove debris and buildup from surfaces. |

| Grease Gun | For applying lubricant to moving parts. |

| Safety Goggles | To protect eyes during maintenance tasks. |

| Oil Can | For maintaining proper lubrication of components. |

Having these tools readily available will streamline your maintenance routine and contribute to the effective operation of your mowing machinery.

Where to Find Parts Diagrams

Locating detailed visual references for machinery components is essential for effective maintenance and repair. These illustrations help users identify specific elements, ensuring they can obtain the correct items for their equipment. Whether for troubleshooting or routine upkeep, accessing reliable resources is key to successful management.

Online Resources

The internet offers a wealth of platforms dedicated to equipment support. Manufacturer websites frequently provide downloadable resources, including visual breakdowns of various models. Additionally, online forums and community groups can be invaluable, as experienced users often share their insights and resources.

Local Dealers and Repair Shops

Visiting authorized dealers or local repair shops can also yield beneficial information. These establishments typically maintain a library of technical resources and can assist in identifying the components needed for specific machinery. They may also provide access to proprietary materials not available online.