When it comes to maintaining your winter equipment, having a clear overview of its essential elements is crucial for effective servicing and repairs. Each segment of the machinery plays a vital role in ensuring optimal performance during the cold months. A well-structured guide to the various components can help users identify, troubleshoot, and replace any malfunctioning parts efficiently.

By familiarizing yourself with the individual elements that comprise your device, you can better understand how they work together to achieve desired results. This knowledge not only empowers you to conduct basic maintenance but also enhances your confidence when seeking assistance or ordering replacements.

Whether you are an experienced user or a newcomer, a thorough exploration of the intricate assembly will unveil the interconnected nature of the system. By recognizing the importance of each piece, you can ensure that your machinery remains in peak condition, ready to tackle whatever winter throws your way.

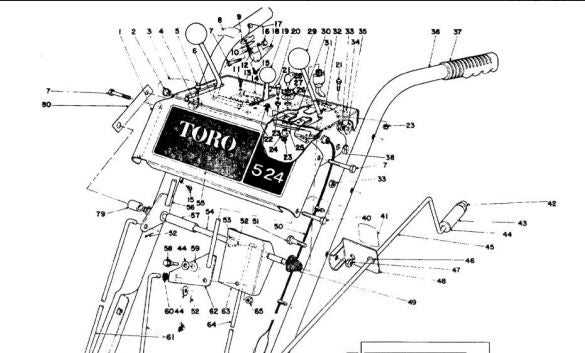

Understanding Toro Snowblower Components

When dealing with winter machinery, comprehending the various elements that contribute to its operation is essential. Each component plays a crucial role in ensuring efficient performance, allowing users to tackle snowy conditions with ease. A clear understanding of these parts not only aids in maintenance but also enhances the overall functionality of the equipment.

Key Elements of the Equipment

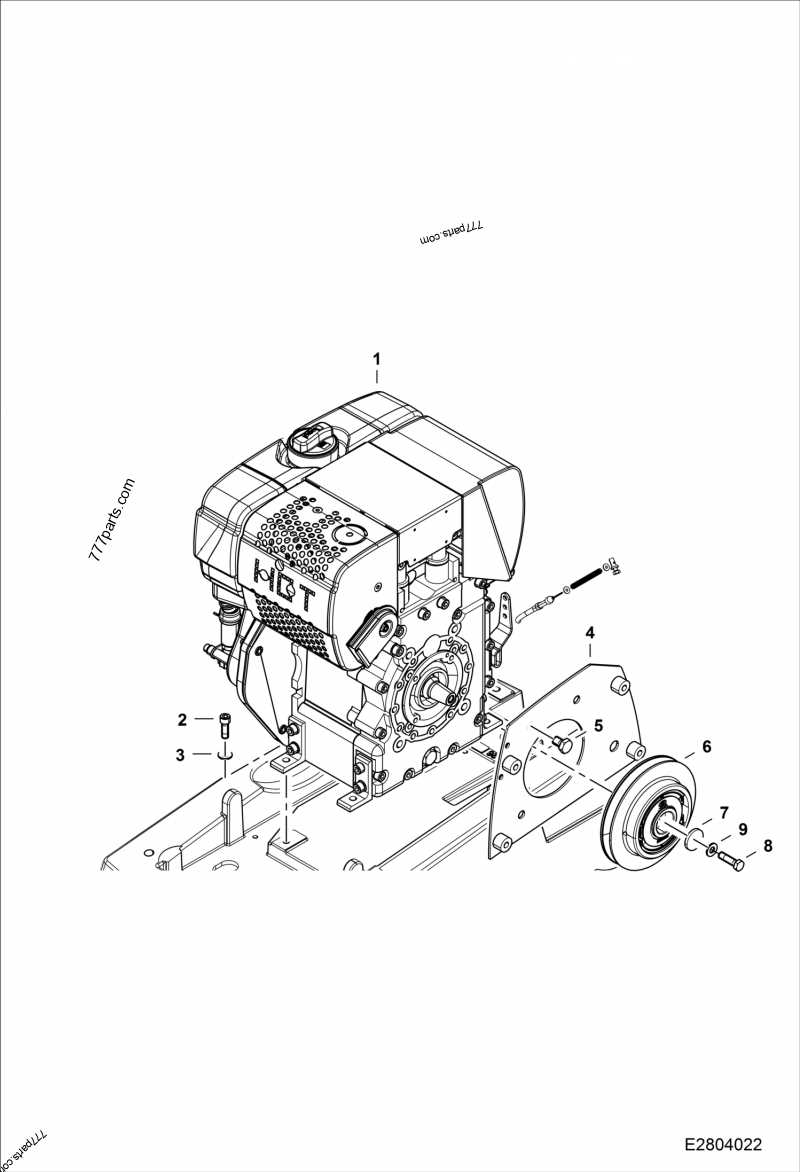

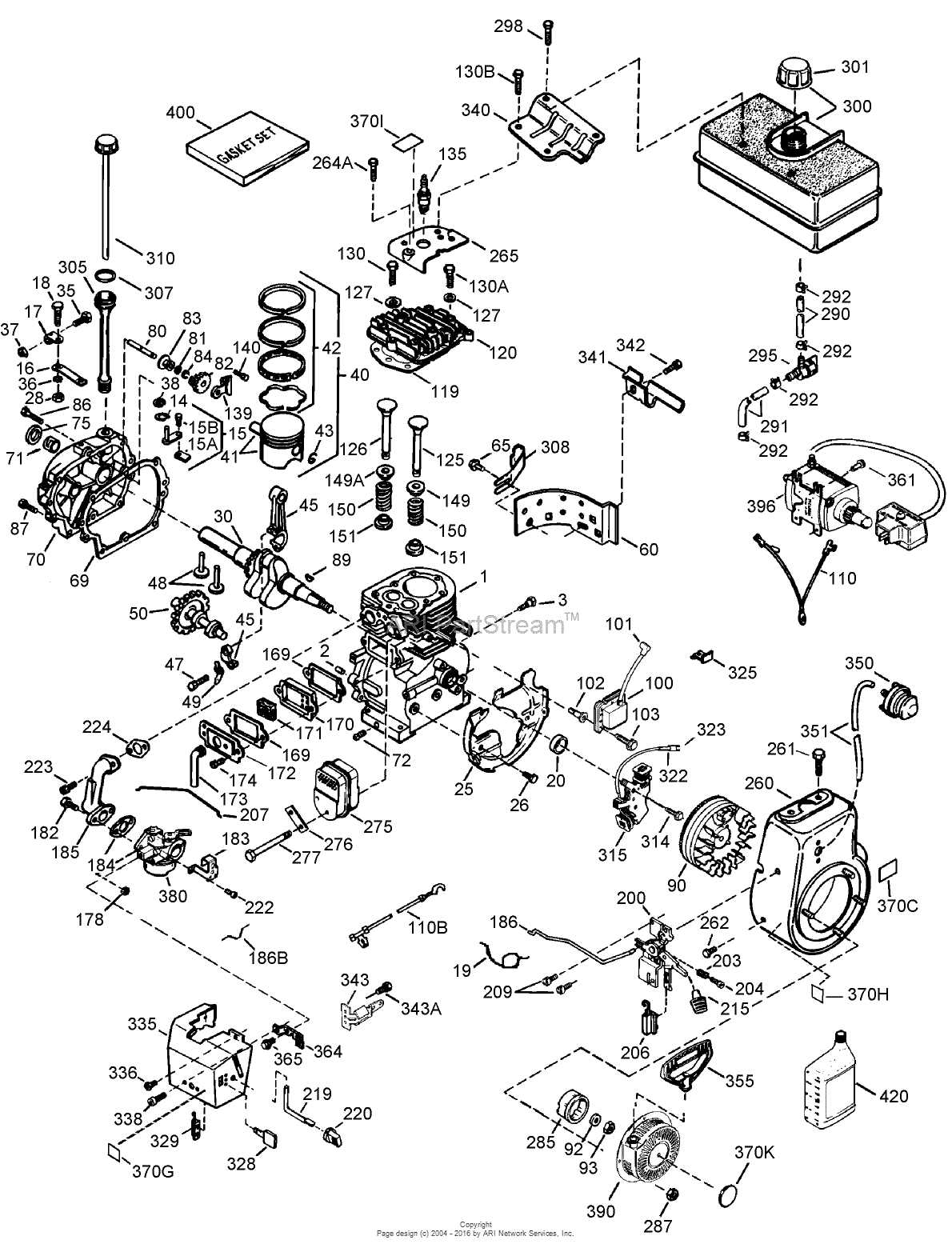

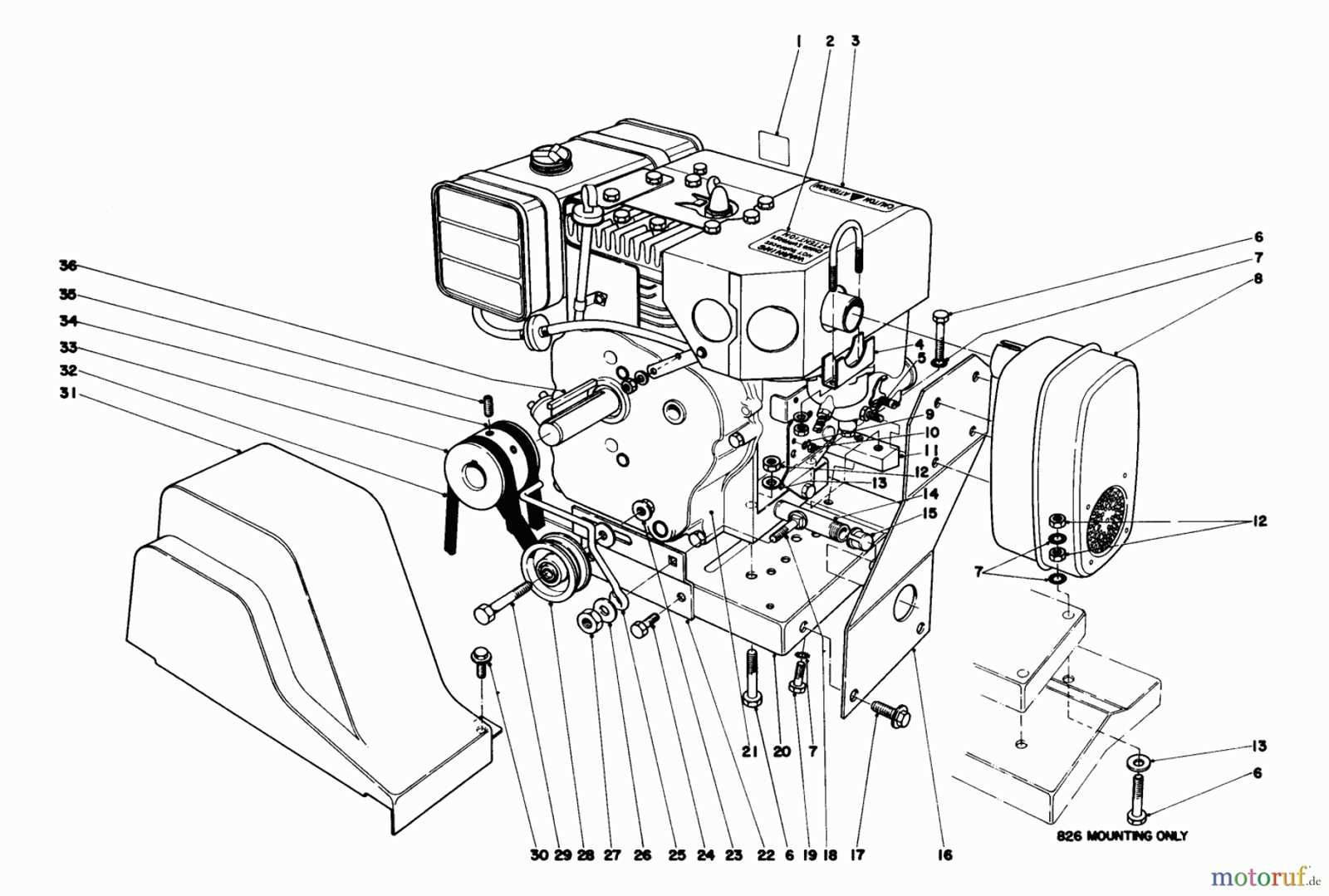

At the heart of any effective winter clearing machine is the engine, which provides the necessary power for operation. Coupled with the drivetrain, it translates energy into movement, enabling the user to navigate through challenging terrains. Additionally, the auger system is instrumental in gathering and propelling snow, while the chute directs the flow for optimal dispersion.

Maintenance and Care

Regular inspection of these essential components is vital for longevity. Checking the belts, bearings, and cables can prevent unexpected breakdowns. Furthermore, lubricating moving parts and replacing worn items promptly ensures that the equipment remains reliable and ready for action when the snow falls.

Key Parts of Toro Snowblowers

This section focuses on the essential components that ensure efficient operation during winter tasks. Understanding these elements can significantly enhance performance and maintenance.

- AUGER: This rotating mechanism is crucial for gathering and breaking up snow, facilitating smooth movement through heavy accumulations.

- IMPELLER: Positioned at the rear, this part aids in propelling snow out of the chute, ensuring effective clearing.

- CHUTE: Directs the flow of snow, allowing users to control where the snow is expelled, which is vital for maneuverability.

- DRIVE SYSTEM: Responsible for powering the unit forward, it can vary between self-propelled and push models, affecting ease of use.

- HANDLEBAR: Provides user control and comfort, often equipped with various controls for adjusting speed and chute direction.

Each component plays a significant role in overall functionality, making it essential for users to familiarize themselves with these elements for optimal performance.

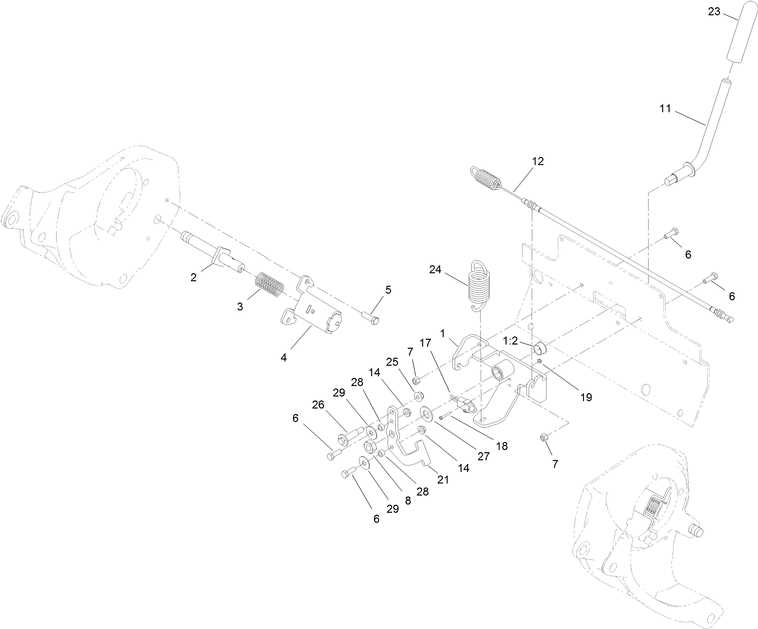

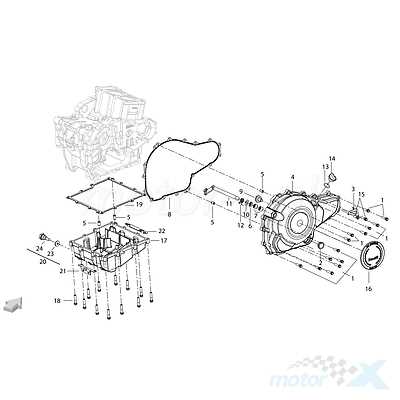

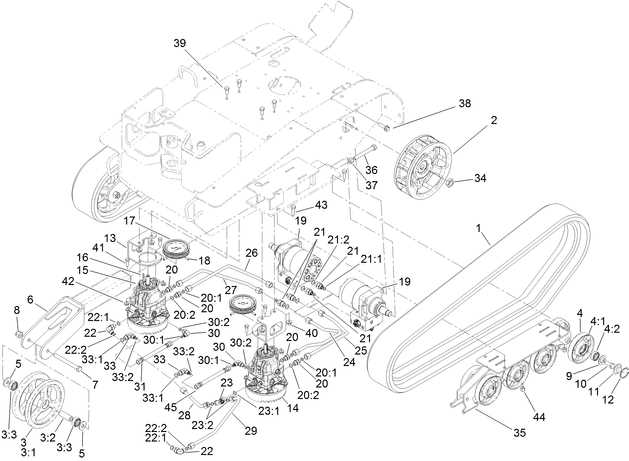

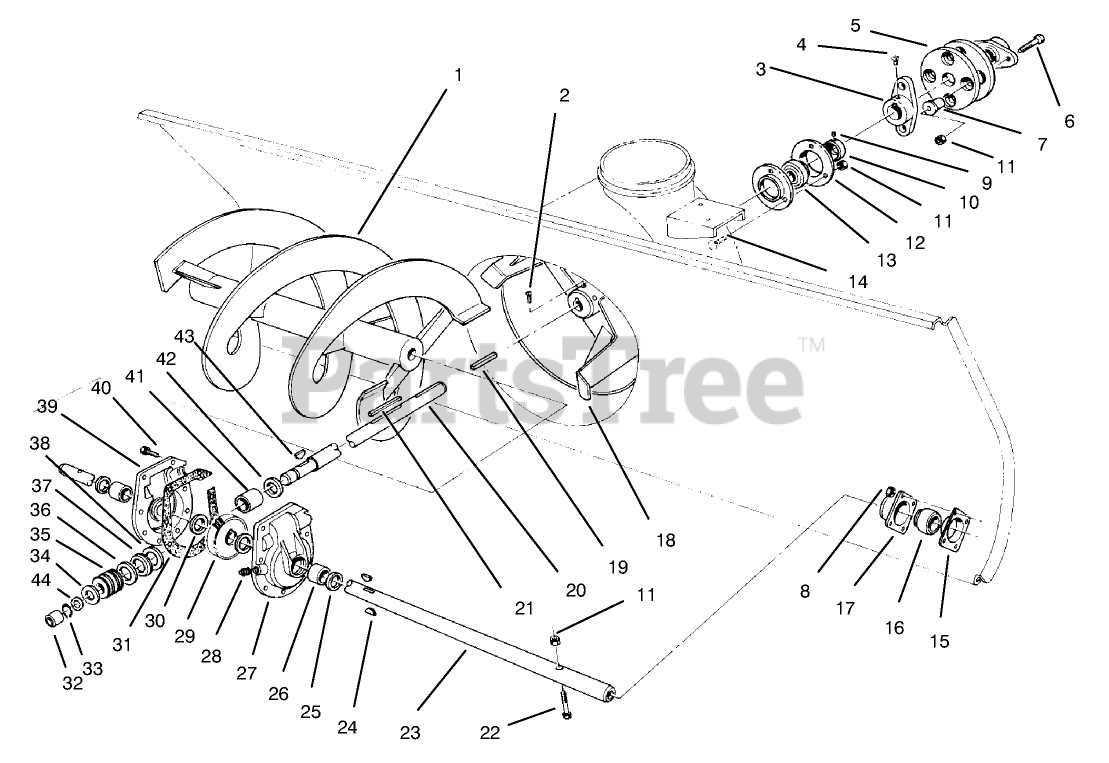

How to Read a Parts Diagram

Understanding the layout of components can significantly enhance your maintenance and repair experience. Familiarity with how these visuals represent individual elements allows for more efficient troubleshooting and assembly.

Follow these steps to effectively interpret the visual representation:

- Identify Key Symbols: Familiarize yourself with common icons that denote specific parts or functions.

- Refer to the Legend: Use the accompanying key to decode any abbreviations or notations provided.

- Examine Connections: Pay attention to lines and arrows indicating relationships and interactions between different components.

- Use Scale References: Check the scale to understand the size and placement of parts in relation to each other.

By mastering these techniques, you will ultimately enhance your ability to navigate and utilize these essential resources effectively.

Common Issues and Solutions

Operating outdoor power equipment can lead to various challenges that may arise during use. Understanding these common problems and their solutions can enhance performance and prolong the lifespan of the machine.

1. Poor Performance

If your equipment is not functioning optimally, check the fuel system and ensure that the air filter is clean. A clogged filter can restrict airflow, causing inefficiency. Regular maintenance of these components can prevent such issues.

2. Starting Difficulties

When experiencing trouble starting, inspect the ignition system and battery connections. A weak battery or faulty spark plug can hinder ignition. Replacing these elements often resolves the issue and restores functionality.

Maintenance Tips for Snowblower Parts

Regular upkeep is essential for ensuring optimal performance and longevity of your winter equipment. By paying attention to various components, you can prevent costly repairs and ensure that your machine operates smoothly during heavy snowfall.

1. Inspect and Clean: Frequently examine all elements for wear and debris. Clearing away snow buildup and dirt can enhance efficiency and reduce the risk of mechanical failure.

2. Lubrication: Proper lubrication of moving parts is crucial. Use suitable oils to minimize friction and wear, ensuring that everything operates seamlessly.

3. Check Belts and Cables: Regularly inspect belts and cables for signs of fraying or damage. Replace any worn components promptly to avoid breakdowns during critical times.

4. Fuel System Maintenance: Keep the fuel system clean and free from contaminants. Consider using fuel stabilizers to prolong the life of fuel when storing your machine.

5. Seasonal Storage: Proper storage after each season is vital. Drain fuel and clean thoroughly to prevent rust and corrosion during off-seasons.

By implementing these practices, you can ensure that your winter equipment remains in peak condition, ready to tackle whatever challenges winter brings.

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, locating suitable components is essential for ensuring optimal performance and longevity. Fortunately, there are several reliable sources where you can obtain the necessary items to keep your machinery running smoothly.

- Manufacturer’s Website: Start by visiting the official site of the equipment maker. They often provide a dedicated section for replacement items, complete with diagrams and part numbers.

- Authorized Dealers: Local retailers that are certified by the manufacturer typically carry a range of components and can assist you in finding exactly what you need.

- Online Marketplaces: Websites such as Amazon, eBay, and specialized outdoor equipment retailers offer a vast selection of items, often at competitive prices.

- Repair Shops: Local repair centers not only service equipment but may also sell original or compatible components directly to customers.

- Salvage Yards: Consider visiting salvage or recycling yards that specialize in outdoor machinery. You might find used items in good condition at a fraction of the cost.

By exploring these options, you can ensure that your equipment remains efficient and reliable throughout its lifespan.

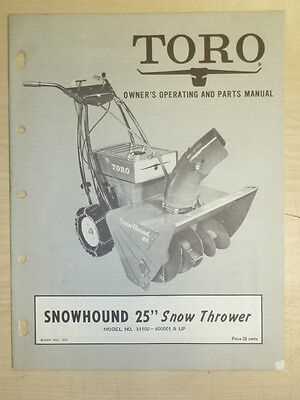

Identifying Your Toro Model

Understanding the specific version of your equipment is crucial for effective maintenance and repairs. Each model may have unique features and components that require attention. Knowing the right identifier helps in sourcing the correct elements and ensuring optimal performance.

To accurately determine your model, follow these steps:

- Check the serial number location, usually found on the frame or under the control panel.

- Refer to the owner’s manual, which typically lists model variations.

- Look for model labels or stickers, often placed on the housing.

- Compare visual features with online resources or community forums for identification.

By following these guidelines, you can confidently pinpoint your specific version, facilitating the search for appropriate components.

Benefits of Using Original Parts

Utilizing authentic components ensures optimal performance and longevity of your equipment. These elements are specifically designed to work seamlessly with your machine, reducing the risk of malfunction and enhancing efficiency. The use of original items can lead to significant savings in maintenance costs over time, as they are less likely to require frequent replacements or repairs.

Enhanced Reliability

Original components are rigorously tested for quality and durability, providing peace of mind that your machine will operate smoothly. This reliability is crucial for maintaining productivity, especially in demanding conditions.

Perfect Fit and Function

Authentic items guarantee a precise fit, which is essential for the overall functionality of your equipment. This perfect alignment minimizes wear and tear, ensuring that all systems operate harmoniously for the best possible results.