When tackling winter’s challenges, having a reliable tool can make all the difference. This section will explore the intricate elements that contribute to the efficiency and performance of a specific snow removal machine. By breaking down these components, users can enhance their understanding and maintenance of this essential equipment.

Grasping the layout and functionality of each element not only aids in effective troubleshooting but also empowers owners to maximize their machine’s capabilities. With a clear visualization of the various segments, individuals can ensure smooth operation and longevity of their snow-clearing tools.

Whether you’re a seasoned user or new to winter equipment, comprehending these details is vital. This guide aims to delve into the ultimate intricacies of the assembly, providing insights that will elevate your snow management experience.

Overview of John Deere Snowblower

This section provides a comprehensive look at a renowned tool designed for effective winter maintenance. Ideal for managing heavy snowfall, this equipment is engineered to tackle challenging conditions, ensuring that pathways and driveways remain clear and accessible. Its robust design and reliable performance make it a staple for homeowners and professionals alike.

Key Features

The machinery boasts a range of features aimed at enhancing usability and efficiency. From powerful engines that facilitate smooth operation to adjustable settings that allow for customized handling of various snow depths, each aspect is crafted with the user’s needs in mind. Additionally, the sturdy construction ensures durability, making it a long-lasting investment for anyone facing winter weather.

Maintenance and Care

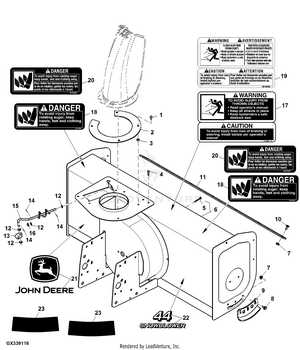

Key Components of Snow Removal Equipment Design

Understanding the essential elements of equipment used for winter maintenance is crucial for optimal performance and durability. Each component plays a significant role in ensuring efficient operation and effectiveness in clearing snow. Below are some of the main features that contribute to the overall functionality of these machines.

Main Features

- Auger: The primary mechanism responsible for gathering and moving snow into the discharge chute.

- Impeller: This part helps to propel the snow out of the chute, ensuring it is discharged far enough away from the pathway.

- Chassis: The frame that supports all components, providing stability and strength during operation.

- Drive System: This includes the engine and transmission, which power the machine and control its speed and movement.

- Skid Shoes: Adjustable feet that help to regulate the height of the auger, allowing for effective operation on various surfaces.

Additional Considerations

- Controls: User-friendly controls enhance maneuverability and ease of use.

- Wheels or Tracks: Depending on the design, these features provide traction and mobility across different terrains.

- Maintenance Accessibility: Components that allow for easy access are essential for regular upkeep and repairs.

Each of these elements is designed to work in harmony, ensuring the machine can effectively manage winter weather challenges. Understanding these components aids in making informed decisions when selecting or servicing equipment.

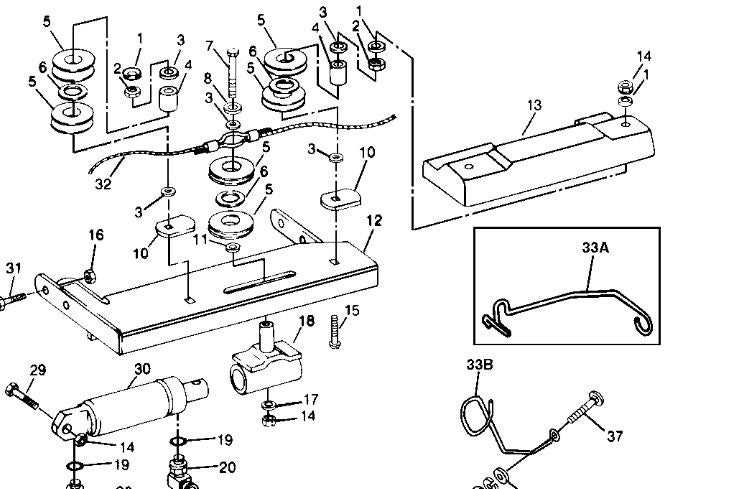

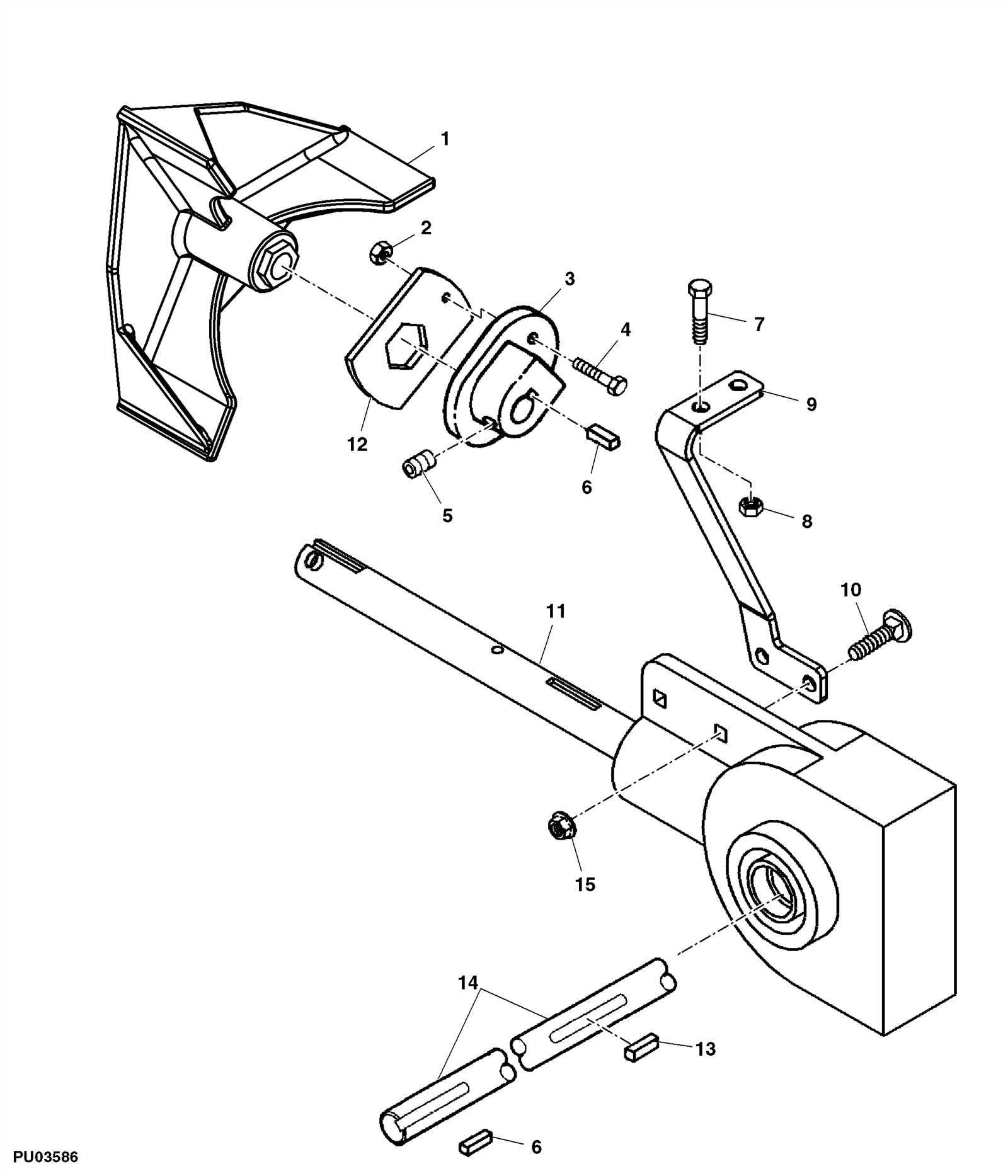

Understanding Parts Diagram Basics

Comprehending the intricacies of mechanical visuals is essential for effective maintenance and repair. These illustrations serve as crucial references, enabling users to identify and understand the various components within a machine. Familiarity with these representations not only enhances problem-solving capabilities but also streamlines the repair process.

Key elements of such visuals include:

- Labeling: Each component is typically marked with a unique identifier, facilitating easy reference.

- Grouping: Related elements are often clustered together, helping to illustrate their interactions and functions.

- Scale: Understanding the proportion of components in relation to one another can provide insights into their operation.

To effectively use these illustrations, one should:

- Identify the specific components you need to examine or replace.

- Cross-reference the identifiers with the accompanying documentation for clarity.

- Follow the visual flow to understand how parts interact within the overall system.

With a solid grasp of these fundamentals, users can navigate the complexities of their machinery with greater confidence and efficiency.

Common Replacement Parts for Efficiency

Maintaining optimal performance in winter machinery requires attention to various essential components. Regularly replacing worn or damaged elements can significantly enhance operational efficiency and prolong the lifespan of the equipment. Understanding which components typically need replacement will help users make informed decisions and ensure their machines run smoothly during the cold months.

Key Components to Consider

Among the critical elements to monitor, the auger assembly stands out. It is responsible for gathering and directing snow into the chute, and any wear can hinder its functionality. Additionally, the impeller plays a vital role in expelling the snow effectively. Regular checks and timely replacements of these components can lead to smoother operation and better results.

Maintenance Tips

Furthermore, ensuring that the belt system is in good condition is crucial, as it transfers power from the engine to the working parts. A damaged belt can lead to inefficient performance and potential breakdowns. Regular lubrication of moving parts also contributes to the overall efficiency, reducing wear and tear. By focusing on these key components and maintenance practices, users can significantly enhance the functionality of their winter equipment.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visuals provide a detailed representation of components and their relationships within a system, allowing users to identify and locate specific elements easily.

To navigate these illustrations successfully, follow these steps:

| Step | Description |

|---|---|

| 1 | Start by familiarizing yourself with the overall layout, noting the main assemblies and their arrangement. |

| 2 | Identify the labeling system used, which may include numbers, letters, or color codes corresponding to a legend. |

| 3 | Pay attention to the connections and orientations depicted, as they indicate how each component interacts with others. |

| 4 | Refer to accompanying documentation for additional context or specifications related to the components shown. |

By mastering these techniques, you can enhance your ability to analyze and utilize technical visuals effectively.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan and performance of your equipment. Regular attention not only enhances efficiency but also helps prevent unexpected breakdowns. By implementing a few key practices, you can ensure that your machine remains in optimal condition throughout its usage.

Regular Inspections

Conduct routine checks to identify wear and tear before they escalate into major issues. Look for any signs of damage or looseness in components. Cleaning parts regularly will prevent the accumulation of debris that can affect functionality. Pay special attention to areas prone to rust or corrosion, as these can compromise the integrity of the machine.

Lubrication and Fluid Maintenance

Keep all moving components adequately lubricated to reduce friction and wear. Use the recommended types of oils and greases as specified by the manufacturer. Additionally, monitor fluid levels consistently, ensuring that hydraulic and fuel systems are filled to appropriate levels. Changing filters regularly will also contribute to the overall health of your equipment.

Where to Find Quality Replacement Parts

Locating high-quality components for your equipment can significantly enhance its performance and longevity. Various sources offer a range of options to ensure you find what you need efficiently and effectively. Understanding where to look can save you time and money while maintaining optimal functionality.

Here are some reliable sources to consider:

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers often provide genuine components with manufacturer warranties, ensuring reliability and compatibility. |

| Online Marketplaces | Websites like eBay or Amazon feature numerous listings, allowing you to compare prices and reviews from different sellers. |

| Local Repair Shops | Many repair shops stock a variety of items and may offer expert advice on the best components for your needs. |

| Manufacturer’s Website | The official site typically lists available products and may offer direct purchasing options or provide links to authorized sellers. |

By exploring these options, you can ensure that your machinery continues to operate at its best with quality replacements that meet your requirements.

DIY Repairs: A Step-by-Step Guide

Embarking on repair tasks can empower you to extend the life of your equipment while saving costs. This guide provides clear steps to tackle common issues, ensuring you can work confidently and efficiently.

Essential Tools Needed

Before beginning, gather the necessary tools to streamline your repair process. Having everything on hand will make your work smoother and more effective.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts |

| Screwdriver Set | To remove and replace screws |

| Pliers | For gripping and manipulating small parts |

| Jack Stands | For safely lifting the equipment |

Repair Steps Overview

Follow these systematic steps for effective repairs. Start by assessing the issue, gathering tools, and then proceeding methodically to ensure everything is fixed properly. Always prioritize safety by wearing protective gear.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance performance and reliability. These specialized pieces are designed to fit and function seamlessly with your machinery, ensuring optimal operation and longevity.

| Advantage | Description |

|---|---|

| Quality Assurance | OEM components are manufactured to exact specifications, guaranteeing high standards of quality. |

| Perfect Fit | Designed specifically for your model, they provide a precise fit that aftermarket alternatives may not achieve. |

| Enhanced Performance | Using original parts can significantly improve the overall performance and efficiency of your equipment. |

| Warranty Protection | Many manufacturers require the use of OEM components to maintain warranty coverage, protecting your investment. |

| Long-Term Cost Efficiency | Although initially more expensive, they often save money in the long run through reduced maintenance and fewer replacements. |