When it comes to maintaining your outdoor machinery, having a clear understanding of its various components and how they fit together is essential. This knowledge ensures not only smooth operation but also helps identify issues quickly and accurately. Whether you’re looking to perform repairs, replacements, or simple maintenance tasks, being familiar with the structure and parts of your equipment is crucial for efficiency and longevity.

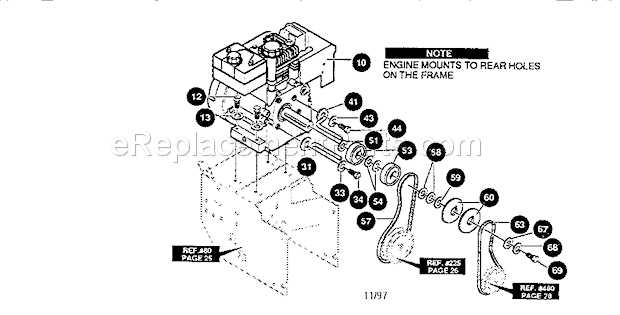

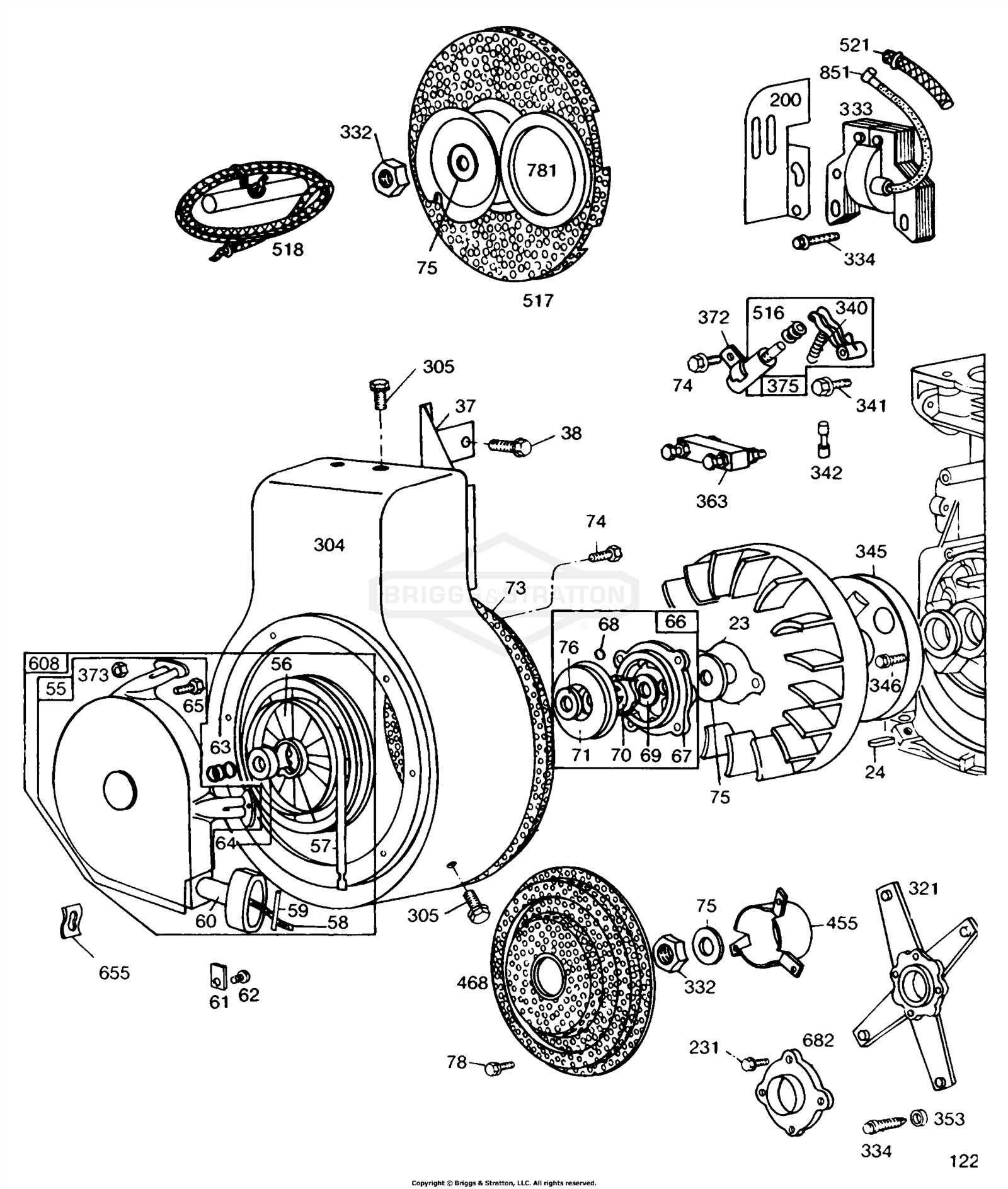

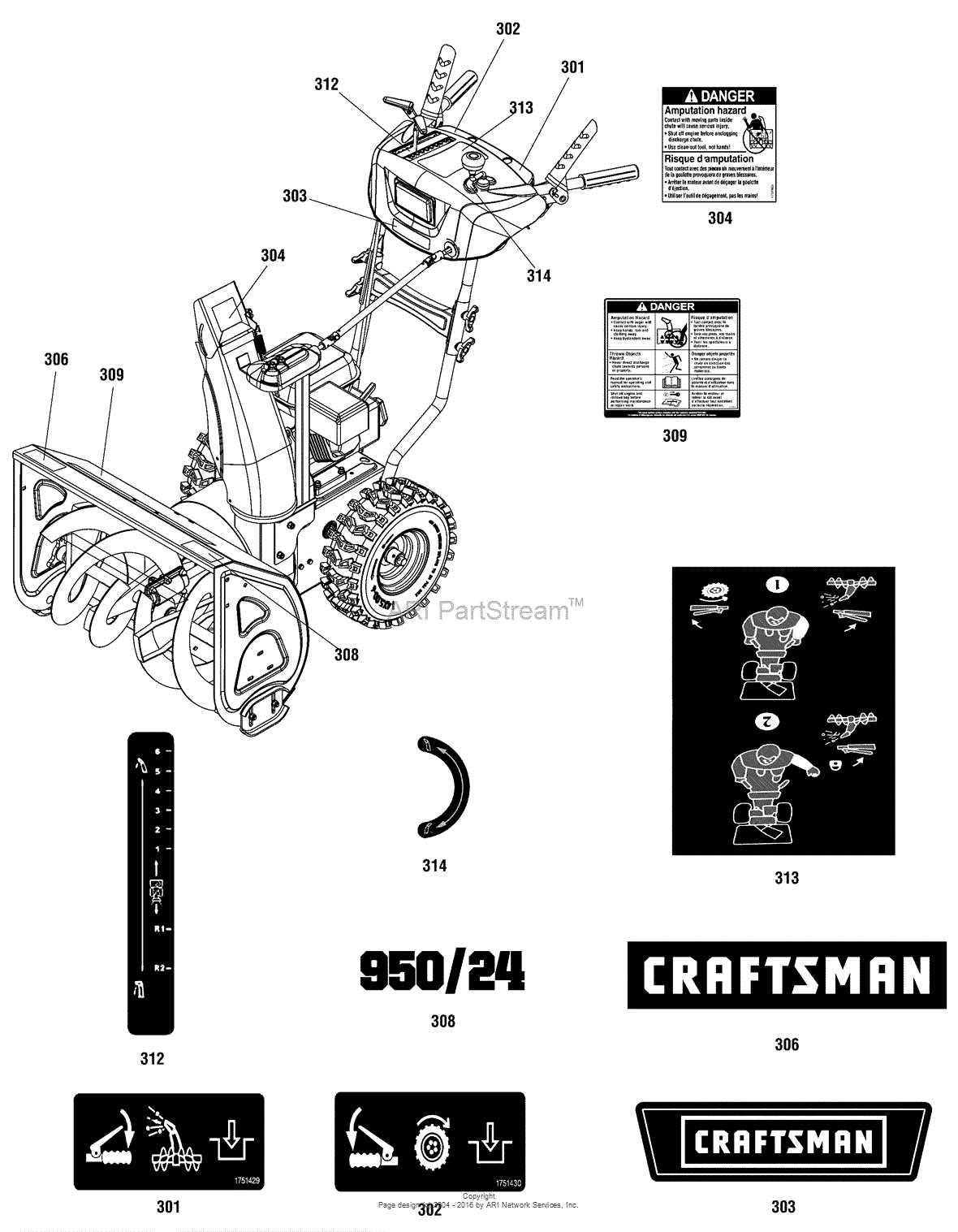

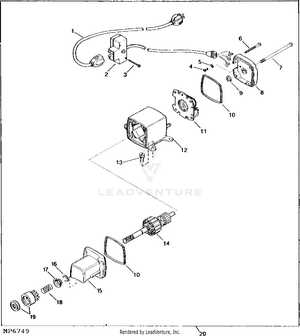

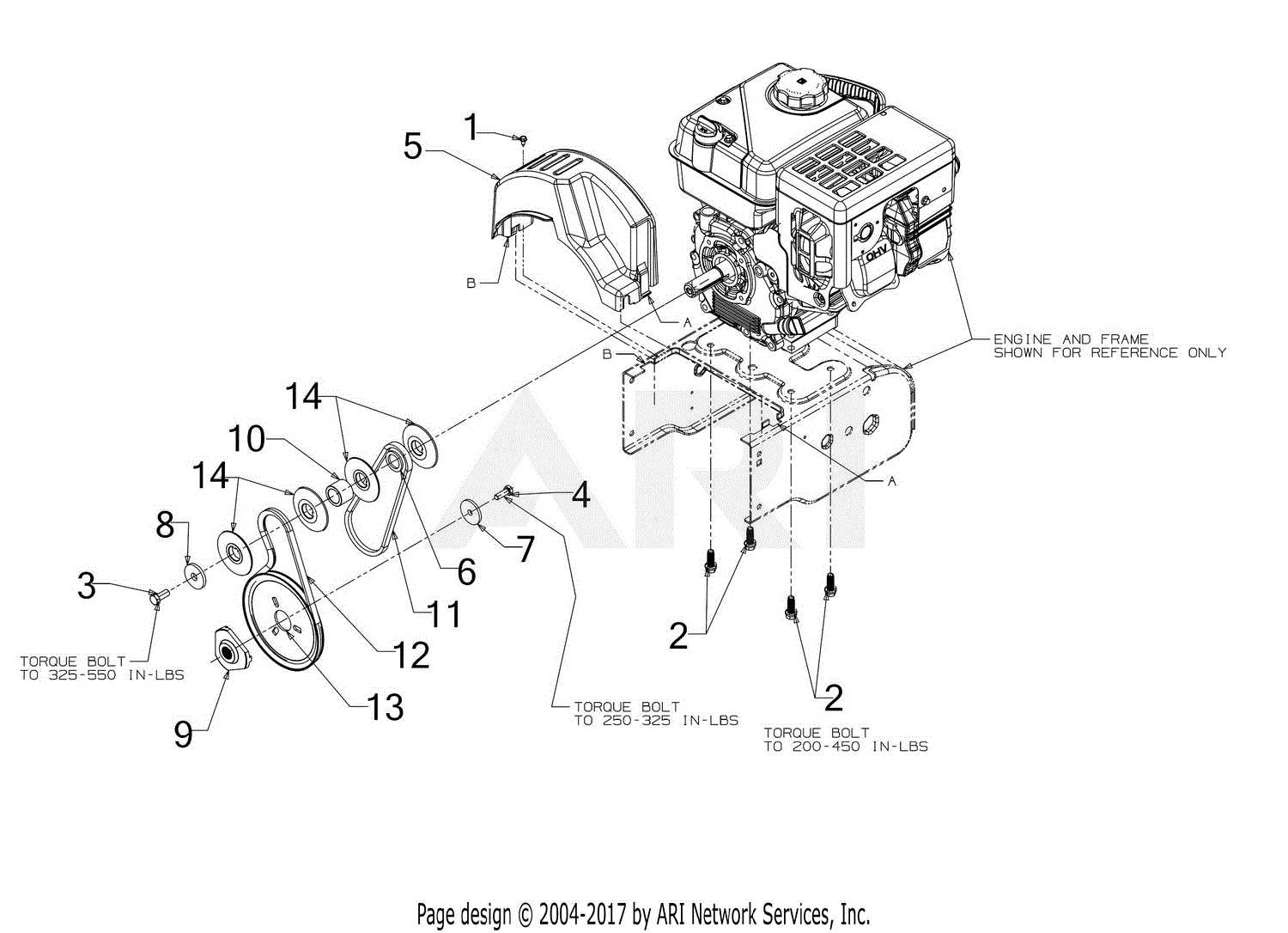

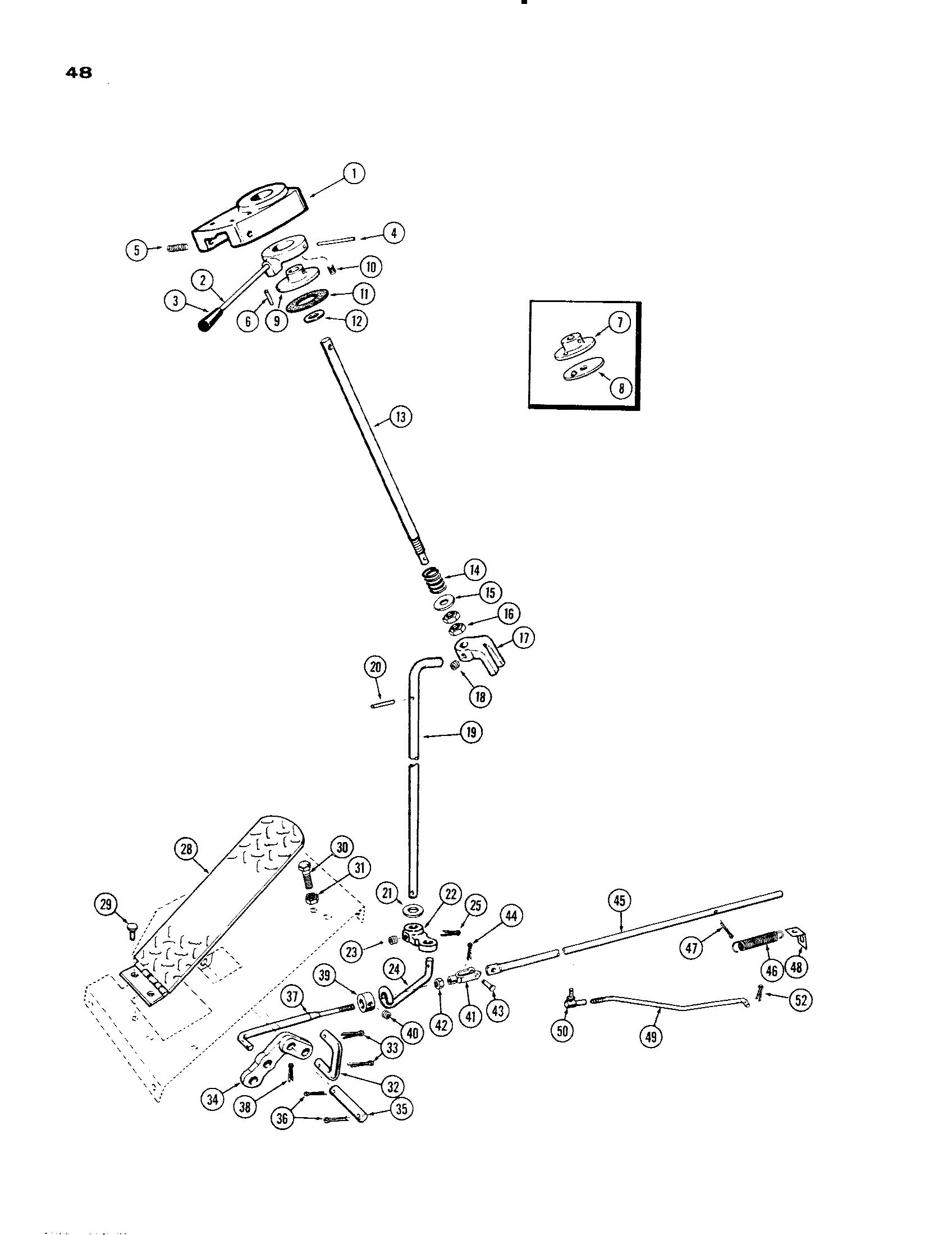

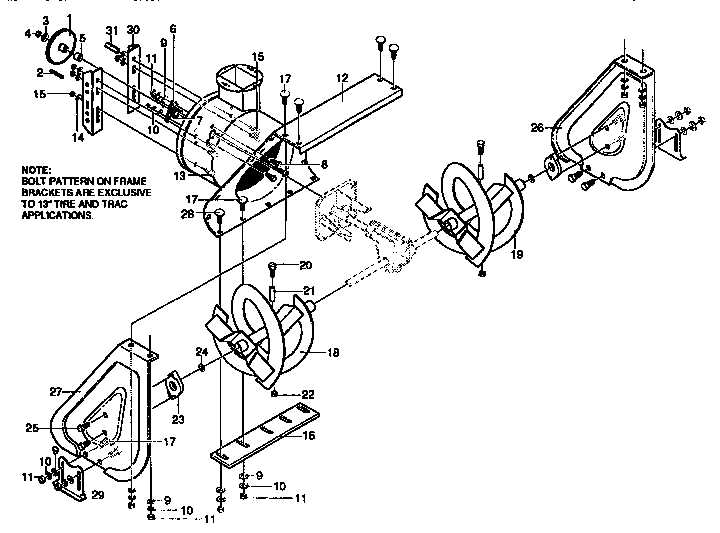

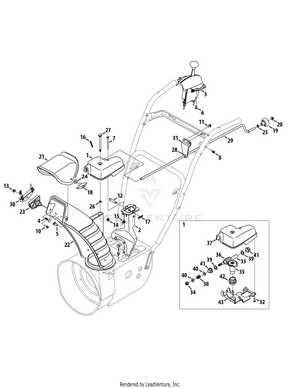

Detailed visual representations can serve as invaluable tools, allowing users to pinpoint specific sections and parts within the machine. These guides often illustrate the placement, connection points, and relationships between different elements. By carefully examining these resources, you can enhance your troubleshooting skills and improve your ability to maintain or repair your equipment with confidence.

In this guide, we will delve into these detailed representations, focusing on their importance in simplifying repairs and replacements. A well-documented layout of the system offers clarity, helping you understand how each part contributes to the overall functionality of the machinery. This practical knowledge is essential for anyone seeking to extend the life and performance of their winter gear.

Understanding Spirit Snowblower Components

Gaining insight into the various elements of a snow-clearing machine is essential for effective maintenance and operation. Each component plays a crucial role in ensuring optimal performance during winter conditions. Familiarity with these individual pieces can significantly enhance the user experience and prolong the machine’s lifespan.

| Component | Function |

|---|---|

| Engine | Provides the necessary power for operation. |

| Auger | Collects and displaces the snow. |

| Chassis | Houses the main components and provides structural integrity. |

| Transmission | Transfers power from the engine to the wheels. |

| Handlebars | Allows for steering and control of the machine. |

Importance of Parts Diagrams

Understanding the internal structure of any mechanical device is crucial for proper maintenance and repair. Visual representations that detail every component of a machine can significantly ease troubleshooting, assembly, and replacement processes. When faced with an issue, a clear and detailed guide to the individual parts ensures that users can quickly locate the problem and resolve it efficiently.

Enhancing Maintenance Efficiency

Having access to a comprehensive visual guide allows users to easily identify and inspect each element. This level of clarity helps in performing routine maintenance or addressing minor issues before they become larger, more costly problems. Knowing exactly where each component is located helps prevent unnecessary disassembly and accelerates the repair process.

Improved Accuracy in Replacements

With a clear map of all the key elements, users can ensure they are replacing the right part. This reduces the risk of incorrect replacements, which could lead to further damage or inefficiencies. By referencing an accurate visual layout, even individuals with limited technical knowledge can confidently make informed decisions during repairs.

Identifying Key Snowblower Parts

Understanding the essential components of a clearing machine is crucial for effective maintenance and operation. Each element plays a significant role in ensuring optimal performance during winter months. Familiarity with these vital sections will aid users in troubleshooting and enhancing the efficiency of their equipment.

Main Components

- Engine: The powerhouse that drives the entire mechanism.

- Auger: The rotating element that gathers and moves the snow.

- Chute: Directs the flow of snow after it has been collected.

- Skids: The base that controls the height and helps glide over surfaces.

- Handles: Provide control and maneuverability during operation.

Supporting Elements

- Gearbox: Transmits power from the engine to the auger.

- Belts: Connect different components and allow for movement.

- Wheels: Facilitate easy transportation across various terrains.

- Controls: The levers and buttons that allow the user to operate the machine.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visual guides provide valuable insights into the components and their arrangement, ensuring efficient troubleshooting and replacement processes.

Familiarize Yourself with the Layout

Before diving in, get accustomed to the general structure of the visual representation. Key elements include:

- Labels: Indicate specific items and their corresponding numbers.

- Sections: Group related components for easier navigation.

- Legend: Often included to explain symbols used in the illustration.

Interpreting the Information

Once you’re familiar with the layout, focus on the following steps:

- Identify the item you need by locating its label.

- Cross-reference the number with the accompanying list for details.

- Take note of any related components that may also require attention.

Common Issues with Snowblower Parts

When operating machinery designed for clearing snow, wear and tear on key components is inevitable. Over time, certain elements may fail or degrade, impacting the overall efficiency and performance. Recognizing these common issues can help owners diagnose and resolve problems quickly, minimizing downtime during critical snow removal tasks.

1. Engine and Starting Issues

One of the most frequent problems encountered with snow-clearing equipment is engine trouble, particularly difficulty starting the unit. This can be caused by a variety of factors:

- Old or stale fuel clogging the carburetor

- Dirty or faulty spark plugs

- Blocked air filters reducing engine efficiency

- Low oil levels or incorrect oil type

Regular maintenance and proper fuel storage can help reduce the likelihood of engine-related malfunctions. However, if issues persist, more thorough checks may be required.

2. Belt and Auger Mechanism Problems

The belt system and auger are critical for effective snow clearing, and wear on these components can result in reduced functionality:

- Slipped or broken belts causing a loss of power to the auger

- Clogged or damaged augers, preventing snow from being picked up or expelled properly

- Misaligned components leading to excessive vibration or inefficient operation

Inspecting belts for cracks and ensuring that the auger is free of debris can go a long way in extending the lifespan of these parts. Regular lubrication is also essential for smooth operation.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular care and attention. By following a few essential practices, you can significantly extend the lifespan of your machinery, keeping it in optimal condition for years to come.

Regular Inspections

Conducting routine checks helps identify wear and tear early. Look for signs of damage or deterioration in critical components, and address any issues promptly to prevent further complications.

Proper Cleaning

Cleaning your equipment after each use is crucial. Remove debris and buildup that can lead to rust or corrosion, and ensure all moving parts remain free from obstructions for smooth operation.

Where to Find Replacement Parts

When it comes to maintaining outdoor machinery, locating suitable components is essential for optimal performance. Whether you are in need of specific elements for repairs or upgrades, several reliable sources can help you find exactly what you require.

Online Retailers

One of the most convenient options is to explore various online retailers. Websites specializing in garden and landscaping equipment often have extensive inventories. Make sure to use the model number to filter your search, ensuring you find compatible items quickly. Additionally, customer reviews can provide insights into the quality and reliability of the products.

Local Dealers and Repair Shops

Visiting local dealers or repair shops can also be beneficial. These establishments not only sell necessary components but may also offer expert advice and support. Establishing a relationship with a local supplier can lead to better service and even insights into compatible aftermarket alternatives.

In summary, whether you choose to shop online or visit a nearby retailer, being informed about your options will streamline the process of finding the right components for your equipment.

DIY Repairs vs. Professional Help

When facing mechanical issues with your equipment, the decision to either tackle the repairs yourself or seek expert assistance can be challenging. Each option has its own set of advantages and drawbacks, and the choice largely depends on the complexity of the problem, your skill level, and the tools at your disposal. While DIY repairs can save you money, professional service might offer quicker and more reliable results in some cases.

Benefits of DIY Repairs

Taking on repairs independently can be a rewarding experience, especially for those with a knack for fixing things. DIY repairs allow you to understand the inner workings of your machinery, providing valuable knowledge for future maintenance. Moreover, doing it yourself can significantly reduce the cost of labor, as you only need to invest in parts and any necessary tools. With the right resources, such as online guides and video tutorials, even complex issues can become manageable.

When Professional Help is Necessary

However, not every repair job is suitable for a DIY approach. For issues involving advanced components or intricate systems, professional help is often the best course of action. Experts can diagnose problems more efficiently and have access to specialized tools that are not available to the average homeowner. Additionally, professionals offer warranties on their work, ensuring peace of mind and potentially avoiding further damage down the line.

In conclusion, whether you choose to handle repairs yourself or hire a specialist depends on your confidence and expertise, as well as the severity of the issue. For some, DIY repairs are an excellent opportunity to learn, while others may prefer to rely on professionals for a hassle-free solution.