When tackling the challenges of winter, having reliable machinery can make all the difference. A well-functioning unit not only simplifies snow removal but also ensures safety during harsh weather conditions. To maintain optimal performance, it is crucial to familiarize yourself with the various elements that contribute to its operation.

In this section, we will delve into the essential components that comprise your winter device. By exploring the intricate relationships between these parts, you can better appreciate their roles and understand how to troubleshoot any issues that may arise. Knowing the layout and function of each element is vital for effective maintenance and repair.

Whether you’re a seasoned user or a novice, grasping the anatomy of your machinery enhances your ability to make informed decisions. We will provide clear visual representations and descriptions to guide you through this process, ensuring you have the knowledge needed for successful upkeep.

Understanding Briggs and Stratton Snowblower Models

In the world of winter equipment, it’s essential to grasp the variety of available models and their unique features. Each design caters to different needs and preferences, making it crucial to understand their functionalities.

- Performance: Assess the engine capacity and power output.

- Design: Explore the build quality and material durability.

- Features: Identify additional functionalities, such as self-propulsion and adjustable augers.

- Maintenance: Consider the ease of upkeep and availability of components.

Familiarizing yourself with these aspects will ultimately help you make informed decisions for your winter tasks.

Common Issues with Snowblower Components

In the realm of winter machinery, certain components often encounter challenges that can hinder performance. Understanding these common problems is crucial for maintaining efficiency and ensuring smooth operation during the cold months.

| Component | Issue | Possible Solution |

|---|---|---|

| Engine | Hard starting | Check fuel quality and spark plug condition. |

| Auger | Jamming | Inspect for debris and ensure proper lubrication. |

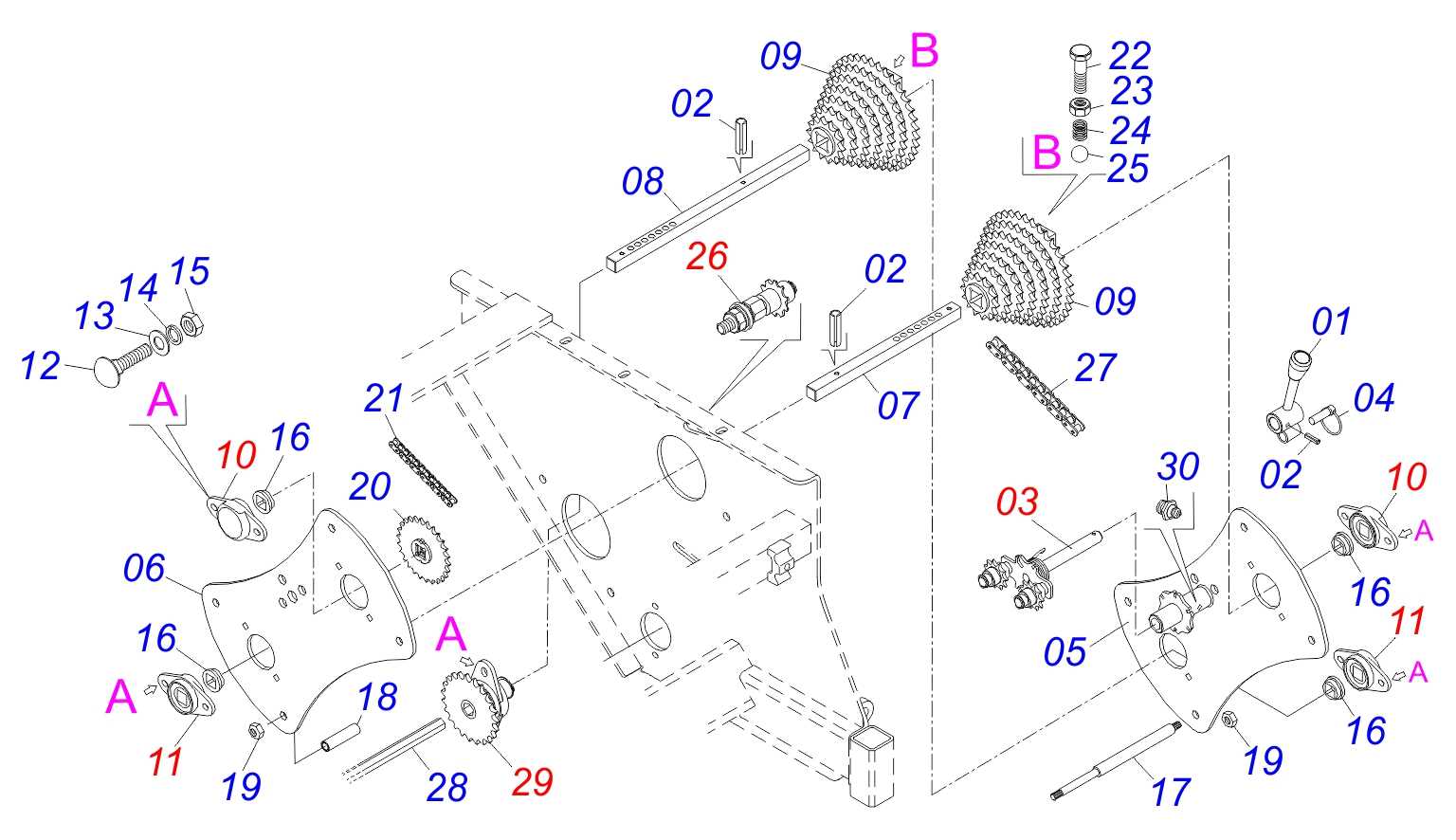

| Drive System | Slipping | Adjust the tension of the drive belt or replace if worn. |

| Chassis | Rust formation | Regularly clean and apply protective coatings. |

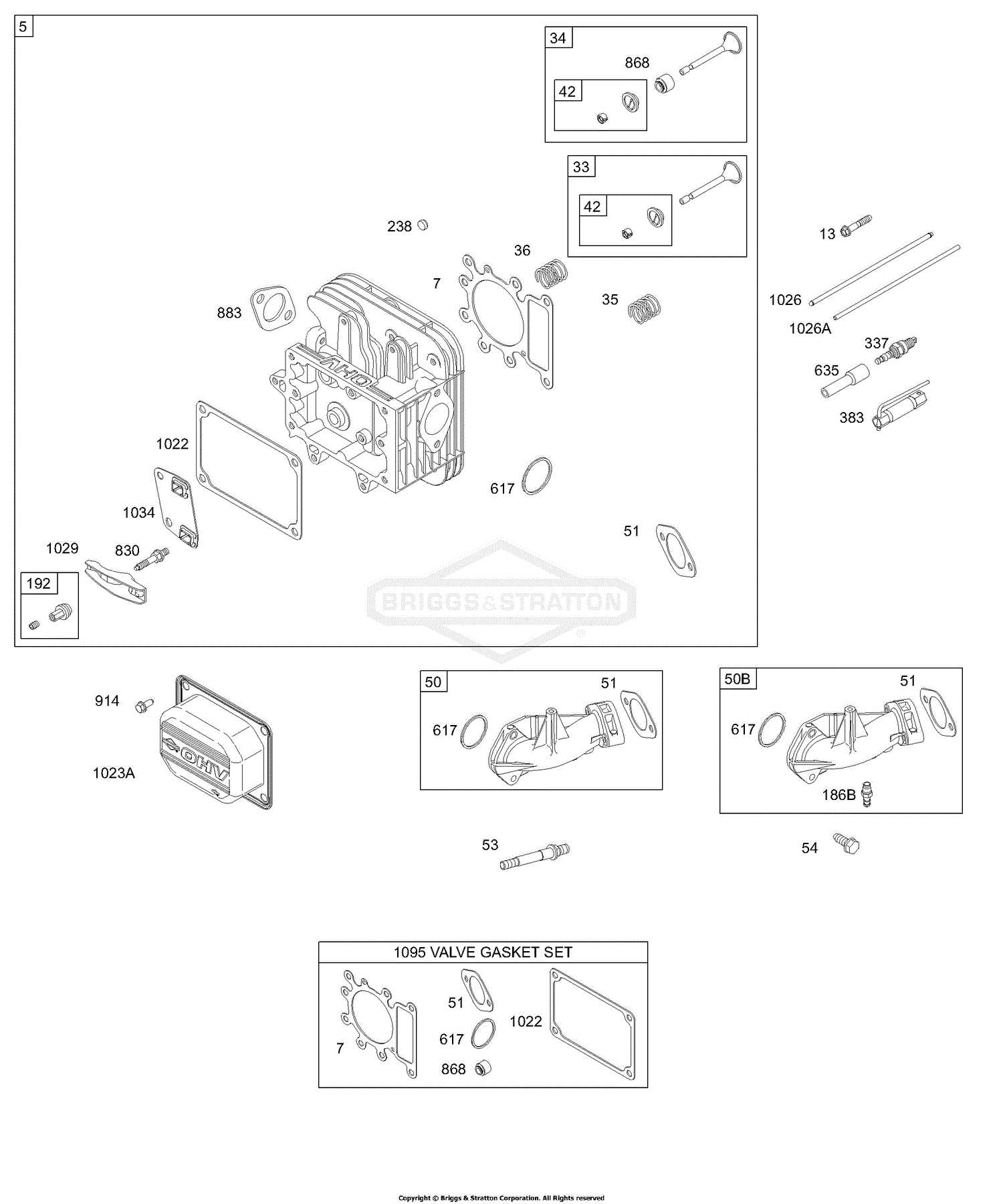

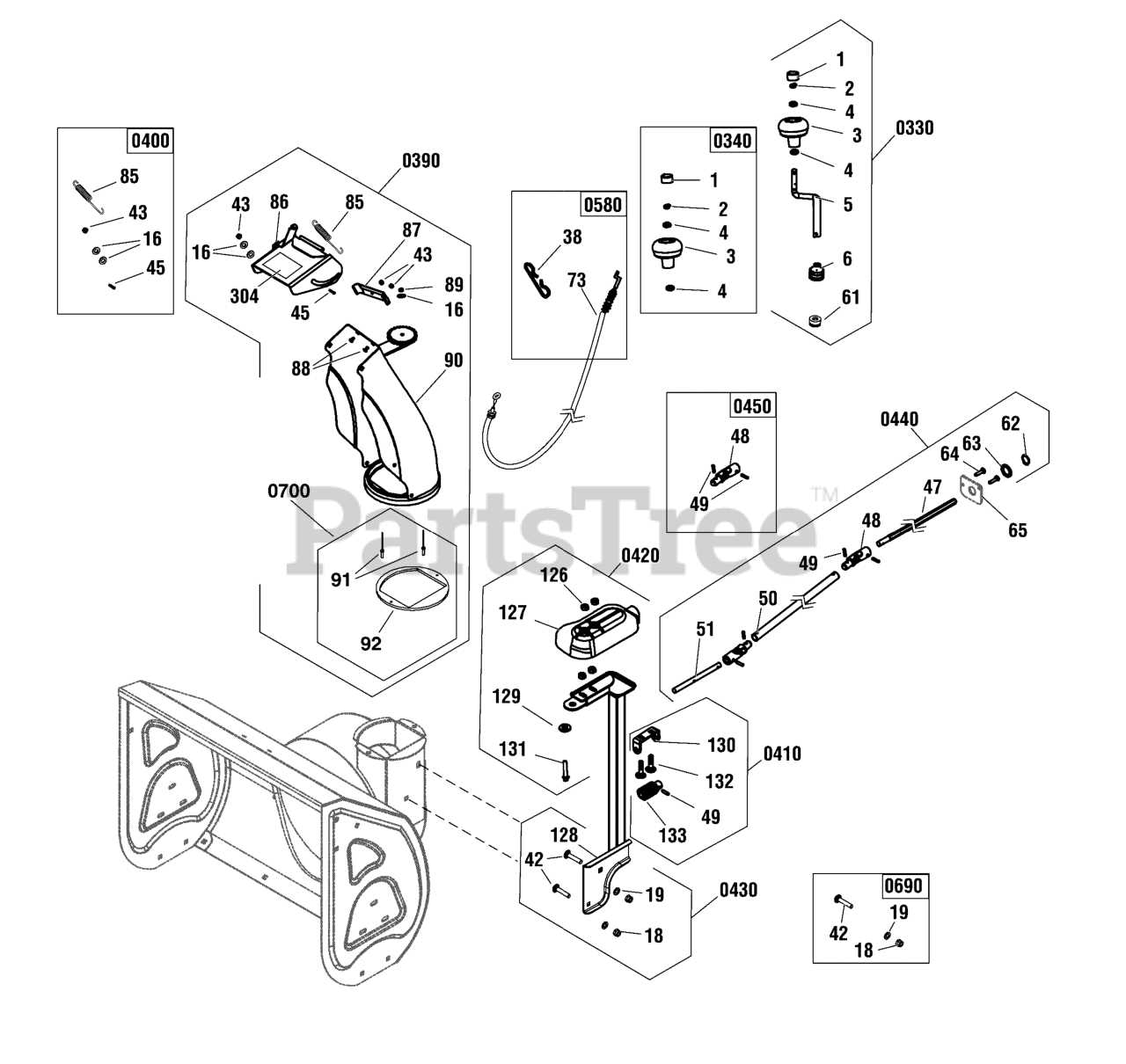

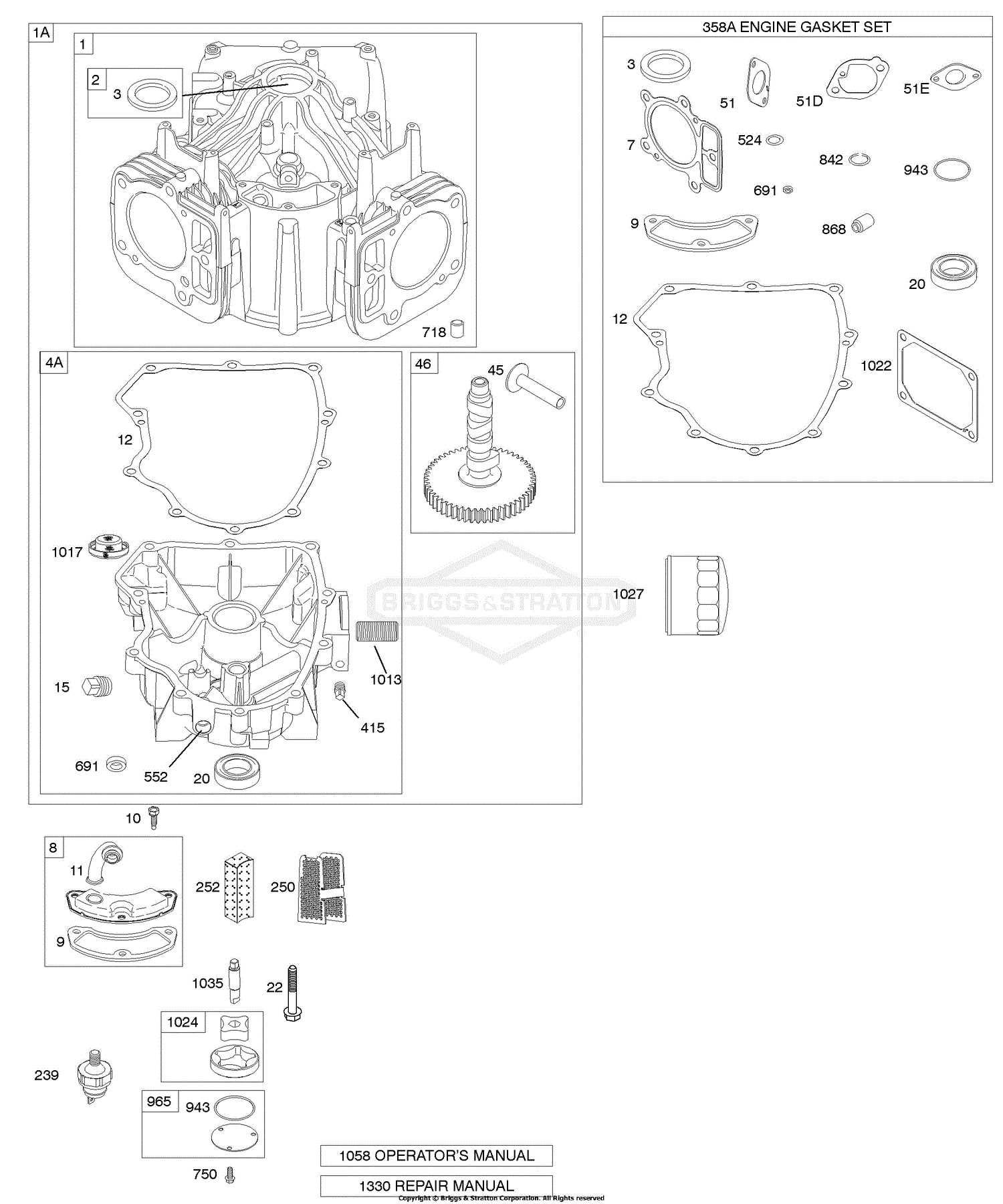

How to Identify Snowblower Parts

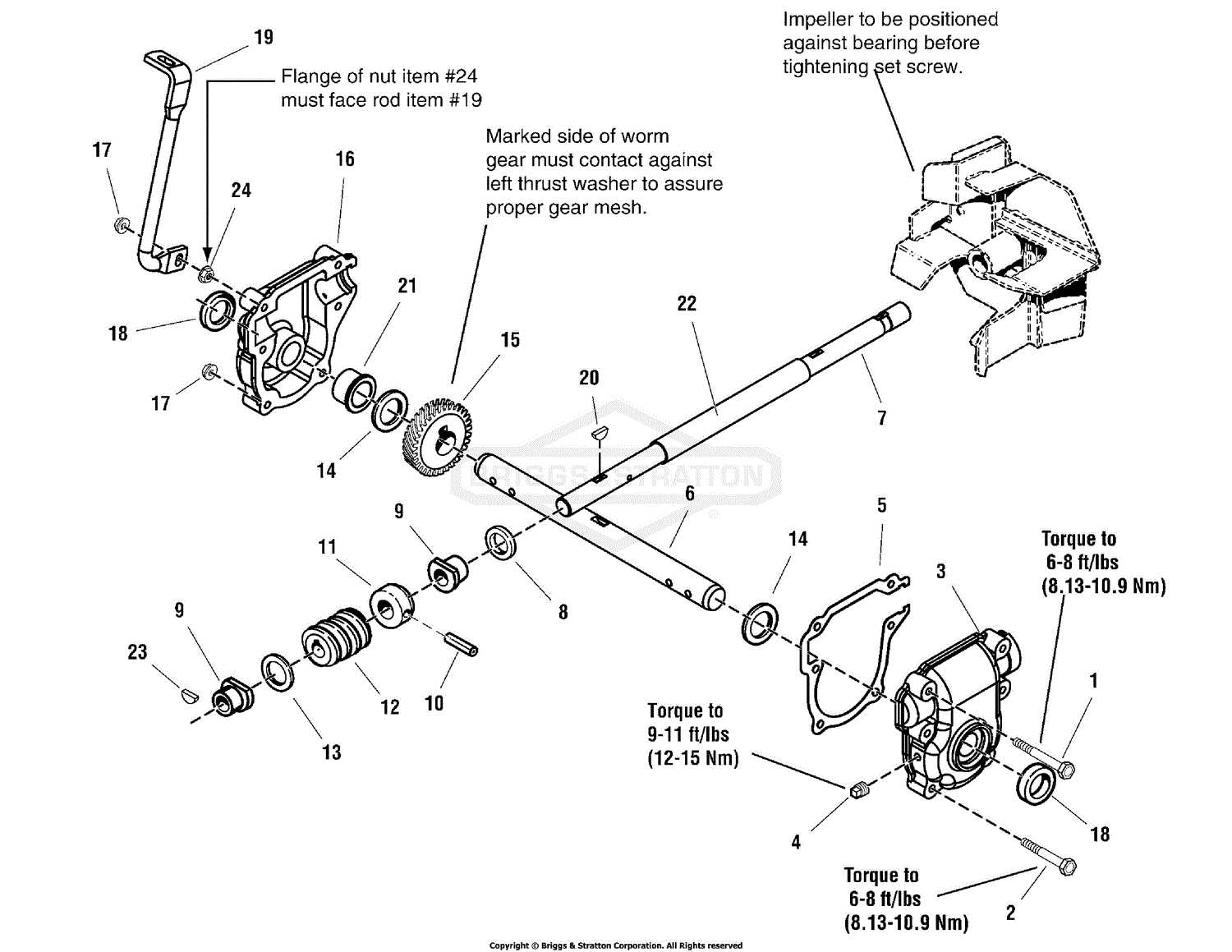

Recognizing components of a snow-clearing machine is essential for effective maintenance and repairs. Each section plays a crucial role in ensuring optimal performance during winter conditions. Familiarizing yourself with these elements can enhance your understanding and facilitate troubleshooting when issues arise.

Visual Inspection

Begin by examining the exterior of the machine. Look for labels or stickers that may provide part numbers or specific names. This visual identification can significantly streamline the process of acquiring replacements.

Consulting Manuals

Refer to the user manual or online resources for detailed descriptions of each element. These documents often include illustrations, helping you delve deeper into the functionality of each section, allowing for a more informed approach to repairs.

Understanding these basics can ultimately lead to a smoother maintenance experience and better performance in challenging weather conditions.

Benefits of Using Original Parts

Utilizing genuine components for your equipment offers numerous advantages that enhance both performance and longevity. These original elements are designed specifically for your machine, ensuring optimal compatibility and functionality.

One of the primary benefits of choosing authentic parts is reliability. Original components undergo rigorous testing to meet strict quality standards, which significantly reduces the risk of failures and breakdowns. This not only prolongs the lifespan of your equipment but also ensures it operates at peak efficiency.

Another important aspect is the warranty coverage. Using non-genuine components may void warranties provided by manufacturers, leaving you exposed to repair costs. By opting for original parts, you maintain your warranty, protecting your investment.

| Benefits | Description |

|---|---|

| Reliability | Designed to fit perfectly and function correctly, minimizing breakdowns. |

| Quality Assurance | Manufactured to meet high standards, ensuring durability and performance. |

| Warranty Protection | Maintains manufacturer’s warranty, safeguarding your investment. |

| Easy Availability | Original parts are readily available through authorized dealers. |

In conclusion, selecting original components not only enhances the performance and reliability of your equipment but also provides peace of mind through quality assurance and warranty protection. Investing in genuine parts is a smart choice for any owner aiming for optimal functionality.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and efficiency of your outdoor equipment. This guide will provide you with a systematic approach to maintain your machine, enhancing its performance and preventing potential issues. By following these steps, you can keep your device in optimal condition throughout the season.

Begin by inspecting the unit for any visible wear or damage. Check the exterior for cracks or loose components that may need tightening or replacement. It’s important to clear away any debris that may have accumulated during use, as this can hinder performance.

Next, focus on the engine. Ensure that the oil level is adequate and replace the oil according to the manufacturer’s recommendations. Changing the air filter is also crucial, as a clean filter promotes better airflow and efficiency.

Don’t forget to examine the fuel system. Use fresh fuel and consider adding a stabilizer to prevent degradation. Inspect fuel lines for any signs of leaks or wear, as these can lead to operational issues.

Finally, check the moving parts. Lubricate any areas that require it, ensuring that everything operates smoothly. After completing these maintenance steps, you will enhance your equipment’s reliability and performance, making it ready for any task ahead.

Where to Find Replacement Parts

Locating the necessary components for your equipment can be a straightforward task if you know where to look. There are various reliable sources available to help you find what you need, ensuring your machine runs smoothly and efficiently.

- Official Manufacturer Website: Start with the official site. They often have a dedicated section for accessories and components, complete with part numbers and specifications.

- Authorized Dealers: Local dealers provide an excellent resource. They can offer expertise and help you identify the correct items for your machinery.

- Online Retailers: Websites like Amazon, eBay, or specialized retailers offer a wide selection. Be sure to read reviews and check ratings for reliability.

- Repair Shops: Many repair centers sell components directly. They can also provide installation services if needed.

- Forums and Community Groups: Engaging with online communities can yield valuable insights. Members often share information about sourcing components and their personal experiences.

By exploring these avenues, you can ensure you find the right replacements to keep your machinery operational.

Exploring Snowblower Repair Manuals

Understanding the intricacies of maintenance and repair can significantly enhance the longevity and efficiency of winter equipment. Comprehensive manuals serve as invaluable resources, providing detailed insights into the assembly, disassembly, and troubleshooting processes necessary for effective upkeep. These guides not only facilitate self-repairs but also empower users to identify potential issues before they escalate.

Benefits of Using Repair Manuals

Utilizing a well-structured guide offers numerous advantages. Firstly, it ensures a systematic approach to maintenance, allowing operators to follow step-by-step instructions with ease. Moreover, these documents often include visual aids, making complex tasks more approachable. Additionally, having access to a repair manual can save time and money by reducing the need for professional service, while also enhancing the user’s confidence in handling repairs independently.

Finding the Right Manual

When searching for an appropriate guide, consider factors such as compatibility with your specific model and the comprehensiveness of the information provided. Online resources, manufacturer websites, and community forums can be excellent starting points for locating the right documentation. Always ensure that the material is up-to-date to reflect the latest practices and recommendations.

Upgrading Your Snowblower Performance

Enhancing the efficiency of your winter clearing equipment can significantly improve its overall functionality and extend its lifespan. By focusing on specific upgrades, you can ensure a smoother operation, better handling of heavy snowfall, and reduced wear and tear on components.

Essential Upgrades to Consider

- Engine Performance: Consider upgrading to a more powerful engine or enhancing the existing one with performance modifications to increase torque and speed.

- Auger and Impeller Blades: Opt for high-quality, durable blades designed to handle thicker snow and improve discharge distance.

- Transmission Enhancements: Improving the transmission can enhance maneuverability and control, allowing for smoother transitions on various terrains.

Maintenance Tips for Optimal Functionality

- Regularly check and replace worn-out components to avoid unexpected breakdowns.

- Keep the equipment clean and free of debris to maintain optimal airflow and prevent overheating.

- Utilize high-grade fuel and lubricants to ensure efficient operation and reduce engine wear.

By focusing on these upgrades and maintenance practices, you can maximize your equipment’s potential and tackle winter conditions with confidence.