In the realm of machinery, the clarity of construction elements plays a crucial role in ensuring efficiency and functionality. Each component is designed to work seamlessly with others, contributing to the overall performance of the system. A visual representation of these individual units enhances comprehension, allowing users to navigate through intricate assemblies with ease.

Examining the layout of these essential elements reveals their interconnections and dependencies. By breaking down complex structures into manageable parts, one can gain insights into their operation and maintenance. This approach not only aids in troubleshooting but also fosters a deeper appreciation of engineering principles.

Moreover, a clear illustration of the various elements can serve as an invaluable resource for both novice and experienced operators. It provides a roadmap for assembly and disassembly, highlighting potential pitfalls and best practices. Embracing such clarity ultimately leads to improved efficiency and reduced downtime in any mechanical endeavor.

Understanding Simplicity Regent Parts

Grasping the components and mechanisms of a specific lawn care machinery line is essential for effective maintenance and optimal performance. This knowledge not only enhances operational efficiency but also extends the longevity of the equipment. Familiarity with individual elements helps users identify issues and implement timely repairs.

Key Elements to Consider

- Functionality: Each component plays a unique role in the overall operation of the machine.

- Compatibility: Understanding how different parts interact can prevent operational problems.

- Maintenance: Regular checks can help spot wear and tear before they lead to failures.

Common Components

- Blades: Essential for cutting grass effectively, requiring regular sharpening.

- Belts: These transfer power and must be inspected for wear.

- Engines: The powerhouse that drives the equipment; understanding its mechanics is crucial.

- Wheels: Ensure mobility and stability during operation; check for alignment and wear.

Being well-informed about these aspects allows users to tackle maintenance tasks confidently and maintain peak performance in their lawn care efforts.

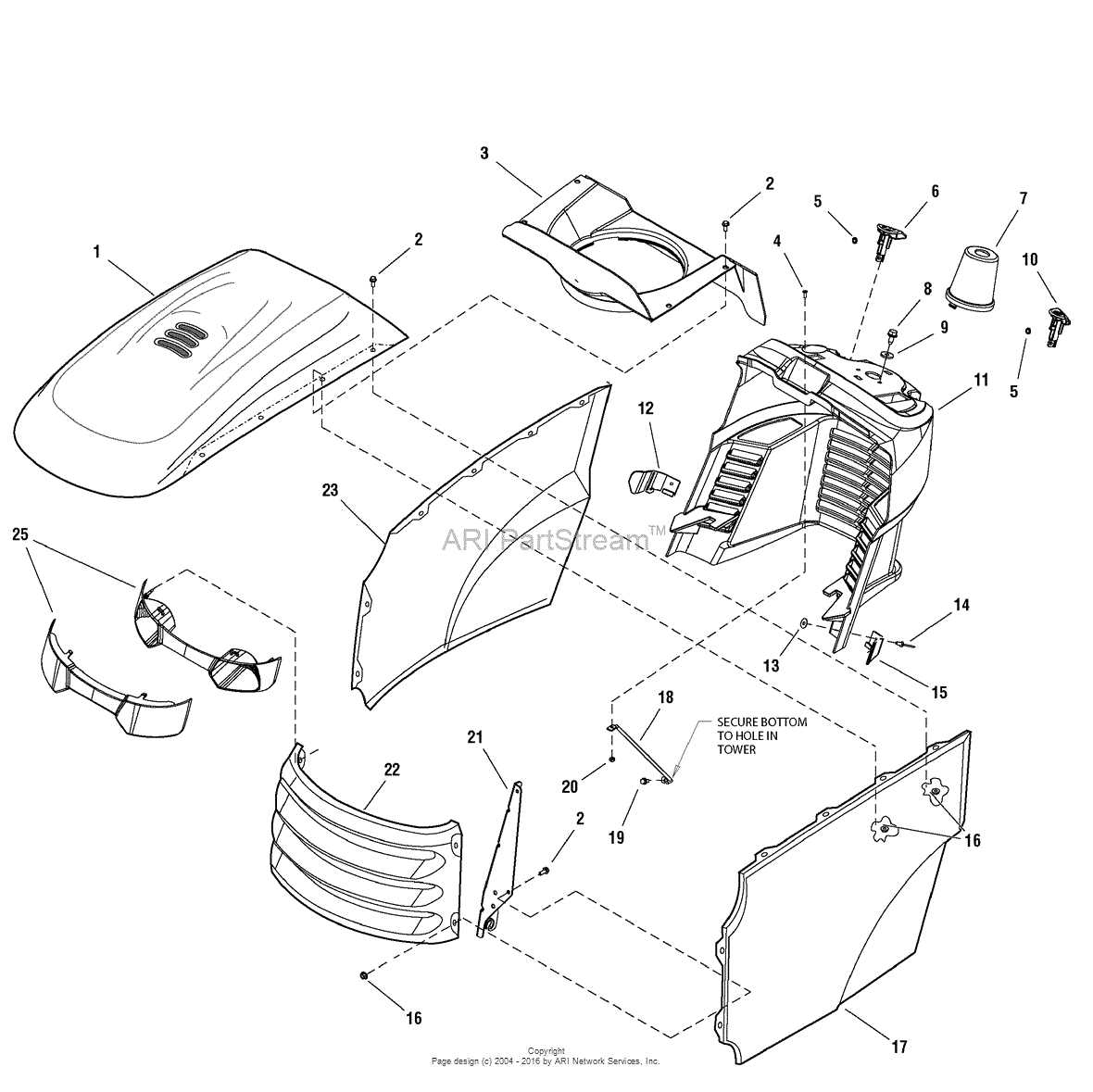

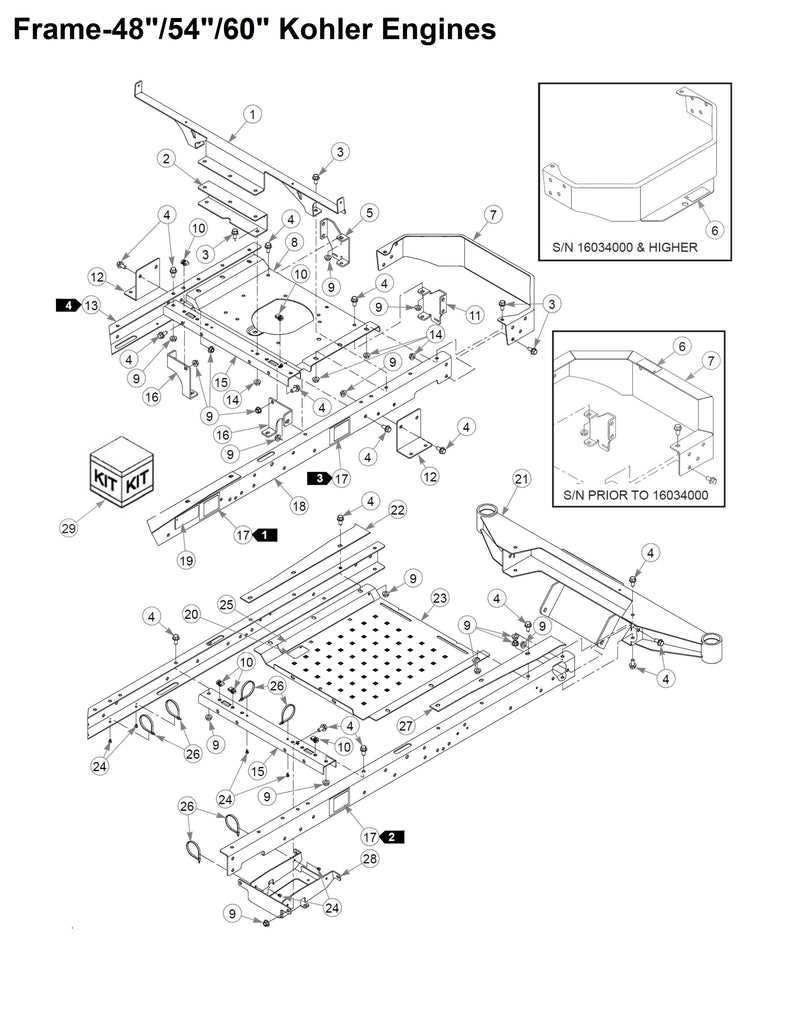

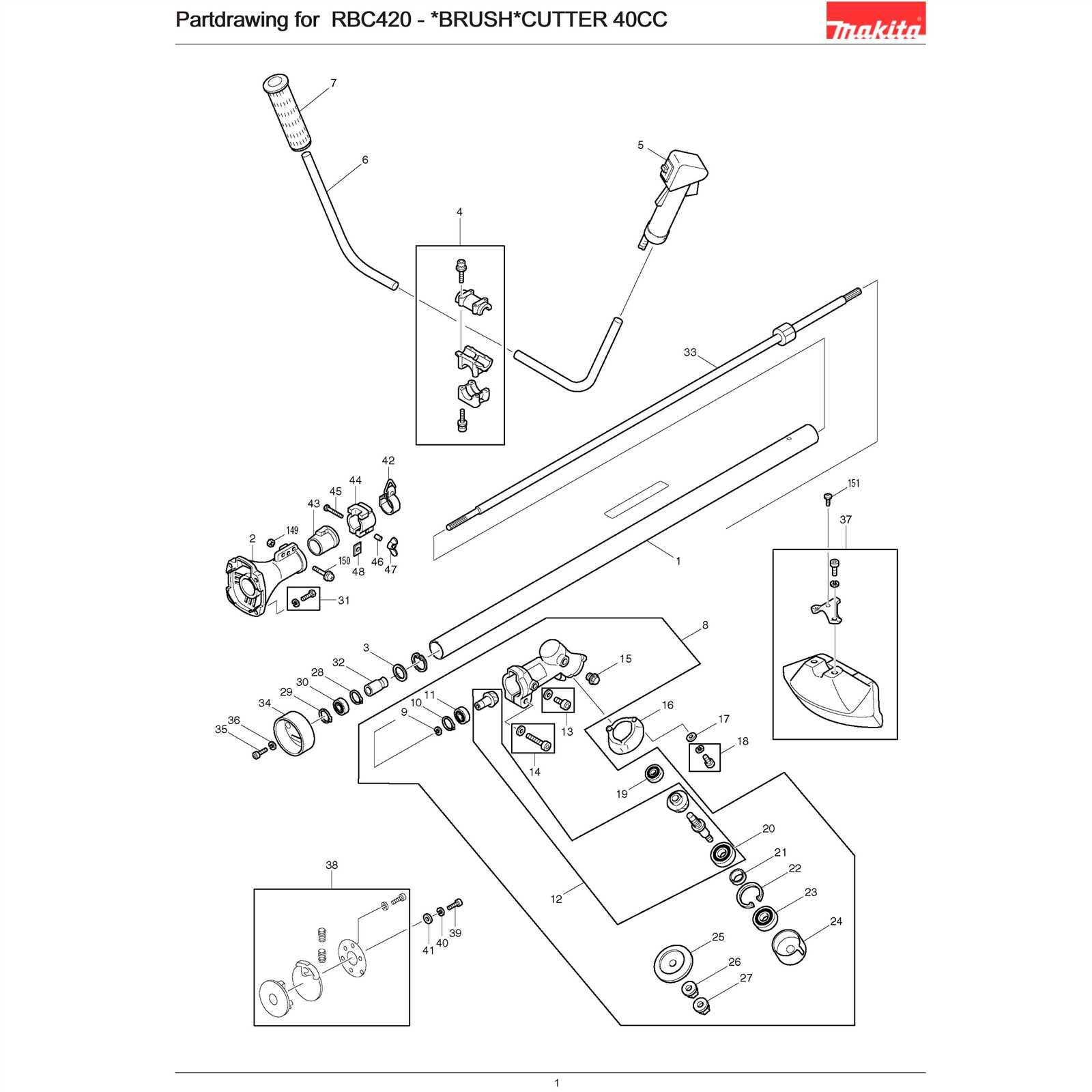

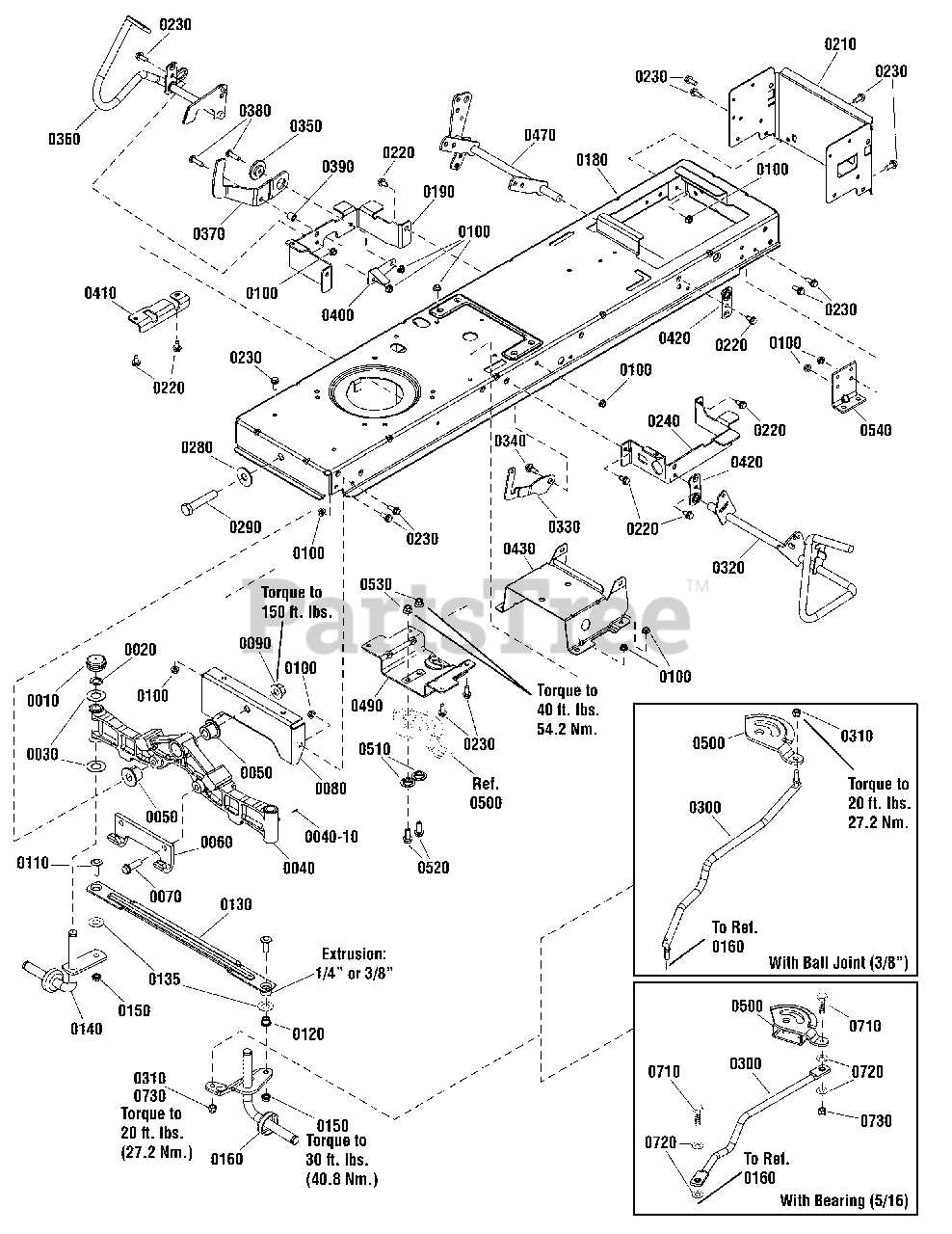

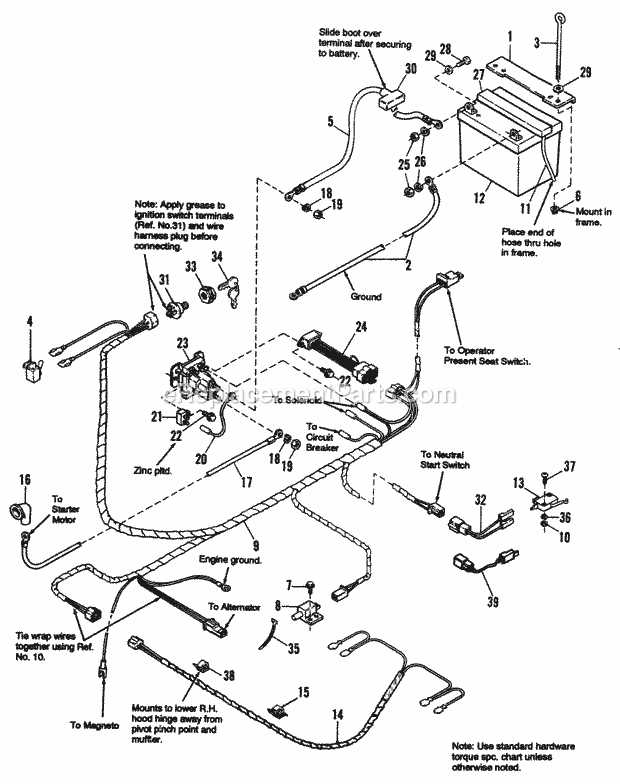

Overview of Regent Parts Diagram

This section provides a comprehensive look at the essential components and their interrelations within a mechanical system. Understanding these elements is crucial for maintenance, troubleshooting, and enhancing overall efficiency. Each segment plays a vital role in ensuring the seamless operation of the equipment.

In any mechanical setup, the layout of various elements is structured to facilitate optimal performance. This organization allows for clear identification of individual units and their functions, making it easier for users to grasp the system’s architecture.

| Component | Description |

|---|---|

| Unit A | Responsible for initiating the operational process. |

| Unit B | Acts as the control center, managing various inputs and outputs. |

| Unit C | Facilitates energy transfer to drive the system. |

| Unit D | Provides structural support and stability. |

Familiarity with these components empowers users to enhance system reliability and efficiency. A thorough understanding of how each element interacts within the broader framework can lead to more informed decisions regarding maintenance and upgrades.

Key Components of the Diagram

The visual representation of a system consists of several essential elements that work together to convey complex information clearly and effectively. Each component plays a crucial role in enhancing understanding and facilitating communication between different stakeholders.

| Element | Description |

|---|---|

| Node | Represents a specific point or object within the structure, serving as a foundational building block. |

| Connection | Illustrates the relationships between various nodes, indicating how they interact or influence one another. |

| Label | Provides clarity by identifying nodes or connections, ensuring that viewers can easily comprehend the information presented. |

| Legend | Offers a key to understanding symbols and colors used in the visual, aiding in the interpretation of complex details. |

| Scale | Ensures that elements are proportionately represented, allowing for accurate comparisons and assessments. |

Importance of Accurate Part Identification

Correctly identifying components within a system is crucial for effective operation and maintenance. Misidentification can lead to errors that compromise functionality and safety, affecting overall performance. Precision in recognizing individual elements ensures that the correct replacements or adjustments are made, minimizing downtime and enhancing reliability.

Impact on Efficiency

When components are accurately identified, the efficiency of processes improves significantly. Tasks can be executed more swiftly, as there is less likelihood of errors during installation or repairs. This not only saves time but also reduces costs associated with troubleshooting and rework, leading to smoother operations overall.

Enhancing Safety

Safety is paramount in any operational environment. Proper identification of elements helps to prevent hazardous situations that may arise from incorrect replacements or misconfigurations. By ensuring that each component is accurately recognized, organizations can protect both personnel and equipment from potential harm.

In conclusion, precise identification of system elements is vital for optimal performance, safety, and operational efficiency.

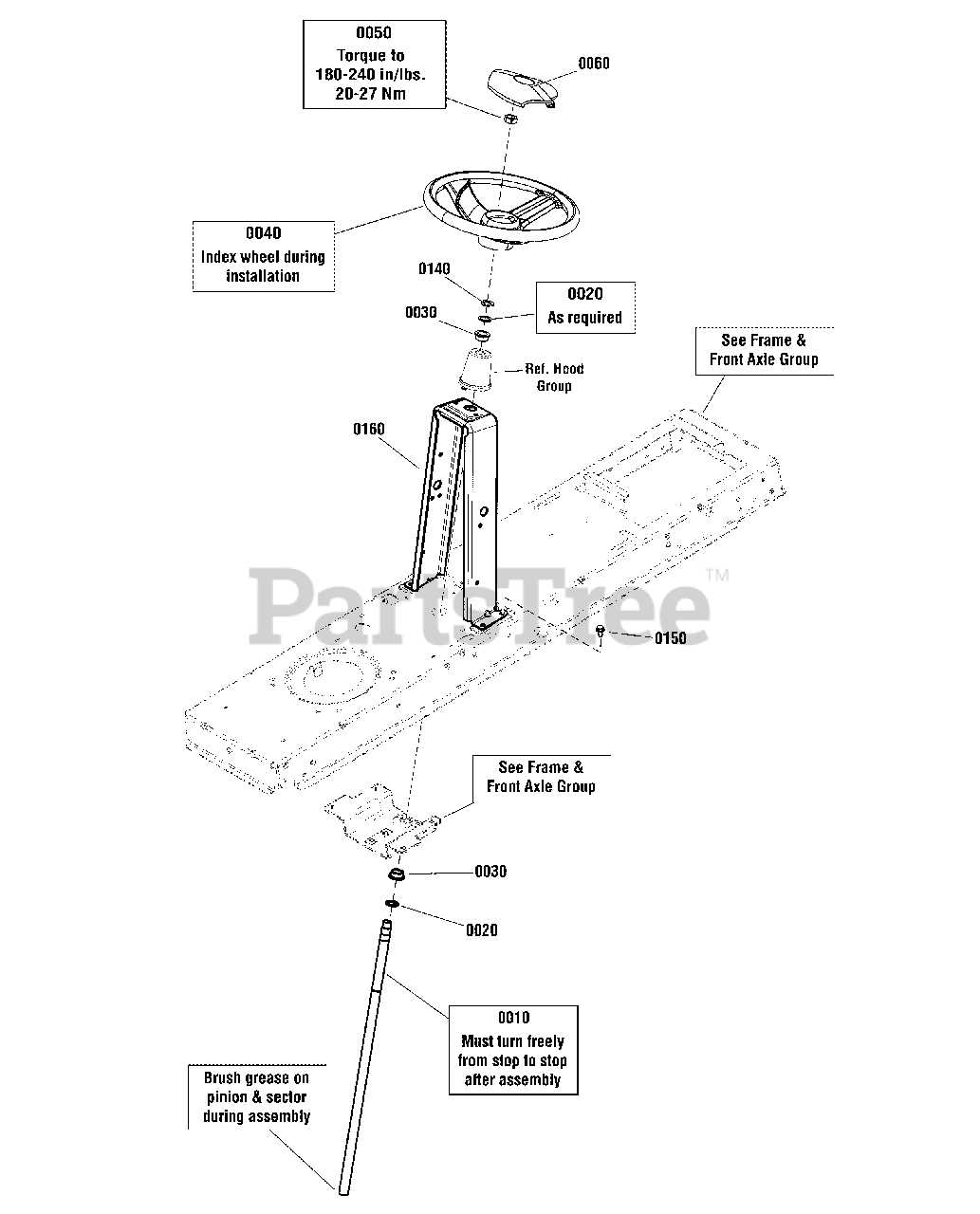

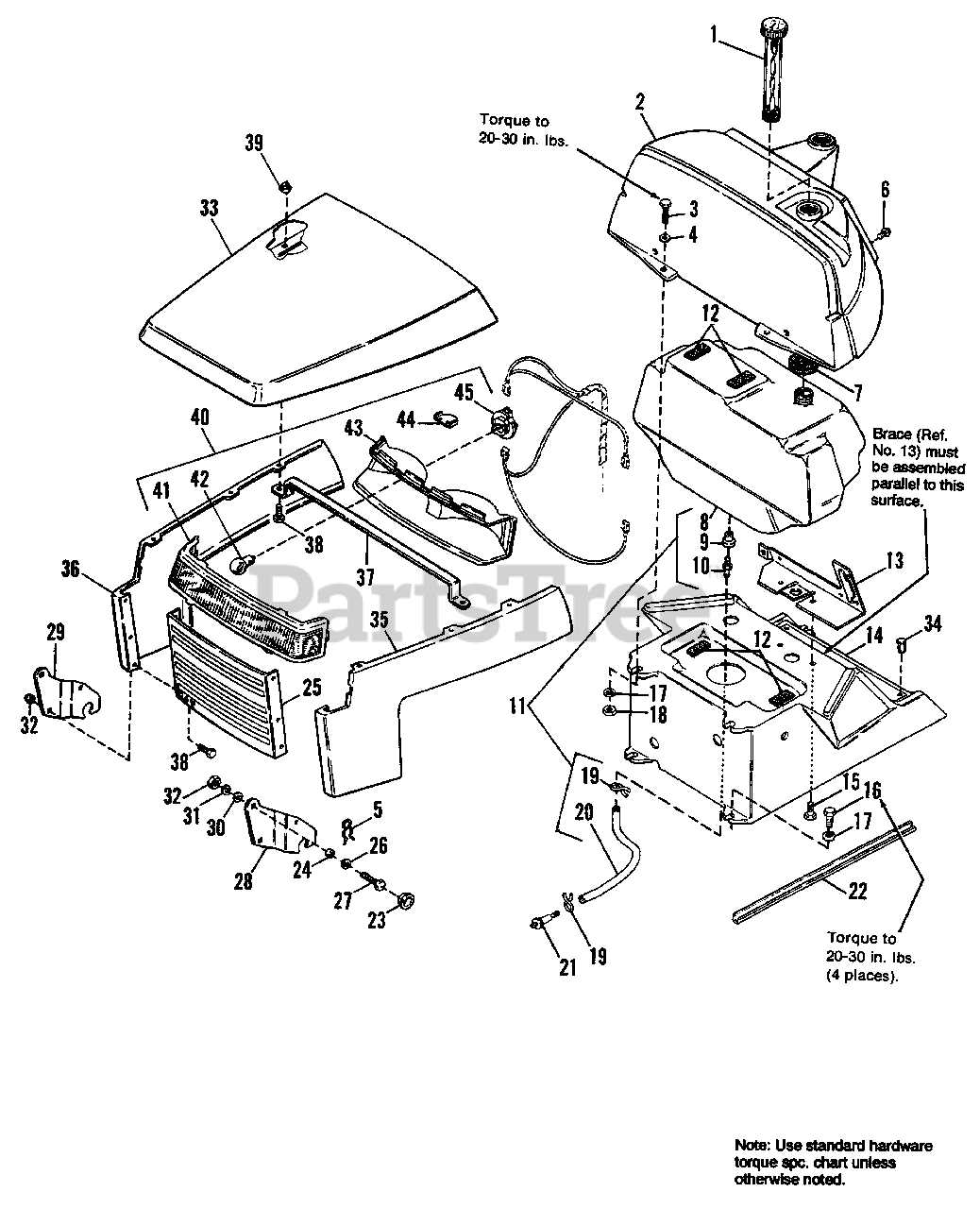

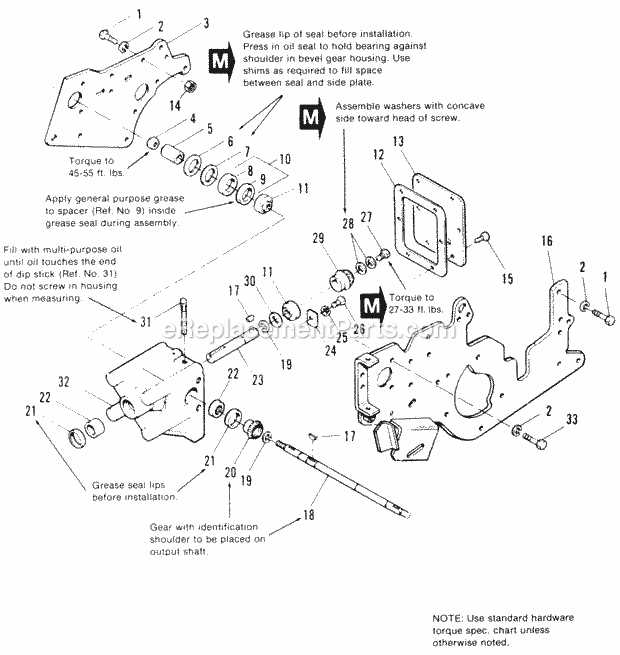

How to Use the Parts Diagram

Understanding the components of a machine can enhance maintenance and repair processes significantly. By utilizing a visual representation, you can easily identify various elements and their relationships, leading to more efficient work.

Here are some steps to effectively navigate the illustration:

- Familiarize yourself with the key symbols used in the visual representation.

- Identify the main sections and components illustrated.

- Refer to the accompanying legend to clarify any unfamiliar markings.

- Cross-reference the visual with your user manual for detailed descriptions.

- Note the connections between parts to understand their interactions.

Utilizing this visual aid will ultimately streamline your repair or maintenance tasks.

Common Issues with Parts Replacement

When undertaking the task of swapping out components in machinery or equipment, various challenges may arise. Understanding these obstacles can streamline the process and enhance the efficiency of repairs. Often, these difficulties stem from compatibility, quality, and installation concerns, which can lead to further complications if not addressed properly.

One of the primary issues encountered is the mismatch between new and existing components. This can result from variations in design, size, or specifications. Additionally, the quality of replacement items can vary significantly, with subpar alternatives leading to premature failure or suboptimal performance.

| Issue | Description |

|---|---|

| Compatibility | New components may not fit or function correctly with the existing system. |

| Quality | Using inferior or counterfeit replacements can result in reliability issues. |

| Installation Challenges | Improper installation techniques can damage components or lead to system failures. |

| Cost | Higher-quality replacements may have a higher initial cost, but save money in the long run. |

Addressing these concerns proactively can lead to more effective and sustainable repairs, ensuring the longevity and reliability of the machinery involved.

Benefits of Regular Maintenance Practices

Consistent upkeep is essential for ensuring the longevity and optimal performance of any system. By adhering to a structured maintenance routine, one can significantly enhance efficiency while reducing the likelihood of unexpected failures.

Enhanced Reliability: Regular inspections and servicing lead to increased reliability, minimizing the chances of breakdowns that can disrupt operations.

Cost Savings: Proactive maintenance often results in lower repair costs over time, as small issues are addressed before they escalate into more significant problems.

Improved Safety: Ensuring that equipment and systems are functioning properly helps create a safer environment for users, reducing the risk of accidents.

Extended Lifespan: Routine care contributes to the extended lifespan of components, maximizing return on investment and delaying the need for replacements.

Optimal Performance: Keeping systems well-maintained ensures they operate at peak performance, enhancing productivity and effectiveness.

Finding Authentic Replacement Parts

When seeking to maintain the efficiency and longevity of your machinery, ensuring the use of genuine components is crucial. Authentic elements not only guarantee optimal performance but also provide peace of mind regarding quality and reliability. Identifying these elements can be a challenging task, but with the right approach, it becomes manageable.

Here are some key strategies to help you locate legitimate components:

| Strategy | Description |

|---|---|

| Research Authorized Dealers | Identify and contact licensed distributors to ensure authenticity. |

| Verify Manufacturer’s Website | Check the official site for lists of recommended suppliers and components. |

| Seek Customer Reviews | Read feedback from other users to gauge the credibility of sellers. |

| Examine Packaging | Look for signs of quality in packaging, which often indicates authenticity. |

| Ask for Documentation | Request certificates or proof of authenticity from suppliers. |

By employing these strategies, you can delve deeper into the realm of genuine components, ensuring your equipment functions at its ultimate best.

Tips for Efficient Repairs and Upgrades

Ensuring smooth and effective maintenance or enhancement of equipment involves a few key strategies. By prioritizing organization and planning, you can streamline the process and achieve better outcomes.

Planning Your Approach

Before starting any work, assess the situation thoroughly. Create a checklist of necessary tools and components to avoid interruptions during the process. This proactive method helps maintain focus and efficiency.

Utilizing Resources

Make use of available manuals and online tutorials for guidance. Connecting with knowledgeable individuals or communities can provide insights that enhance your repair and upgrade strategies.

| Tip | Description |

|---|---|

| Assess Thoroughly | Identify issues and necessary materials before starting. |

| Stay Organized | Keep tools and parts in designated areas to minimize search time. |

| Consult Resources | Use manuals and online platforms for expert advice. |