The intricate design of agricultural machinery is a testament to engineering excellence, ensuring optimal performance in the field. These machines are composed of various elements that work in harmony to facilitate tasks ranging from planting to harvesting. A comprehensive understanding of these components is essential for effective maintenance and operation.

For anyone involved in the management or upkeep of agricultural equipment, having a clear overview of the assembly and functionality of each element is crucial. This knowledge not only aids in troubleshooting but also enhances the efficiency of the machinery during its operation. Identifying each component’s role can lead to better decision-making regarding repairs and replacements.

In this section, we will explore the various elements that comprise these vital machines. By analyzing the layout and interconnections, operators can gain insights into optimizing performance and ensuring longevity. Understanding the structural arrangement is key to harnessing the full potential of agricultural equipment, contributing to increased productivity on the farm.

Massey Ferguson 383 Overview

This section provides a comprehensive examination of a notable agricultural machine, highlighting its features and capabilities. Renowned for its robust design and efficient performance, this model has become a staple in various farming applications.

Engine Performance: The power unit of this tractor delivers exceptional reliability, making it suitable for both heavy-duty tasks and everyday operations. Its efficient fuel consumption ensures that users can maximize productivity while minimizing operational costs.

Transmission System: Featuring a well-engineered transmission system, this machine offers seamless gear shifting and optimal torque delivery. This design allows for smooth handling and adaptability to different working conditions.

Comfort and Usability: The operator’s environment is designed for ease of use, with intuitive controls and comfortable seating. This focus on user experience enhances efficiency during prolonged periods of operation, making it a favorite among farmers.

Versatility: Equipped to handle a variety of attachments and implements, this agricultural vehicle can easily switch from plowing to hauling, demonstrating its multifunctional capabilities. This adaptability makes it an invaluable asset in modern farming practices.

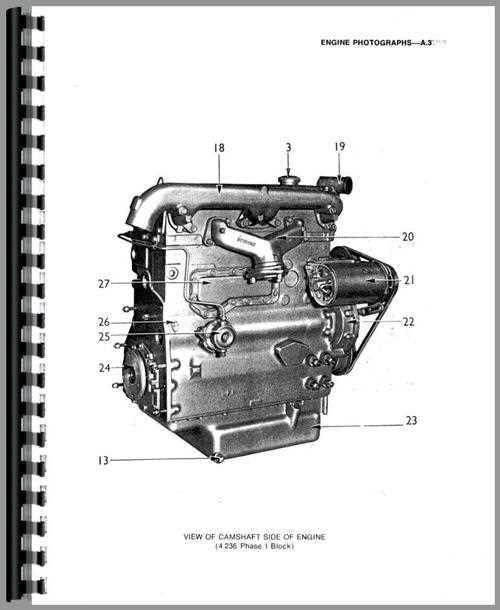

Key Components of the MF 383

This section highlights the essential elements that contribute to the functionality and performance of the agricultural machine. Understanding these components is crucial for effective maintenance and operation, ensuring that the equipment remains in optimal working condition.

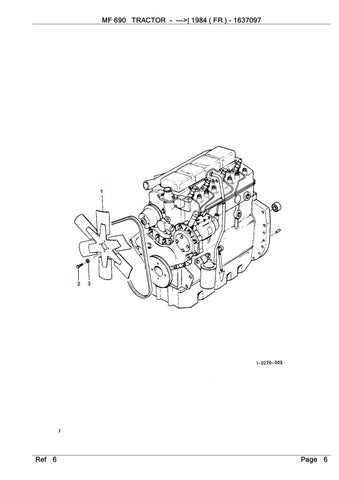

Engine System

The engine is the powerhouse of any agricultural machinery. In this context, it serves as the primary source of power, driving various operations and attachments. Key features include:

- Fuel efficiency for prolonged usage

- Robust design for enhanced durability

- High torque output for effective fieldwork

Transmission Mechanism

The transmission system plays a vital role in transferring power from the engine to the wheels. It allows for smooth operation across different terrains and conditions. Important aspects include:

- Multiple gear ratios for flexibility

- Efficient power transfer to minimize energy loss

- Ease of use for the operator during various tasks

Maintenance Tips for MF 383

Proper upkeep of agricultural machinery is essential for optimal performance and longevity. Regular maintenance not only ensures that equipment runs smoothly but also prevents unexpected breakdowns and costly repairs. Adhering to a structured maintenance routine can significantly enhance the efficiency of your machine.

1. Regular Inspection: Conduct frequent checks on all components, including the engine, transmission, and hydraulic systems. Look for signs of wear, leaks, or loose connections. Addressing minor issues promptly can prevent more significant problems in the future.

2. Fluid Levels: Maintain appropriate levels of oil, coolant, and hydraulic fluid. Regularly check these fluids to ensure they are clean and at the right levels. Replacing them as needed is crucial for the machine’s overall health.

3. Air Filters: Clean or replace air filters as recommended by the manufacturer. Clogged filters can reduce engine efficiency and increase fuel consumption. Keeping air intake systems clear ensures optimal performance.

4. Tire Maintenance: Regularly check tire pressure and tread wear. Properly inflated tires improve traction and fuel efficiency. Rotate tires as needed to promote even wear.

5. Battery Care: Inspect battery terminals for corrosion and ensure connections are secure. Keep the battery charged and replace it when necessary to avoid starting issues.

6. Cleaning: Regularly clean the machine to remove dirt, debris, and residue. This practice helps prevent corrosion and maintains visibility for operators.

7. Scheduled Servicing: Adhere to the manufacturer’s recommended servicing schedule. Professional inspections and servicing can identify potential issues before they escalate and keep the machinery in peak condition.

Common Issues and Solutions

This section focuses on frequent challenges faced by operators of agricultural machinery, along with effective remedies to ensure optimal performance. Understanding these common problems can help in maintaining the equipment and avoiding costly repairs.

| Issue | Description | Solution |

|---|---|---|

| Engine Overheating | Excessive temperature due to low coolant levels or a faulty thermostat. | Check and replenish coolant levels, and replace the thermostat if necessary. |

| Poor Fuel Efficiency | Increased fuel consumption, often caused by dirty filters or improper air intake. | Replace air and fuel filters regularly to improve efficiency. |

| Hydraulic System Failure | Malfunctioning hydraulic components can lead to reduced lifting capacity. | Inspect hydraulic fluid levels and check for leaks; replace worn seals. |

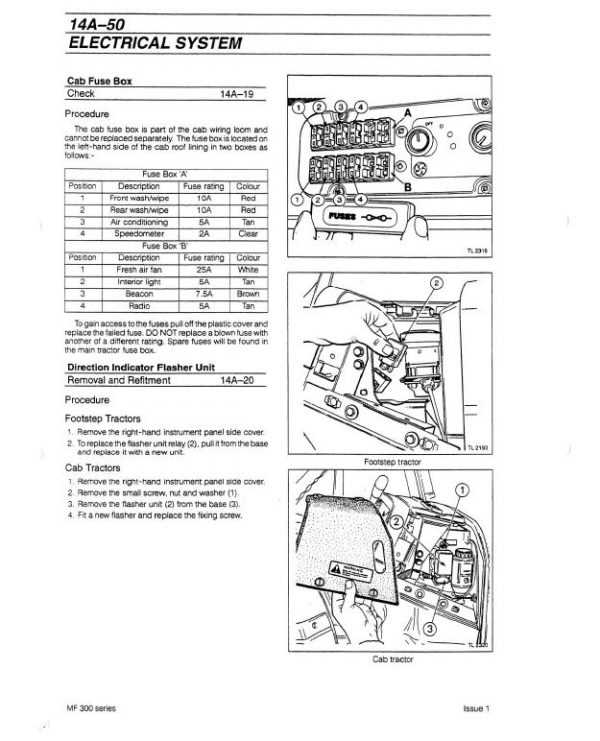

| Electrical Problems | Issues with starting or lighting due to faulty wiring or battery failure. | Examine wiring for damage and ensure the battery is fully charged and connections are clean. |

| Transmission Difficulties | Challenges in shifting gears can indicate low fluid levels or internal wear. | Check transmission fluid levels and change the fluid regularly to prevent wear. |

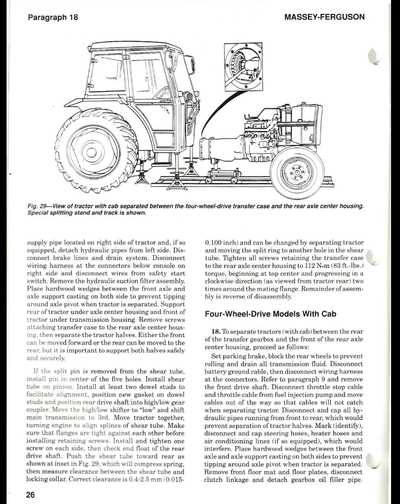

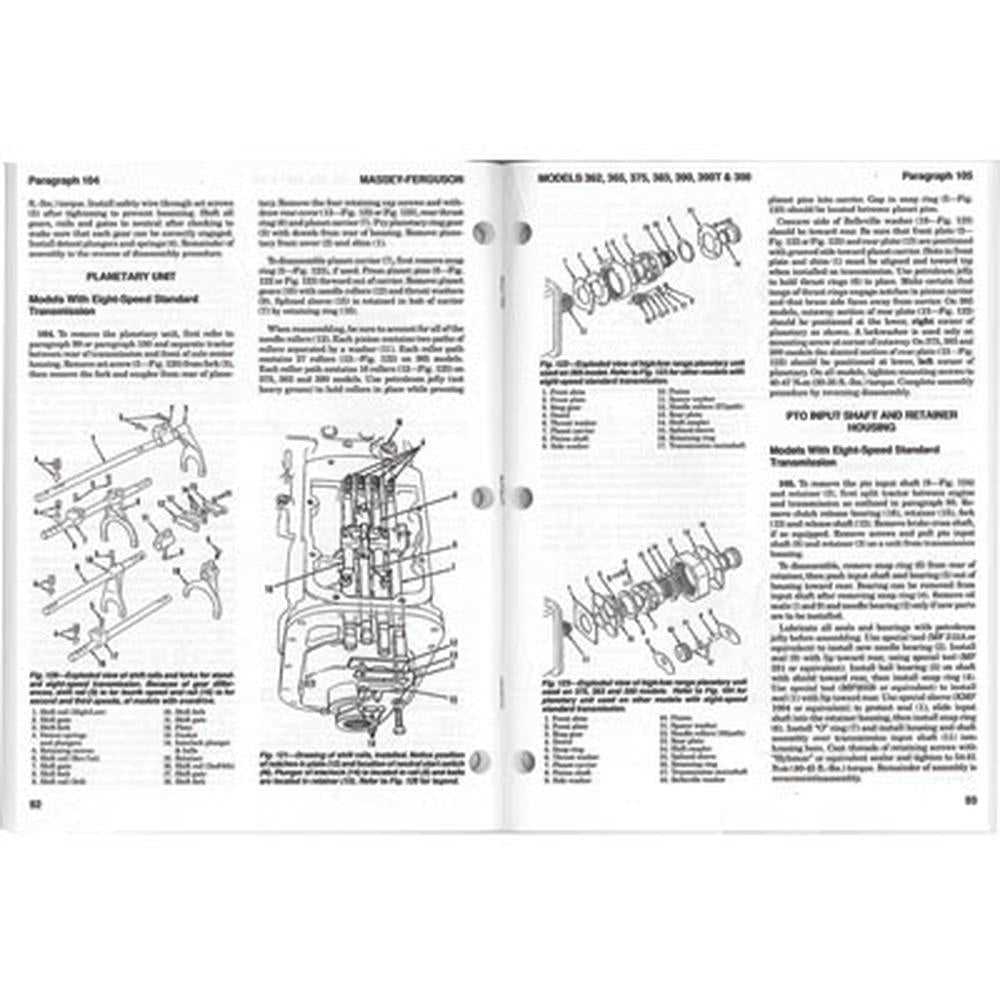

Understanding the Parts Diagram

Grasping the layout of a machine’s components is essential for efficient maintenance and repair. Such illustrations provide a visual representation of various elements, aiding in identifying each section’s function and relationship with others. By understanding these visuals, operators can more effectively manage upkeep and troubleshoot issues that may arise during operation.

Importance of Component Identification

Recognizing individual elements within the illustration allows users to locate specific areas needing attention. This familiarity enhances the ability to perform repairs without confusion and reduces the risk of misplacing or improperly installing components. Moreover, being aware of each element’s purpose fosters a deeper understanding of the machine’s overall functionality.

Utilizing the Illustration for Maintenance

When conducting maintenance, referring to the visual guide streamlines the process. It ensures that each step is followed accurately, minimizing the chances of oversight. Additionally, this resource can assist in ordering the correct replacements, ensuring compatibility and efficiency in restoration efforts. Overall, a well-understood visual guide serves as a valuable tool in preserving the machine’s performance.

Replacement Parts Availability

Access to essential components is crucial for maintaining the efficiency and performance of agricultural machinery. Availability of these items ensures that operators can quickly address any issues that arise, minimizing downtime and maintaining productivity on the farm. Various options exist for sourcing these crucial elements, catering to both original equipment and aftermarket solutions.

Sources for Components

Operators can explore multiple avenues for acquiring the necessary items. Authorized dealerships provide genuine components with manufacturer support, ensuring quality and compatibility. Additionally, independent suppliers often offer competitive alternatives that can be equally effective, allowing for flexibility in budget and choice.

Online Platforms

In the digital age, online marketplaces have become invaluable resources for locating specific items. Websites dedicated to agricultural machinery often feature extensive inventories, enabling users to search for specific elements quickly. This accessibility can lead to more informed purchasing decisions and potential cost savings through comparison shopping.

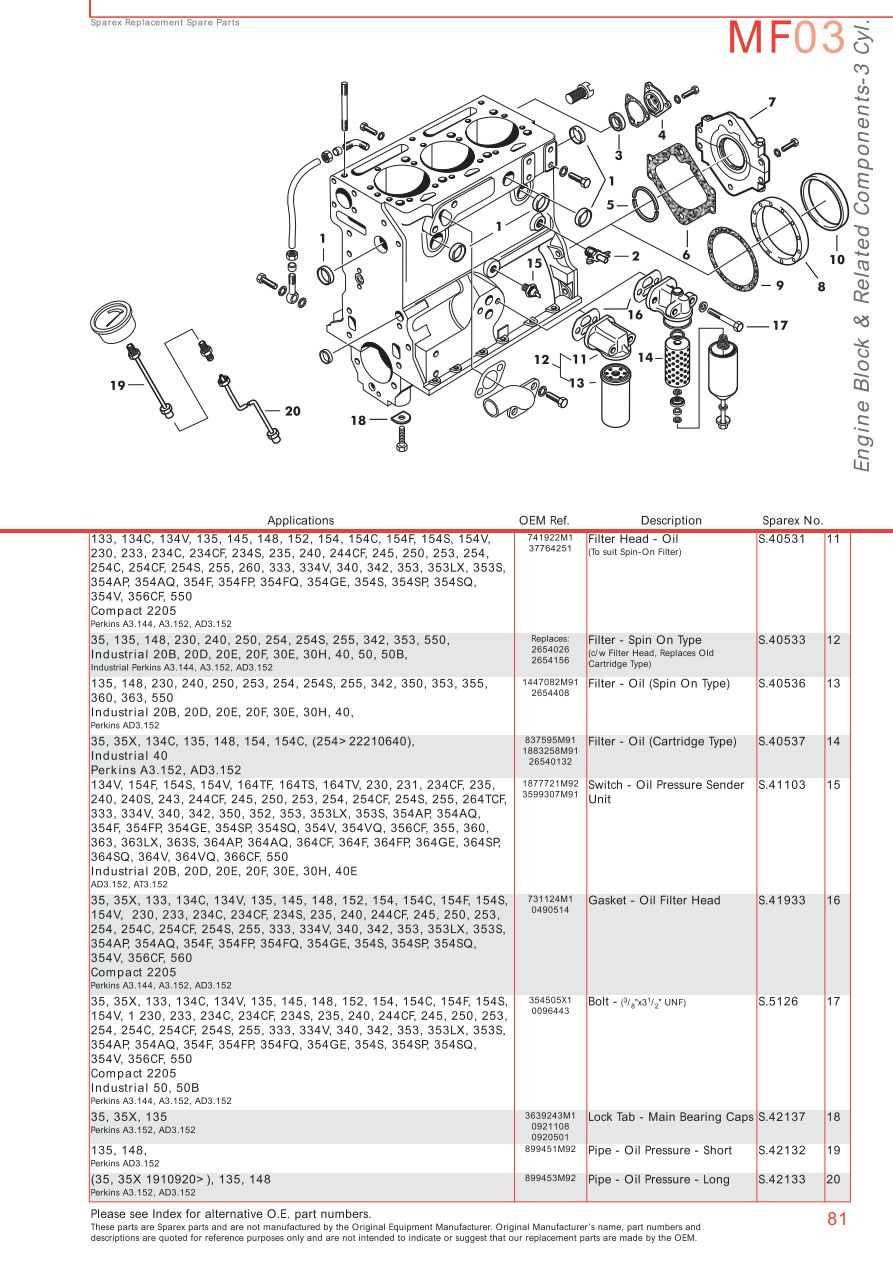

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide valuable insights into the relationships between various elements and their respective functions within machinery. By grasping the conventions used in these visuals, users can navigate complex assemblies with ease.

Here are some key strategies to enhance your comprehension of these visuals:

- Familiarize Yourself with Symbols: Each representation utilizes specific icons to signify various elements. Learning these symbols will enable you to interpret the illustration accurately.

- Follow the Flow: Observe how components are connected and organized. Understanding the flow of the assembly can help you identify how each part interacts with others.

- Note the Numbering System: Many visuals include a numbering scheme that corresponds to a list of components. This can be crucial for identifying specific items needed for repairs or replacements.

- Refer to the Legend: Most illustrations come with a legend that explains symbols and color codes. Consult this section to clarify any uncertainties regarding the components.

- Practice Regularly: The more you engage with these visuals, the more adept you will become at interpreting them. Regular practice will boost your confidence and proficiency.

By applying these techniques, you can significantly improve your ability to navigate and understand component representations, ultimately leading to more efficient repairs and maintenance tasks.

Benefits of Using Genuine Parts

Utilizing authentic components in machinery ensures optimal performance and longevity. These original items are designed specifically for the equipment, providing superior compatibility and reliability. Choosing genuine items over aftermarket alternatives can prevent unforeseen issues and contribute to the overall efficiency of operations.

Quality Assurance

Authentic components undergo rigorous testing and quality control processes. This guarantees that each part meets the highest industry standards, minimizing the risk of premature failure. When using original components, users can be confident in their durability and effectiveness, leading to reduced maintenance costs over time.

Enhanced Performance

Original components are engineered to work seamlessly with the machinery, ensuring optimal functionality. This synergy results in improved efficiency, which translates to better productivity. In contrast, aftermarket parts may not offer the same level of performance, potentially leading to increased wear and tear on the equipment.

| Feature | Genuine Parts | Aftermarket Parts |

|---|---|---|

| Quality Control | High standards and testing | Varies widely |

| Performance | Optimal and reliable | Inconsistent |

| Warranty | Typically included | Limited or absent |

| Longevity | Enhanced lifespan | May wear out faster |

FAQs About MF 383 Parts

This section addresses common inquiries regarding components for a well-known agricultural machine. Understanding the available elements and their specifications can significantly aid in maintenance and repair efforts. Below are frequently asked questions that provide insight into the necessary components, ensuring that users can make informed decisions when seeking replacements or enhancements.

What should I consider when purchasing components?

When looking to acquire elements for your equipment, it is essential to verify compatibility with your specific model. Additionally, consider the quality of the components, as opting for genuine or high-quality aftermarket items can enhance performance and longevity. Always check for warranties and return policies to safeguard your investment.

Where can I find reliable information about available components?

Reliable sources for information on available components include authorized dealers, online marketplaces, and dedicated agricultural equipment forums. Many manufacturers provide catalogs and specifications on their official websites, which can also assist in identifying suitable replacements.