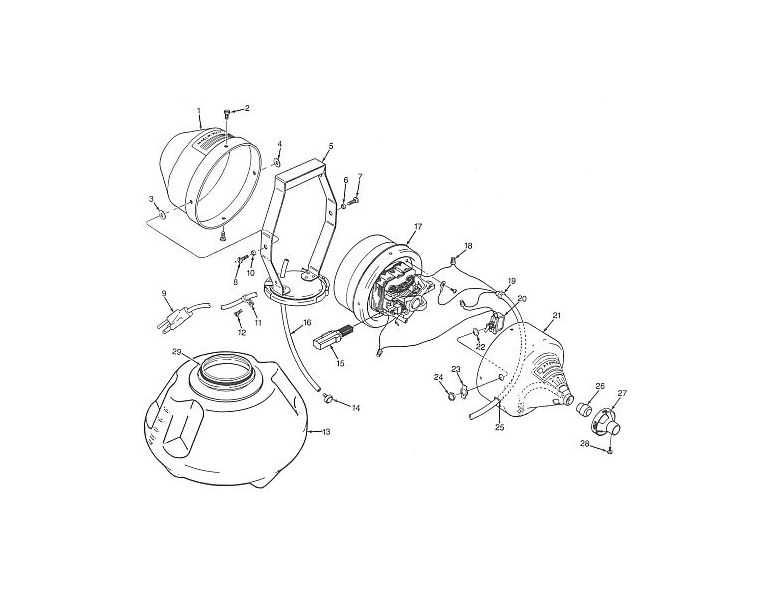

When working with complex devices, it’s essential to know how individual elements come together to create a functional system. Proper identification and understanding of each element help ensure smooth operation and facilitate easy troubleshooting in case of any issues. The layout of these elements offers clarity on how different segments interconnect to form a cohesive unit.

Each component plays a critical role in maintaining the overall performance. Whether you’re looking to improve efficiency or simply familiarize yourself with the setup, having a clear overview of the structure is invaluable. Understanding the specific functions of individual elements allows for more precise adjustments and maintenance, ultimately extending the lifespan of the equipment.

By gaining insight into the arrangement and purpose of each segment, users can efficiently address operational challenges and maintain optimal functionality. Knowing where to focus when making adjustments or repairs can save time and

Understanding the Components of a Sprayer

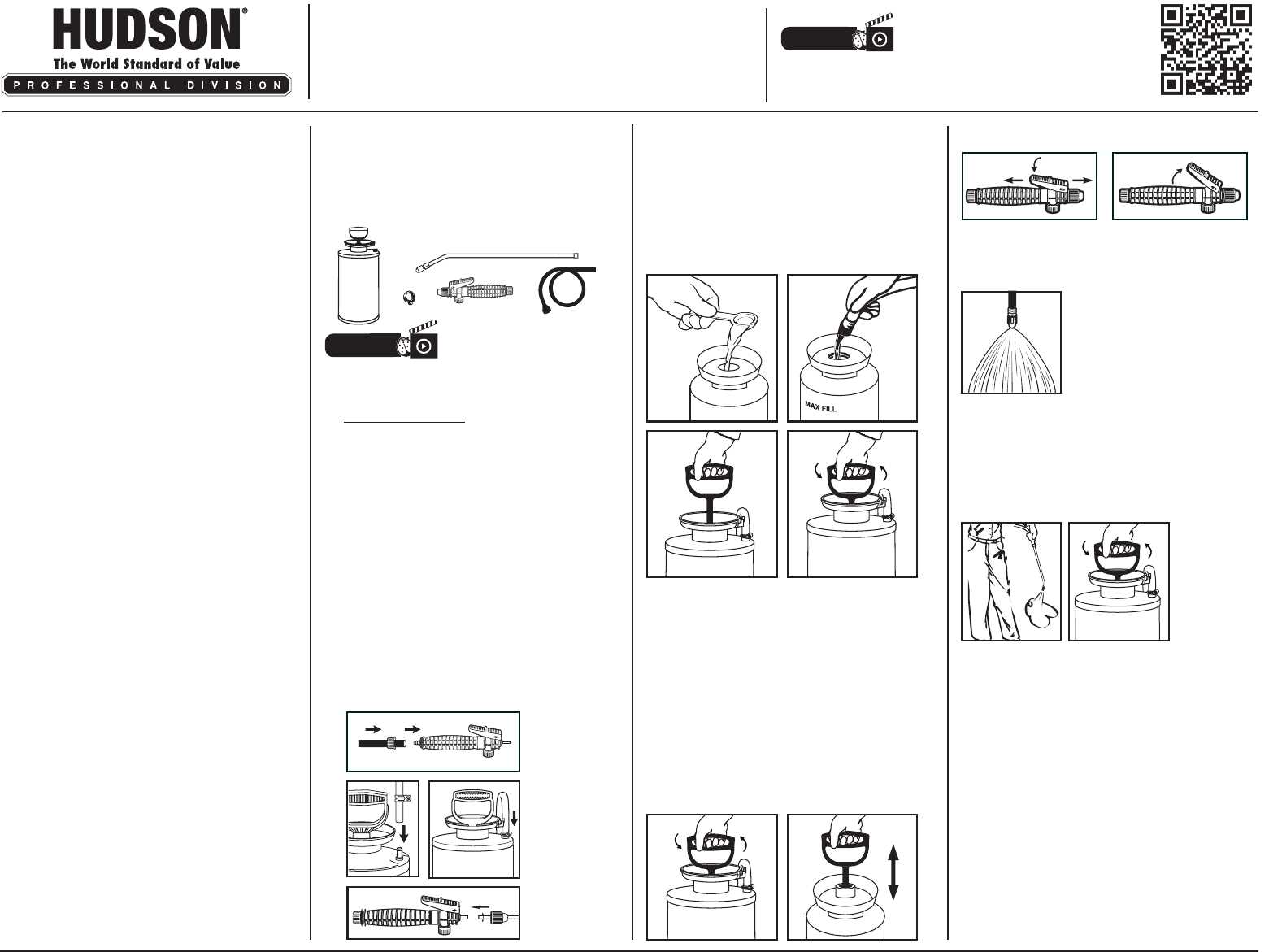

Each piece of equipment used for liquid dispersion plays a crucial role in ensuring even distribution and efficiency. Whether for gardening, cleaning, or industrial use, these systems rely on multiple interconnected elements that work in harmony to deliver precise results. By understanding how each part functions, one can ensure proper maintenance and optimal performance.

Main Elements and Their Functions

The core mechanisms involve several critical sections, each designed for a specific task. The container holds the liquid, while the pump generates the necessary pressure. A series of valves control the flow, ensuring smooth operation. These elements are essential for a consistent and even spray, allowing users to adjust the output according to their needs.

Key Features for Efficient Operation

How a Sprayer Works: Key Insights

Understanding the basic function of a fluid-dispensing tool can provide valuable insights into its operation. These devices are designed to distribute liquids efficiently over a targeted area, relying on a few key components that work together to achieve optimal results. The mechanism combines pressure and controlled release, ensuring precise application.

Pressure Mechanism: One of the central aspects involves creating sufficient internal force to propel the liquid. This can be achieved through either manual or automated means, depending on the type of device being used.

Fluid Release: The liquid is expelled through a nozzle, where flow and spread can be regulated. This allows users to manage the quantity and range of distribution, making the device adaptable to different tasks and environments.

These tools, when used correctly

Common Issues and Their Solutions

In various mechanical devices, users often encounter recurring challenges that can affect performance and longevity. Understanding the frequent malfunctions and knowing how to address them can help maintain optimal operation and extend the life of the equipment.

- Inconsistent Pressure: A drop in pressure can often be attributed to blockages or wear in key components. Regular cleaning and replacing worn-out parts can restore smooth operation.

- Leakage: Leaks may arise due to damaged seals or loose connections. Inspecting these areas and tightening or replacing the faulty elements is essential to prevent further issues.

- Clogging: Debris buildup in the system can restrict flow and reduce efficiency. Regular flushing and using filters can help prevent this problem from occurring.

- Component Wear: Over time, certain elements may wear down, leading to reduced effectiveness

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-term functionality of any equipment. Regular attention to key elements, careful cleaning, and prompt replacements of worn components can extend the lifespan significantly. Below are a few important guidelines to help maintain optimal performance and reliability over time.

- Routinely inspect all connections and joints to prevent potential leaks or malfunctions.

- After each use, thoroughly rinse internal and external surfaces to avoid buildup that could impair efficiency.

- Store in a dry, sheltered area to protect from environmental damage or unnecessary wear.

- Replace seals, gaskets, or other vulnerable parts as soon as they show signs of deterioration.

- Periodically lubricate moving parts to reduce friction and ensure smooth operation.

By following these steps, you can significantly enhance the durability and effectiveness of your equipment, ensuring that it serves you well for years to come.

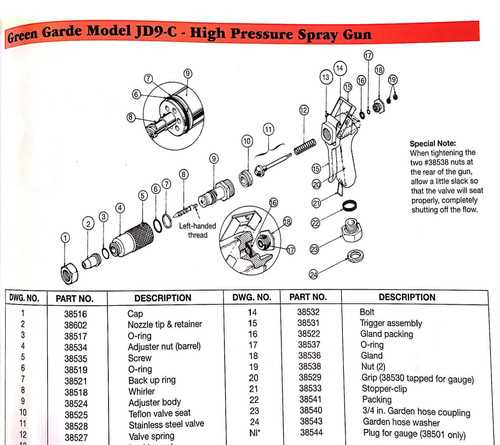

Replacing Essential Parts: A Guide

When it comes to maintaining optimal performance, knowing how to replace key components is crucial. Regular wear and tear can lead to reduced efficiency, and replacing the right elements ensures longevity and reliability. This guide provides a step-by-step overview of the process, highlighting important aspects without diving into overly technical details.

To get started, it’s important to gather the necessary tools and prepare the equipment properly. Here are the main steps to follow:

- Identify the component that needs to be replaced, ensuring it’s the correct one for your model.

- Disconnect any connections

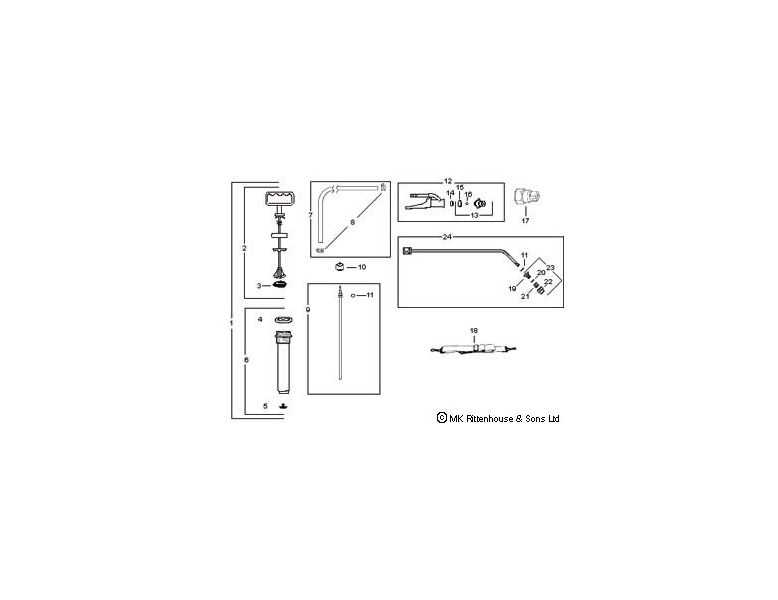

Choosing the Right Nozzle for Your Needs

Selecting the appropriate nozzle is crucial for achieving optimal results in various applications. The right choice can enhance efficiency, improve coverage, and ensure effective distribution of liquids, whether for gardening, cleaning, or agricultural purposes. Understanding the specific requirements of your tasks will guide you in making an informed decision.

Types of Nozzles

There are several types of nozzles available, each designed for particular tasks. Flat fan nozzles are ideal for broad coverage, making them suitable for spraying herbicides or pesticides. In contrast, cone nozzles are designed for targeted applications, offering a focused spray pattern for more precise work.

Factors to Consider

When choosing a nozzle, consider factors such as flow rate, pressure, and application technique. The flow rate will determine how much liquid is dispensed over time, while pressure affects the spray pattern and droplet size. Matching these factors to your specific tasks will help achieve the desired results efficiently.

Troubleshooting Pressure Problems

Pressure-related issues can significantly impact the performance of your equipment, leading to inefficiencies and operational challenges. Identifying the root causes of these problems is essential for restoring optimal functionality. This section provides insights into common pressure issues and their potential resolutions, enabling users to maintain consistent performance.

Common Symptoms of Pressure Issues

Users may notice irregular spray patterns, reduced flow, or unexpected drops in pressure during operation. These symptoms often indicate underlying mechanical or system-related issues that require attention. Regular inspections can help detect problems early, allowing for timely interventions and preventing further complications.

Steps to Resolve Pressure Challenges

To address pressure concerns effectively, start by checking all connections for leaks or blockages. Ensure that filters are clean and unobstructed, as accumulated debris can restrict flow. Additionally, verify that the pressure regulator is functioning correctly and adjust it if necessary. Regular maintenance and prompt attention to identified issues can significantly enhance the overall performance of your equipment.

Cleaning and Storing Your Equipment Properly

Maintaining your tools and devices in optimal condition is essential for their longevity and efficiency. Proper cleaning and storage not only enhance performance but also ensure safety during use. Following a systematic approach can significantly extend the life of your equipment and prevent unnecessary wear and tear.

To begin with, regular cleaning should be a part of your maintenance routine. Here are some steps to consider:

- Rinse: After each use, rinse the equipment thoroughly to remove any residues that could cause corrosion or clogging.

- Disassemble: If applicable, take apart the components to clean each piece effectively.

- Scrub: Use a soft brush or cloth to scrub away any stubborn deposits or dirt.

- Dry: Ensure all parts are completely dry before reassembling to prevent moisture damage.

Once the cleaning process is complete, proper storage becomes crucial. Here are some tips to keep in mind:

- Choose a dry location: Store your equipment in a cool, dry place to avoid exposure to moisture.

- Avoid direct sunlight: Keep the tools away from direct sunlight to prevent degradation of materials.

- Organize: Use racks or bins to organize equipment, preventing unnecessary damage and making access easier.

- Inspect regularly: Conduct routine checks for any signs of wear or damage while in storage.

By incorporating these practices into your routine, you can ensure that your tools remain in excellent condition and are always ready for use.