When working with outdoor maintenance equipment, it’s essential to have a clear understanding of how each component functions and interacts with others. This knowledge can significantly improve performance and longevity, ensuring the machine operates smoothly under various conditions. Whether you’re dealing with regular upkeep or troubleshooting, familiarizing yourself with the layout of key elements is crucial for efficient operation.

In the next sections, we’ll explore the main mechanisms and their configuration. By examining how different elements are arranged and connected, you can gain a deeper insight into the structure and the purpose of each part. This will make it easier to address any technical issues and carry out maintenance effectively, minimizing downtime and maximizing productivity.

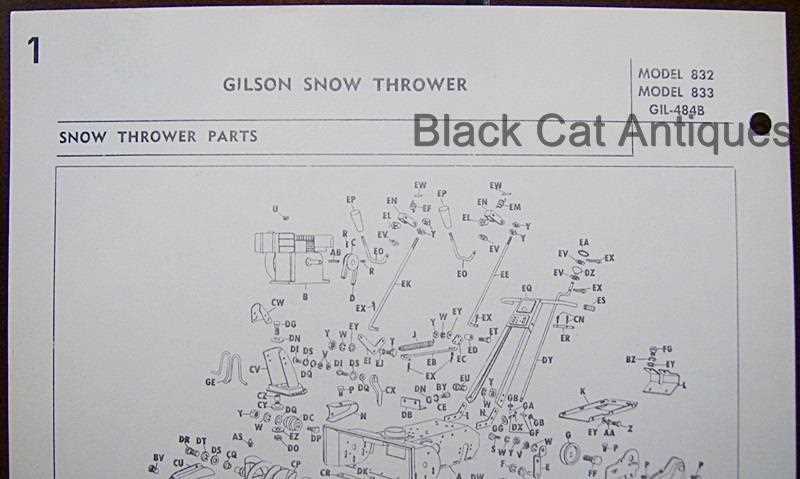

Understanding the Components of a Snowblower

The operation of a winter clearing machine involves various interconnected elements working together to remove snow efficiently. Each part plays a crucial role in ensuring smooth performance, allowing the machine to handle different conditions and surfaces. A good understanding of these components helps in maintaining and optimizing the equipment for long-term use.

Key Mechanical Elements

At the heart of the machine are its mechanical systems. These include moving parts that provide the force needed to collect and throw snow away from the clearing path. Components such as rotating mechanisms, drive systems, and control levers all contribute to the device’s ability to operate effectively in winter weather.

Structural and Functional Features

Equally important are the structural components that support and protect the machine. Frames, housings, and panels safeguard the internal mechanisms while ensuring the machine maintains stability during use. Adjustments and settings also allow users to modify performance depending on snow conditions, adding versatility to the overall design.

Key Mechanical Elements of a Snowblower

The essential mechanical components of a winter clearing machine play a crucial role in its functionality and overall performance. Each part is designed to handle specific tasks, from moving snow efficiently to ensuring the operator’s control over the machine. Understanding these key components can help in maintaining and optimizing the equipment’s effectiveness during use.

Engine System: The engine provides the necessary power to drive the machine, turning mechanical energy into motion. This system is often robust, built to withstand harsh winter conditions while delivering consistent output.

Auger and Impeller Mechanisms: These elements work together to gather and eject snow, making them vital for clearing pathways. The auger pulls in material from the surface, while the impeller expels it through a chute, ensuring the job is done swiftly and efficiently.

Drive and Transmission System: The propulsion mechanism allows the machine to move forward or backward, offering the operator full control over its direction. Depending on the model, there can be multiple speed settings for better handling of various terrains.

Chassis and Frame: A sturdy framework ensures that all components are securely held together, providing stability and durability during operation. The frame must be designed to handle the weight and stress of continuous use without compromising structural integrity.

Controls and Adjustments: The operational interface includes levers and handles that allow the user to manage speed, direction, and chute positioning. These controls are designed to be intuitive, enabling quick adjustments as conditions change.

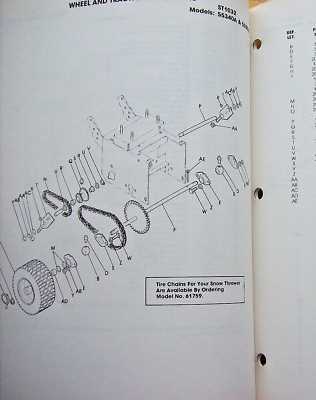

Diagram of the Drive System in Snowblowers

The drive system is a crucial mechanism that enables efficient operation by transferring power from the engine to the movement controls. This system relies on various interconnected components, each playing a role in ensuring smooth propulsion and control. Understanding the structure and flow within this mechanism is essential for maintaining optimal functionality and troubleshooting any potential issues.

| Component | Function |

|---|---|

| Drive Belt | Transfers power from the motor to the wheels or tracks. |

| Friction Disc | Regulates speed by controlling the contact between moving parts. |

| Transmission | Enables gear shifting, allowing for variable speeds and torque control. |

| Axle | Supports the wheels or tracks, facilitating movement. |

| Control Lever | Allows the operator to adjust direction and speed. |

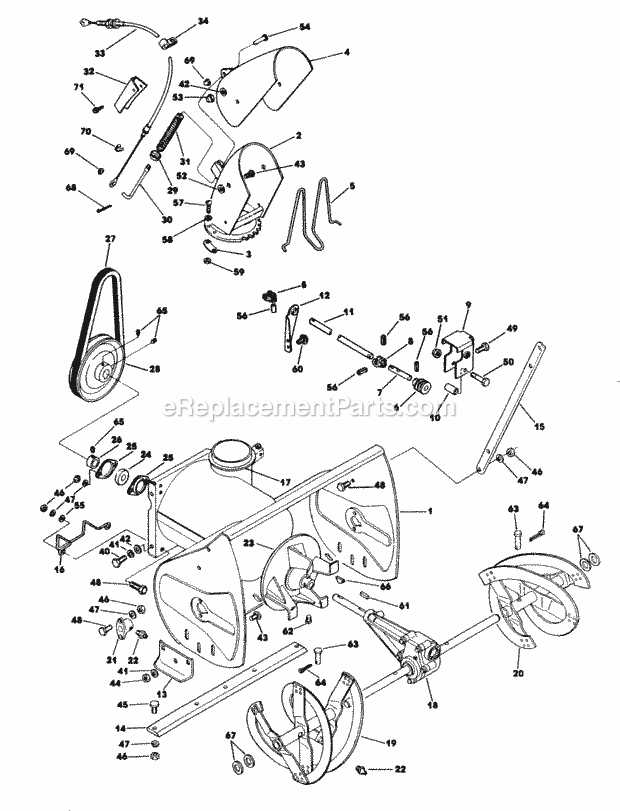

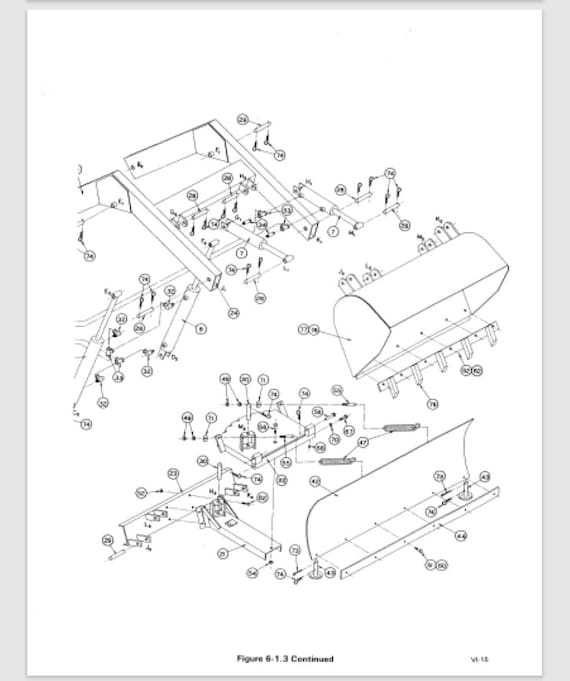

Exploring the Auger Assembly Structure

The auger assembly plays a crucial role in the overall performance of a machine designed to handle challenging conditions. This component is responsible for moving materials efficiently, ensuring smooth operation. Understanding how the various elements of the assembly work together helps in maintaining the system’s functionality and prolonging its life.

Main Components

- Blades: These are the primary elements that engage with the material, moving it toward the desired destination. Their shape and size directly affect the efficiency.

- Axle: The central shaft that supports the rotating blades. It serves as the backbone of the assembly, transferring the force needed for proper movement.

- Bearings: Placed strategically along the axle, these reduce friction and ensure smooth rotation.

Functionality and Maintenance

- Regular inspection of blades for wear and damage helps prevent operational issues.

- Ensuring the axle remains straight and free of debris promotes consistent performance.

- Proper lubrication of bearings reduces the chance of mechanical failure.

Blower Housing and Impeller Design

The structure of the blower housing and the design of the impeller play a crucial role in the overall performance of a machine designed to handle heavy-duty materials. These components are engineered to enhance airflow, ensuring effective propulsion and efficient removal of debris. Understanding how these elements interact helps optimize their performance.

The blower housing is responsible for containing the airflow and directing it efficiently, while the impeller’s function is to generate the necessary force to propel material. The shape and material of the impeller directly affect the velocity and volume of air moved.

- Housing construction: Typically crafted from durable materials, it must withstand high-speed operation and environmental stresses.

- Impeller design: The number and shape of the blades significantly influence airflow and efficiency.

- Performance impact: A well-designed combination of housing and impeller ensures reduced clogging and maximizes the device’s power.

When assessing these components, attention to detail in their design can lead to longer operational life and better overall efficiency, contributing to smoother and more reliable operation.

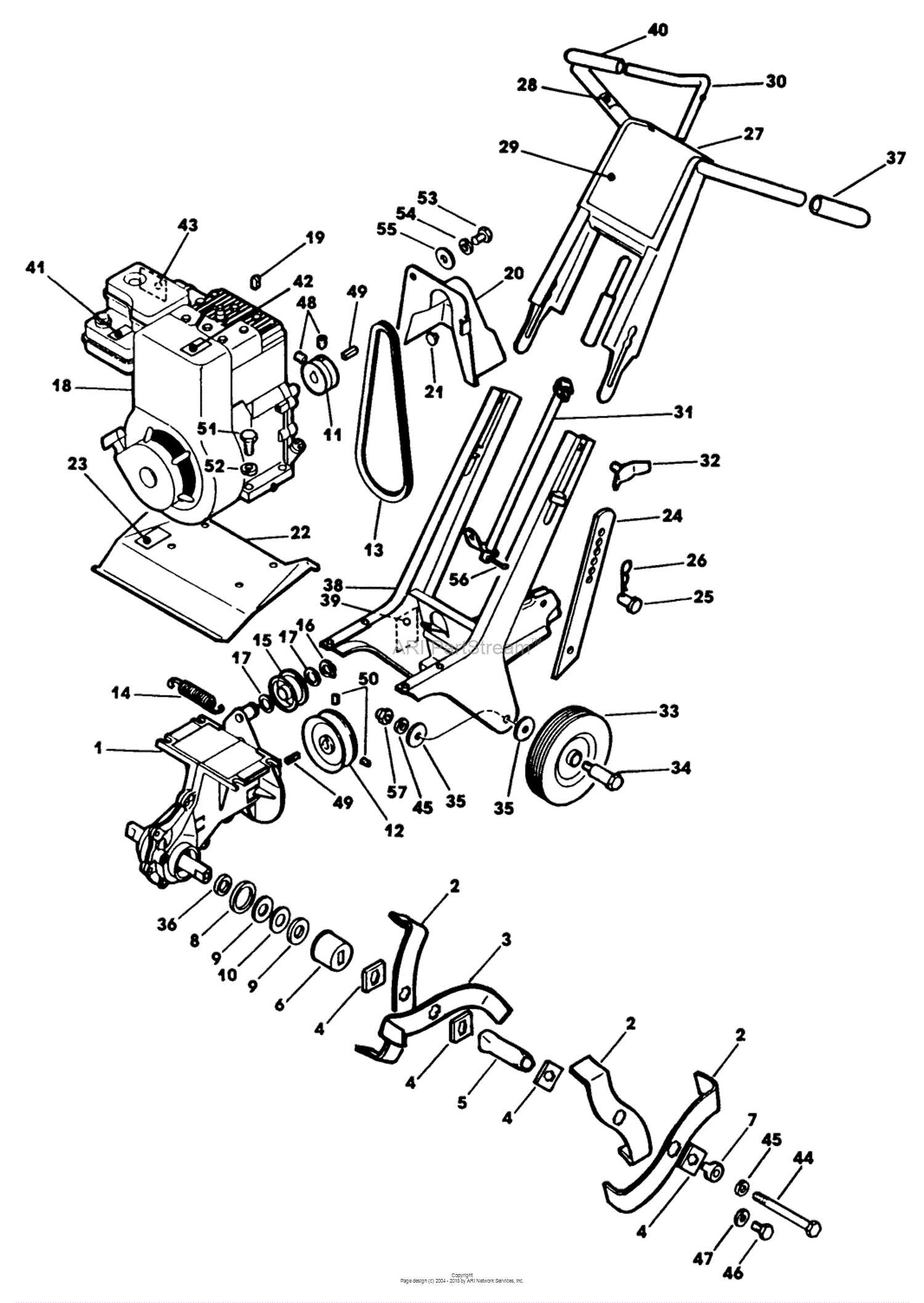

Snowblower Chassis and Frame Overview

The chassis and frame of a snow-clearing machine serve as the foundation, providing stability and support for all other components. This structure is crucial for maintaining the machine’s integrity during operation, ensuring that it can withstand the rigors of heavy use in challenging winter conditions. Understanding the design and function of this framework is essential for effective maintenance and performance optimization.

The frame is typically constructed from durable materials that can endure harsh environments while resisting corrosion. It houses various essential elements, including the engine and drivetrain, and is designed to facilitate easy access for repairs and replacements. A well-designed chassis not only enhances the machine’s overall functionality but also contributes to user comfort and control during operation.

Regular inspections of the chassis are vital for identifying wear and tear, which can affect performance. Ensuring that the frame remains in good condition is key to maximizing the longevity and efficiency of the equipment. Proper maintenance routines should include checking for any signs of damage, ensuring that all components are securely mounted, and addressing any rust or corrosion issues promptly.

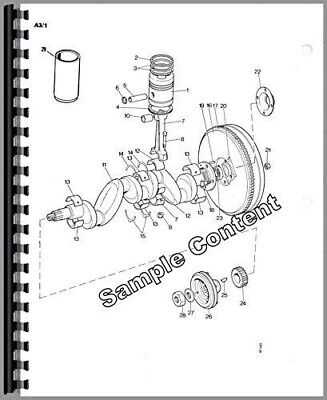

Engine and Transmission Parts Breakdown

This section provides an overview of the key components involved in the power and movement systems of outdoor machinery. Understanding the roles of various elements can enhance the maintenance and repair process, ensuring optimal performance during operation. Each component serves a vital function in converting energy into mechanical motion, contributing to the overall efficiency of the equipment.

The engine serves as the heart of the machinery, responsible for generating the necessary power. It comprises several critical components, including the cylinder, pistons, and crankshaft, each working in harmony to facilitate combustion and energy conversion. The transmission, on the other hand, plays a crucial role in transferring this power to the wheels or other moving parts. It typically includes gears, belts, and other mechanisms that allow for speed variation and torque management, enabling the machinery to operate effectively in various conditions.

Regular inspection and maintenance of these systems are essential for ensuring reliability and longevity. Identifying worn or damaged components early can prevent more significant issues, allowing for timely repairs and replacements. A thorough understanding of these systems contributes to improved performance and a smoother operational experience.

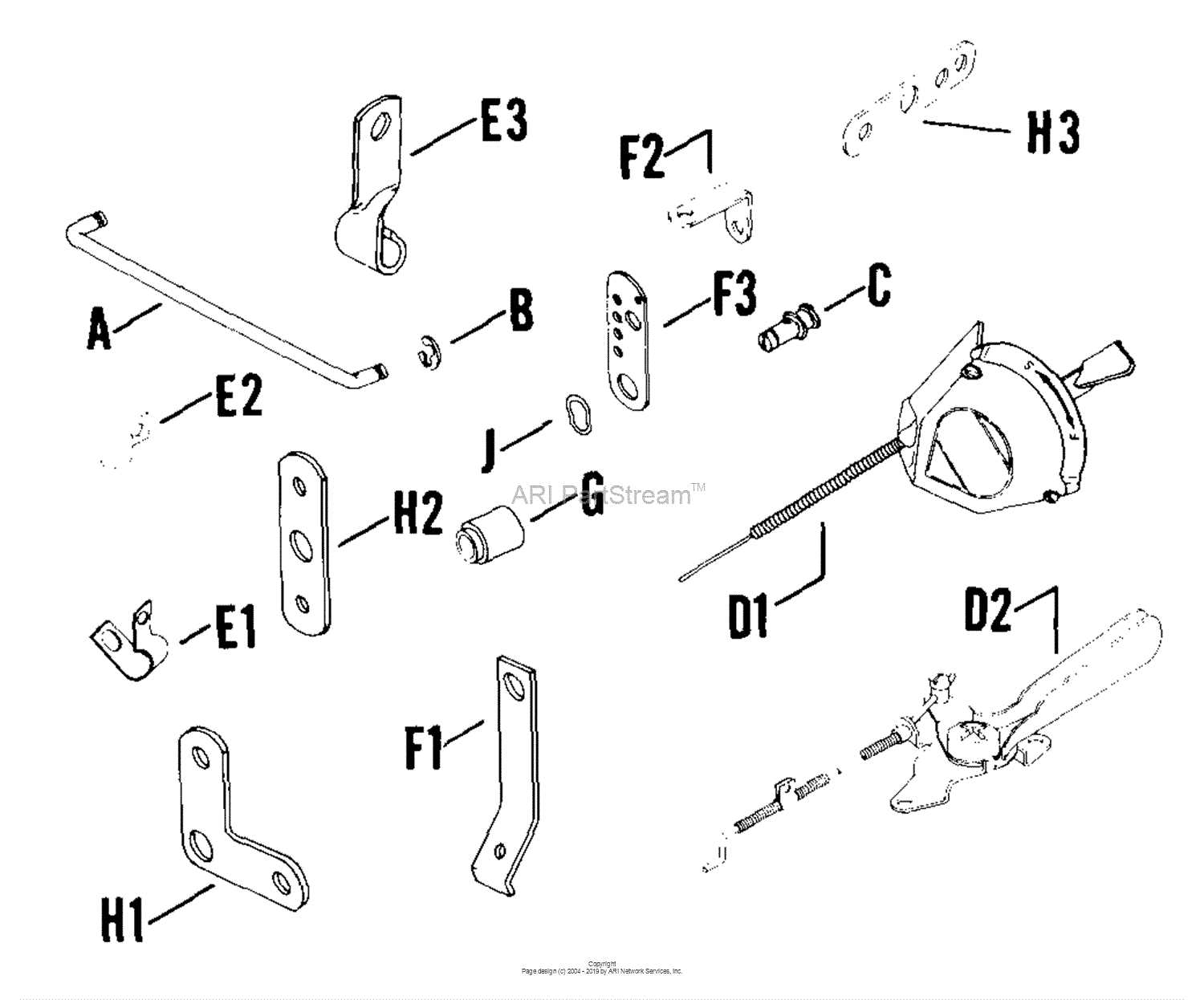

Linkage and Control Mechanisms in Snowblowers

In any outdoor equipment designed for winter maintenance, the interplay of various components is crucial for effective operation. The connection systems and control features play a vital role in ensuring that the machinery responds accurately to user inputs, enabling efficient maneuvering and adjustment during operation.

Linkage systems serve as the backbone of these machines, facilitating the transmission of force from the operator to different mechanisms. These linkages are designed to convert manual inputs into specific actions, such as height adjustment or directional changes. Understanding the layout and functionality of these linkages is essential for anyone involved in maintenance or troubleshooting.

Additionally, the control mechanisms are integral to the overall functionality of the equipment. They provide the means to regulate various operations, including speed settings and chute direction. By mastering these controls, operators can enhance efficiency and effectiveness when clearing snow from driveways or pathways.

Ultimately, a thorough comprehension of the linkage and control systems enables users to maintain their machinery effectively, ensuring long-lasting performance and reliability in challenging winter conditions.

Common Replacement Parts and Their Functions

When maintaining outdoor equipment, understanding the various components that may require replacement is crucial for optimal performance. Each element plays a specific role in ensuring the machinery operates efficiently, helping to tackle tasks effectively during the winter months.

- Auger: This rotating mechanism is essential for breaking up and collecting frozen material, allowing for effective clearing.

- Impeller: A vital component that moves the collected snow through the chute, ensuring that it is expelled away from the working area.

- Drive Belts: These components transfer power from the engine to the auger and wheels, facilitating movement and operation.

- Skid Shoes: Located on the sides, these adjustable elements control the height at which the equipment operates, allowing for better maneuverability over different surfaces.

- Choke Cable: This control mechanism regulates the engine’s air intake, helping to start the machinery in various conditions.

Understanding these components and their functions can aid in making informed decisions when it comes to maintenance and replacements, ensuring longevity and efficiency in operation.