When it comes to maintaining outdoor machinery, having a clear visual representation of its various elements is crucial. A comprehensive overview of the individual pieces can enhance both troubleshooting and repair processes, ensuring optimal performance during harsh winter conditions.

Each component plays a significant role in the functionality of the machine, and recognizing how they interact can lead to better upkeep and longevity. A well-structured reference not only aids in identifying wear and tear but also assists in sourcing replacements when necessary.

In this exploration, we will delve into a detailed outline of the essential components, providing insights that can empower users to make informed decisions regarding maintenance and repairs. By understanding the ultimate layout of these crucial elements, operators can enhance their efficiency and extend the lifespan of their equipment.

Understanding the TRS27 Snowblower

This section delves into a specific model designed for effective snow removal, highlighting its essential components and operational features. The device is engineered to tackle harsh winter conditions, ensuring efficiency and reliability during snowfall. Familiarity with its assembly will aid users in maintaining optimal performance.

The machine typically consists of a powerful engine, an auger system, and a chute for directing snow. Each element plays a crucial role in the overall functionality, from gathering snow to expelling it away from pathways. Understanding how these components interact is vital for both troubleshooting and routine maintenance.

Regular inspections and knowledge of the various mechanisms involved can significantly enhance longevity. By ensuring that each part is in good working condition, users can prevent potential breakdowns and maintain a smooth operation throughout the winter season.

In conclusion, a thorough comprehension of this equipment not only facilitates effective usage but also empowers operators to handle repairs and adjustments confidently, maximizing their investment in winter maintenance tools.

Key Components of John Deere TRS27

Understanding the essential elements of this powerful machine is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance and durability, allowing users to tackle winter conditions with confidence.

Engine: The heart of the unit, the engine provides the necessary power for all functions. Its efficiency and reliability are vital for tackling heavy snow loads.

Auger: This component is responsible for gathering and breaking up snow. Its design ensures that the material is efficiently moved towards the impeller for further processing.

Impeller: Working in tandem with the auger, the impeller directs the snow out of the chute. A well-designed impeller maximizes throwing distance and minimizes clogging.

Chassis: The sturdy frame supports all other parts and provides stability during operation. A durable chassis enhances the machine’s longevity and performance on uneven surfaces.

Controls: User-friendly controls allow for easy operation and adjustment of settings, making it simple to adapt to varying snow conditions.

Tracks or Wheels: These provide mobility and traction, crucial for navigating through deep snow and ensuring stability on slopes.

Each of these components is integral to the overall functionality, making regular inspection and maintenance essential for keeping the equipment in peak condition.

Importance of Regular Maintenance

Routine upkeep is essential for the longevity and performance of any equipment. Neglecting this critical aspect can lead to decreased efficiency, costly repairs, and potential safety hazards. By committing to consistent maintenance, users can ensure that their machinery operates at its best, avoiding unexpected breakdowns and extending its lifespan.

Preventive care helps in identifying potential issues before they escalate into major problems. Regular inspections allow for the detection of wear and tear, ensuring that components function correctly and reducing the risk of failure during operation. This proactive approach not only saves time and money but also enhances reliability.

Moreover, proper maintenance contributes to optimal performance levels. Equipment that is well cared for typically operates more efficiently, leading to better results in the field. Additionally, it fosters a safer working environment, as malfunctioning machinery can pose significant risks to operators and bystanders alike.

Investing time in upkeep is not just about preserving machinery; it’s about safeguarding investments and ensuring smooth operations. Establishing a routine can yield significant benefits, making regular maintenance a wise and necessary practice for any owner.

Common Issues and Solutions

When operating a powerful outdoor equipment, users may encounter various challenges that can affect performance. Identifying these issues promptly is crucial for ensuring optimal functionality and longevity. Below are some frequently observed problems along with effective solutions to address them.

1. Difficulty Starting: If the machine struggles to start, it may be due to old fuel or a clogged fuel line. Solution: Replace the fuel with fresh, high-quality gasoline and check for any blockages in the lines.

2. Reduced Power: A noticeable drop in power during operation can stem from a dirty air filter or worn spark plug. Solution: Regularly clean or replace the air filter and inspect the spark plug for wear, replacing it as needed.

3. Uneven Clearing: If the clearing width is inconsistent, it may indicate an issue with the blades or the height adjustment settings. Solution: Ensure that the blades are sharp and correctly aligned, and adjust the height settings according to the manufacturer’s guidelines.

4. Excessive Vibrations: Vibrations during use can be caused by loose screws or unbalanced components. Solution: Tighten all screws and inspect the equipment for any signs of imbalance or damage.

5. Blockages: Clogs can occur, especially in heavy snowfall conditions. Solution: Regularly check and clear any material buildup in the discharge chute to maintain smooth operation.

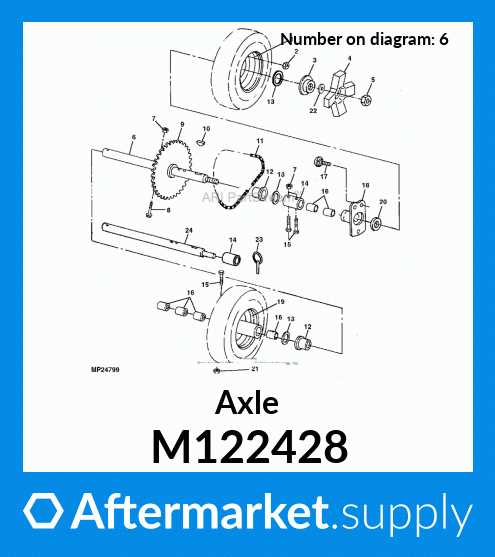

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process if you follow the right steps. Understanding where to seek reliable resources and how to interpret available information is crucial for a seamless replacement experience.

Online Resources

- Manufacturer’s Website: Explore the official site for a comprehensive catalog of available components.

- Third-party Retailers: Check specialized online shops that cater to a wide range of models.

- Forums and Community Groups: Engage with other enthusiasts to gather insights and recommendations on sourcing.

Manuals and Guides

- User Manual: Always refer to the owner’s manual for diagrams and part numbers specific to your model.

- Service Manuals: These often provide in-depth information on assembly and compatibility.

- Video Tutorials: Visual aids can simplify the identification of components and the replacement process.

By leveraging these resources, you can efficiently find what you need and ensure your equipment remains in optimal condition.

Tips for Effective Snow Removal

When winter brings its icy blanket, efficient clearing methods become essential for safety and accessibility. Proper techniques not only expedite the process but also help maintain equipment longevity and personal safety.

Preparation is Key

- Ensure all tools are in good condition before the first snowfall.

- Keep pathways clear of obstacles to facilitate movement.

- Wear appropriate footwear for grip and warmth.

Technique Matters

- Start from the center and work outward to avoid piling snow back onto cleared areas.

- Use a systematic approach, tackling smaller sections at a time.

- Take breaks to avoid fatigue, which can lead to injuries.

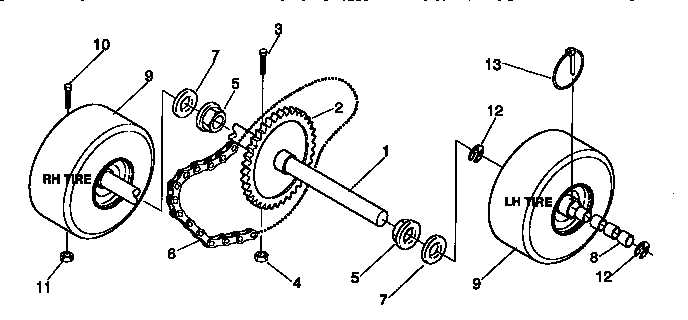

Assembly and Disassembly Guide

This section provides essential instructions for assembling and disassembling your equipment efficiently and safely. Proper handling of components is crucial for maintaining performance and prolonging the lifespan of your machinery. By following these guidelines, you will ensure a smooth process, whether you are performing maintenance or replacing specific elements.

Disassembly Instructions

Begin by ensuring the equipment is powered off and disconnected from any power source. Remove any covers or shields that may obstruct access to the internal components. Carefully document each step of the disassembly process to facilitate reassembly. Use appropriate tools to avoid damaging parts, and store removed components in an organized manner to prevent loss.

Assembly Instructions

To reassemble, start by referencing your documentation from the disassembly phase. Ensure that all components are clean and free of debris. Follow the original configuration precisely, paying attention to any specific alignment or fitting requirements. Tighten all fasteners securely, but avoid over-tightening, which can lead to damage. Finally, perform a thorough inspection before testing the equipment to ensure everything is functioning correctly.

Safety Precautions for Operation

Ensuring safety during the use of outdoor machinery is crucial to prevent accidents and injuries. Adhering to specific guidelines can help create a secure environment for both the operator and bystanders.

Pre-Operation Checks

Before starting any equipment, it is vital to conduct thorough inspections. Check for any loose components, fuel leaks, or damaged parts. Always ensure that the area is clear of obstacles and that proper safety gear, such as gloves and goggles, is worn.

Operational Guidelines

While in use, maintain a safe distance from others and never operate under the influence of substances. In case of unexpected situations, such as jams, always turn off the machine and disconnect the power source before attempting any troubleshooting. Awareness and vigilance are key to safe operation.

Resources for Further Assistance

For those seeking additional support and information related to maintenance and repairs, a variety of resources are available. Whether you’re looking for technical documentation, community forums, or expert guidance, these platforms can help enhance your understanding and ensure efficient operation of your equipment.

Online Communities

Engaging with online forums dedicated to machinery enthusiasts can provide valuable insights. Users share experiences, troubleshoot common issues, and offer tips based on personal encounters. Participating in these discussions can lead to finding solutions that may not be readily available in manuals.

Manufacturer Support

The official website of the equipment manufacturer is a reliable source for technical documents, including user manuals and maintenance guides. Additionally, customer support services are often available for direct inquiries, offering personalized assistance for specific questions or concerns.