In the world of outdoor power tools, the effectiveness and reliability of a chainsaw hinge on its intricate assembly. Each individual element plays a crucial role in ensuring optimal performance and durability, making it essential for users to grasp the relationships between these various parts.

For enthusiasts and professionals alike, familiarizing oneself with the internal structure of these machines is not just beneficial but vital for maintenance and repair. By comprehensively exploring the layout and function of each component, users can enhance their knowledge and skills, leading to improved operational efficiency.

In this discussion, we will delve into the specifics of a renowned chainsaw model, highlighting its essential features and offering insights that cater to both novice and experienced users. Understanding how each piece works together ultimately empowers users to make informed decisions regarding repairs and enhancements.

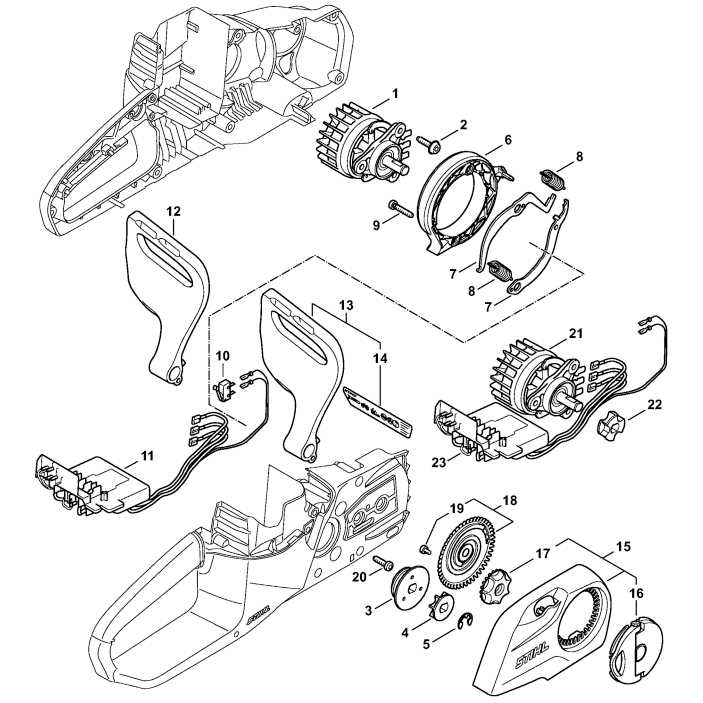

Understanding the Stihl MS 660 Parts

When operating a powerful tool, familiarity with its components is essential for optimal performance and maintenance. Recognizing the individual elements that comprise the machinery allows users to troubleshoot issues effectively and enhance the lifespan of their equipment. Each segment plays a vital role in ensuring the overall functionality and efficiency of the device.

Key Components: Among the most critical elements are the engine, bar, and chain. The engine serves as the powerhouse, converting fuel into mechanical energy, while the bar and chain work in tandem to deliver cutting action. Understanding how these elements interact is crucial for proper operation.

Maintenance and Repair: Regular upkeep involves checking wear and tear on various components. Identifying specific parts that may require replacement can prevent larger mechanical failures. Knowledge of the layout and function of these sections simplifies the maintenance process, making it easier to locate and address potential issues.

Additionally, being aware of compatible replacements and upgrades can enhance performance and adapt the tool for different tasks. An informed user can make educated decisions regarding modifications, ensuring that the tool remains efficient and reliable over time.

Importance of a Parts Diagram

Understanding the components of any machine is essential for effective maintenance and repair. A visual representation of the elements not only aids in identifying individual parts but also enhances the overall comprehension of how they interact within the system. This clarity is crucial for both novice users and experienced technicians alike.

Facilitating Repairs

When it comes to fixing or upgrading equipment, having a clear illustration of the assembly can significantly streamline the process. By referencing a detailed visual guide, individuals can easily pinpoint the location of each component, reducing the time spent on troubleshooting and minimizing the risk of overlooking critical elements.

Enhancing Safety

Knowledge of the machine’s structure promotes safety during operation and maintenance. Recognizing where each part fits and how it functions helps prevent accidents that could arise from improper handling. Additionally, a thorough understanding of the components encourages users to adhere to safety protocols, ultimately leading to a more secure working environment.

Key Components of the Chainsaw

A chainsaw is a powerful tool designed for cutting through wood with efficiency and precision. Understanding its essential elements helps users operate the device safely and effectively. Each component plays a vital role in the overall performance, contributing to the machine’s capability to tackle various tasks, from felling trees to trimming branches.

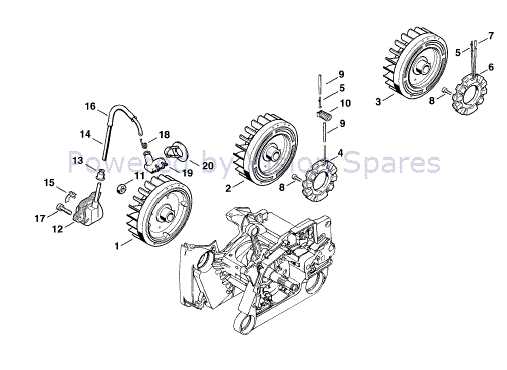

Engine and Power System

The engine is the heart of the chainsaw, providing the necessary power to drive the chain and cutting bar. It typically operates on a two-stroke or four-stroke mechanism, with fuel and oil mixtures ensuring optimal performance. The power system includes components such as the ignition system and carburetor, which regulate fuel flow and ensure the engine runs smoothly.

Cutting Mechanism

The cutting mechanism consists of the guide bar and chain, which work in tandem to slice through wood. The guide bar provides a stable surface for the chain to rotate around, while the chain features sharp teeth designed for efficient cutting. Proper maintenance of these elements is crucial to ensure longevity and effectiveness during use.

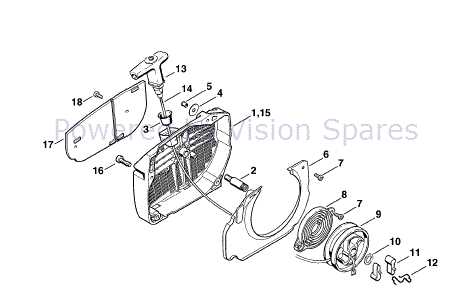

How to Read the Diagram

Understanding a technical illustration can significantly enhance your ability to service and maintain equipment effectively. By familiarizing yourself with the visual representation, you can identify components, their functions, and how they interact within the overall system.

Familiarize with Symbols

Start by recognizing common symbols and notations used in the illustration. Each element typically represents a specific part, often accompanied by a reference number or label. Knowing these can help you quickly locate and comprehend each section.

Follow the Flow

Next, observe the layout and flow of the illustration. Many technical drawings are designed to illustrate the assembly or operational flow. Following this progression will give you insights into how each component fits into the larger mechanism, ultimately aiding in troubleshooting and repairs.

Common Replacement Parts Needed

Maintaining a high-performance chainsaw often requires replacing specific components over time. Understanding which elements are prone to wear and tear can significantly enhance the longevity and efficiency of the machine. By keeping an eye on these commonly needed components, users can ensure their equipment operates smoothly and reliably.

One frequently replaced item is the guide bar, which can suffer from damage due to prolonged use or improper maintenance. Additionally, the chain itself is essential for optimal cutting performance and may need regular replacement to maintain sharpness and efficiency. Spark plugs also play a crucial role in the engine’s performance; worn plugs can lead to starting issues and reduced power.

Air filters are vital for maintaining airflow and preventing debris from entering the engine, so checking and replacing them regularly is advisable. Fuel filters, too, should not be overlooked, as they ensure that the fuel system remains clean and free from contaminants. Finally, tensioning mechanisms may require adjustment or replacement to keep the chain at the proper tightness, preventing accidents and ensuring effective operation.

Tips for Maintenance and Repairs

Regular upkeep and timely repairs are crucial for prolonging the lifespan of your equipment. Adopting a systematic approach can enhance performance and ensure safety during use. This section outlines essential practices that can aid in maintaining optimal functionality.

Routine Inspections

Conducting frequent checks is vital. Look for signs of wear and tear, ensuring that all components are securely attached. Pay close attention to the cutting mechanism and lubrication levels to prevent unnecessary damage.

Cleaning and Storage

After each use, clean the machinery thoroughly to remove debris and residue. Proper storage in a dry, sheltered environment will protect it from the elements, minimizing rust and other forms of deterioration.

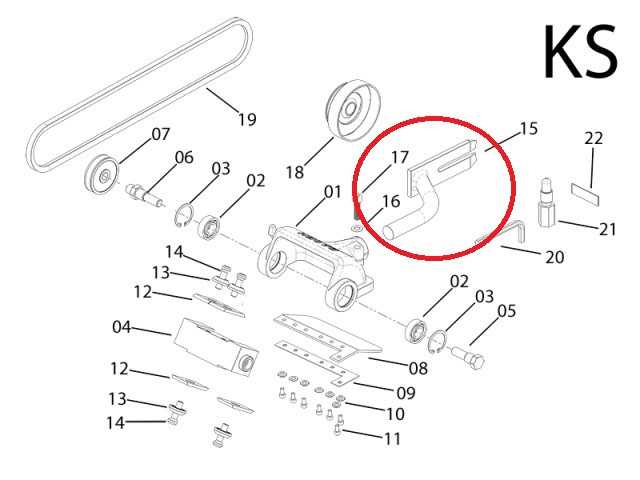

Identifying Parts by Model Number

Understanding the components of a machine can significantly enhance maintenance and repair processes. Each model is associated with a unique identifier, allowing users to pinpoint specific elements essential for optimal performance. By utilizing these identifiers, individuals can efficiently locate and procure the necessary items for their equipment.

Model numbers serve as a key reference, guiding users in differentiating between various components. This approach not only simplifies the search for replacements but also ensures compatibility with the original design. When approaching a project, having the correct model number at hand is invaluable, as it streamlines the process of identification and selection.

To effectively utilize the model number, one should refer to the manufacturer’s documentation or online resources. Many platforms offer comprehensive listings, making it easier to navigate through various options. This practice not only saves time but also helps in avoiding potential errors when ordering.

In summary, leveraging model identifiers is crucial for anyone looking to maintain or repair their machinery. It enhances accuracy and efficiency, ultimately leading to better performance and longevity of the equipment.

Where to Buy Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Choosing the right supplier ensures that you receive high-quality items designed specifically for your machine, enhancing its efficiency and reliability.

Authorized Dealers

One of the most reliable options for purchasing authentic components is through authorized dealers. These retailers are certified to sell genuine items and often provide warranty support as well. Additionally, they can offer expert advice on compatibility and installation.

Online Retailers

In today’s digital age, many online platforms specialize in offering authentic components. It’s important to verify that the website is reputable and offers a return policy in case the item does not meet your expectations. Always check customer reviews to gauge reliability.

| Source | Benefits | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, expert support | May have limited stock |

| Online Retailers | Convenience, wide selection | Risk of counterfeits, check reviews |

Resources for Stihl MS 660 Owners

For enthusiasts and users of high-performance outdoor equipment, having access to the right resources can greatly enhance the ownership experience. Whether you are looking for maintenance tips, troubleshooting advice, or upgrade options, numerous platforms and tools are available to support you in keeping your machine in top condition.

Online Forums and Communities

Connecting with fellow owners can provide invaluable insights and shared experiences. Here are some popular platforms:

- ArboristSite – A community for tree care professionals and enthusiasts.

- TractorByNet – A forum for discussing various outdoor machinery, including troubleshooting and repairs.

- RedFlagDeals – A discussion board where you can find tips and deals on tools and equipment.

Repair and Maintenance Guides

Understanding how to maintain and repair your equipment is crucial for longevity. Consider the following resources:

- YouTube – A vast array of instructional videos covering maintenance and repair techniques.

- ManualsLib – An online repository for user manuals and service guides.

- E-Repair Manuals – Offers downloadable service manuals for detailed repair instructions.

By leveraging these resources, owners can ensure their equipment remains reliable and efficient for years to come.