The efficiency and reliability of a chain saw heavily depend on its individual elements. Familiarity with these components is essential for both maintenance and repair, allowing users to enhance the performance of their equipment. By visualizing the assembly, one can gain valuable insights into how each part contributes to the overall functionality.

In this section, we will explore the intricate arrangement of crucial elements within the device. Recognizing the role of each segment not only simplifies troubleshooting but also aids in making informed decisions during upgrades or replacements. A clear representation of the assembly helps users identify potential issues before they escalate, ensuring that the tool remains in optimal condition.

Moreover, understanding these components fosters a deeper appreciation for the craftsmanship behind such machinery. Whether you’re a novice or a seasoned operator, having a comprehensive view of the internal workings empowers you to tackle challenges with confidence. Let’s delve into the essential features that keep your equipment running smoothly.

Understanding the Stihl MS250 Chainsaw

This section explores the essential features and components of a popular cutting tool widely used for various tasks. It highlights the machine’s efficiency and durability, making it a preferred choice among both professionals and hobbyists.

Key aspects to consider include:

- Engine Performance: The power output and efficiency of the motor play a significant role in the tool’s overall capability.

- Bar Length: Different sizes of bars cater to specific cutting requirements, impacting maneuverability and cutting speed.

- Weight and Balance: A well-balanced tool reduces fatigue during extended use, enhancing the user experience.

- Safety Features: Integrated systems designed to protect users during operation are crucial for safe handling.

Understanding these elements helps users select the right equipment and maintain it effectively. Regular maintenance, including cleaning and replacing worn components, ensures optimal performance and longevity.

Moreover, familiarizing oneself with the layout of individual components can simplify troubleshooting and repairs. This knowledge empowers users to tackle challenges confidently, ensuring their cutting tasks are completed efficiently and safely.

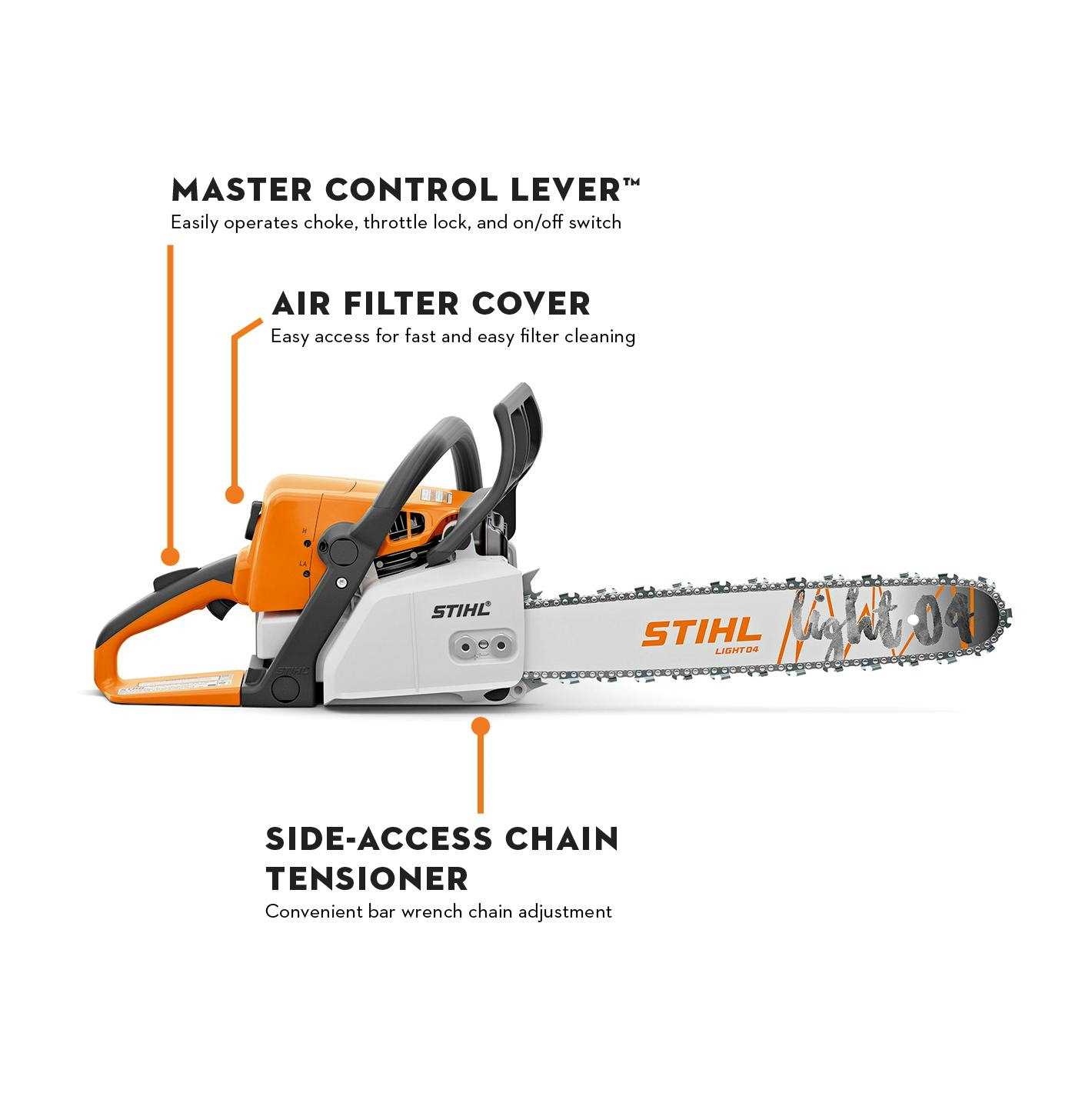

Key Components of the MS250 Model

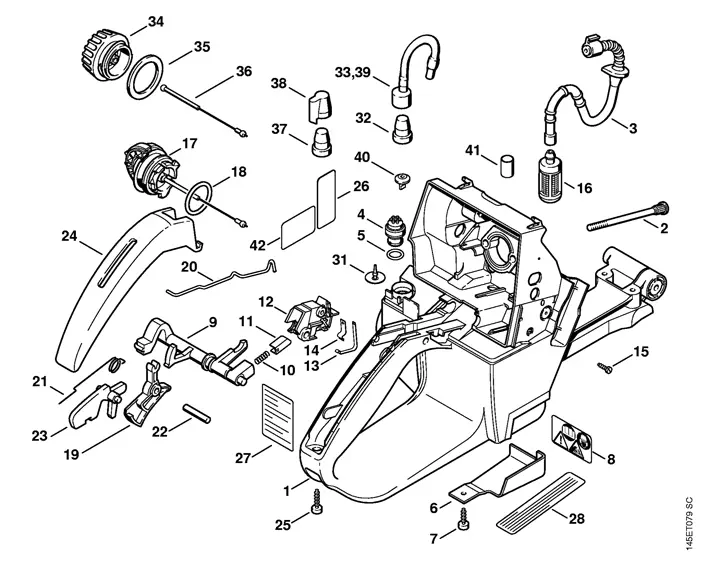

Understanding the fundamental elements of this cutting tool is essential for both maintenance and optimal performance. Each component plays a vital role in ensuring that the machine operates efficiently and safely, contributing to its overall effectiveness in various tasks.

Essential Elements

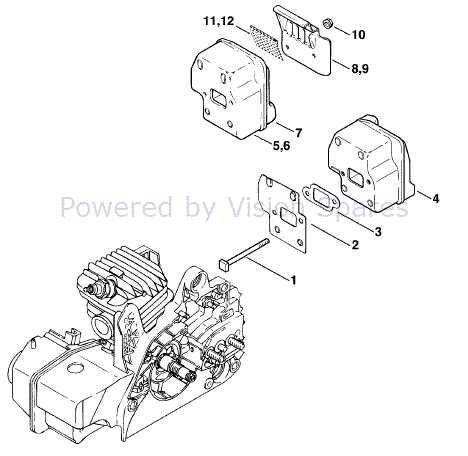

- Engine: The power unit drives the entire system, providing the necessary force to operate the saw.

- Bar and Chain: These components work together to perform the cutting action, with the bar providing stability and the chain executing the cut.

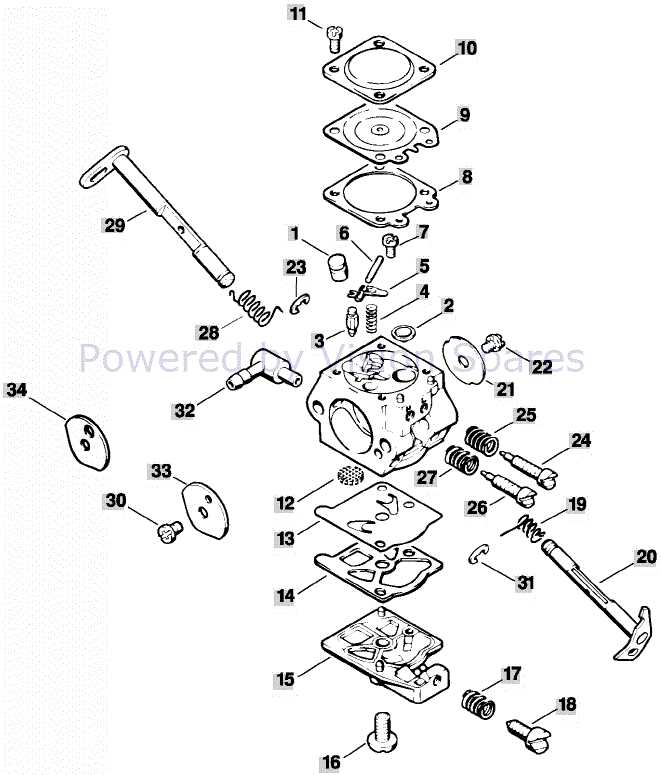

- Fuel System: This includes the fuel tank and carburetor, which are crucial for delivering the right mixture of fuel and air to the engine.

- Ignition System: Responsible for starting the engine, it ensures that the fuel is ignited at the correct time for optimal performance.

- Housing: The outer casing protects internal components while providing a comfortable grip for the operator.

Supporting Features

- Vibration Dampening: Reduces operator fatigue by minimizing vibrations during use.

- Chain Brake: Enhances safety by stopping the chain in case of kickback.

- Air Filter: Keeps the engine clean by preventing dust and debris from entering the combustion chamber.

Familiarity with these critical parts not only aids in troubleshooting but also helps in the proper upkeep of the equipment, ensuring it remains a reliable tool for a variety of cutting tasks.

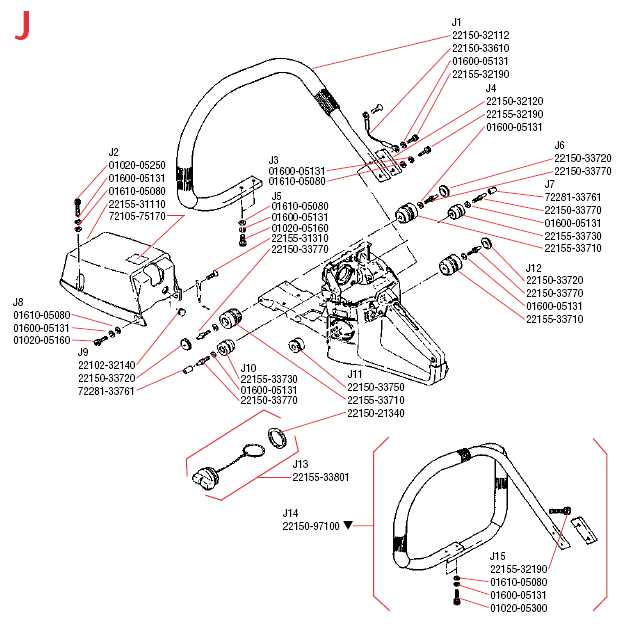

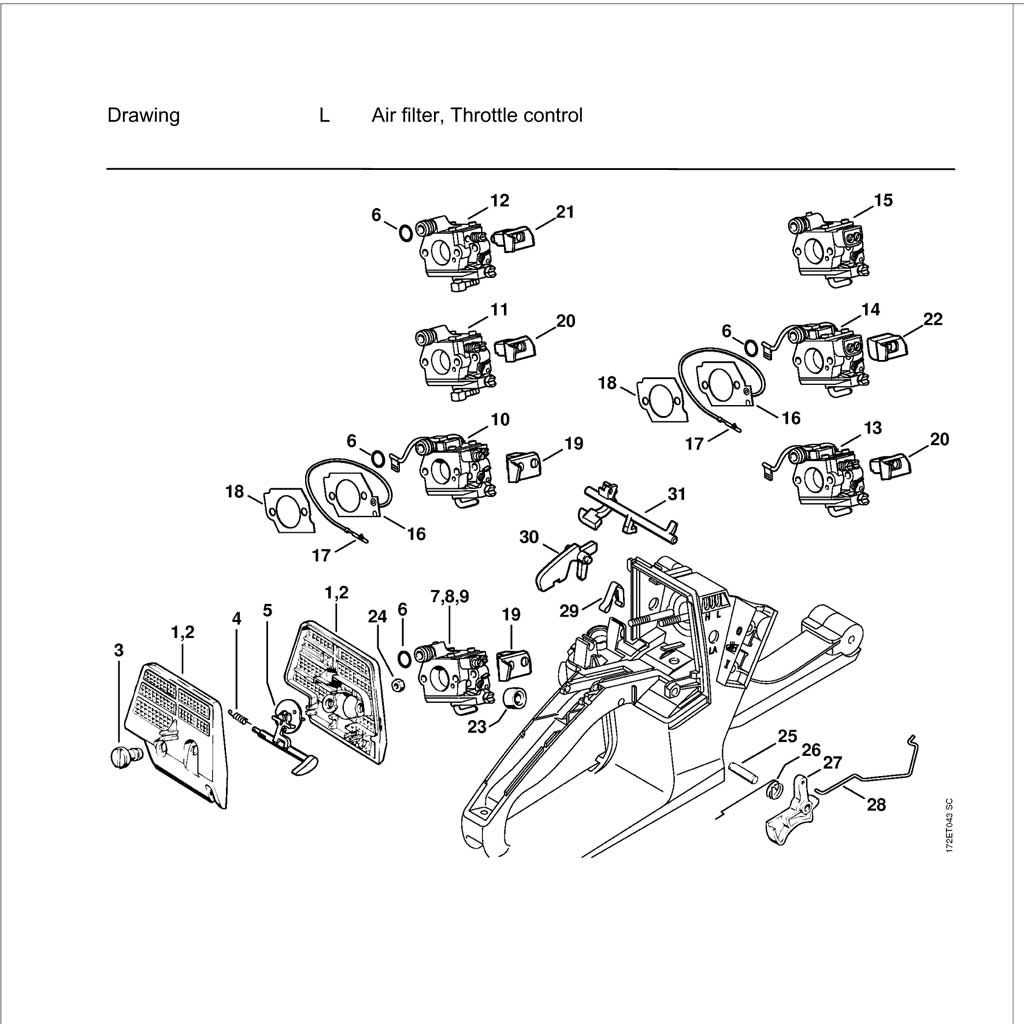

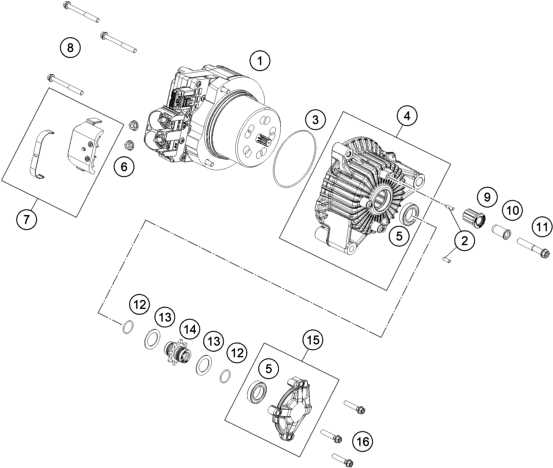

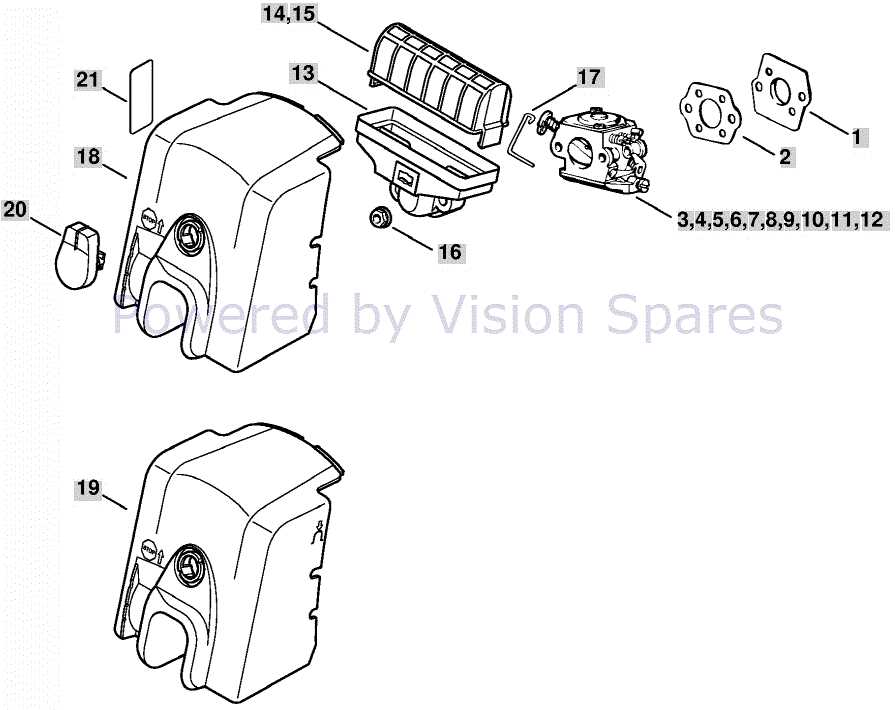

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations offer a detailed overview, highlighting each element’s position and function within a larger system. Familiarity with these graphics can significantly enhance your ability to identify and replace faulty parts.

Key Elements to Focus On

Pay attention to labels and numbers that correspond to individual components. Often, a legend or reference guide accompanies these visuals, providing valuable information about each item’s specifications and compatibility. This knowledge is crucial for ensuring that replacements fit correctly.

Interpreting Connections and Relationships

Observe how different elements are interconnected. Understanding the relationships between various parts can help you identify potential issues and streamline the repair process. Analyzing these connections will enable you to approach maintenance tasks with confidence and precision.

Common Issues with MS250 Parts

When working with outdoor power equipment, certain components can experience wear and tear, leading to performance issues. Understanding these common problems can help users maintain their tools effectively and ensure they operate smoothly.

- Fuel System Problems:

- Clogged filters can restrict fuel flow.

- Old fuel can cause poor combustion.

- Fuel lines may develop leaks or cracks.

- Ignition Issues:

- Faulty spark plugs can prevent starting.

- Wiring issues may disrupt the ignition circuit.

- Coils can fail, leading to inconsistent firing.

- Chain and Bar Concerns:

- Worn chains can lead to decreased cutting efficiency.

- Bars may become damaged, affecting alignment.

- Improper lubrication can cause overheating.

- Air Filter Maintenance:

- Clogged filters can limit airflow, impacting performance.

- Dirty filters can lead to excessive engine wear.

- Vibration and Noise:

- Loose components can create excessive vibration.

- Worn bearings may contribute to increased noise levels.

Regular inspection and maintenance of these elements can help prevent issues and extend the lifespan of your equipment.

Where to Find Replacement Parts

When your outdoor equipment requires a fix, locating suitable components is essential for restoring its performance. Various sources offer a wide range of options, ensuring that you can find the necessary items to keep your machinery running smoothly.

Authorized Dealers

Visiting certified retailers is one of the most reliable ways to acquire high-quality components. These dealers provide:

- Genuine items specifically designed for your equipment

- Expert advice on compatibility and installation

- Warranty options for peace of mind

Online Marketplaces

The internet offers numerous platforms for purchasing replacement components. Consider these benefits:

- A wide selection of aftermarket and original items

- Competitive pricing and potential discounts

- User reviews to guide your choices

Always ensure that the seller has a good reputation to avoid issues with quality or fit. By exploring both local and online options, you can easily find what you need to maintain your equipment’s efficiency.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your equipment. Regular care not only enhances performance but also prevents costly repairs in the future. Here are some essential practices to ensure your tools remain in top condition for years to come.

- Regular Cleaning: Keep your equipment free from dirt and debris. Clean after each use to prevent buildup that can lead to corrosion and inefficiency.

- Check and Replace Filters: Inspect air and fuel filters regularly. Replace them as needed to maintain optimal airflow and fuel efficiency.

- Sharpen Cutting Tools: Dull blades can cause strain on the engine. Regularly sharpen or replace cutting components to ensure smooth operation.

Additionally, follow these guidelines:

- Oil Levels: Regularly check and maintain appropriate oil levels. Use the recommended type for optimal lubrication.

- Inspect Cables and Hoses: Look for signs of wear and tear. Replace any damaged components to prevent leaks or failures.

- Store Properly: When not in use, store your equipment in a dry, sheltered area. Protect from extreme temperatures and humidity.

By adhering to these maintenance tips, you can enhance the durability and reliability of your tools, ensuring they perform at their best whenever you need them.

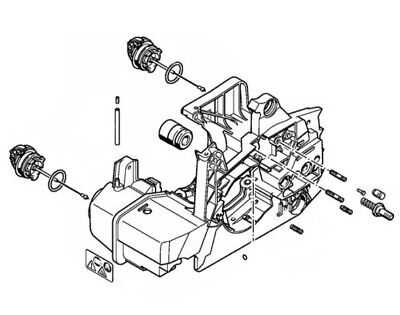

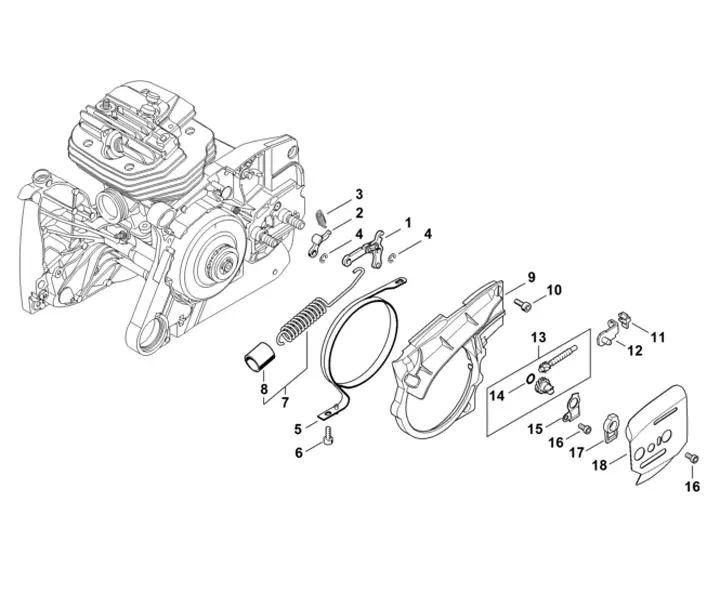

Assembly Instructions for the MS250

When assembling your chainsaw, it is essential to follow a systematic approach to ensure proper functionality and safety. Each component plays a critical role in the overall performance, and understanding the assembly process can prevent potential issues.

Step 1: Begin by gathering all necessary components. Ensure you have the engine, guide bar, chain, handle, and any additional hardware required for assembly.

Step 2: Start with the engine. Securely attach the handle, ensuring that all screws are tightened according to the manufacturer’s specifications. This step is vital for maintaining control during operation.

Step 3: Next, install the guide bar and chain. Make sure the chain is properly oriented and tensioned. A correctly installed chain minimizes the risk of kickback and enhances cutting efficiency.

Step 4: After the chain is in place, double-check all connections and fastenings. It’s crucial to verify that everything is secure before proceeding to test the machine.

Step 5: Finally, perform a safety check. Inspect for any loose parts or irregularities. Familiarize yourself with the safety features to ensure a secure and effective operation.

By following these guidelines, you can confidently assemble your equipment, ready for reliable performance in your tasks.

Upgrading Parts for Better Performance

Enhancing the efficiency of your machinery can significantly improve its overall functionality and lifespan. By carefully selecting and replacing certain components, you can boost performance, reduce wear, and increase reliability. This approach not only optimizes power output but also ensures smoother operation, making your tasks more manageable and enjoyable.

Key Components to Consider

When looking to upgrade, several critical elements can lead to noticeable improvements. Below is a summary of essential components that are often targeted for enhancement:

| Component | Benefits of Upgrading |

|---|---|

| Air Filter | Improves airflow, enhancing combustion efficiency and power. |

| Spark Plug | Ensures better ignition, leading to smoother starts and improved fuel efficiency. |

| Chain | Offers increased cutting speed and reduces vibration for better handling. |

| Fuel Lines | Enhances fuel delivery, ensuring consistent performance and preventing leaks. |

Choosing the Right Upgrades

Selecting the most suitable components depends on your specific needs and the tasks you frequently undertake. Research and consult with experts to find the best upgrades that align with your goals. Investing in quality parts will yield substantial returns in performance and efficiency, transforming your experience with the equipment.

Frequently Asked Questions About MS250

This section addresses common inquiries related to the popular chainsaw model, providing insights into its functionality, maintenance, and troubleshooting. Whether you’re a beginner or an experienced user, these answers aim to enhance your understanding and improve your overall experience with the tool.

What fuel mixture should I use for optimal performance?

It is crucial to use the recommended fuel-to-oil ratio to ensure efficient operation and longevity. A common mixture is 50:1, but always refer to the user manual for specific guidelines.

How often should I sharpen the chain?

The frequency of sharpening depends on usage. Generally, you should sharpen the chain after every few hours of heavy use. A sharp chain cuts more efficiently and reduces wear on the engine.

What are the signs of a worn-out chain?

Look for indicators such as poor cutting performance, increased effort needed to cut, or visible damage to the chain links. Regular inspection is essential for safety and effectiveness.

How do I replace the air filter?

To replace the air filter, locate the air filter cover, remove it, and carefully take out the old filter. Install the new filter, ensuring it fits securely before replacing the cover.

Is it safe to operate in wet conditions?

While the tool is designed for outdoor use, it’s advisable to avoid operating in heavy rain or wet conditions. Moisture can affect performance and pose safety risks.

What maintenance should I perform regularly?

Regular maintenance includes cleaning the air filter, checking the spark plug, inspecting the chain tension, and ensuring the bar and chain are lubricated properly. This will extend the life of your equipment.

Where can I find replacement components?

Replacement components can typically be found at authorized dealers, online retailers, or specialty stores. It’s important to choose genuine parts to maintain compatibility and reliability.