When it comes to maintaining your outdoor machinery, having a comprehensive view of its elements is essential. Each component plays a crucial role in ensuring optimal performance and longevity, making it vital to understand their arrangement and function.

In this guide, we will explore a detailed representation of the various sections of your tool. By examining the layout and interconnections of these elements, you can enhance your maintenance skills and troubleshoot issues more effectively.

As you delve into the intricacies of this equipment, you will uncover the ultimate insights needed for repairs and upgrades. Understanding how each piece interacts with others will empower you to make informed decisions about your machinery’s care.

Understanding the Stihl 251 Model

This section aims to provide insights into a popular power tool renowned for its efficiency and reliability. Users appreciate its robust design and the versatility it brings to various outdoor tasks. With a well-balanced structure, this model is ideal for both beginners and seasoned professionals, making it a staple in landscaping and maintenance activities.

One of the standout features is its lightweight construction, which facilitates easy handling during extended use. The ergonomic design enhances comfort, reducing fatigue and allowing for more precise control. Furthermore, the tool’s engine delivers impressive performance, ensuring that users can tackle even the most demanding jobs with ease.

Maintenance is straightforward, with easily accessible components that simplify routine checks and repairs. Understanding the various elements of this equipment is crucial for maximizing its lifespan and efficiency. Familiarity with each section not only aids in upkeep but also enhances overall operational knowledge.

In conclusion, this model exemplifies a blend of innovation and practicality, catering to the diverse needs of users. Its design and functionality make it a worthwhile investment for anyone looking to enhance their outdoor tool collection.

Key Features of Stihl 251

This segment explores the distinctive characteristics of a popular power tool, highlighting its innovative design and functionality. Understanding these features can enhance user experience and performance in various applications.

- Engine Efficiency: The machine boasts a powerful engine that delivers optimal performance while minimizing fuel consumption.

- Lightweight Design: Engineered for ease of handling, this model reduces fatigue during prolonged use, making it ideal for extended projects.

- Vibration Reduction: Advanced technology mitigates vibration, contributing to comfort and control for the operator.

- Easy Start System: The intuitive starting mechanism simplifies the ignition process, ensuring quick readiness for operation.

- Durable Construction: Built with high-quality materials, the tool is designed to withstand rigorous use in demanding environments.

These features collectively enhance the user experience, making the tool suitable for both amateur and professional tasks.

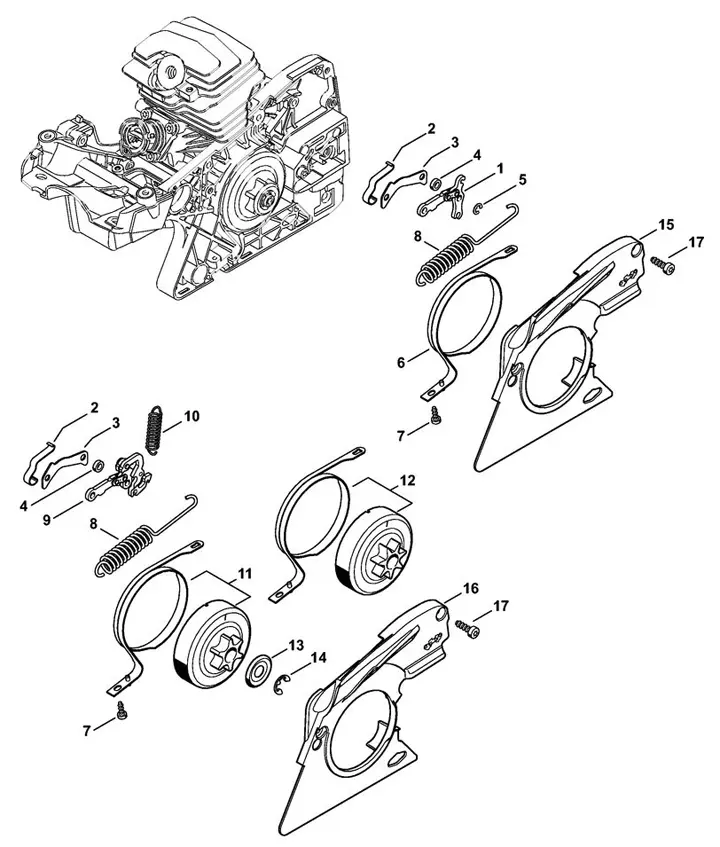

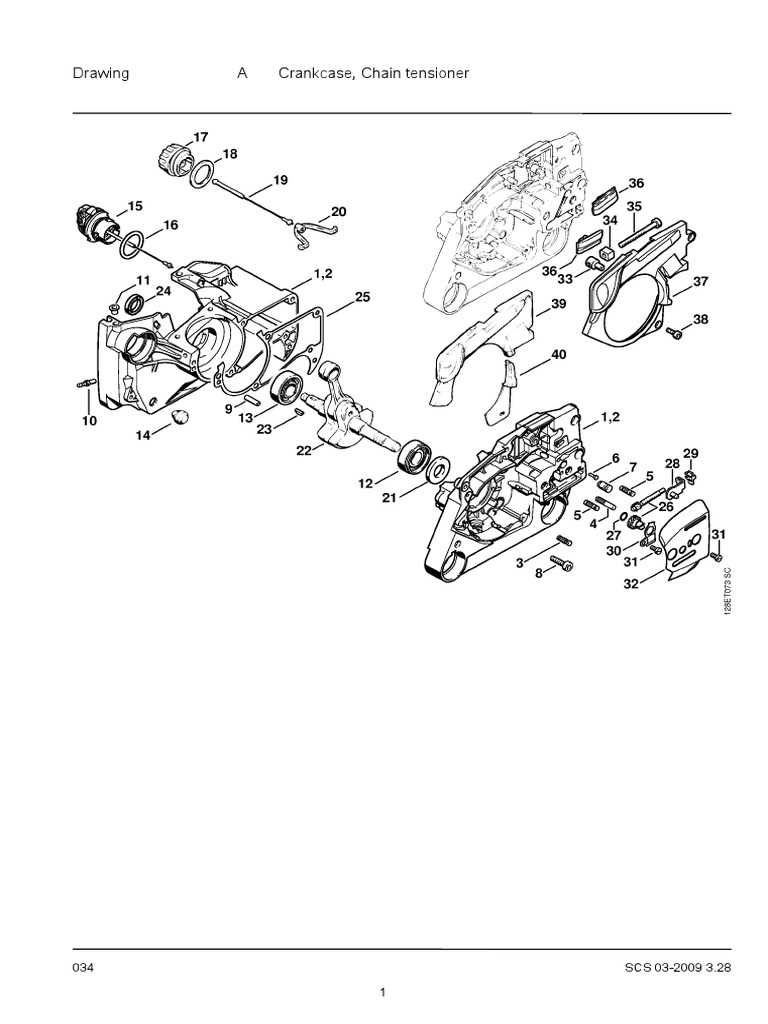

Importance of Parts Diagrams

Understanding the intricacies of machinery and tools is essential for effective maintenance and repair. Visual representations of components serve as crucial resources, aiding users in identifying and locating specific elements within a device. Such illustrations enhance the overall efficiency of troubleshooting and assembly tasks, ultimately contributing to the longevity of the equipment.

Benefits of Visual Representations

- Clarifies Component Relationships: Visual aids help users see how individual elements interact with one another.

- Facilitates Accurate Repairs: Detailed images allow for precise identification of parts that may need replacement or adjustment.

- Simplifies Reassembly: Knowing where each piece belongs streamlines the reassembly process after maintenance.

- Enhances Learning: Visual learning can significantly improve comprehension for those new to equipment handling.

Practical Applications

- DIY Repairs: Homeowners can perform maintenance tasks without professional help.

- Training: Technicians can use these visuals as educational tools during training sessions.

- Inventory Management: Clear illustrations assist in keeping track of spare parts and supplies.

Incorporating visual guides into maintenance practices not only saves time but also reduces the likelihood of errors, making them indispensable for anyone involved in equipment upkeep.

How to Access the Diagram

Finding a visual representation of components can significantly enhance your understanding and maintenance of your equipment. This section outlines effective methods to obtain these illustrations, ensuring you can easily reference the various elements involved.

Online Resources

- Manufacturer’s Website: Visit the official site where you can often find downloadable resources, including comprehensive guides.

- Authorized Dealers: Reach out to certified retailers who may offer detailed schematics for their products.

- Forums and Community Groups: Join online communities where users share resources and insights, often including valuable links to illustrations.

Printed Manuals

- Purchase a Hard Copy: Many retailers offer printed manuals that include detailed visuals of the components.

- Request Documentation: If you already own a unit, contacting customer support may yield access to printed materials specific to your model.

Common Stihl 251 Replacement Parts

Maintaining your outdoor power equipment is essential for optimal performance and longevity. Over time, certain components may wear out and require replacement to ensure your machine operates smoothly. This section highlights some of the most frequently replaced items to keep in mind for efficient upkeep.

Essential Components

Key elements that often need replacing include the air filter and spark plug. A clean air filter ensures proper airflow, enhancing engine efficiency, while a well-functioning spark plug is crucial for reliable ignition. Regularly checking these components can prevent larger issues down the line.

Maintenance Items

Other notable items include the chain and bar, which are vital for cutting performance. Replacing a dull or damaged chain can significantly improve productivity. Additionally, don’t overlook the importance of lubrication components, which help minimize friction and wear during operation.

Investing time in understanding these crucial elements can lead to a more reliable and effective machine, ready to tackle any outdoor task with ease.

Identifying Component Functions

Understanding the roles of various elements within a machine is crucial for effective maintenance and operation. Each part plays a unique role in the overall functionality, contributing to the performance and efficiency of the device.

| Component | Function |

|---|---|

| Engine | Converts fuel into mechanical energy to power the device. |

| Blade | Responsible for cutting through materials with precision. |

| Handle | Provides control and stability during operation. |

| Fuel Tank | Stores the fuel needed for the engine’s operation. |

| Air Filter | Prevents dirt and debris from entering the engine. |

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Adopting a proactive approach to maintenance not only enhances performance but also minimizes the likelihood of unexpected issues. Here are some practical suggestions to keep your machine running smoothly.

Routine Checks

- Inspect the air filter regularly and clean or replace it as needed to ensure proper airflow.

- Examine the spark plug for wear and replace it if it appears damaged or dirty.

- Keep the fuel system clean by using fresh fuel and a fuel stabilizer.

Lubrication and Storage

- Apply lubrication to moving parts to reduce friction and prevent wear.

- Store your equipment in a dry, sheltered area to protect it from the elements.

- Before long periods of inactivity, empty the fuel tank to avoid potential issues with stale fuel.

By following these maintenance tips, you can significantly improve the reliability and performance of your equipment, ensuring it operates effectively whenever needed.

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential for maintaining performance and longevity. Reliable sources ensure you receive quality items that meet the specifications necessary for optimal functioning.

Authorized Dealers

- Visit official distributors for verified merchandise.

- Check local listings for nearby outlets.

- Inquire about warranty options and support services.

Online Retailers

- Explore reputable e-commerce platforms for a wide selection.

- Look for customer reviews to gauge quality and reliability.

- Compare prices and shipping options for the best deal.

Prioritizing genuine components ultimately enhances the efficiency and safety of your machinery.