When maintaining or repairing machinery, a clear understanding of its various elements is essential. Recognizing how each component interacts can significantly enhance performance and longevity. This section aims to provide a comprehensive overview of essential parts and their functions.

Through detailed visual aids and descriptive content, users can gain insight into the layout and relationships between different sections. This knowledge empowers individuals to troubleshoot effectively and make informed decisions regarding repairs or upgrades.

Ultimately, mastering the intricacies of your device’s assembly not only simplifies maintenance but also enhances overall efficiency. Delving into the specifics of these components will equip you with the necessary tools for successful handling of your equipment.

Understanding the Craftsman T130 Model

This section aims to provide insights into a specific model known for its reliability and performance in various tasks. By examining its components and overall design, users can appreciate the functionality that contributes to its popularity.

Key features of this model include a robust engine and user-friendly controls, making it suitable for both beginners and seasoned professionals. Its durable construction ensures longevity, while the ease of maintenance allows for efficient upkeep.

Additionally, exploring the assembly of different elements reveals how they work together to enhance operational efficiency. Understanding these aspects not only aids in troubleshooting but also empowers users to make informed decisions regarding upgrades or replacements.

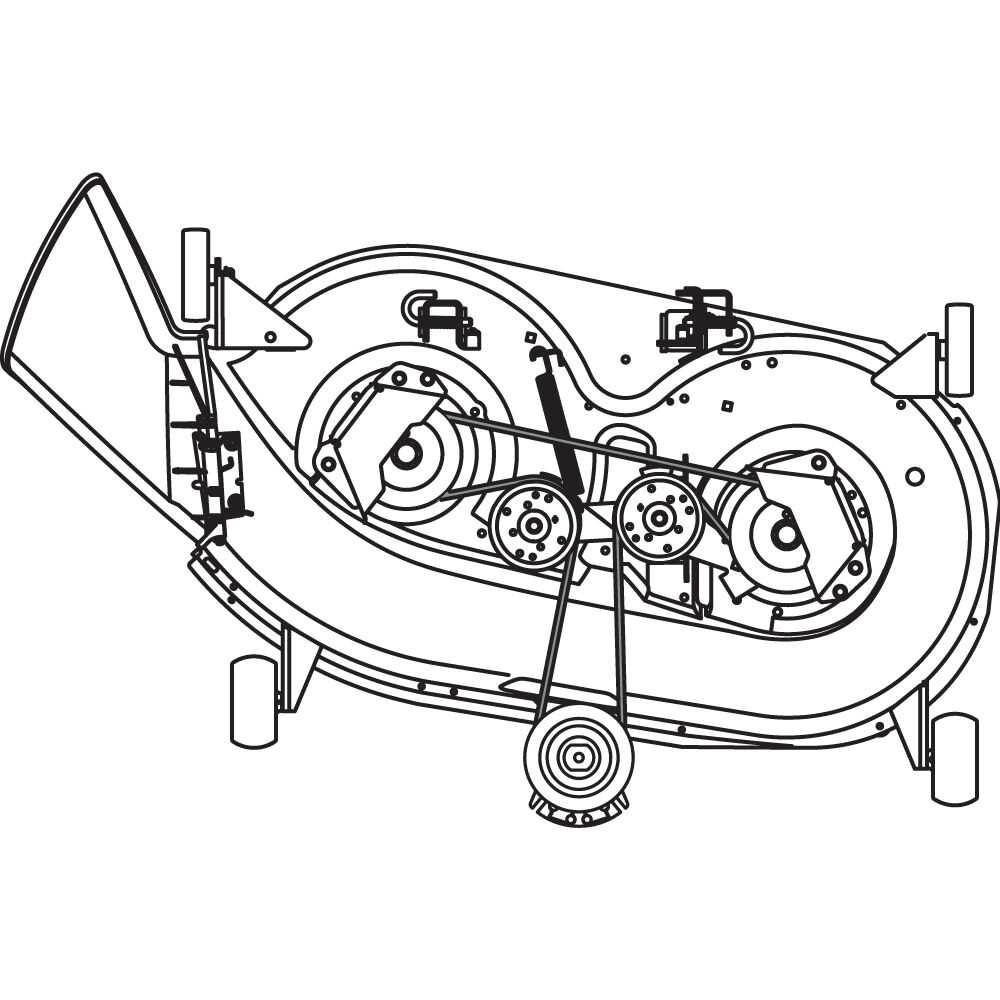

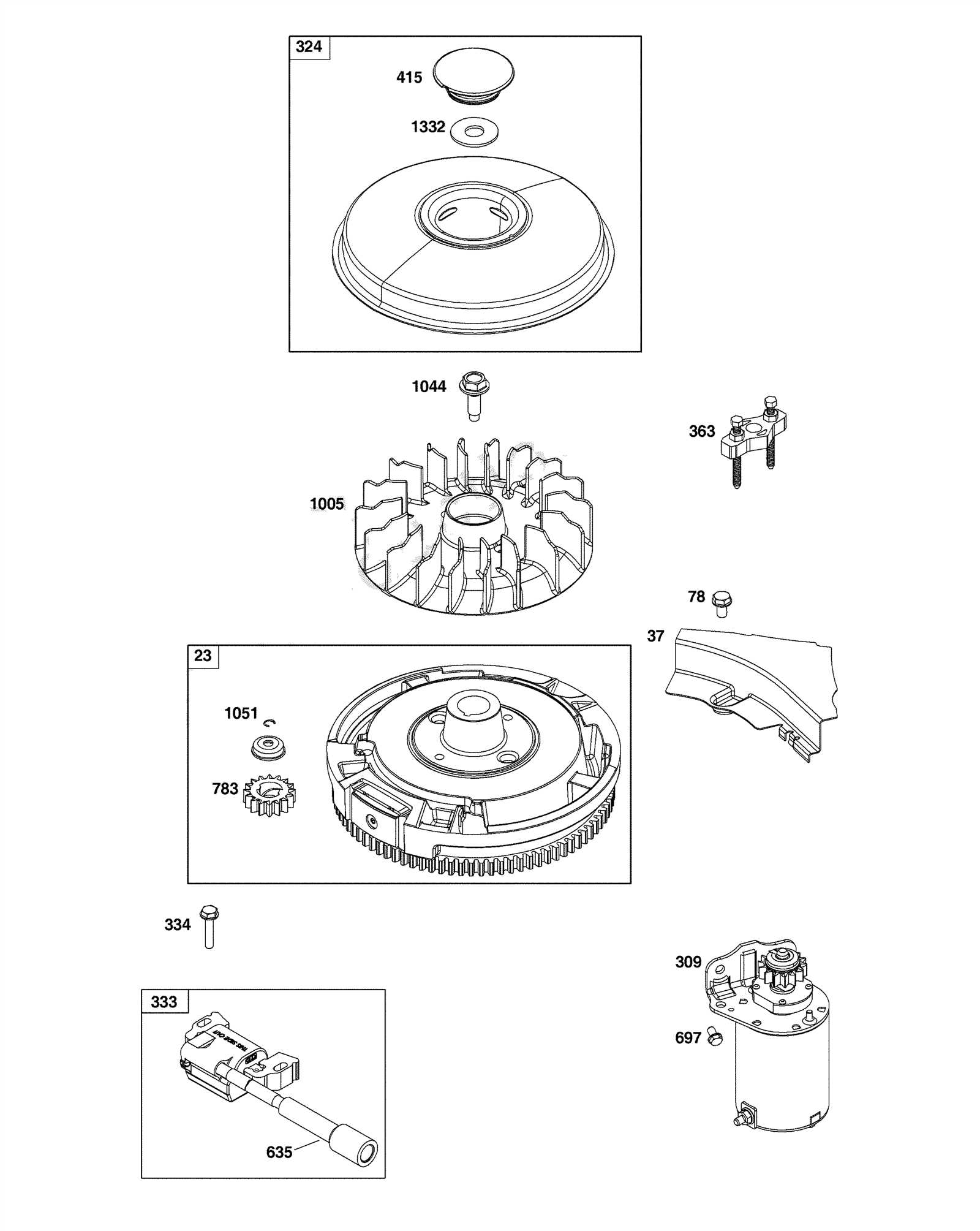

Key Components of the T130 Diagram

Understanding the essential elements of any mechanical layout is crucial for effective maintenance and repair. Each segment plays a vital role in the overall functionality, ensuring optimal performance and longevity of the equipment. Familiarity with these core components enables users to troubleshoot issues and make informed decisions regarding repairs or replacements.

1. Engine Assembly: The powerhouse of the system, responsible for generating the necessary force to operate various functions. Its efficiency directly impacts the overall performance.

2. Drive System: This component transmits power from the engine to the operational elements, ensuring seamless movement and functionality. Proper alignment and condition are essential for smooth operation.

3. Control Mechanism: The interface that allows the user to interact with the machinery. It encompasses levers and switches, which provide control over different operations.

4. Chassis: The structural framework that supports all other components. A robust chassis is vital for stability and durability during use.

5. Safety Features: Integral to preventing accidents and ensuring user protection. Familiarity with these systems is essential for safe operation.

Importance of Parts Identification

Recognizing the components of any machinery or tool is crucial for effective maintenance and repair. Understanding each element ensures optimal functionality and extends the lifespan of the equipment.

There are several reasons why identifying individual pieces is essential:

- Efficiency in Repairs: Knowing the specific parts allows for quicker diagnostics and targeted fixes, reducing downtime.

- Cost-Effectiveness: Accurate identification helps in sourcing the right components, avoiding unnecessary purchases and expenses.

- Safety: Properly recognizing and replacing worn or damaged elements can prevent accidents and ensure safe operation.

- Improved Performance: Regular identification and maintenance of components contribute to better overall performance of the tool.

Ultimately, familiarity with the individual elements of any device not only enhances functionality but also promotes a proactive approach to care and upkeep.

Common Issues with Craftsman T130

Many users encounter various challenges with their outdoor equipment over time. Understanding these common problems can help in identifying solutions and ensuring efficient operation. Here are some prevalent issues that might arise:

- Engine Performance:

- Difficulty starting the engine.

- Inconsistent power delivery during operation.

- Electrical Components:

- Battery not charging properly.

- Faulty wiring connections leading to malfunctions.

- Transmission Problems:

- Issues with shifting gears smoothly.

- Strange noises coming from the transmission area.

- Cutting Mechanism:

- Uneven cutting performance.

- Blades becoming dull or damaged quickly.

Addressing these concerns promptly can enhance the longevity and performance of the equipment. Regular maintenance checks and following manufacturer guidelines are essential in preventing these common issues.

How to Access Replacement Parts

When your equipment requires new components, finding the right replacements can significantly enhance its performance. The process involves identifying the necessary items and locating reliable sources for acquisition. By following a few straightforward steps, you can efficiently secure the items you need.

First, consult the user manual or manufacturer’s website to understand the specific components required for your device. This ensures you know exactly what to look for. Next, explore online marketplaces and local retailers that specialize in tools and machinery. Many of these platforms provide comprehensive catalogs that allow you to delve into various options.

Additionally, joining online forums or community groups can be beneficial. Other users often share valuable insights and recommendations, leading you to trustworthy suppliers. Ultimately, being informed and resourceful will help you find the most suitable replacements for your needs.

Step-by-Step Repair Guide

This guide provides a systematic approach to troubleshooting and fixing common issues encountered with your equipment. By following each step carefully, you can ensure that the restoration process is both efficient and effective, leading to optimal performance.

Preparation and Tools

Before starting the repair, gather all necessary tools and materials. Having everything at hand will streamline the process and reduce frustration.

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and secure screws. |

| Wrench | For loosening and tightening nuts and bolts. |

| Replacement Parts | To swap out damaged components. |

Repair Steps

Begin by identifying the issue and carefully disassembling the unit. Document each step, taking notes and photos if necessary. Replace any faulty components and reassemble the device, ensuring everything is securely in place. Finally, test the equipment to confirm successful repair.

Maintenance Tips for Longevity

Proper upkeep of your tools is essential for maximizing their lifespan and ensuring optimal performance. Regular maintenance not only helps prevent breakdowns but also enhances efficiency, making your work smoother and more enjoyable. Here are some key practices to keep your equipment in excellent condition.

Regular Cleaning

One of the simplest yet most effective maintenance tasks is keeping your tools clean. Dust and debris can cause wear and affect functionality. Follow these steps:

- Wipe down surfaces after each use to remove dirt and residue.

- Use a soft brush to clear out any debris from hard-to-reach areas.

- For stubborn grime, a gentle cleaner may be used; ensure to rinse thoroughly.

Routine Inspections

Frequent checks can help identify potential issues before they become serious. Implement the following routine:

- Examine all moving parts for signs of wear or damage.

- Check for loose screws and tighten them as needed.

- Look for any leaks or irregularities in performance.

By following these maintenance tips, you can significantly extend the life of your tools, ensuring they remain reliable and efficient for all your projects.

Where to Find Reliable Diagrams

Finding trustworthy illustrations for equipment maintenance is crucial for effective repairs and enhancements. Numerous sources exist that provide detailed visual guides, making it easier for users to identify components and their arrangement.

Online Resources

The internet is a rich resource for users seeking detailed schematics. Websites dedicated to tools and machinery often feature downloadable manuals and clear visuals. Look for forums and communities where enthusiasts share their knowledge, as these can be invaluable for acquiring rare or specific guides.

Local Retailers and Workshops

Physical stores and local repair workshops can also serve as great sources. Many retailers keep printed manuals or can direct you to reputable publishers. Engaging with professionals in these settings can provide insights and additional resources that may not be readily available online.

Customer Reviews and Experiences

This section aims to highlight the insights and stories shared by users regarding their encounters with a specific product. Feedback from individuals who have engaged with similar tools can provide valuable perspectives on performance, reliability, and overall satisfaction. By examining these testimonials, potential buyers can gain a clearer understanding of what to expect and how to make informed decisions.

User Feedback on Performance

Many users have expressed their appreciation for the effectiveness of this equipment. Numerous reviews highlight its durability and ability to handle various tasks with ease. One customer noted, “I was pleasantly surprised by how well it performed even in tough conditions.” Such experiences underscore the reliability that others can anticipate when investing in this type of tool.

Overall, the consensus among users is overwhelmingly positive. Several reviewers recommend this tool to friends and family, citing its affordability and functionality as major benefits. One user shared, “It has truly exceeded my expectations and has become an essential part of my toolkit.” These testimonials reflect a strong sense of confidence in the product, encouraging new customers to consider it for their own projects.