When maintaining outdoor power equipment, a clear understanding of its essential elements is crucial. This section aims to provide valuable insights into the various components that contribute to the efficient functioning of your gardening tool. Each element plays a pivotal role in ensuring optimal performance during landscaping tasks.

Exploring the intricate layout of these components can empower users to identify any issues and facilitate necessary repairs or replacements. By familiarizing yourself with the configuration of your device, you can enhance its longevity and effectiveness.

In this guide, we will delve into the specific parts of your trimmer, detailing their functions and how they interconnect. This comprehensive approach will ultimately lead to more informed maintenance practices and a better gardening experience.

Understanding the Craftsman Weed Wacker

This section aims to provide insights into a versatile gardening tool designed for maintaining neat outdoor spaces. Its efficiency and reliability make it a popular choice among homeowners and professionals alike.

Key features of this tool include:

- Lightweight design for easy maneuverability

- Powerful engine that handles tough vegetation

- Adjustable handle for user comfort

- Multiple attachments for various gardening tasks

When operating this equipment, understanding its components is crucial for optimal performance. Familiarity with the following elements will enhance user experience:

- Engine: The heart of the tool that drives its performance.

- Cutting mechanism: Responsible for trimming grass and other plants.

- Fuel system: Ensures efficient energy delivery to the engine.

- Handle: Provides control and comfort during use.

By grasping the functionalities of each part, users can effectively maintain and troubleshoot their equipment, ensuring longevity and efficiency in their gardening endeavors.

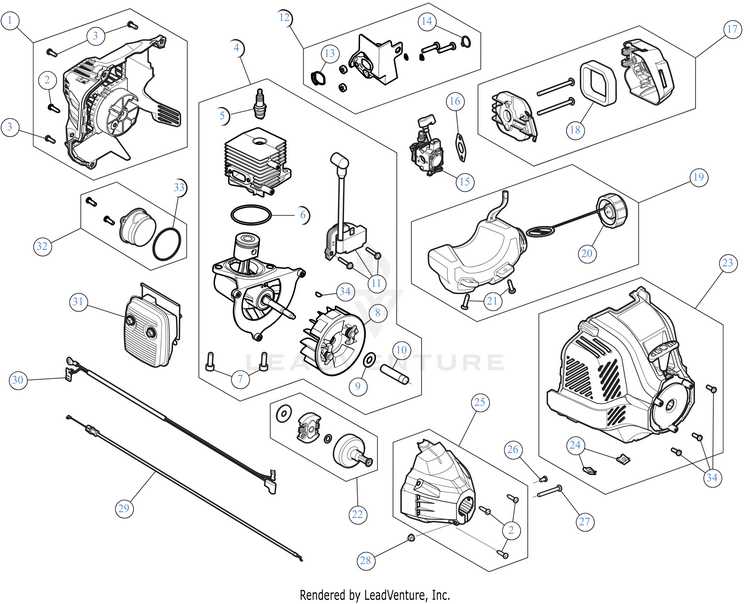

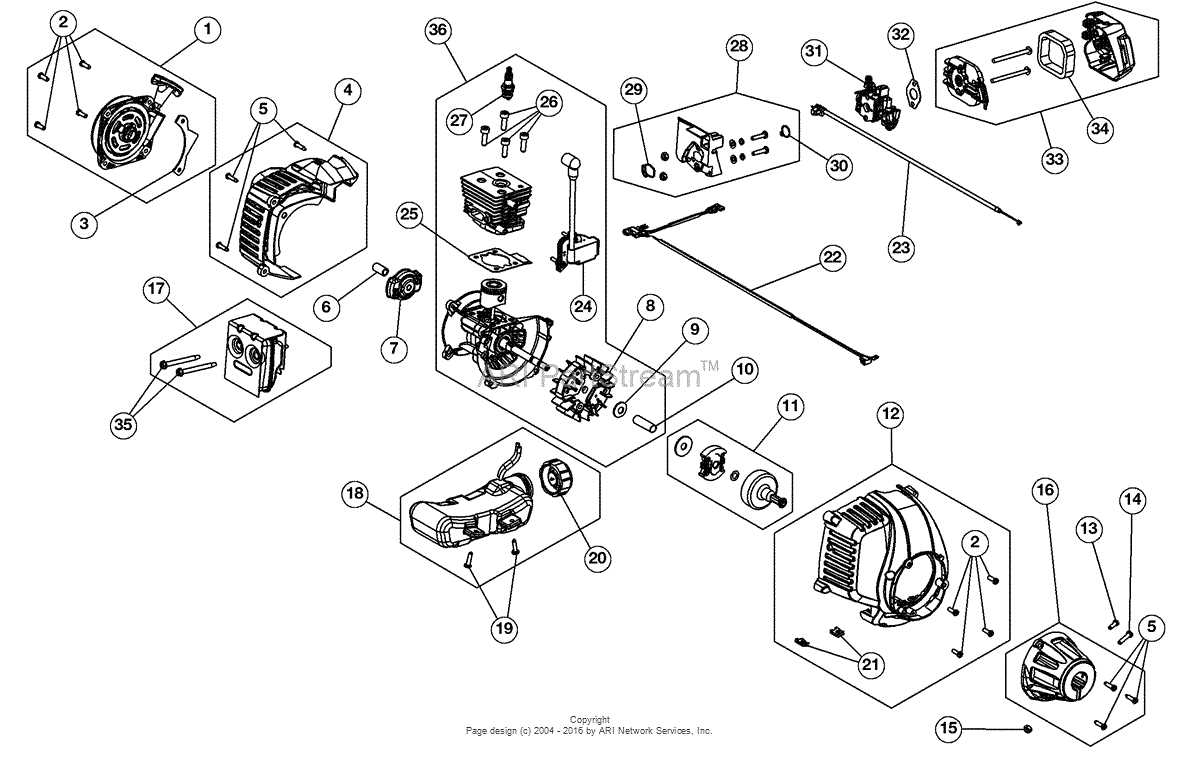

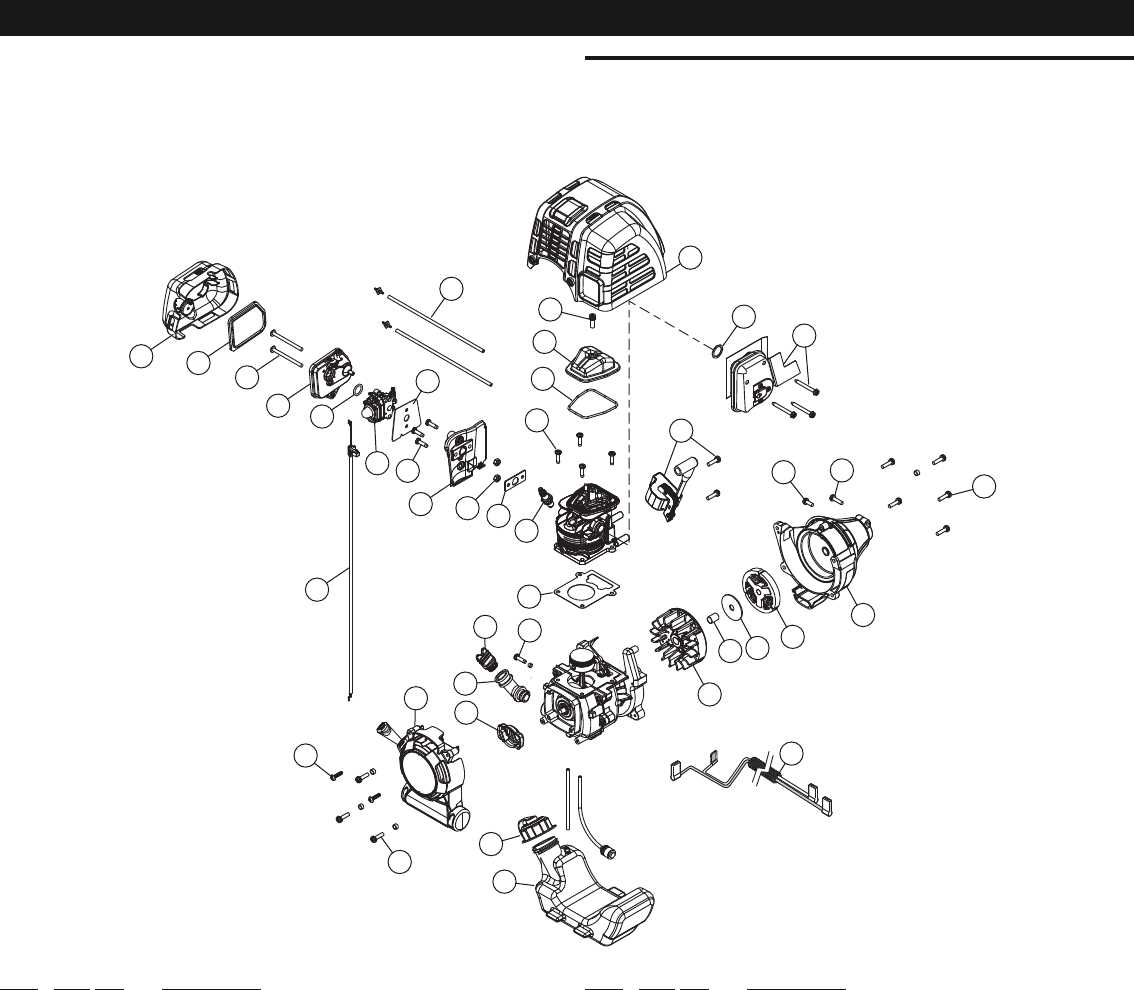

Essential Components of the 27cc Model

This section explores the vital elements that contribute to the functionality and efficiency of a specific garden tool. Understanding these components will enhance maintenance practices and ensure optimal performance.

Power System

The engine serves as the heart of the machine, providing the necessary force for operation. It converts fuel into energy, allowing for effective cutting and trimming tasks.

Cutting Mechanism

The cutting assembly is crucial for executing precise actions in various landscaping tasks. This includes the blade and line systems, designed for durability and efficiency to tackle different types of vegetation.

Regular maintenance of these key components can significantly improve the longevity and reliability of the equipment, ensuring it meets the user’s needs effectively.

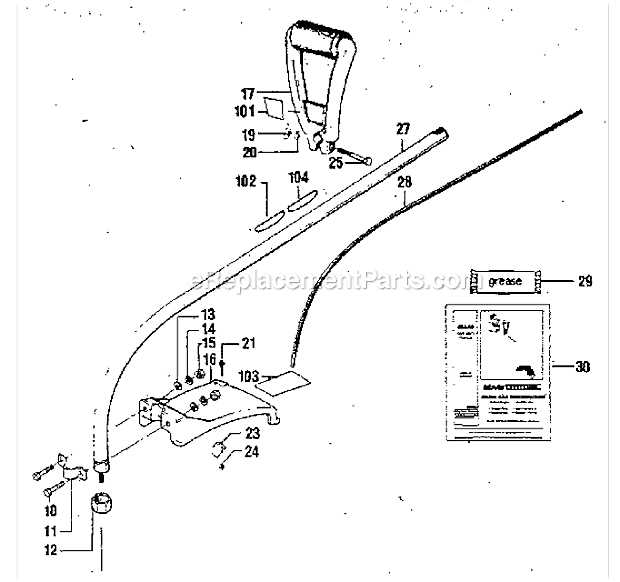

How to Read the Parts Diagram

Understanding a schematic can greatly enhance your ability to maintain and repair equipment. This guide will help you decipher the visual representation of components, allowing you to identify each part and its function.

Follow these steps to effectively interpret the layout:

- Familiarize Yourself with the Key:

- Locate any legends or keys that explain symbols used in the illustration.

- Pay attention to color coding, which often indicates different materials or functions.

- Identify Major Sections:

- Look for grouped components that perform similar tasks.

- Recognize sections like the power unit, handling area, and cutting mechanism.

- Trace the Flow:

- Follow arrows or lines that demonstrate how parts connect or interact.

- Understand the sequence of assembly and disassembly for effective repairs.

- Note Part Numbers:

- Take note of any numerical identifiers associated with each component.

- Use these numbers to order replacements or verify specifications.

By mastering these elements, you will improve your ability to troubleshoot issues and ensure your equipment operates efficiently.

Common Issues with Weed Wacker Parts

Maintaining a garden tool requires attention to detail, as various components can wear out or become damaged over time. Understanding typical problems associated with these elements can help users diagnose issues effectively and ensure the longevity of their equipment.

Frequent Malfunctions

One of the most common difficulties arises from the fuel system. Clogs in the fuel lines or a dirty carburetor can lead to poor engine performance or starting issues. Regular cleaning and maintenance can mitigate these problems.

Wear and Tear

Another prevalent issue is the degradation of cutting attachments. Blades may become dull or chipped, affecting their ability to trim effectively. Inspecting and replacing these components periodically is essential to maintain optimal performance and efficiency.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring that your outdoor equipment operates efficiently over time. Regular maintenance not only enhances performance but also extends the lifespan of your machinery. By following a few simple guidelines, you can keep your tools in top condition, minimizing the need for repairs and replacements.

Routine Cleaning

After each use, it’s important to remove any debris or dirt that may have accumulated. This can prevent corrosion and maintain optimal performance. Use a soft brush or cloth to clean the exterior, and ensure that air vents are free from obstructions. Regular cleaning helps to keep the internal components functioning smoothly.

Check and Replace Parts

Regularly inspect the critical components for wear and tear. Blades, filters, and other key parts should be checked frequently. If you notice any signs of damage, replacing these components promptly will prevent further issues. Keeping a log of replacements can help you track maintenance and ensure that everything is functioning as intended.

Additionally, refer to the manufacturer’s recommendations for specific maintenance schedules and procedures. This proactive approach will help you enjoy reliable performance and longevity from your equipment.

Replacing Worn Parts Efficiently

Maintaining outdoor equipment in optimal condition is crucial for ensuring longevity and performance. When components become degraded, timely replacement is essential to avoid further damage and maintain functionality. Understanding the process of substitution can save time and enhance efficiency, allowing you to return to your tasks swiftly.

Identifying Necessary Components

Begin by inspecting the tool for signs of wear or damage. Look for cracks, rust, or decreased performance. Taking note of these issues will help you determine which elements need replacement. Refer to the manufacturer’s guide for a comprehensive list of components, which can serve as a checklist during your inspection.

Efficient Replacement Process

Once you’ve identified the components that require attention, gather the necessary tools and new items. Organizing your workspace can significantly improve the efficiency of the replacement process. Follow the manufacturer’s instructions meticulously, and consider documenting each step. This approach not only facilitates a smoother replacement but also serves as a reference for future maintenance.

Tools Needed for Repairs

Performing maintenance and repairs on outdoor power equipment requires a specific set of tools to ensure efficiency and effectiveness. Having the right instruments at your disposal can significantly simplify the process, making it easier to tackle various tasks with confidence.

Essential tools include a variety of screwdrivers, wrenches, and pliers. These basic instruments are crucial for disassembling components and making necessary adjustments. Additionally, a socket set is invaluable for working with different sizes of fasteners, providing flexibility during repairs.

Furthermore, a multimeter is useful for diagnosing electrical issues, while a fuel container helps ensure that you have the right type of fuel readily available for your equipment. Having a reliable cleaning brush and compressed air can also aid in keeping the equipment in optimal condition, preventing buildup of debris and ensuring proper functionality.

Finally, investing in a repair manual can guide you through specific procedures and troubleshooting techniques, making the repair process more manageable and informed.

Where to Buy Replacement Parts

When your outdoor tool requires specific components, finding the right source is essential for optimal performance. Various retailers and online platforms offer a wide selection of these necessary items, ensuring you can maintain your equipment efficiently.

Local Hardware Stores: Many neighborhood shops stock essential items, providing the advantage of immediate availability. Staff can often assist in identifying the correct components for your model.

Online Retailers: Websites such as Amazon and specialized gardening equipment sites provide extensive catalogs, often featuring user reviews and competitive pricing. This option allows you to compare multiple brands and select the ultimate fit for your needs.

Manufacturer’s Website: Visiting the official site can be beneficial, as it typically includes a comprehensive list of compatible components. Purchasing directly ensures authenticity and quality.

Second-Hand Options: Consider browsing platforms like eBay or local classifieds for gently used items. This approach can lead to significant savings while still providing reliable replacements.

Benefits of Regular Maintenance Practices

Implementing consistent upkeep routines is essential for ensuring optimal performance and longevity of any outdoor equipment. Regular maintenance not only enhances efficiency but also reduces the likelihood of unexpected breakdowns, ultimately saving time and resources.

Improved Performance

- Regular checks and servicing help maintain peak functionality.

- Cleaned and adjusted components ensure smoother operation.

- Proper lubrication minimizes friction and wear, enhancing power output.

Cost Savings

- Preventative maintenance can identify issues before they escalate.

- Minimized repair costs through early detection of problems.

- Increased lifespan of the equipment leads to lower replacement expenses.

In conclusion, adopting regular maintenance practices significantly contributes to the effectiveness and durability of equipment, providing both performance enhancements and financial benefits over time.