Understanding how various elements of a machine work together is crucial for ensuring smooth operation and timely maintenance. Each individual piece plays an important role in the overall performance, and having a clear view of these can help in diagnosing issues and preventing malfunctions.

In this section, we delve into the essential mechanical units that are fundamental to the operation of the equipment. By breaking down the main features and their specific functions, we aim to provide a clearer understanding of how these systems interconnect and contribute to the overall functionality.

Maintenance and replacement of these essential elements are critical for long-term reliability. We will guide you through the various aspects of these components, focusing on the importance of recognizing potential wear and tear before it affects performance.

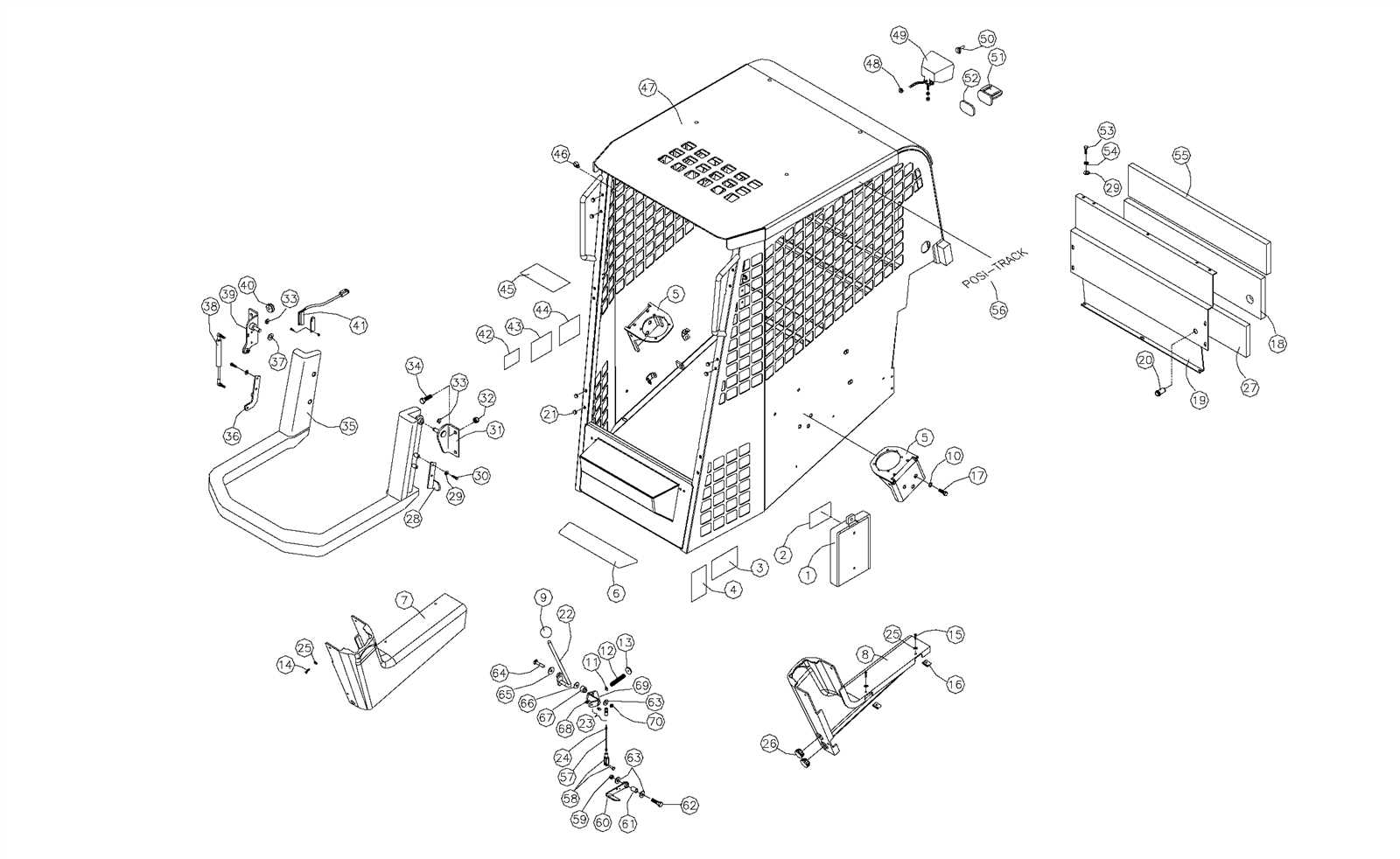

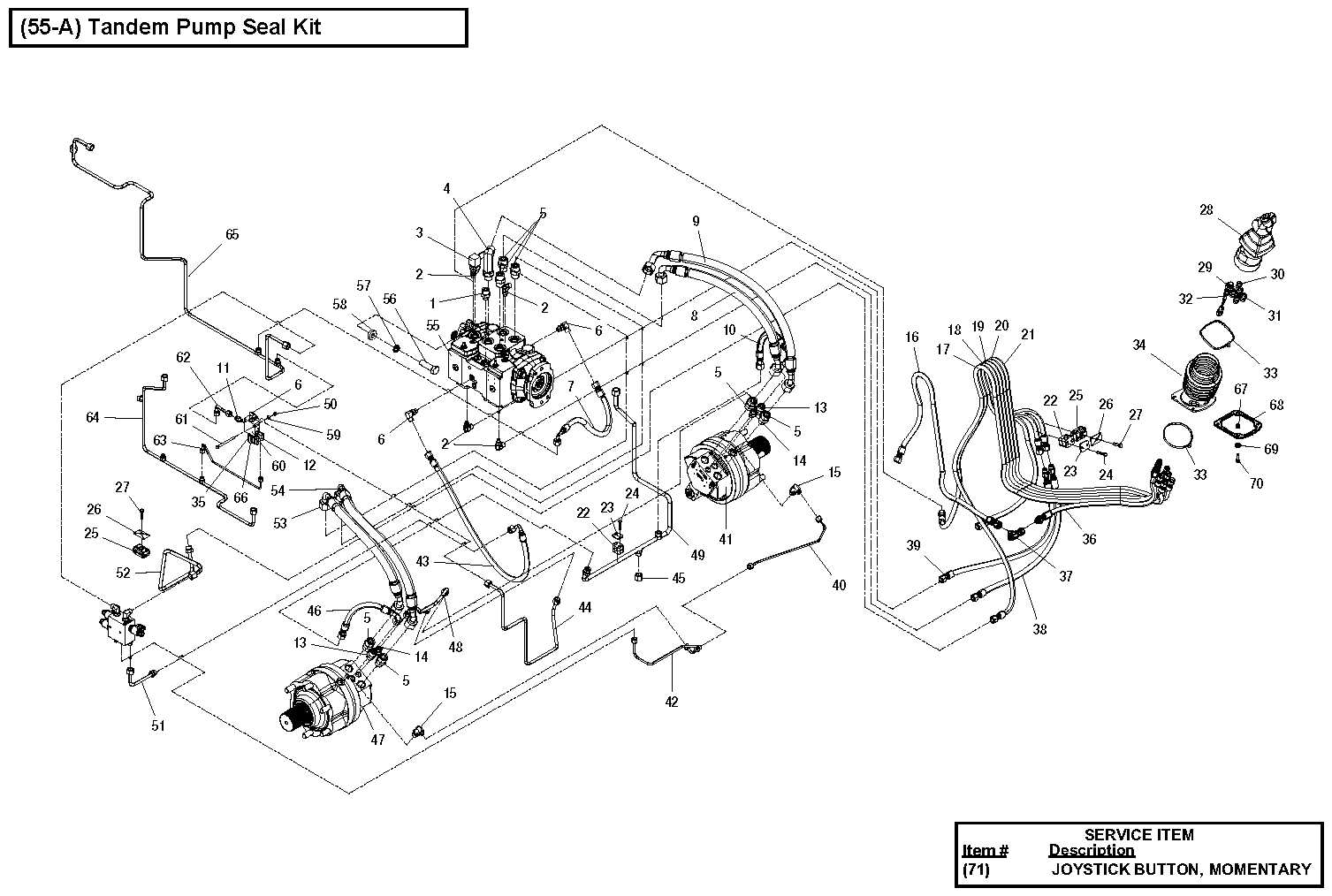

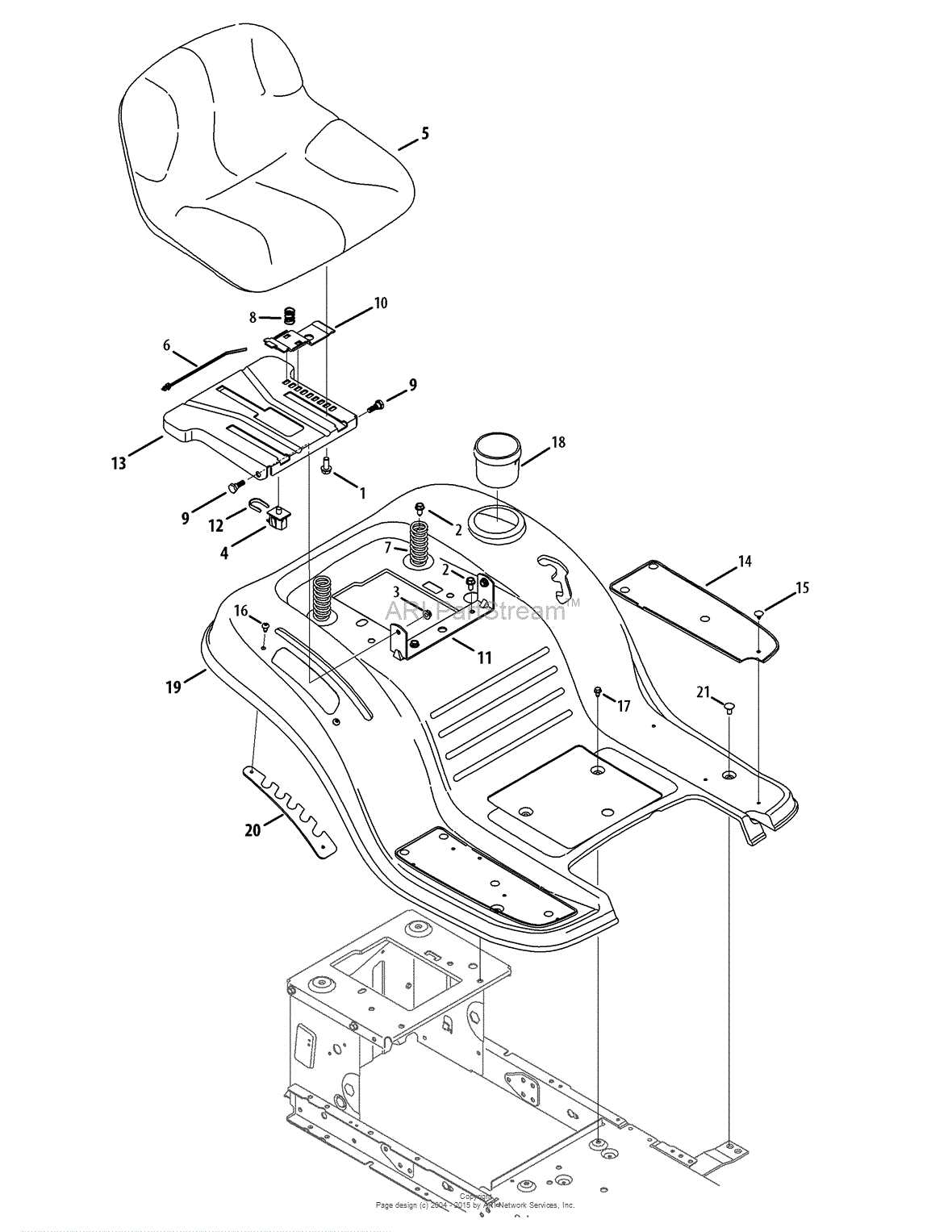

Components Layout Overview

In this section, we provide an in-depth look at the arrangement of various elements found in this model. Each component plays a critical role in ensuring the optimal functioning of the machine. The layout is designed to be user-friendly, allowing for easier identification and maintenance of key elements. Understanding how these elements fit together is essential for ensuring smooth operation and longevity.

Mechanical Assembly: The mechanical structure is built with precision, ensuring that every part operates in harmony. This system is designed for durability and efficiency.

Internal Mechanisms: The internal elements are arranged in a way that supports smooth functionality and minimizes wear and tear over time. Proper maintenance of these components is vital for long-term performance.

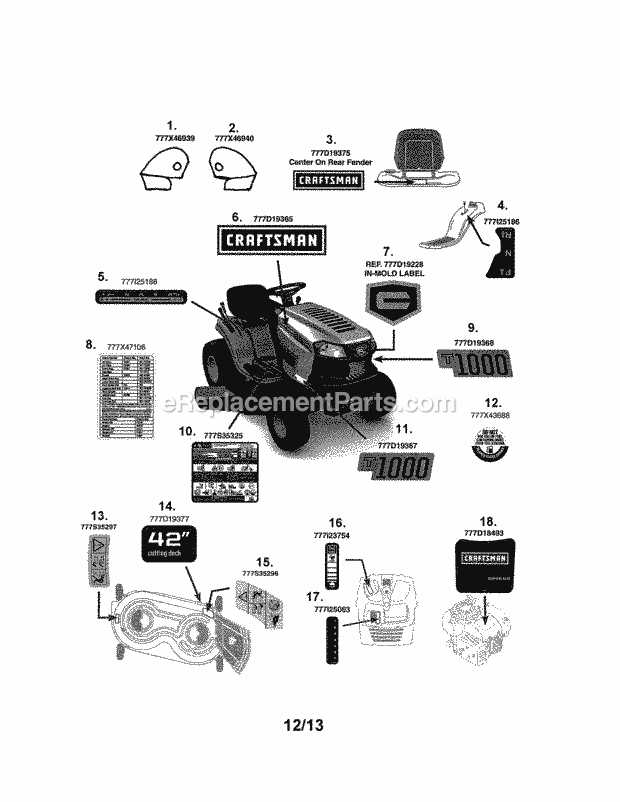

Key Components of the Craftsman T140

The primary elements of this lawn equipment are designed to ensure efficient performance and long-lasting durability. Each component has a specific function that contributes to the overall operation, making it essential to understand how these parts work together. Proper knowledge of the key sections and mechanisms helps in maintenance and troubleshooting.

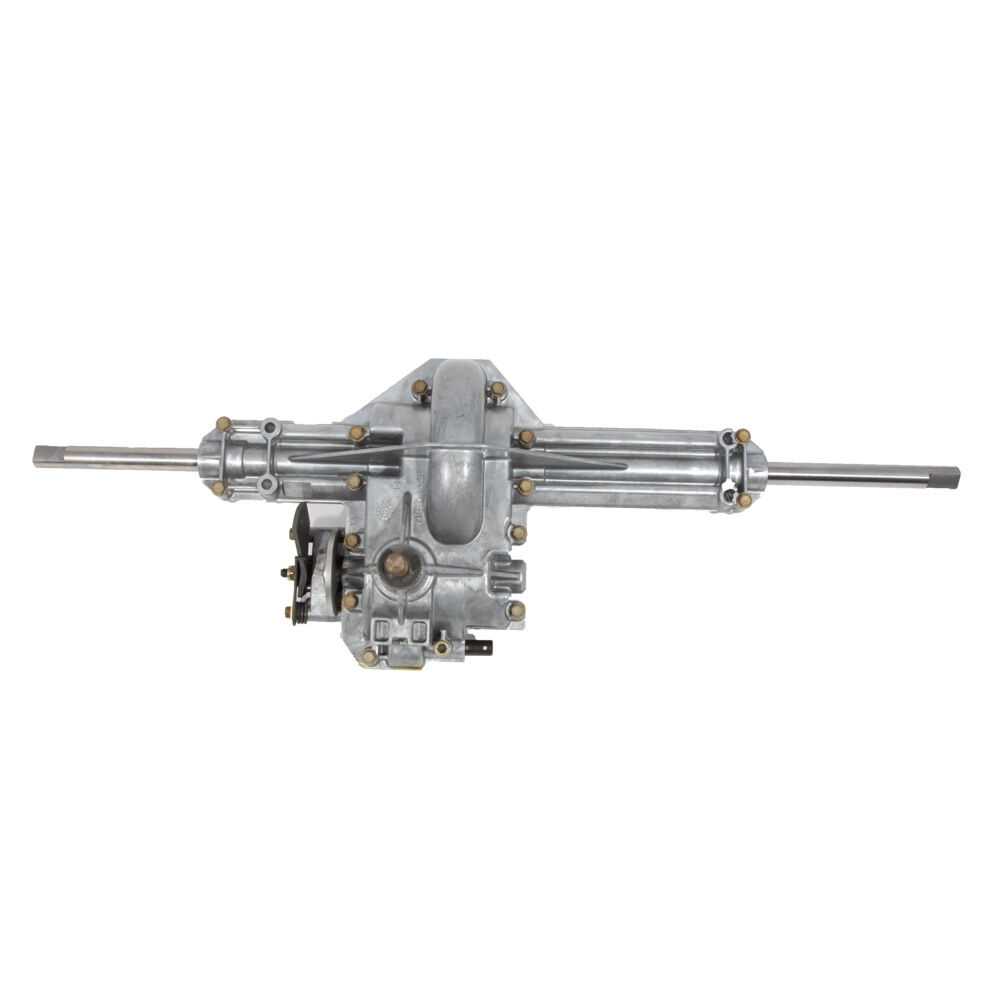

Engine and Transmission

The motor powers the equipment, providing the necessary force to tackle various terrains. The transmission, on the other hand, allows smooth shifts between speed levels, ensuring a consistent pace during operation. These core elements are crucial for delivering reliable power and control.

Cutting System

The blades and their housing make up the cutting system, designed to deliver clean and precise grass trimming. The adjustable height feature ensures flexibility, allowing users to set the desired cutting length depending on the lawn’s condition.

Engine and Transmission System Layout

The engine and transmission system forms the backbone of any motorized machine, providing the necessary power and torque for smooth operation. This section focuses on the arrangement and interaction of these two crucial components, detailing how they work together to ensure efficient performance.

Engine Structure Overview

The engine, responsible for generating power, consists of several key elements that work in sync to deliver energy. These components include:

- Pistons and cylinders

- Crankshaft and camshaft

- Valves and spark plugs

- Cooling and lubrication systems

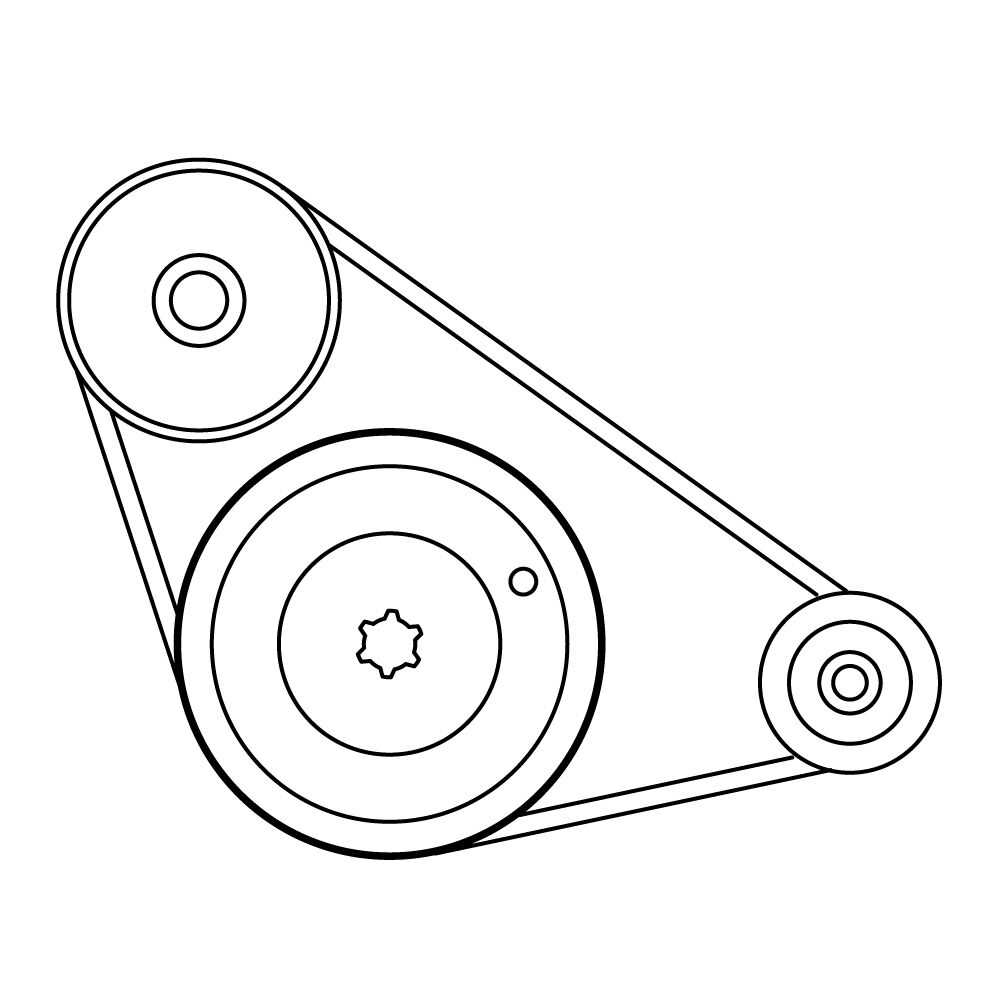

Transmission Mechanism

The transmission is tasked with

Understanding the Steering and Control Mechanisms

Steering and control systems are crucial for ensuring smooth maneuverability and precision during operation. These components work together to allow the user to direct movement with ease and accuracy, responding to commands for both navigation and adjustments in speed. The effectiveness of these systems is dependent on the integration of various elements that provide stability and control.

- Steering Wheel: The primary control device used to direct movement, connected to the mechanical system that turns the front wheels.

- Linkage: A series of rods and joints that transmit the steering wheel’s motion to the front axle, allowing precise wheel direction changes.

- Axle: A critical component that bears the load and facilitates turning movements by transferring the steering input to the wheels.

- Brakes: Integrated within the control system, the brakes provide necessary stopping power, aiding in smooth deceleration and preventing oversteering.

- Speed Control Lever: This mechanism regulates acceleration and deceleration, enabling the operator to adjust the speed smoothly

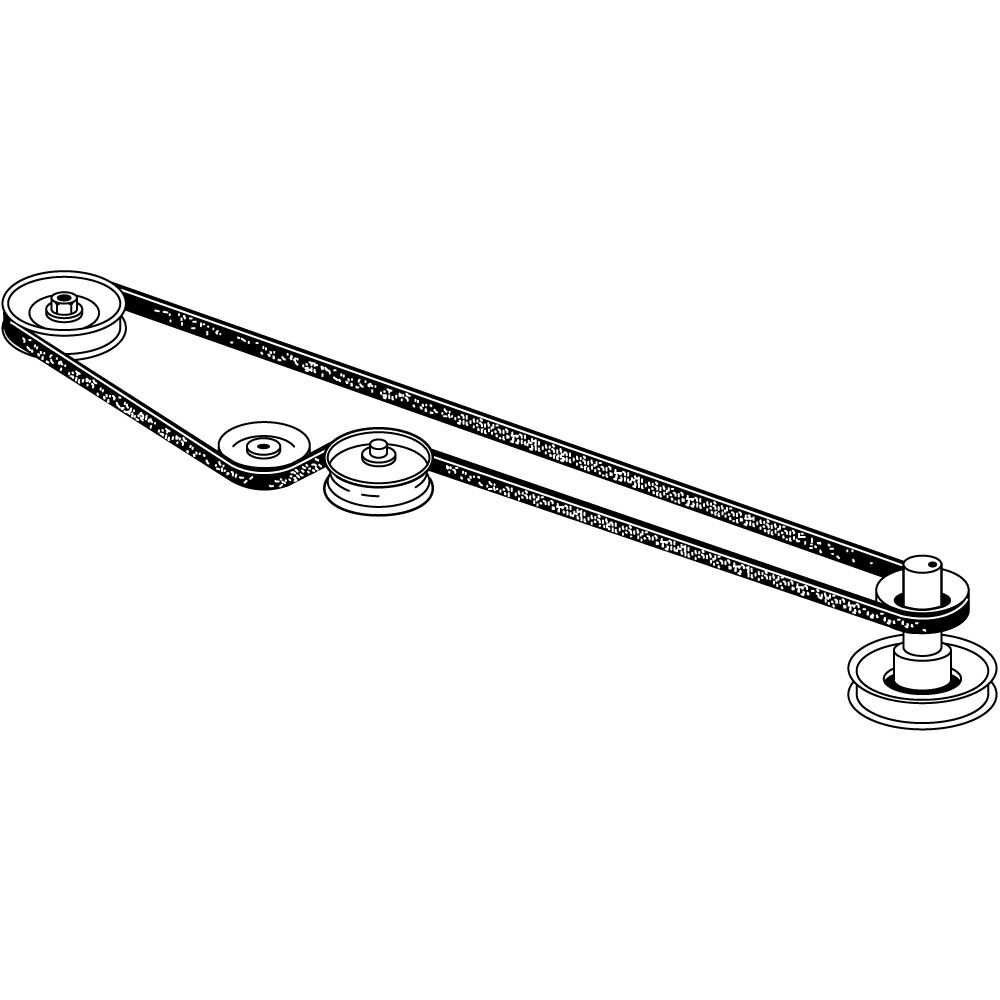

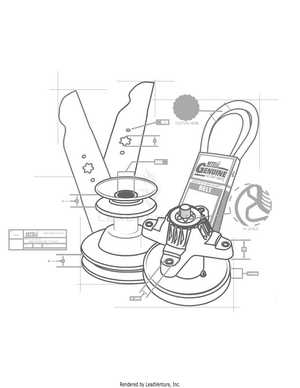

Blade and Mower Deck Configuration

The blade and mower deck setup plays a critical role in ensuring efficient grass cutting and optimal performance. Proper alignment and configuration of these components are essential for smooth operation and even cutting results. Understanding how the blade interacts with the deck system helps in maintaining balance, reducing vibrations, and extending the longevity of the equipment.

Blade Positioning and Alignment

Correct blade positioning ensures uniform cutting height and prevents scalping the lawn. It’s important to regularly check for any misalignment, as even small deviations can affect the quality of the cut. Balanced blades also reduce unnecessary strain on the engine, contributing to overall durability.

Deck Structure and Adjustments

The mower deck’s design supports the blade and influences airflow, which aids in cutting and mulching. Regular inspections of the deck, such as cleaning out grass build-up and adjusting the height settings, ensure that the cutting process remains efficient. Keeping the deck level is key to achieving a clean, even mow.

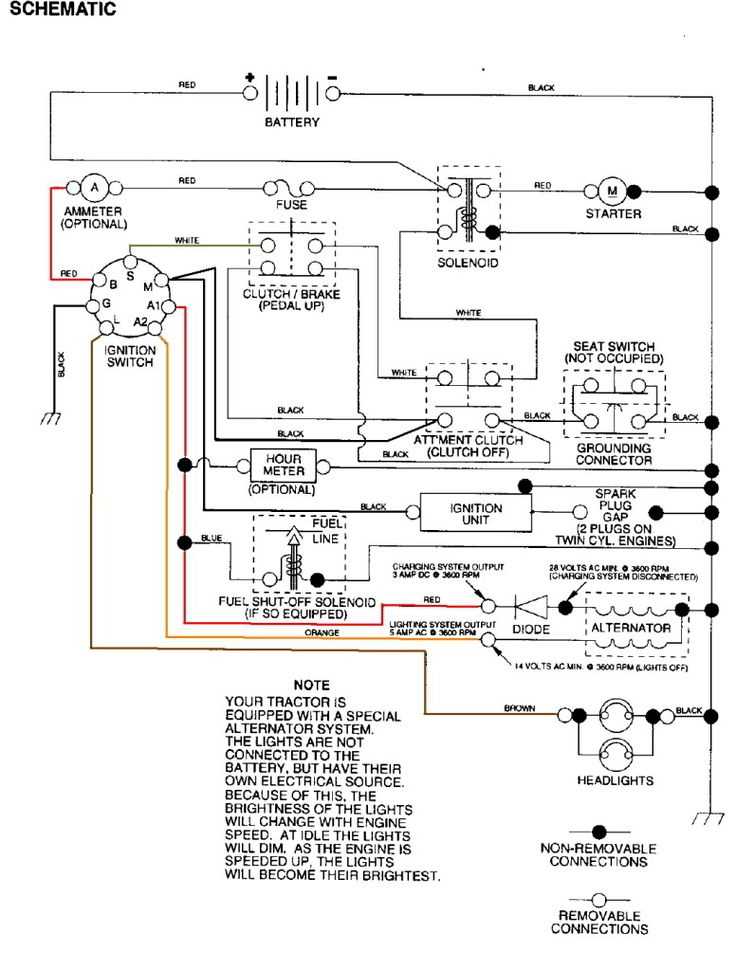

Electrical and Wiring Connections Explained

Understanding the intricacies of electrical and wiring connections is crucial for ensuring the efficient operation of various machinery. These connections facilitate the flow of electricity, allowing components to function in harmony. Proper knowledge of wiring layouts and electrical pathways can enhance performance and prevent potential issues.

Key Components of Electrical Systems

The electrical system consists of several essential elements, including switches, connectors, and wires. Each component plays a vital role in creating a reliable circuit. For instance, switches control the flow of electricity, while connectors secure the wiring, ensuring stable connections. Utilizing high-quality materials in these components can significantly reduce the risk of electrical failure.

Importance of Correct Wiring Techniques

Employing appropriate wiring techniques is fundamental for safety and functionality. Proper insulation and organization of wires prevent short circuits and potential hazards. Additionally, adhering to manufacturer guidelines when installing or replacing electrical components ensures optimal performance and longevity of the equipment. Regular inspections of wiring connections can also identify wear and tear, enabling timely maintenance.

Fuel System and Exhaust Assembly Details

The fuel system and exhaust assembly are critical components that ensure the optimal performance of small engine machinery. Understanding these elements helps in maintaining efficiency and reducing emissions, thereby extending the lifespan of the equipment. This section provides an overview of the essential elements involved in fuel delivery and exhaust management.

Fuel Delivery Mechanism

The fuel delivery mechanism includes several key parts that work together to supply the engine with the necessary fuel. It typically comprises the fuel tank, fuel lines, filter, and carburetor. The tank stores the fuel, while the lines transport it to the engine. A filter ensures that impurities do not reach the carburetor, which mixes air and fuel for combustion.

Exhaust System Components

The exhaust system plays a vital role in directing harmful gases away from the engine and operator. It generally consists of the exhaust manifold, muffler, and exhaust pipes. The manifold collects exhaust gases from the engine, while the muffler reduces noise levels. The pipes then expel the gases safely into the atmosphere, minimizing environmental impact.

Maintenance Tips for Craftsman T140 Parts

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular attention to its components can prevent unexpected breakdowns and enhance functionality. Here are some helpful practices to maintain your machinery effectively.

- Regular Cleaning: Keep all surfaces free of dirt and debris. Use a soft brush or cloth to remove any buildup that can hinder performance.

- Lubrication: Apply appropriate lubricants to moving parts as specified in the manual. This reduces friction and wear.

- Inspection: Periodically check components for signs of wear or damage. Look for cracks, rust, or loose connections.

- Replacement Schedule: Establish a timeline for replacing worn-out items based on usage and manufacturer recommendations.

- Storage: Store the equipment in a dry, sheltered location to protect it from the elements when not in use.

By following these guidelines, you can ensure your equipment operates smoothly and efficiently, leading to a more enjoyable experience during use.

How to Identify and Replace Worn Parts

Identifying and replacing worn components is crucial for maintaining the efficiency and longevity of your equipment. Over time, various elements may become degraded, leading to diminished performance. Recognizing the signs of wear and knowing how to address them can help ensure optimal functionality.

Signs of Worn Components

- Unusual noises during operation

- Decreased efficiency or performance

- Visible damage or wear

- Difficulty in operation or response

Steps to Replace Worn Components

- Disconnect the equipment from the power source to ensure safety.

- Inspect the components thoroughly for signs of wear.

- Carefully remove the damaged parts, taking note of how they are attached.

- Replace them with new, compatible components.

- Reassemble the equipment and test its functionality.