When considering the essential elements of any vehicle, the underlying structure plays a crucial role in ensuring both durability and safety. The interconnected sections beneath the body provide the necessary support for various mechanical systems and contribute to the overall stability of the vehicle.

Understanding the configuration of these components helps in maintaining and repairing the vehicle, especially when it comes to ensuring that each section is functioning optimally. By gaining insight into the various segments, it’s easier to address potential wear and ensure longevity in performance.

Knowing how different parts are aligned and connected allows for a clearer perspective on potential upgrades or replacements. This knowledge becomes invaluable during maintenance, ensuring that each section receives the proper attention it requires.

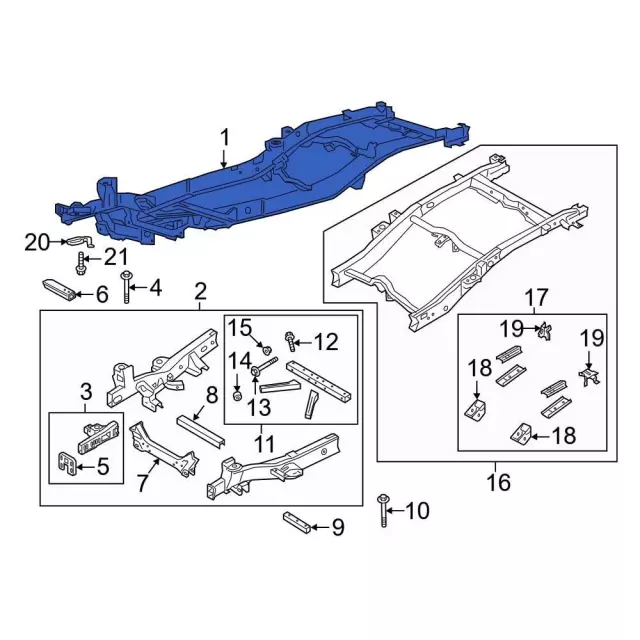

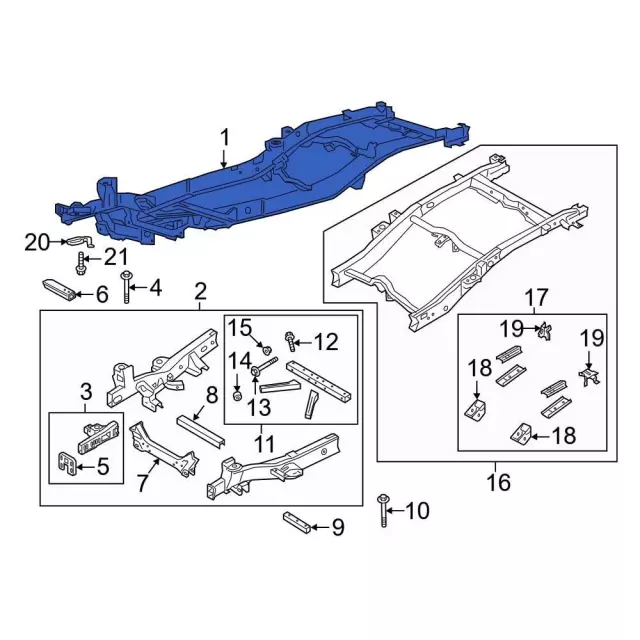

Ford Ranger Frame Structure Overview

The backbone of this vehicle’s construction is designed to provide exceptional durability and stability. It supports the overall body, offering a solid foundation for various systems and components. This structural design ensures optimal handling, safety, and performance, accommodating different terrains and driving conditions.

High-strength materials are used to enhance resilience, while specific reinforcements help distribute weight and absorb impacts efficiently. The layout maximizes load-bearing capacity, making it suitable for both off-road adventures and heavy-duty tasks.

With its carefully engineered architecture, this platform contributes to the vehicle’s agility and durability, ensuring a reliable driving experience for a wide range of uses.

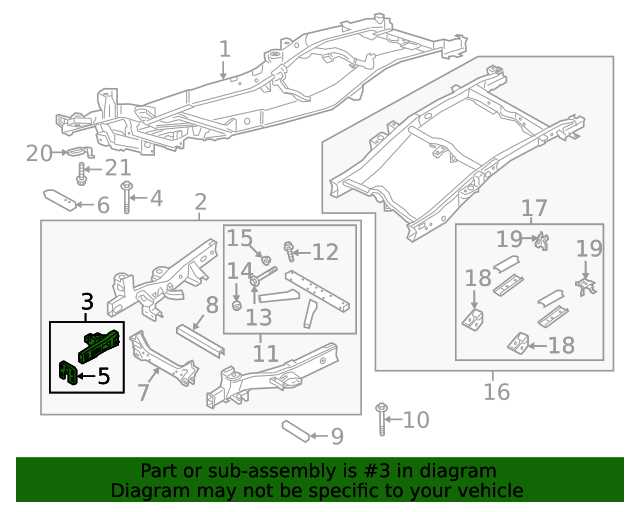

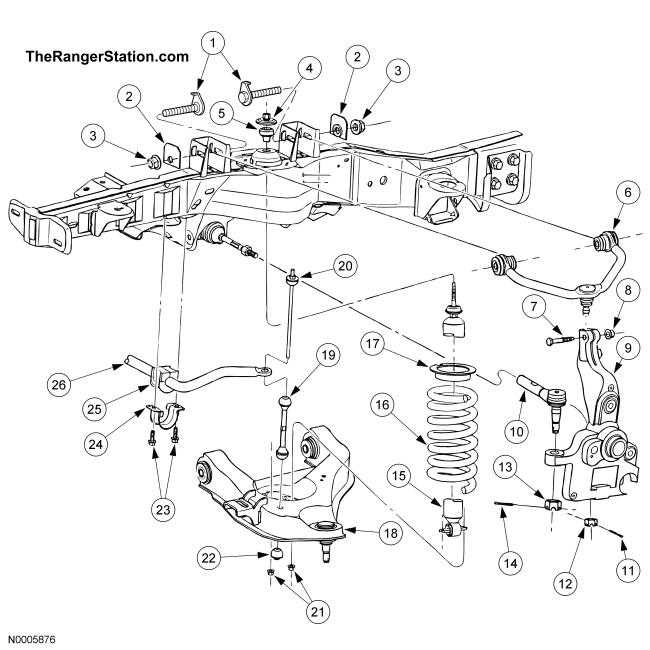

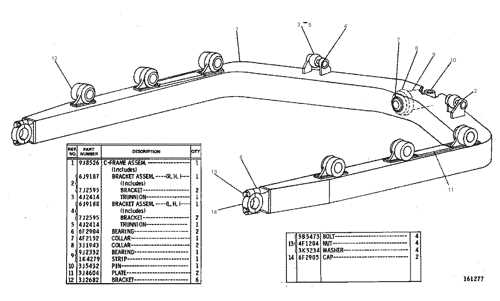

Main Components of the Ford Ranger Frame

The foundation of this type of vehicle consists of several key elements that provide both structural integrity and support for various systems. These elements are crucial in ensuring stability, durability, and the overall performance of the vehicle, especially under challenging conditions.

| Component |

Description |

| Chassis Rail |

The main support structure running longitudinally, responsible for bearing most of the vehicle’s load. |

| Crossmember |

Transverse beams connecting the primary supports, enhancing rigidity and distributing weight. |

| Mounting Brackets |

Attachment points for securing suspension, drivetrain, and other essential components. |

| Bumper Reinforcement |

Reinforced section at the front and rear to absorb impact and protect the vehicle’s core structure. |

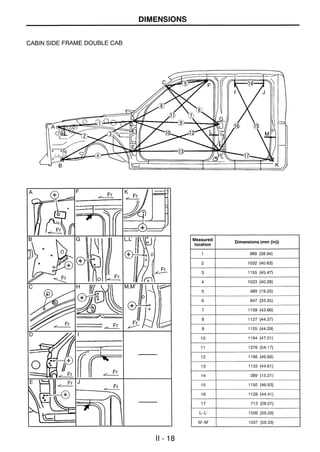

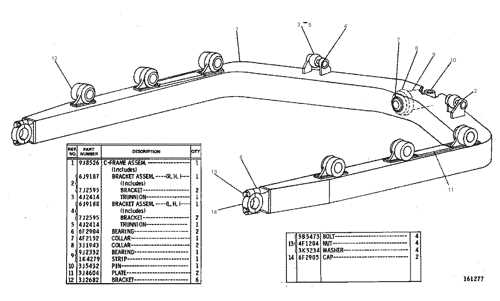

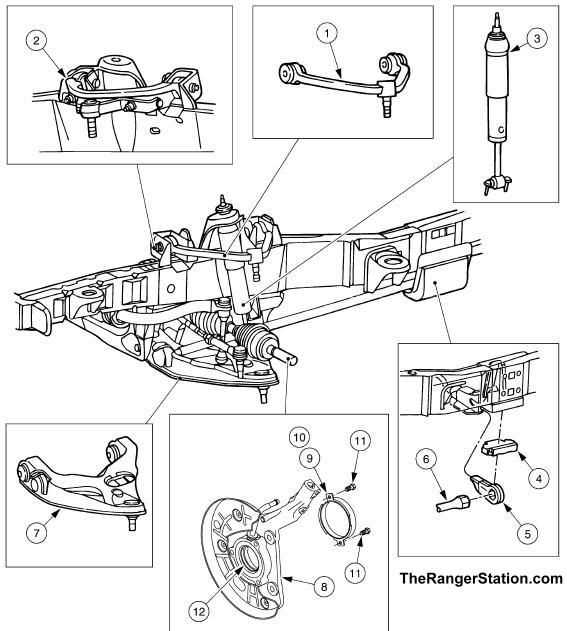

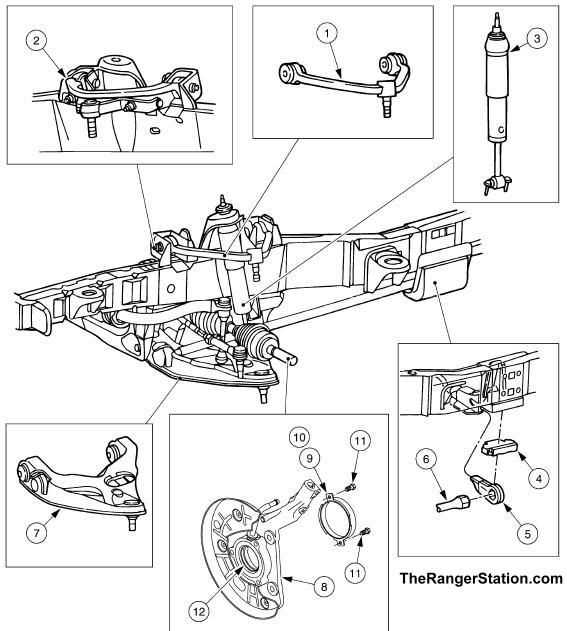

Key Reinforcements in the Frame Design

When considering the structural integrity of a vehicle, key enhancements are crucial to ensure durability and safety. These specific strengthening elements are designed to support the overall build, absorbing stresses and distributing loads more effectively. Reinforced sections play a vital role in withstanding various driving conditions, whether on smooth highways or rugged terrains.

Cross-Member Support

Cross-members provide essential lateral stability, connecting opposite sides and enhancing the resilience of the main structure. By offering additional support, they prevent excessive bending and flexing, especially during heavy loads or sudden impacts. This reinforcement ensures long-term reliability and consistent performance.

Strategic Gusseting

To further fortify the design, gussets are added at crucial junctions. These plates are placed at key connection points, distributing force across a wider area and minimizing the risk of stress fractures. This strategic reinforcement helps maintain the integrity of the structure under extreme conditions.

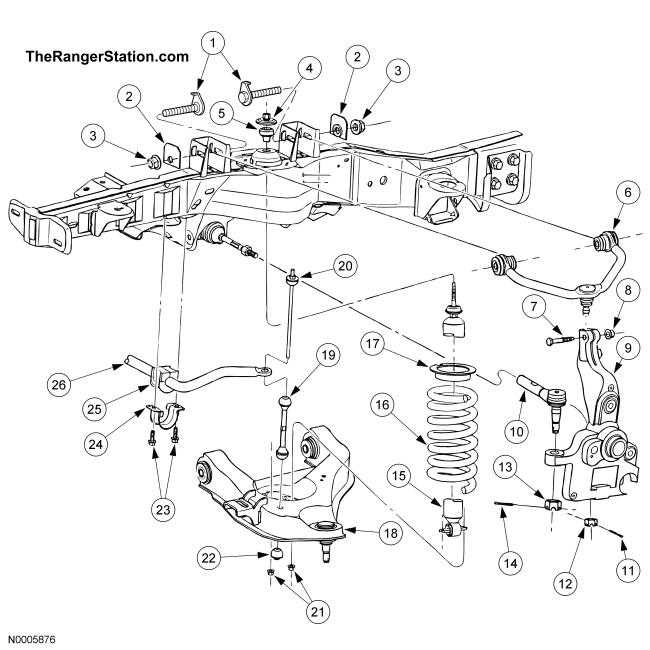

Mounting Points and Their Functions

Mounting points serve as critical locations on a vehicle’s structure where various components are secured. These positions are strategically placed to ensure stability, alignment, and proper functioning of interconnected elements. Understanding the role of each mounting area is essential for maintaining the vehicle’s overall integrity and performance.

Key Types of Mounting Points

Mounting locations vary depending on the part or system they support. Each type is designed to handle specific loads and stresses, ensuring the durability of the vehicle over time. The placement and design of these points are optimized for weight distribution and the safety of the vehicle.

Main Functions of Mounting Points

| Mounting Point |

Function |

| Engine Mounts |

Secure the engine and reduce vibrations. |

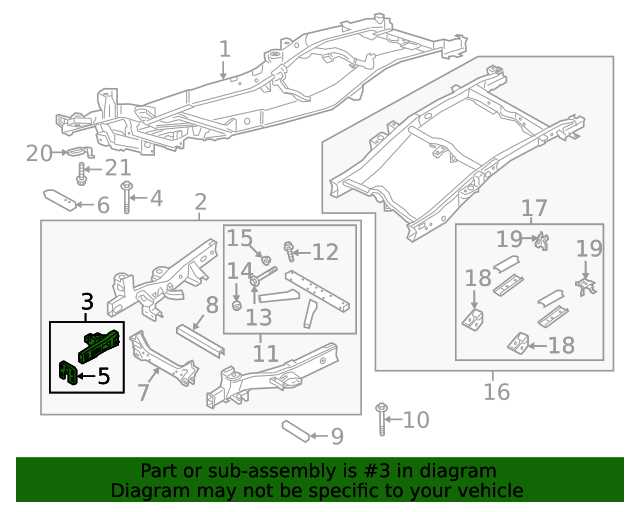

Compatibility of Frame Parts Across Models

The ability to interchange structural components between various vehicle models is often a topic of interest for those looking to maintain or upgrade their automobiles. While many vehicles may share common design principles, certain key differences may affect the compatibility of their structural elements. Understanding these differences can help ensure that parts are correctly matched and function effectively.

When evaluating compatibility, several factors come into play:

- Year of production and the evolution of design specifications

- Variations in body styles and wheelbase lengths

- Engine size and drivetrain configurations

- Regional production differences or special editions

Some vehicles across different production years may share significant similarities, allowing for the reuse of certain structural components. However, it’s essential to verify that the dimensions and mounting points align perfectly to avoid any issues during installation.

In addition, aftermarket components designed to fit multiple models may offer an alternative solution when looking

Common Frame Issues and Fixes

Vehicles often experience structural challenges that can impact their durability and performance. Recognizing potential weak points and addressing them promptly helps maintain longevity and safety on the road. Below are some of the most typical structural problems and suggested solutions.

- Corrosion: One of the most frequent issues, especially in areas with harsh weather conditions, is rusting. Regular inspections and applying anti-rust treatments can significantly prevent this problem.

- Bending or Warping: Heavy

Choosing Aftermarket Frame Parts

When considering enhancements for your vehicle’s structural components, selecting high-quality replacements is crucial. Aftermarket options can provide improved performance, durability, and aesthetic appeal compared to original equipment. Here are some factors to consider when making your choice:

- Material Quality: Look for components made from robust materials like high-strength steel or aluminum, which can offer better resistance to wear and tear.

- Compatibility: Ensure that the selected items are designed to fit your specific model year and specifications, as proper alignment is essential for optimal performance.

- Brand Reputation: Research manufacturers known for their reliability and positive customer feedback. Trusted brands often have a history of producing durable and effective components.

- Warranty: Check for warranties or guarantees that indicate the manufacturer’s confidence in their products, which can offer peace of mind regarding your investment.

- Cost vs. Value: While it may be tempting to choose the cheapest option, consider the long-term value of investing in higher-quality replacements that may last longer and require fewer repairs.

By taking these factors into account, you can make informed decisions that enhance the performance and longevity of your vehicle.

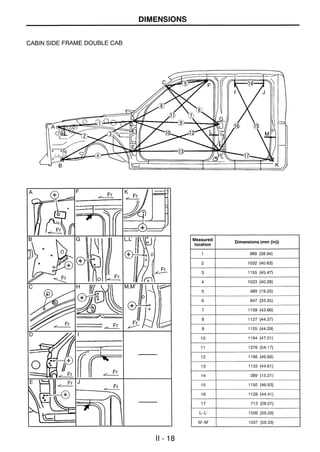

Frame Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s structural components requires consistent care and attention. Regular upkeep not only extends the lifespan of these essential elements but also enhances overall safety and performance. Here are some essential practices to keep in mind.

Firstly, regular inspections are crucial. Check for signs of wear, rust, or damage that could compromise the integrity of the structure. Early detection can prevent more significant issues down the line.

| Maintenance Task |

Frequency |

Description |

| Visual Inspection |

Every 6 months |

Look for rust, cracks, or misalignments that may indicate problems. |

| Rust Treatment |

As needed |

Address any rust spots immediately to prevent further corrosion. |

| Cleaning |

Monthly |

Wash the area to remove dirt, salt, and debris that can cause damage. |

| Lubrication |

Quarterly |

Apply protective sprays or coatings to minimize rust development. |

In conclusion, adopting these maintenance habits will significantly contribute to the longevity and reliability of your vehicle’s structure. Prioritize regular checks and timely interventions to enjoy a safer driving experience.