When it comes to maintaining outdoor machinery, having a comprehensive visual representation of its essential elements is invaluable. This guide aims to enhance your understanding of the various components that make up your equipment, ensuring you can effectively troubleshoot and repair as needed.

By exploring the intricate details of your machine, you’ll gain insights into its operation and functionality. Knowing each part’s role is crucial for achieving optimal performance and extending the lifespan of your investment.

Whether you are a seasoned technician or a novice user, familiarizing yourself with the structure of your equipment can empower you to make informed decisions. The ultimate goal is to equip you with the knowledge necessary for successful maintenance and repairs, ensuring your machinery remains in peak condition.

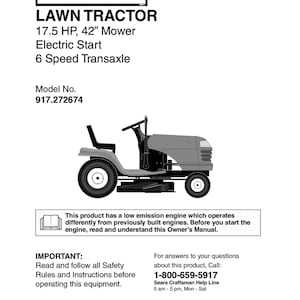

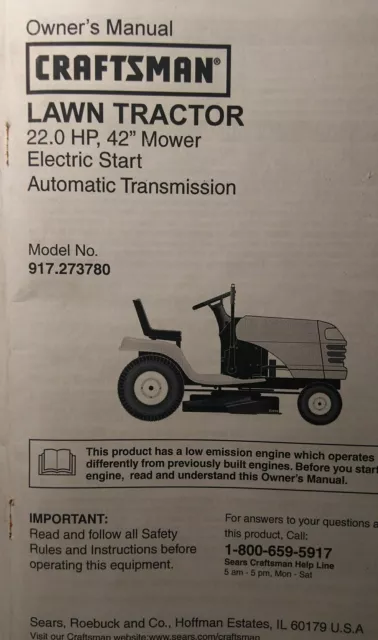

Understanding the Craftsman DYT 4000

This section explores the essential aspects of a popular lawn care machine, focusing on its components and functionalities. By examining its structure, users can enhance their maintenance skills and overall experience.

Key Features

- Powerful engine for efficient operation

- User-friendly controls for easy handling

- Durable construction for longevity

Maintenance Tips

- Regularly check oil levels and replace as needed.

- Inspect and clean air filters to ensure optimal performance.

- Sharpen blades to maintain cutting efficiency.

Key Features of the DYT 4000

This model stands out for its exceptional design and functionality, making it a popular choice among users seeking efficiency and reliability in their outdoor tasks. With a combination of innovative technology and user-friendly features, it caters to a wide range of needs.

One notable aspect is its powerful engine, which ensures robust performance, enabling the user to tackle various terrains effortlessly. Coupled with a smooth transmission system, it provides seamless operation and enhances maneuverability.

Moreover, the cutting deck is engineered for precision, allowing for a clean and uniform cut every time. This feature is particularly beneficial for maintaining a well-groomed lawn with minimal effort.

In addition, the comfort-focused design includes an adjustable seat and intuitive controls, making it easy for operators to navigate and work efficiently over extended periods. These thoughtful elements contribute to an enjoyable user experience, regardless of the task at hand.

Lastly, the durability of the construction materials ensures longevity, reducing the need for frequent maintenance and repairs. This reliability makes it a valuable investment for any homeowner looking to enhance their outdoor maintenance routine.

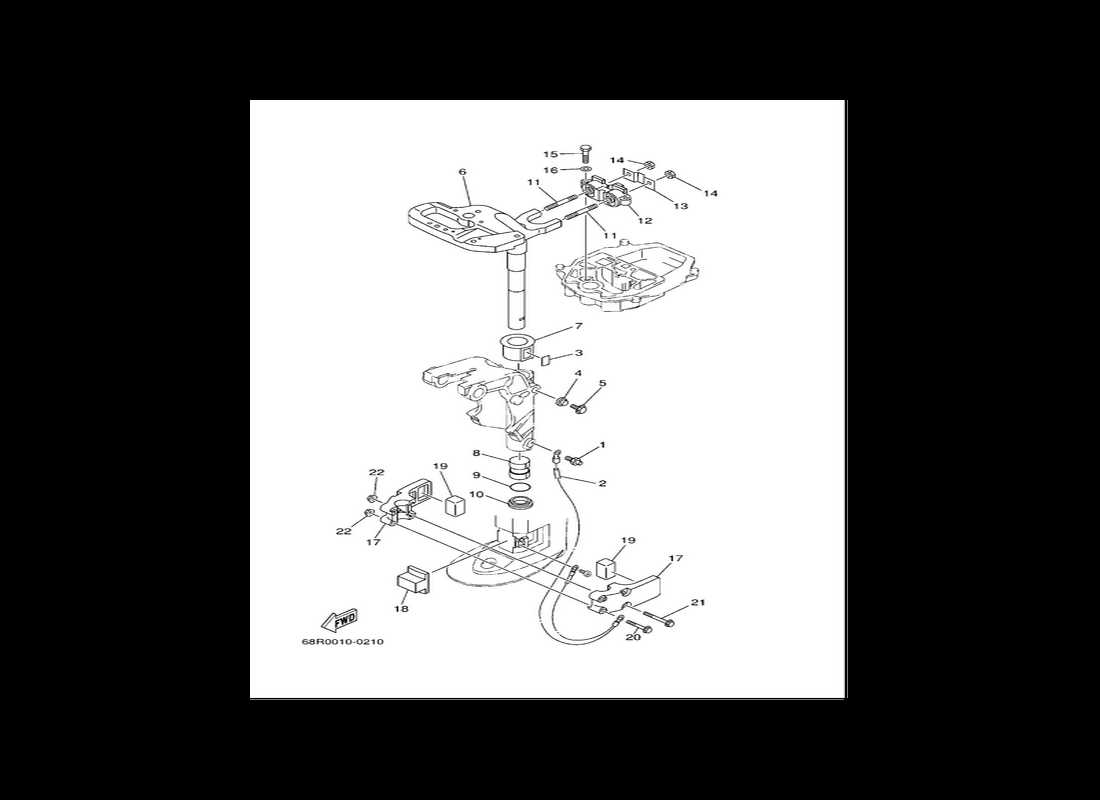

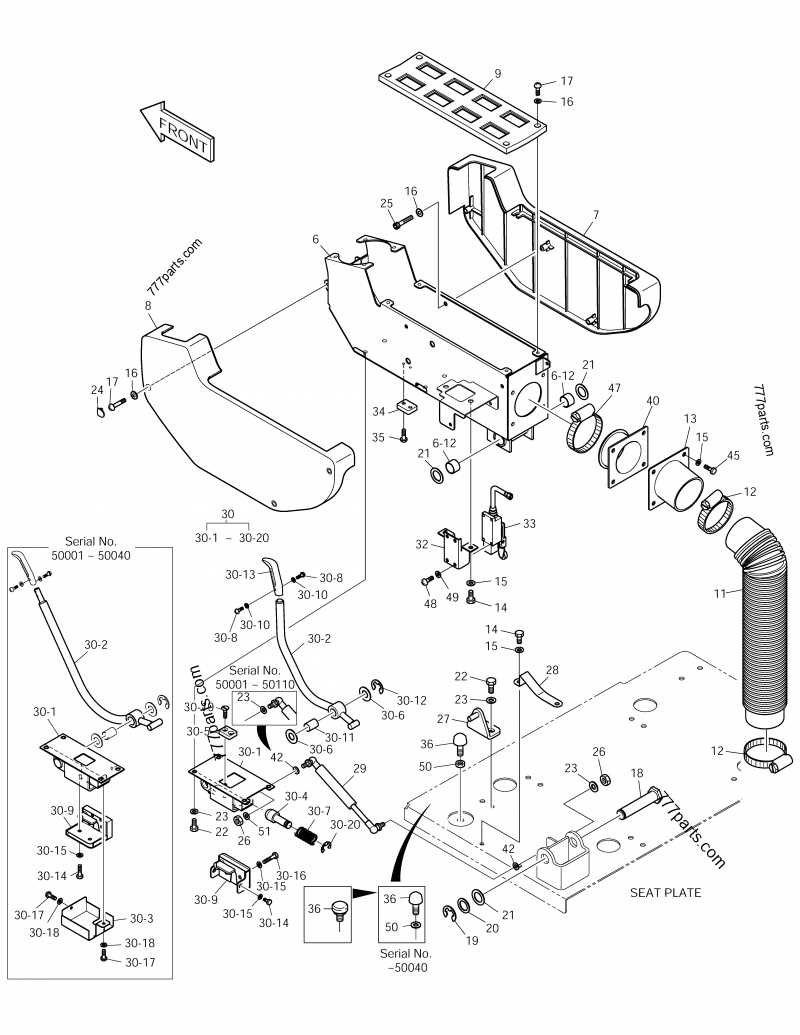

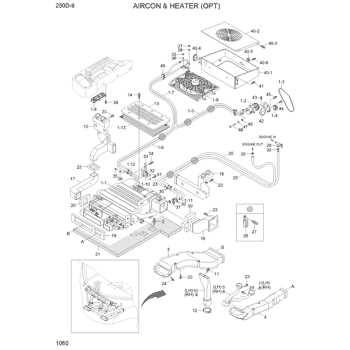

Importance of a Parts Diagram

Understanding the layout of components within a machine is crucial for effective maintenance and repair. A visual representation of these elements not only enhances comprehension but also streamlines the process of identifying and replacing specific sections when needed. Such illustrations serve as a valuable reference, ensuring that users can navigate through the complexities of their equipment with ease.

Enhanced Maintenance

When individuals have access to a clear illustration of their machinery’s structure, they are better equipped to perform regular upkeep. This resource enables users to pinpoint wear and tear or malfunctioning areas quickly, minimizing downtime and prolonging the lifespan of the equipment.

Efficient Repairs

In the event of a breakdown, having a detailed representation allows for swift identification of required replacements. Technicians can reference the layout to acquire the correct components without unnecessary delays, leading to a more efficient repair process. Overall, such visuals are essential tools that promote both understanding and efficiency in the maintenance and restoration of machinery.

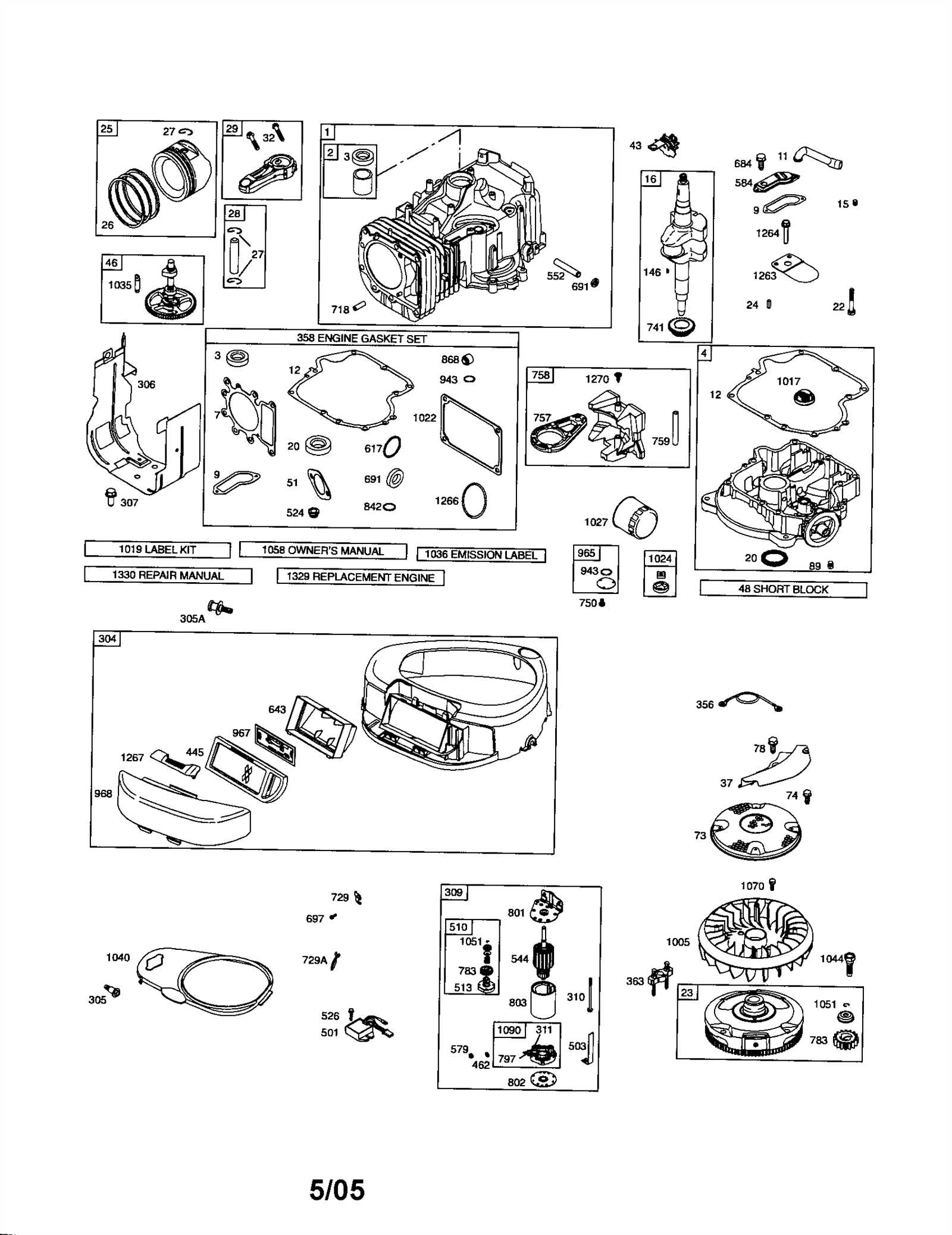

Common Repairs for DYT 4000

Maintaining a lawn care machine is essential for its longevity and optimal performance. Various issues may arise over time, requiring attention to ensure smooth operation. Understanding common repairs can help users identify problems early and take appropriate actions to resolve them efficiently.

Engine Troubles: One frequent issue is engine malfunction. Symptoms may include difficulty starting or uneven running. Regular checks of the fuel system, spark plug condition, and air filter cleanliness can help mitigate these problems. Replacing worn parts promptly can restore functionality.

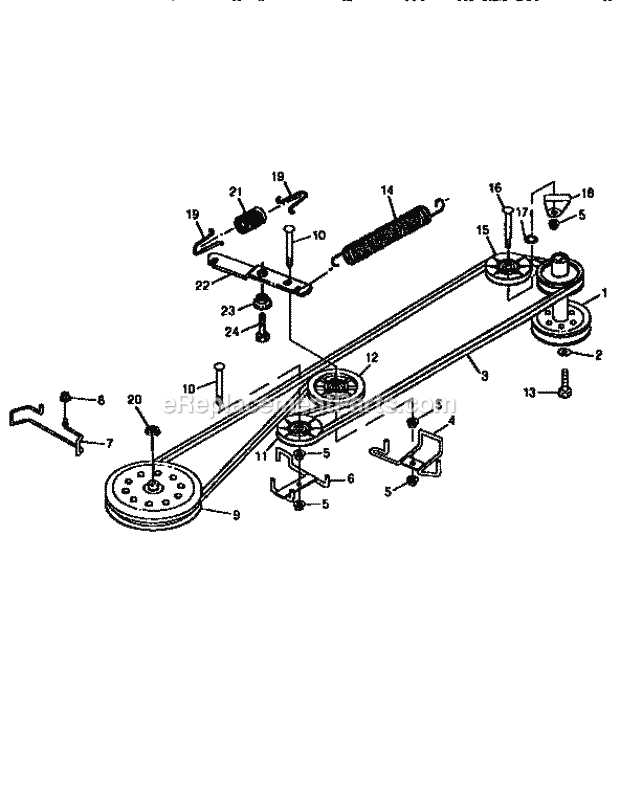

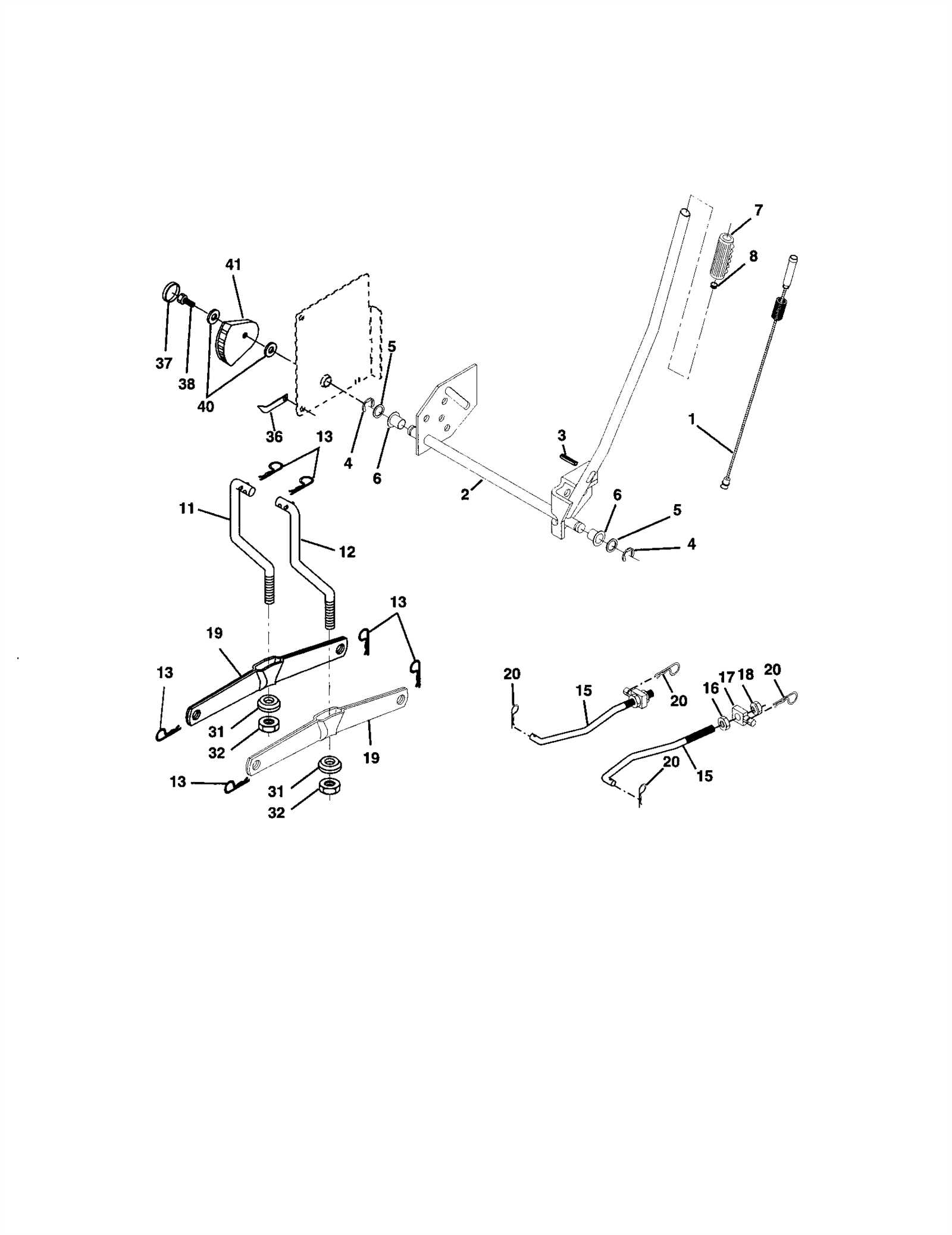

Transmission Issues: If the machine struggles to shift gears or moves slowly, the transmission may need servicing. Inspecting the fluid levels and looking for leaks are crucial steps. Additionally, ensuring the belts and pulleys are in good condition can prevent further complications.

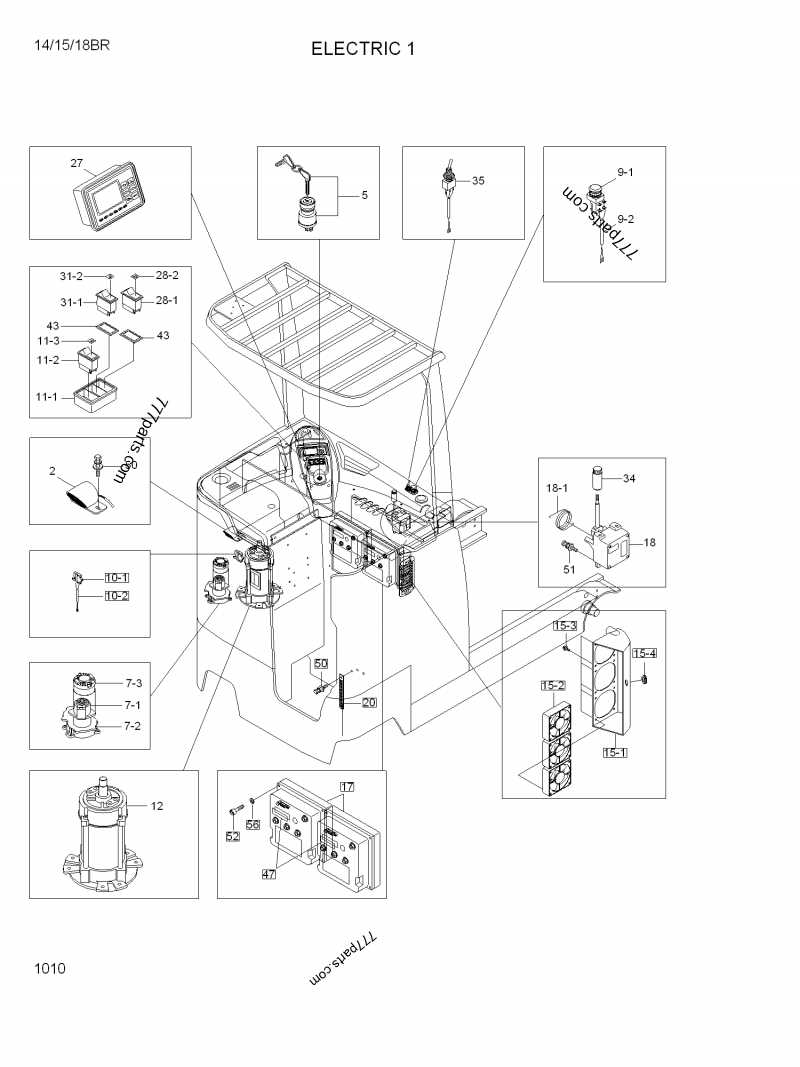

Electrical Failures: Electrical problems often manifest as non-responsive controls or dim lights. Checking the battery connections and fuses should be the first step. If issues persist, examining the wiring for signs of wear or corrosion is recommended.

Deck Maintenance: The cutting deck is vital for effective lawn care. Clogs from grass buildup can hinder performance. Regularly cleaning the deck and inspecting the blades for sharpness can improve cutting efficiency and extend the life of the components.

Tire and Wheel Care: Flat or worn tires can impact maneuverability. Regularly inspecting tire pressure and tread depth ensures optimal handling. Rotating or replacing tires as needed will enhance overall performance.

By being proactive and addressing these common issues, users can enjoy a reliable and efficient lawn care experience, minimizing downtime and maximizing productivity.

Where to Find Replacement Parts

Finding components for machinery can often be a challenge, but numerous resources are available to assist in locating the necessary items. Whether you need original or compatible alternatives, various avenues can help you secure the right pieces.

Online Retailers

- Visit dedicated websites that specialize in machinery components.

- Check major e-commerce platforms for a wide selection.

- Utilize manufacturer websites for specific recommendations.

Local Supply Stores

- Explore nearby hardware shops that may carry a variety of components.

- Inquire at specialty stores focused on outdoor equipment.

- Consult with local mechanics for advice on sourcing items.

DIY Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of your equipment. By integrating a few simple practices into your routine, you can ensure optimal performance and minimize the need for costly repairs. Regular maintenance not only improves efficiency but also promotes safety during operation.

1. Regular Cleaning: Keep your machinery free from dirt and debris. This prevents wear and tear on components and ensures smooth functioning.

2. Lubrication: Apply the right lubricants to moving parts to reduce friction. This step is vital for preventing overheating and extending the life of the equipment.

3. Inspections: Schedule routine checks to identify any wear before it becomes a major issue. Early detection can save time and money.

4. Follow Manufacturer Guidelines: Adhere to maintenance schedules and guidelines provided by the manufacturer. These recommendations are designed to maximize the longevity of your machinery.

5. Store Properly: When not in use, store your equipment in a dry, sheltered area. Protecting it from the elements can prevent rust and deterioration.

By following these straightforward tips, you can significantly enhance the durability and reliability of your machinery.

Exploring Craftsman Support Resources

Accessing reliable assistance and guidance is crucial for maintaining and enhancing the functionality of your equipment. Numerous support channels exist to provide valuable information, whether you seek troubleshooting tips, maintenance advice, or replacement components. Understanding these resources can significantly streamline your experience and ensure your machinery operates at peak performance.

Online Knowledge Bases

Many manufacturers host comprehensive online repositories filled with user manuals, FAQs, and troubleshooting guides. These platforms offer instant access to a wealth of information, enabling users to find solutions to common issues without the need for direct contact. Utilizing these resources can empower you to tackle minor repairs and enhancements independently.

Customer Support Services

In addition to self-service options, direct support channels are available for those requiring personalized assistance. Engaging with customer service representatives can provide tailored solutions to more complex problems. Whether through phone, email, or live chat, these experts can help guide you through specific concerns and ensure you receive the right information and parts needed for repairs.

Embracing these resources can lead to a more efficient maintenance process, ensuring your equipment remains reliable and functional for years to come. By leveraging both online tools and direct support, users can effectively manage their equipment needs with confidence.

Safety Guidelines When Repairing

Engaging in maintenance and repair tasks requires careful consideration to ensure both personal safety and the integrity of the equipment. Adhering to established precautions is essential to minimize risks associated with handling tools and machinery.

Wear Appropriate Personal Protective Equipment (PPE): Always equip yourself with suitable protective gear, including safety glasses, gloves, and sturdy footwear. This will safeguard against potential injuries from debris, sharp edges, or heavy components.

Ensure Proper Ventilation: When working in enclosed spaces, make sure there is adequate airflow to prevent the buildup of harmful fumes or dust. This is particularly crucial when using solvents or other chemicals during repairs.

Disconnect Power Sources: Before beginning any maintenance work, always disconnect the power supply. This simple step helps prevent accidental starts that could lead to injury.

Use Tools Correctly: Familiarize yourself with the operation of tools before use. Employ the right tool for each task to avoid accidents and ensure efficient work.

Keep the Workspace Organized: A tidy workspace reduces the risk of tripping hazards and allows for better focus on the task at hand. Store tools and materials properly after each use.

Read Manuals and Safety Instructions: Always consult the user manual and safety guidelines specific to the equipment being repaired. Understanding the manufacturer’s recommendations can significantly reduce the likelihood of accidents.

Have an Emergency Plan: Be prepared for emergencies by knowing the location of first aid kits and fire extinguishers. Ensure that someone nearby is aware of your work and can assist if needed.

Upgrading Your DYT 4000 Components

Enhancing the functionality and performance of your lawn tractor can significantly improve your gardening experience. By focusing on specific components, you can achieve better efficiency, reliability, and longevity. This guide outlines essential upgrades to consider, ensuring your equipment remains in top condition.

Key Areas for Improvement

- Engine Performance

- Cutting Efficiency

- Transmission and Drive System

- Electrical System

Recommended Upgrades

- Air Filter: Replace with a high-flow option to enhance airflow and engine performance.

- Blades: Upgrade to precision-cut blades for a cleaner, more efficient cut.

- Battery: Consider a higher-capacity battery for improved starting power and longevity.

- Transmission Fluid: Use high-quality fluid for smoother operation and better handling.

Investing in these upgrades not only boosts the overall performance but also ensures a smoother and more enjoyable experience while maintaining your lawn.