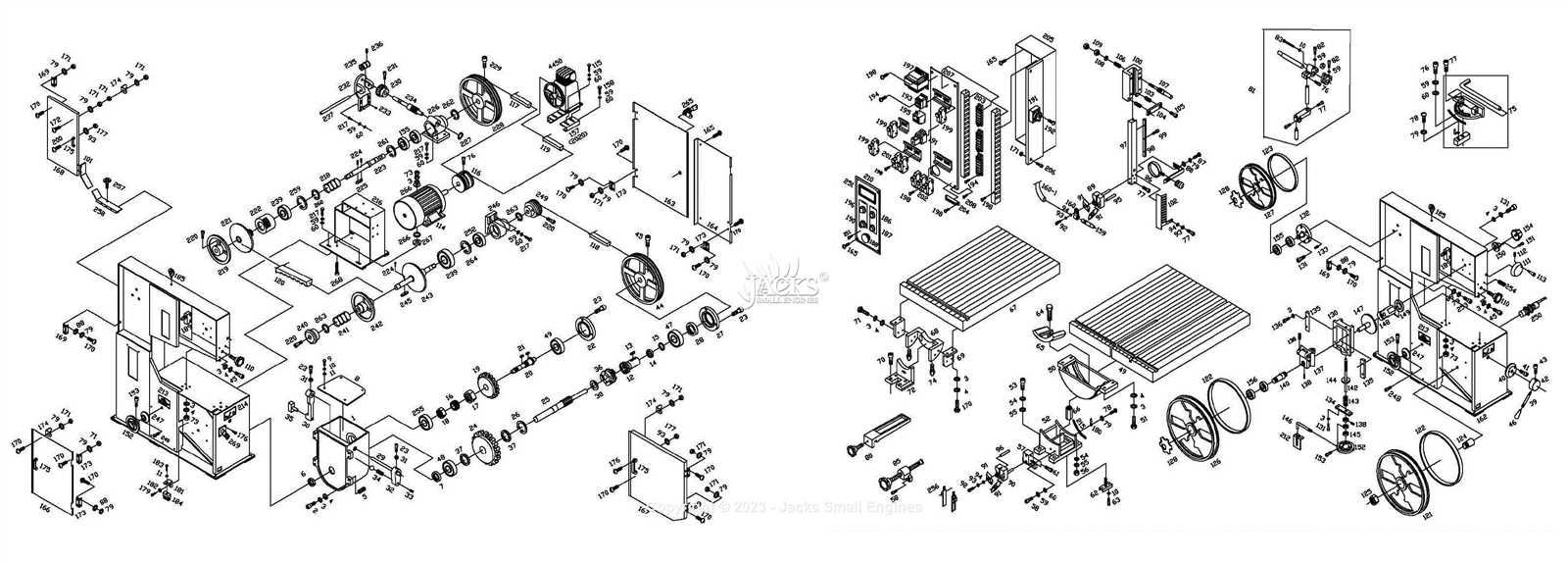

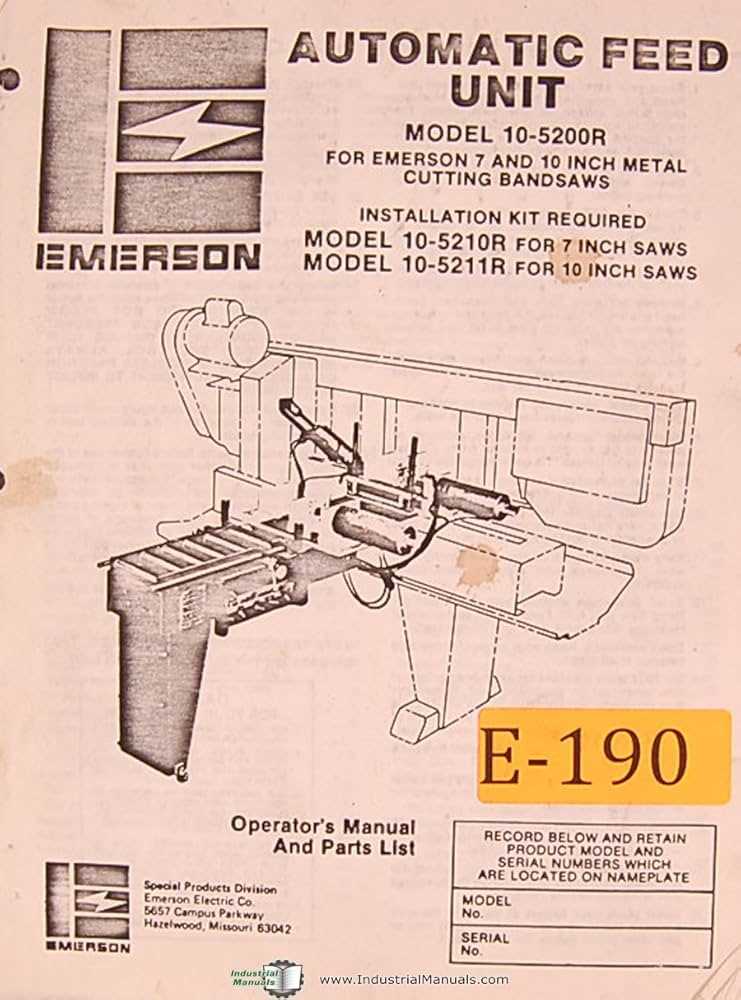

In the realm of woodworking machinery, understanding the intricate workings of a pivotal apparatus allows craftsmen to maintain and enhance their operational efficiency. This comprehensive exploration delves into the various elements comprising a foundational structure engineered for precision cutting tasks.

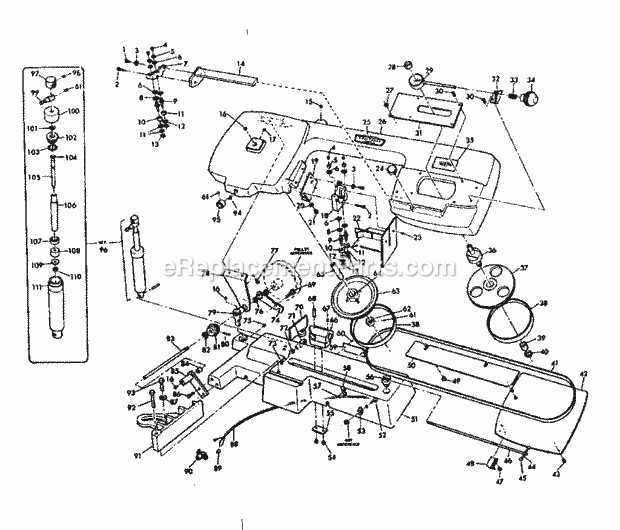

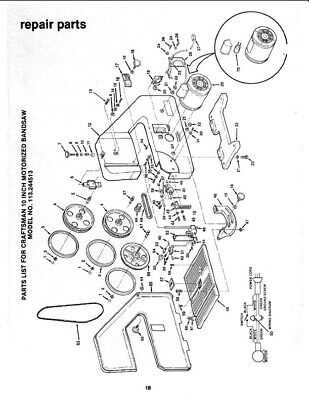

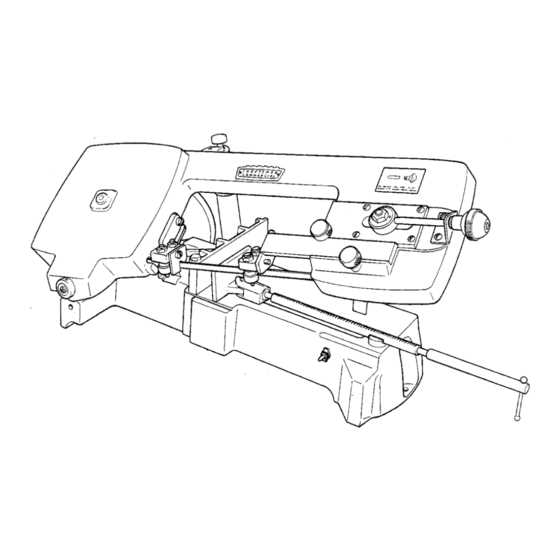

Exploring the anatomy of this device reveals a network of interconnected parts, each playing a vital role in the seamless execution of cutting procedures. From pivotal components that facilitate fluid blade movements to stabilizing elements ensuring operational steadiness, every detail serves a purpose in optimizing woodworking outcomes.

Furthermore, a closer examination of these integral constituents highlights the intricate synergy of mechanical components, harmoniously orchestrated to uphold the tool’s functional integrity. Understanding these elements not only enhances operational prowess but also empowers craftsmen to troubleshoot and maintain their apparatus with adept proficiency.

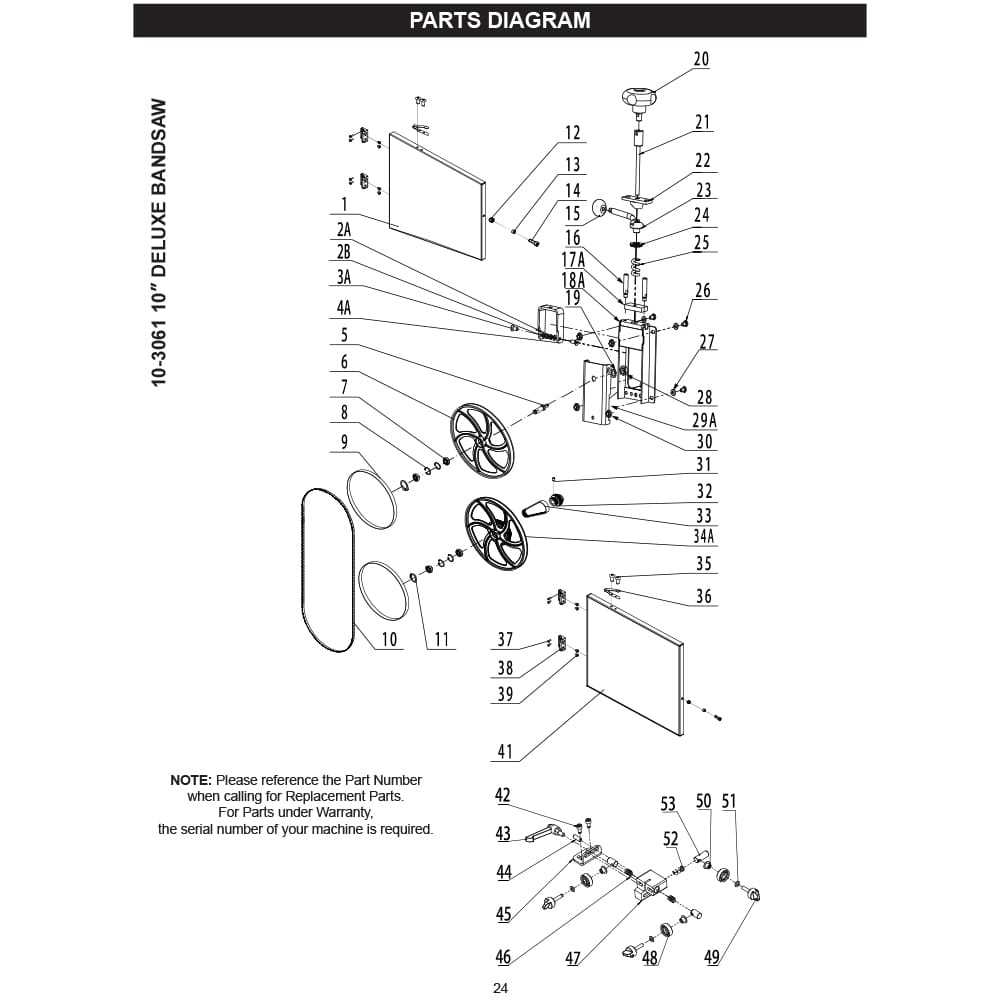

Understanding the Components of a 10-Inch Band Saw

In this section, we delve into the key elements that comprise a 10-inch band saw, exploring its fundamental structures and functionalities. Each component plays a crucial role in the overall operation and efficiency of the tool, contributing to its precision and performance.

Main Frame and Base

The main frame and base provide the structural integrity and stability needed for the band saw’s operation. It supports the entire assembly, ensuring minimal vibrations during cutting operations, which is essential for accurate cuts and user safety.

Blade and Tensioning Mechanism

At the heart of the band saw is its blade and tensioning mechanism. The blade, often made of durable materials like carbon steel or bi-metal, executes the cutting action. The tensioning mechanism maintains the optimal tension in the blade, preventing deflection and ensuring consistent cutting performance.

These critical components, along with others such as the guides, table, and motor, work in tandem to deliver precise cuts across a variety of materials, making the 10-inch band saw a versatile tool for both professional workshops and hobbyists alike.

Essential Features of a Band Saw

When considering the key elements of a cutting tool designed for precision, several characteristics stand out. These attributes enhance the functionality, usability, and overall effectiveness of the machine, making it an indispensable asset for woodworking and metalworking enthusiasts alike.

Power and Speed Control

One of the most critical aspects is the machine’s motor strength and its ability to adjust speed settings. A robust motor ensures consistent performance, while variable speed control allows users to tailor the tool’s operation to different materials and cutting tasks. This versatility is vital for achieving clean, accurate cuts.

Blade and Table Features

The quality of the cutting edge and the design of the work surface significantly impact the user experience. High-quality blades made from durable materials can withstand prolonged use and deliver superior results. Additionally, a spacious and adjustable work surface facilitates handling larger pieces, improving both safety and efficiency during operation.

Blade Mechanism and Adjustments

The functionality of a cutting tool largely hinges on the design and operation of its blade mechanism. Proper adjustments ensure optimal performance, precision, and longevity of the tool. Understanding how to fine-tune these components can significantly enhance the cutting experience.

Understanding the Blade Mechanism

The blade mechanism comprises several essential elements that work in harmony. Key components include:

- Blade: The primary cutting element.

- Tensioning system: Maintains the appropriate tightness of the blade.

- Guide rollers: Keep the blade aligned during operation.

- Tracking adjustment: Ensures the blade moves smoothly along its path.

Adjustments for Optimal Performance

To achieve the best results, it’s crucial to perform regular adjustments. Consider the following steps:

- Blade Tension: Adjust the tension using the built-in mechanism. Proper tension prevents blade slippage and breakage.

- Tracking Adjustment: Align the blade with the wheels to ensure it runs true. This prevents wear and prolongs blade life.

- Guide Roller Alignment: Set the guide rollers close to the blade to minimize deflection and improve cutting accuracy.

- Blade Replacement: Regularly check for wear and replace the blade when necessary to maintain cutting efficiency.

Regular maintenance and fine-tuning of the blade mechanism will lead to a more effective and reliable cutting process, ensuring projects are completed with precision and ease.

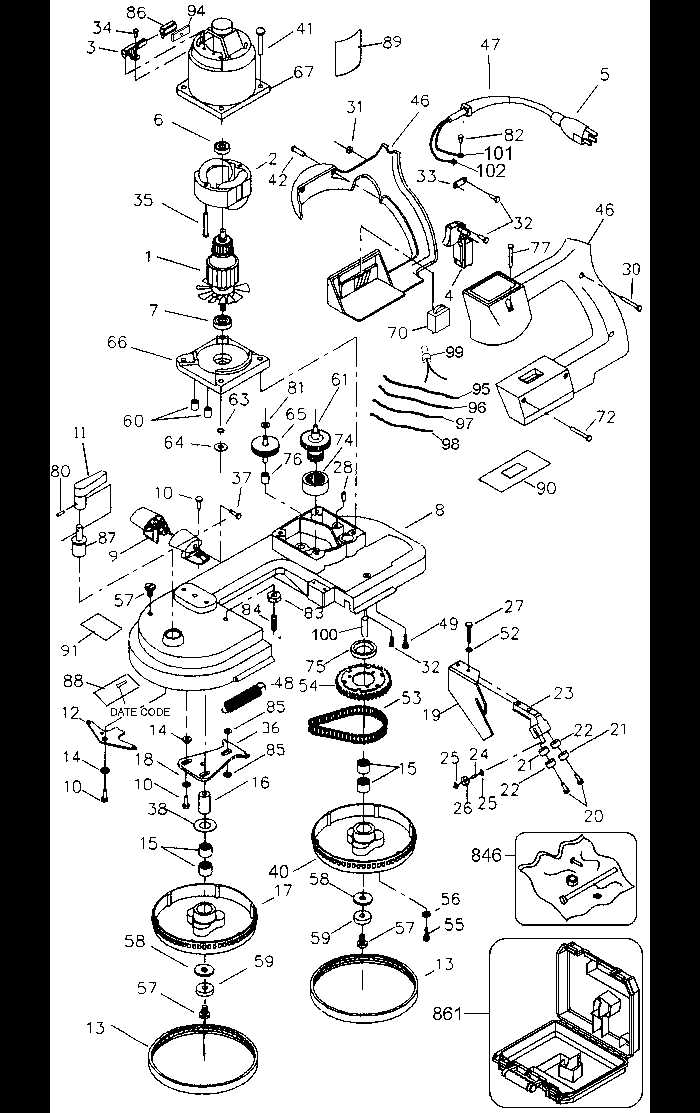

How the Motor Drives the Saw

The motor serves as the heart of the cutting tool, transforming electrical energy into mechanical power. This energy conversion initiates a series of actions that enable precise cutting. Understanding this mechanism is essential for optimizing performance and maintenance.

Energy Conversion Process

The initial step involves the motor generating rotational force, which is transferred through a series of pulleys and belts. This setup ensures that the motion is both efficient and effective, allowing for smooth operation. Torque produced by the motor is crucial for sustaining consistent speed, thereby enhancing the overall cutting experience.

Importance of Maintenance

Regular upkeep of the motor and its components is vital to ensure longevity and functionality. Neglecting maintenance can lead to inefficiencies and potential failures. Keeping the motor clean and well-lubricated not only prolongs its life but also ensures optimal performance during use.

Guide System for Accurate Cuts

A reliable guide system is essential for achieving precise results in any cutting project. Proper alignment and support can significantly enhance the quality of cuts, ensuring that materials are processed efficiently and accurately. Understanding the components and their functions can lead to improved performance and longevity of your equipment.

Key Components of a Guide System

- Vertical Support: This feature helps maintain stability, allowing the user to keep the material in the desired position throughout the cutting process.

- Adjustable Guides: These allow for customization based on material thickness and type, ensuring that the blade remains aligned and reduces the risk of drift.

- Fencing System: A reliable fence provides a straight edge for making accurate cuts, essential for repeatability and consistency.

Tips for Optimal Use

- Regularly check the alignment of the guides to maintain accuracy.

- Use the appropriate settings based on the material you are cutting.

- Keep the equipment clean and free of debris to prevent interference during operation.

By understanding and utilizing an effective guide system, users can greatly improve their cutting precision, resulting in cleaner edges and more professional outcomes in their projects.

Tensioning the Blade for Efficiency

Properly adjusting the tension of the cutting edge is crucial for optimal performance. A well-tensioned blade enhances precision and extends the lifespan of the tool, reducing the risk of damage and improving overall functionality.

To achieve the ideal tension, follow these guidelines:

| Step | Description |

|---|---|

| 1 | Ensure the tool is powered off and unplugged before making any adjustments. |

| 2 | Locate the tension adjustment mechanism, usually found at the top of the unit. |

| 3 | Loosen the existing tension if necessary, and gently insert a new blade if applicable. |

| 4 | Gradually tighten the mechanism until you reach the recommended tension level. |

| 5 | Check for proper alignment and adjust if necessary to prevent binding. |

Regularly monitoring and adjusting the tension will ultimately lead to enhanced cutting efficiency and better results in your projects.

Exploring the Table and Fence Setup

Setting up the workspace effectively is crucial for achieving precision in woodworking projects. The arrangement of the surface and the guide plays a vital role in ensuring straight and accurate cuts, which can significantly enhance the quality of the finished product.

Understanding the Surface Configuration

The surface serves as the primary platform for material placement. A stable and level base is essential to prevent movement during operation. Regular maintenance and proper alignment can optimize performance and accuracy.

Importance of the Guide System

The guide system allows for enhanced control during cutting. Adjusting the guide to the desired angle and distance from the blade can facilitate cleaner and more efficient cuts. It is advisable to check the alignment regularly to maintain optimal functionality.

| Component | Description |

|---|---|

| Surface | Flat area for material placement |

| Guide | Adjustable system for cut precision |

| Clamp | Holds the material securely |

Maintaining the Bearings and Wheels

Regular upkeep of the rotating components is essential for optimal performance and longevity of your equipment. Proper maintenance minimizes wear and ensures smooth operation, preventing costly repairs and replacements down the line.

Importance of Regular Inspection

Periodic checks of the wheels and bearings are crucial. Here are key reasons to stay vigilant:

- Identifies wear and tear early.

- Ensures alignment and balance.

- Prevents overheating and friction issues.

Maintenance Steps

Follow these steps to maintain the wheels and bearings effectively:

- Clean the Components: Use a soft brush and cloth to remove debris and dust.

- Check for Damage: Inspect for cracks or chips in the wheels and bearings.

- Lubricate Bearings: Apply appropriate lubricant to reduce friction.

- Ensure Proper Tension: Adjust wheel tension to the manufacturer’s specifications.

- Monitor Performance: Listen for unusual noises during operation as they may indicate a problem.

By adhering to these maintenance practices, you will enhance the efficiency and lifespan of your equipment, ensuring it operates smoothly and reliably.

Troubleshooting Common Issues in the Saw

Every tool can encounter challenges during operation, leading to frustration and decreased performance. Understanding typical problems and their solutions can enhance efficiency and extend the life of your equipment. Below are some common concerns you might face and how to address them effectively.

Unstable Cutting Performance: If you notice inconsistent cuts or wavering lines, check the alignment of the blade. Ensure that it is properly tensioned and seated in the guides. Additionally, inspect the workpiece for any obstructions that may be causing resistance.

Excessive Vibration: Vibration can stem from several sources, such as an imbalanced blade or loose components. Tighten all bolts and screws, and verify that the blade is correctly installed. If the issue persists, consider replacing the blade with a new one to ensure stability.

Overheating: When the tool becomes too hot, it may indicate inadequate lubrication or a dull blade. Regularly lubricate moving parts and replace blades that show signs of wear. This will not only maintain optimal performance but also prevent potential damage to the machine.

Increased Noise Levels: Unusual sounds can signal a problem. Inspect for debris lodged in the mechanism and clear any obstructions. If noise continues, examine bearings and other moving parts for wear and replace them as necessary to restore quiet operation.

By addressing these common issues promptly, you can ensure your equipment operates smoothly and efficiently, helping you achieve precise results in your projects.