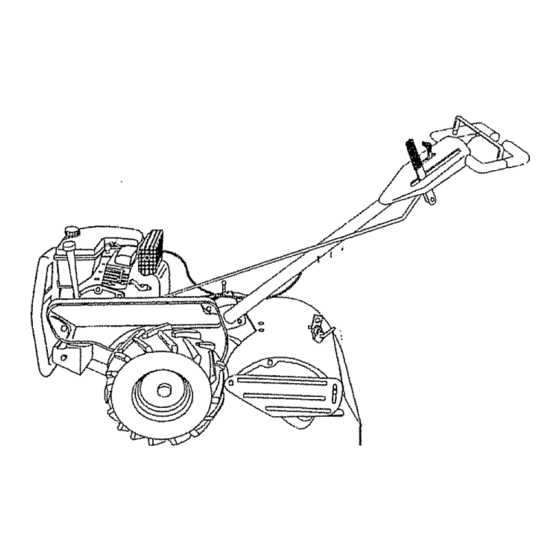

The successful operation of a garden cultivation tool relies heavily on the understanding of its various elements. Familiarity with each component ensures not only efficient use but also the ability to diagnose issues when they arise. Whether you are a seasoned gardener or a novice, having a clear mental image of the tool’s assembly can enhance your gardening experience.

Visual aids play a crucial role in comprehending the intricate relationships between the individual elements. By examining an organized layout of the different sections, users can easily identify where each piece fits within the larger mechanism. This knowledge empowers you to perform maintenance, troubleshoot problems, and even undertake upgrades to improve functionality.

Moreover, grasping the purpose of each component can lead to better decision-making when it comes to repairs or replacements. Understanding the nuances of your equipment not only extends its lifespan but also maximizes its performance, making every gardening endeavor more rewarding.

Understanding Craftsman Tiller Components

When it comes to the effective operation of soil cultivation equipment, a solid grasp of its individual elements is essential. Each component plays a crucial role in the overall functionality, contributing to efficiency and performance during gardening tasks. Recognizing how these pieces work together can enhance maintenance and improve the longevity of your equipment.

Key Elements of Soil Cultivation Machinery

Central to the operation are the drivetrain components, which facilitate movement and power transmission. This includes gears, belts, and engines that ensure the device operates smoothly. Equally important are the tilling implements, which directly interact with the soil. Their design and durability influence how effectively they can break up hard ground and prepare it for planting.

Maintenance and Care

Understanding these essential elements allows users to perform better upkeep. Regular inspections of the drive system and tilling accessories can prevent breakdowns and costly repairs. Familiarizing oneself with the various parts enables timely replacements and adjustments, ensuring that the machinery remains in optimal working condition.

Importance of Tiller Parts Diagram

Understanding the components of agricultural equipment is crucial for effective maintenance and repair. A visual representation that outlines the various elements involved not only enhances comprehension but also streamlines the troubleshooting process. This clarity aids users in identifying issues promptly and performing necessary adjustments efficiently.

Efficiency in Repairs: When users have access to a clear layout of the machinery, they can quickly locate specific sections that require attention. This reduces the time spent searching for problems and accelerates the repair process, leading to increased productivity in agricultural tasks.

Enhanced Learning: For those new to machinery, a visual guide serves as an educational tool, fostering a deeper understanding of how different components interact. This knowledge not only empowers users to perform basic repairs but also builds confidence in managing equipment independently.

Safety Considerations: Familiarity with the machinery’s structure promotes safer operation. Users who can easily identify components are better equipped to follow safety protocols and avoid accidents during maintenance or operation.

In summary, a well-structured visual representation of equipment components plays a vital role in promoting efficient repairs, enhancing learning, and ensuring safe operation. This tool is indispensable for both novice and experienced users alike.

Common Components of Craftsman Tillers

Understanding the essential elements of garden cultivation machines is crucial for effective maintenance and operation. These devices are designed to aid in soil preparation, making gardening tasks more efficient. Familiarity with their core components can help users troubleshoot issues and perform necessary repairs.

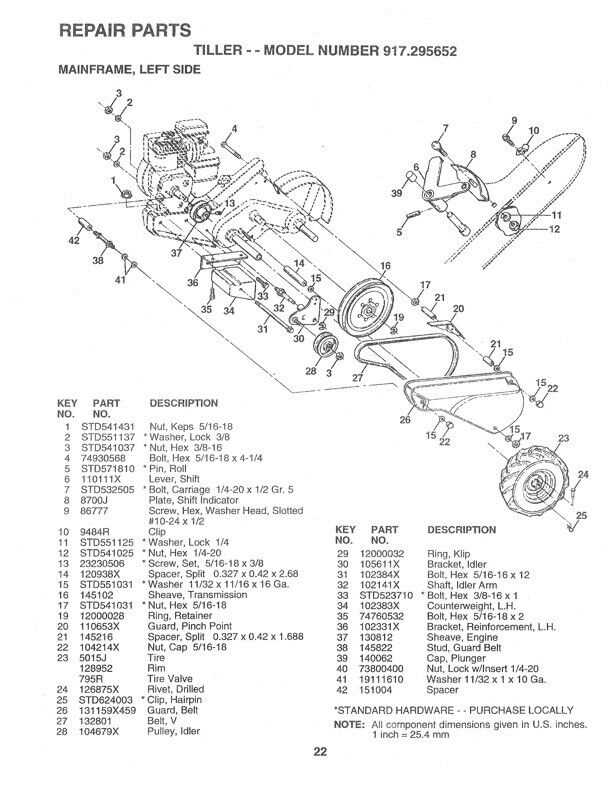

Main Elements

- Engine: The powerhouse that drives the machine, providing the necessary torque and speed.

- Handlebars: The part that allows for steering and control, often adjustable for user comfort.

- Rotors: Blades that break up the soil, critical for aeration and preparation.

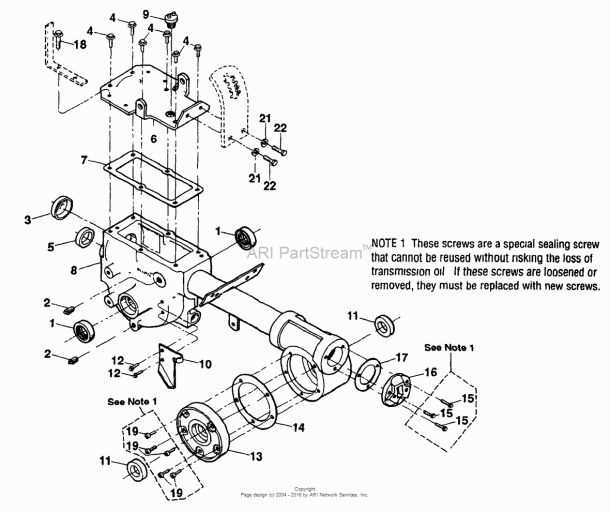

- Transmission: Transfers power from the engine to the wheels or rotors, affecting speed and maneuverability.

- Wheels: Provide mobility, with some models featuring larger wheels for easier navigation over rough terrain.

Additional Components

- Gearbox: Houses gears that control the operation of various parts.

- Fuel Tank: Stores the necessary fuel for the engine, typically designed for easy access and refilling.

- Clutch: Engages and disengages the rotors, allowing for easier operation and control.

- Chassis: The framework that supports the entire structure, ensuring durability and stability.

How to Read a Parts Diagram

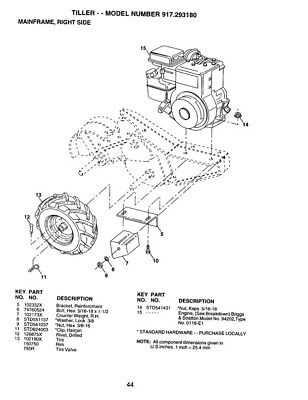

Understanding a component schematic is essential for anyone working with mechanical devices. These illustrations provide a visual breakdown of the system’s construction, helping identify individual elements and their assembly sequence. By studying the layout, you can easily locate specific elements, recognize their function, and determine the correct way to replace or repair them.

| Step | Description | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Identify the main sections. Look for labeled areas that divide the system into manageable parts. | |||||||||

| 2 | Locate each individual element by following the numbering or labeling system in the illustration. | |||||||||

| 3 | Note the positioning of each component relative to others, paying attention to their con

Identifying Replacement Parts EasilyWhen maintaining equipment, finding the correct components for replacement is essential for ensuring smooth operation and longevity. The process of identifying necessary items can be streamlined with a basic understanding of the machine’s structure and knowing where to look for essential details. Recognizing the key areas where parts commonly wear out can save time and effort when sourcing replacements. Understanding Equipment AnatomyEach machine is made up of various sections, each with specific elements that may require attention over time. Learning the layout and functions of these sections allows for quicker identification of potential problem areas. This approach helps you stay proactive with maintenance, reducing downtime. Utilizing Model Numbers and LabelsMaintenance Tips for Tiller PartsProper upkeep of equipment components is essential to ensure longevity and smooth operation. Regular care helps prevent breakdowns, reduces wear, and enhances overall performance. By following specific steps and inspecting key areas, you can avoid costly repairs and ensure that your machine operates at its best. Inspecting moving mechanisms is crucial. Regularly check for debris or dirt buildup, which can hinder motion and cause unnecessary strain. Clean these areas thoroughly, and apply lubrication where needed to minimize friction. Another important step is to check fasteners and connections. Over time, bolts, nuts, and other connections may loosen due to vibrations and usage. Tightening them periodically will prevent malfunction and ensure stable performance. Lastly, monitor the condition of worn components. Replace any that show signs of damage or excessive use. This will not only enhance efficiency but also prevent further wear on surrounding parts, saving you from more extensive repairs in the future. Where to Find Quality Replacement Parts

When it’s time to replace essential components of your equipment, finding reliable and durable alternatives is crucial for maintaining its performance. There are several options available to help ensure you get the best quality without compromising the integrity of your machinery.

|