When it comes to maintaining outdoor equipment, understanding the layout and connections of individual elements is essential for smooth operation. Whether you’re dealing with routine upkeep or troubleshooting issues, having a clear picture of how everything is organized can make the process much more efficient.

Identifying critical elements in a machine setup can prevent unexpected breakdowns and ensure that everything runs optimally. By familiarizing yourself with how these items interact, you gain better insight into the machinery’s overall function, allowing you to address concerns swiftly.

Additionally, knowing where each element is positioned within the system helps streamline any maintenance or repair tasks. This knowledge can save time and reduce the likelihood of errors when replacing or inspecting specific areas.

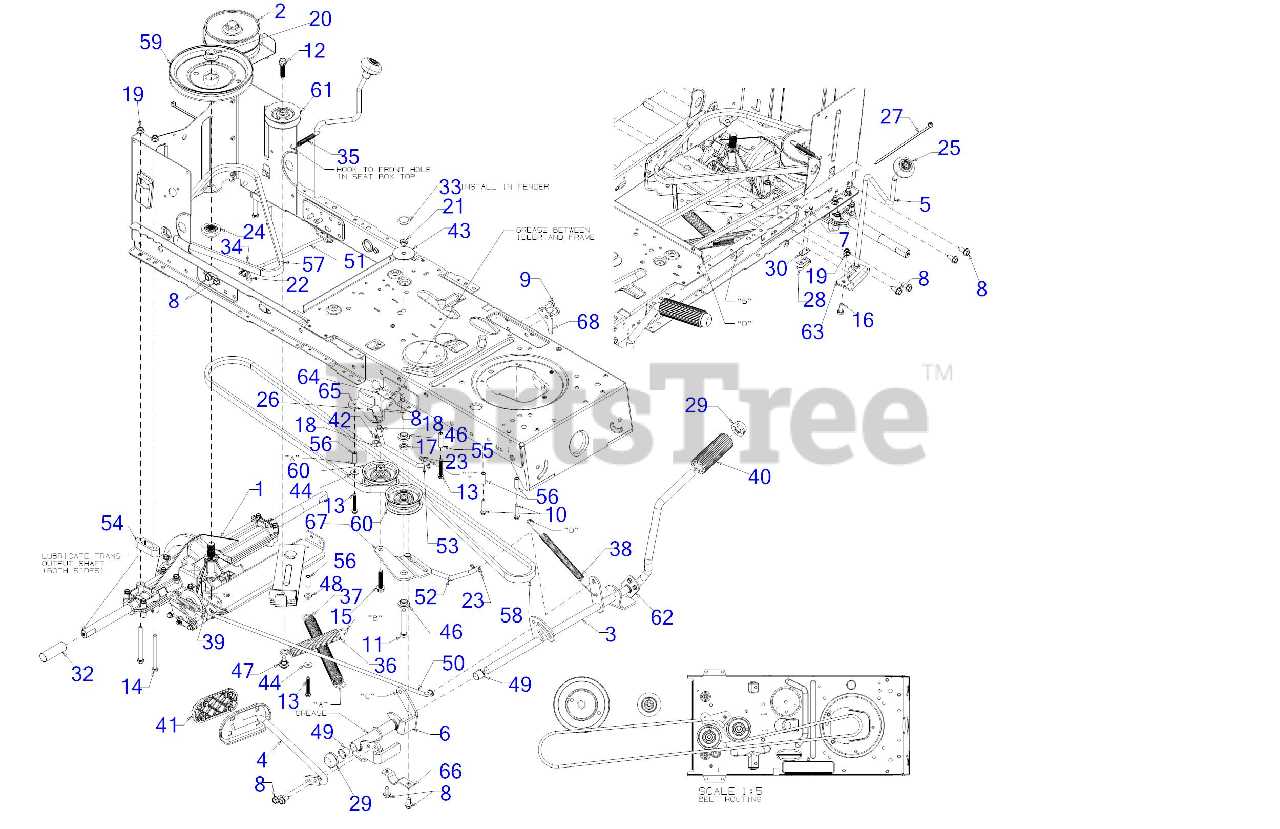

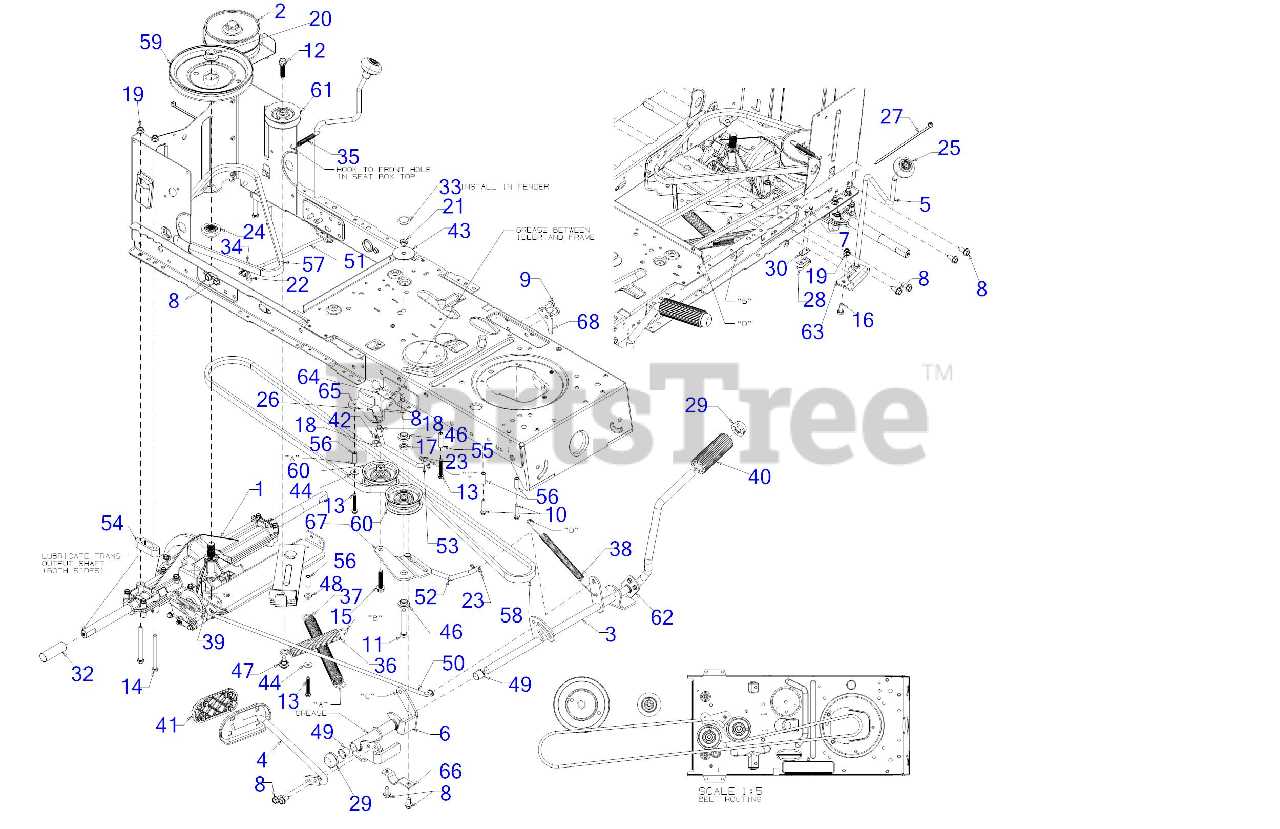

Understanding the Key Components of the T3000

When exploring the essential elements of any modern lawn equipment, it is crucial to grasp the importance of each system working in harmony. These elements are designed to ensure the device performs optimally, providing efficiency and reliability. The arrangement and interaction of the various mechanical and electrical components make it possible for the machine to handle a wide range of tasks seamlessly.

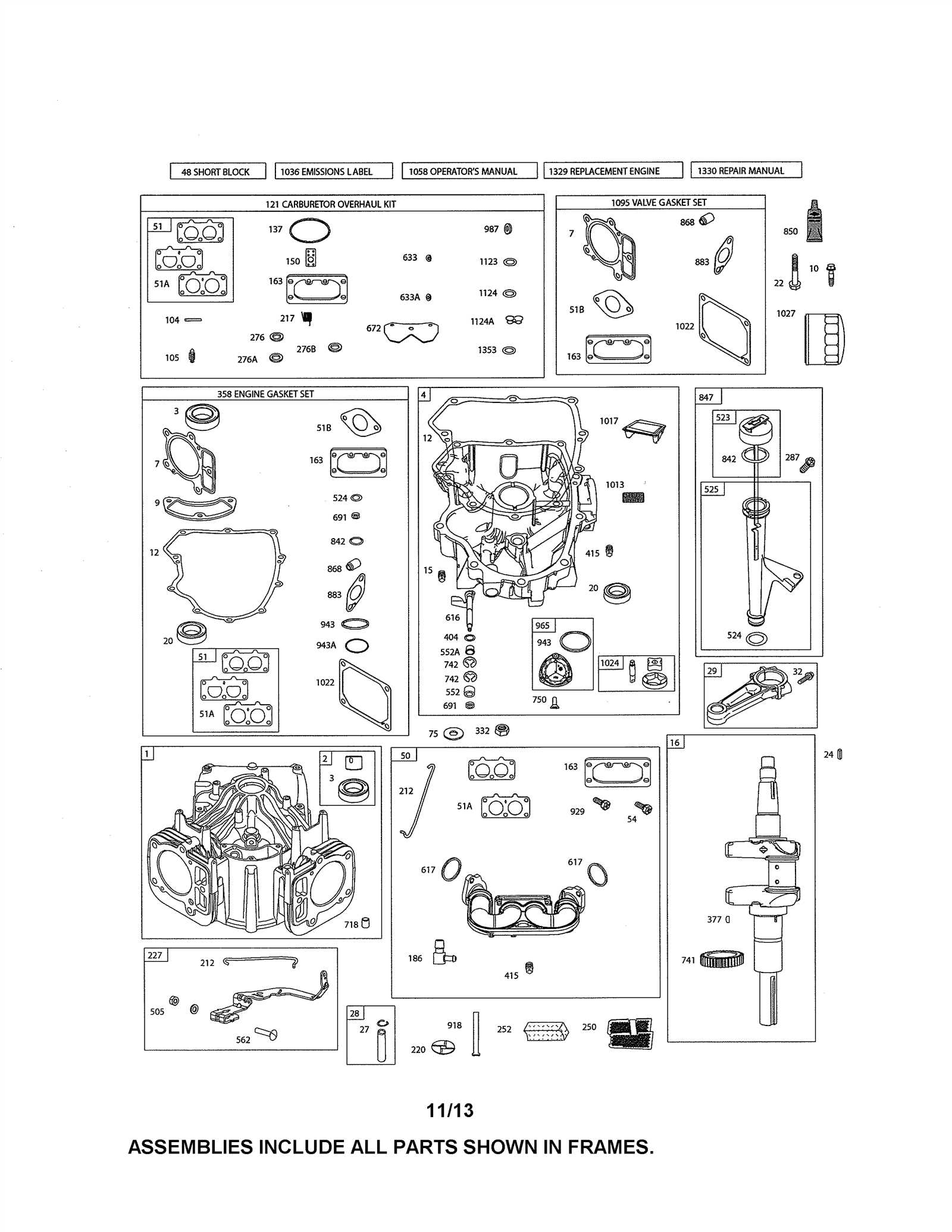

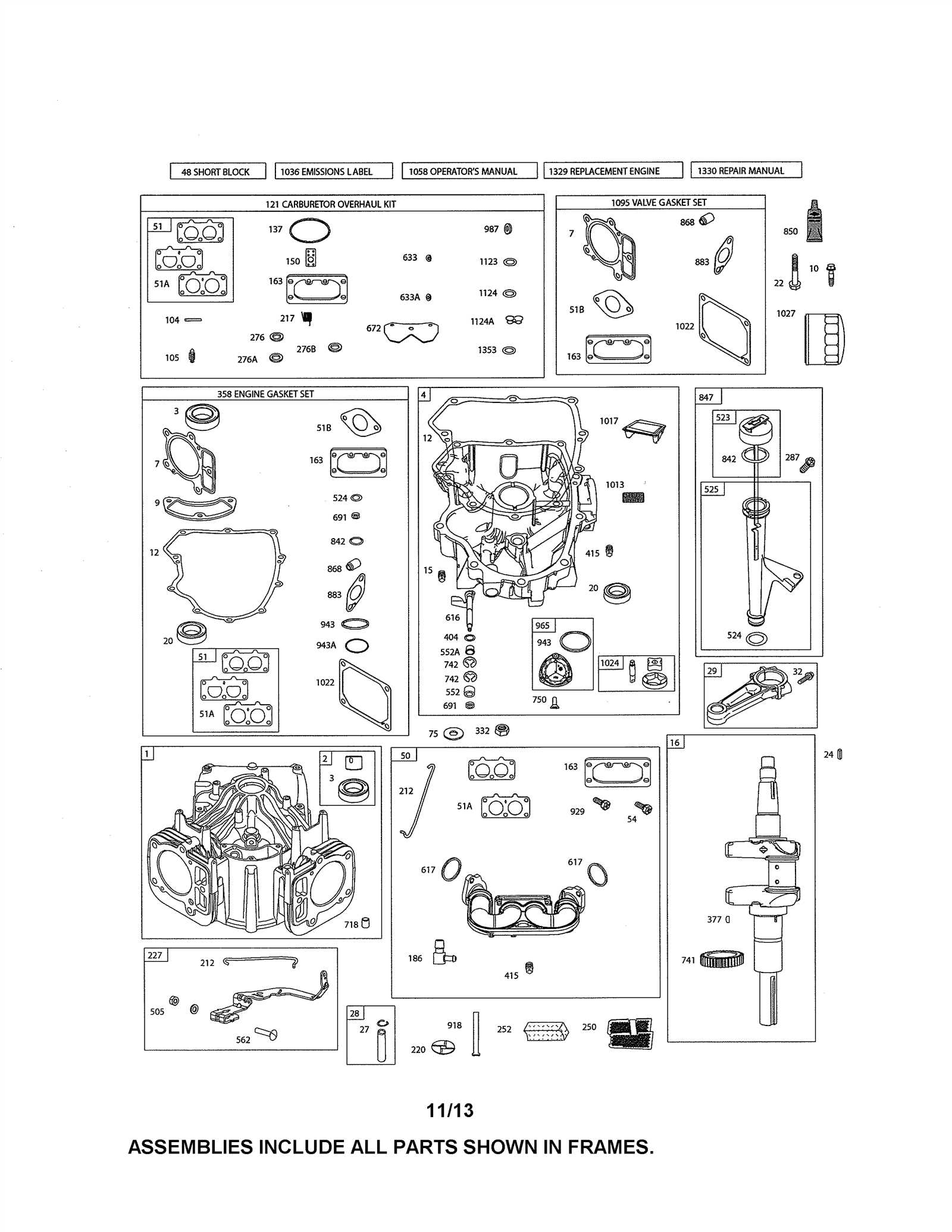

Engine System

The engine serves as the heart of the machine, delivering the power needed to drive the entire operation. A well-maintained engine ensures smooth performance, allowing other systems to function without strain. Regular upkeep, including oil changes and air filter replacements, can prolong its life and enhance efficiency.

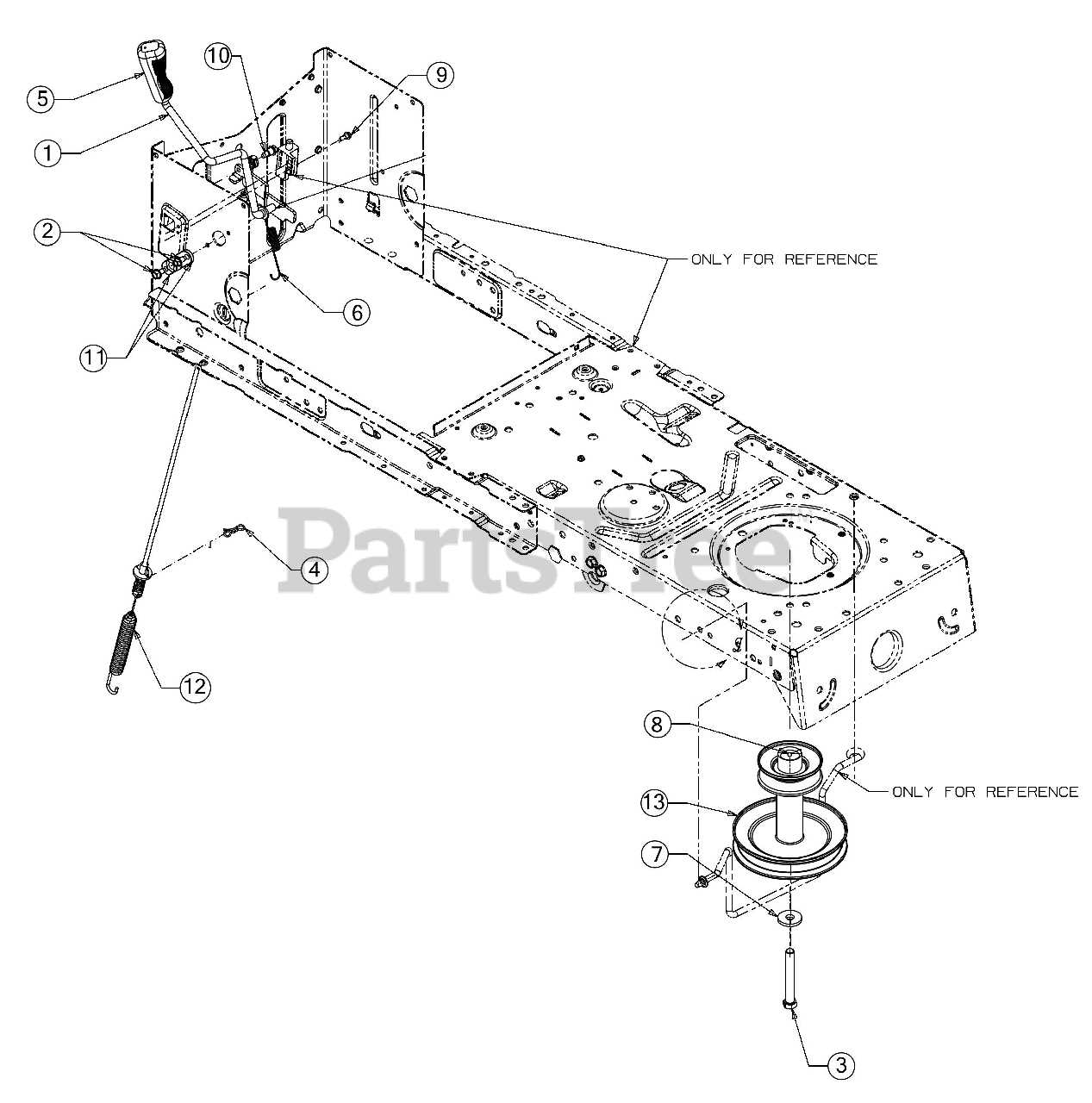

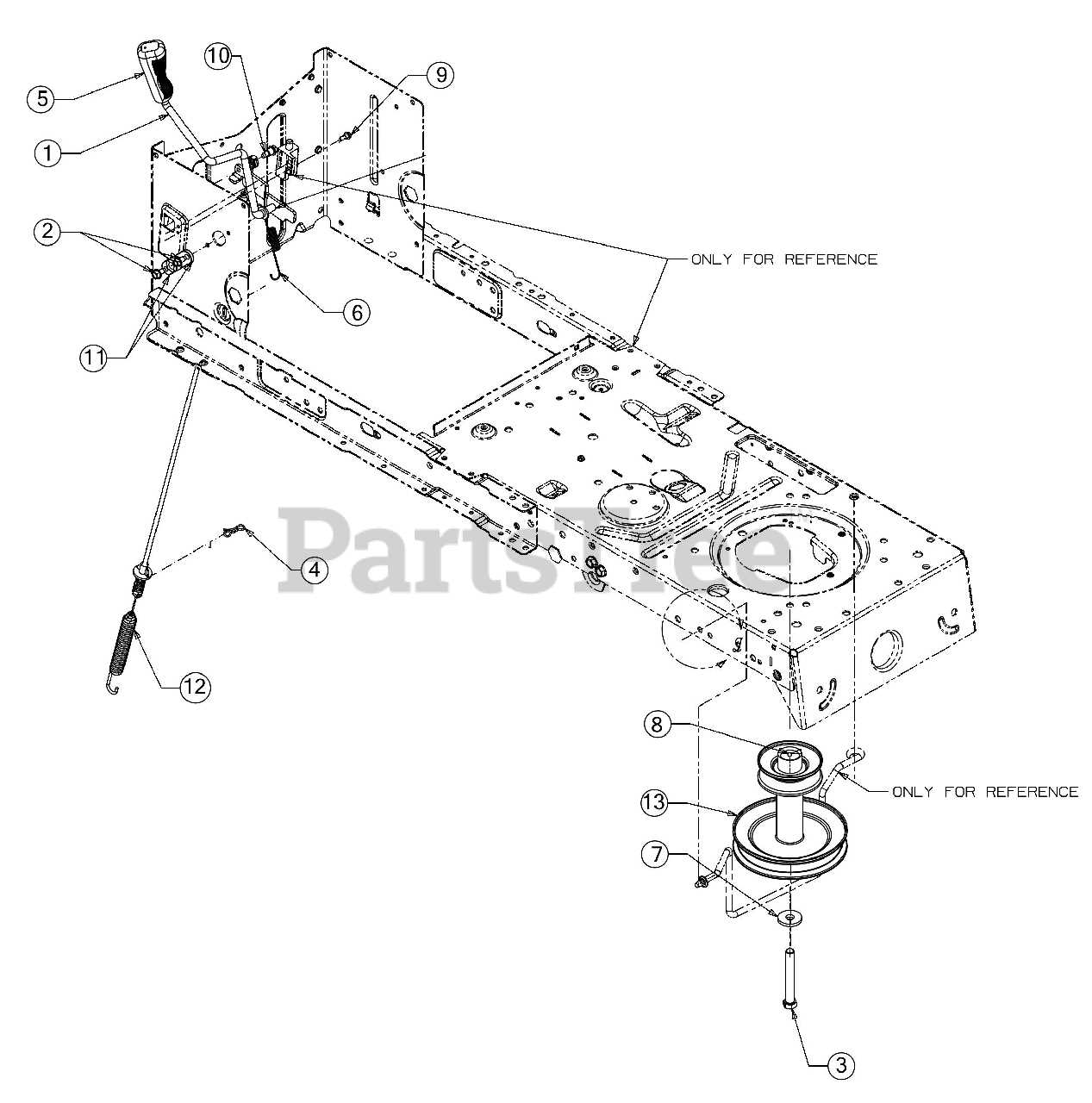

Drive Mechanism

The drive system is responsible for converting the engine’s power into motion. Through a combination of belts, gears, and axles, this mechanism allows the machine to move with precision and control. Proper adjustment and lubrication of these components are essential for maintaining optimal traction and maneuverability, especially on uneven surfaces.

Engine and Drive System Overview

The motor and propulsion mechanism form the essential foundation of any riding machine. These components work in unison to deliver smooth power transfer, ensuring reliable movement and efficient performance. The core of this setup lies in the careful balance between energy generation and the transmission of that energy to the wheels, providing seamless operation in various conditions.

Engine Structure

The motor consists of key elements that convert fuel into mechanical energy. This transformation process is integral to providing the force needed for forward movement. The design focuses on efficiency and power, enabling the machine to handle different terrains and workloads.

Drive System Functionality

The drive mechanism is responsible for transferring the motor’s output to the wheels. It includes a set of gears, belts, and other components that ensure controlled movement and optimal speed. This system allows for the adjustment of speed and direction, contributing to the overall functionality of the machine.

| Component |

Function |

| Engine Block |

Houses the main mechanical components for fuel conversion |

| Transmission |

Transfers power from the engine to the wheels |

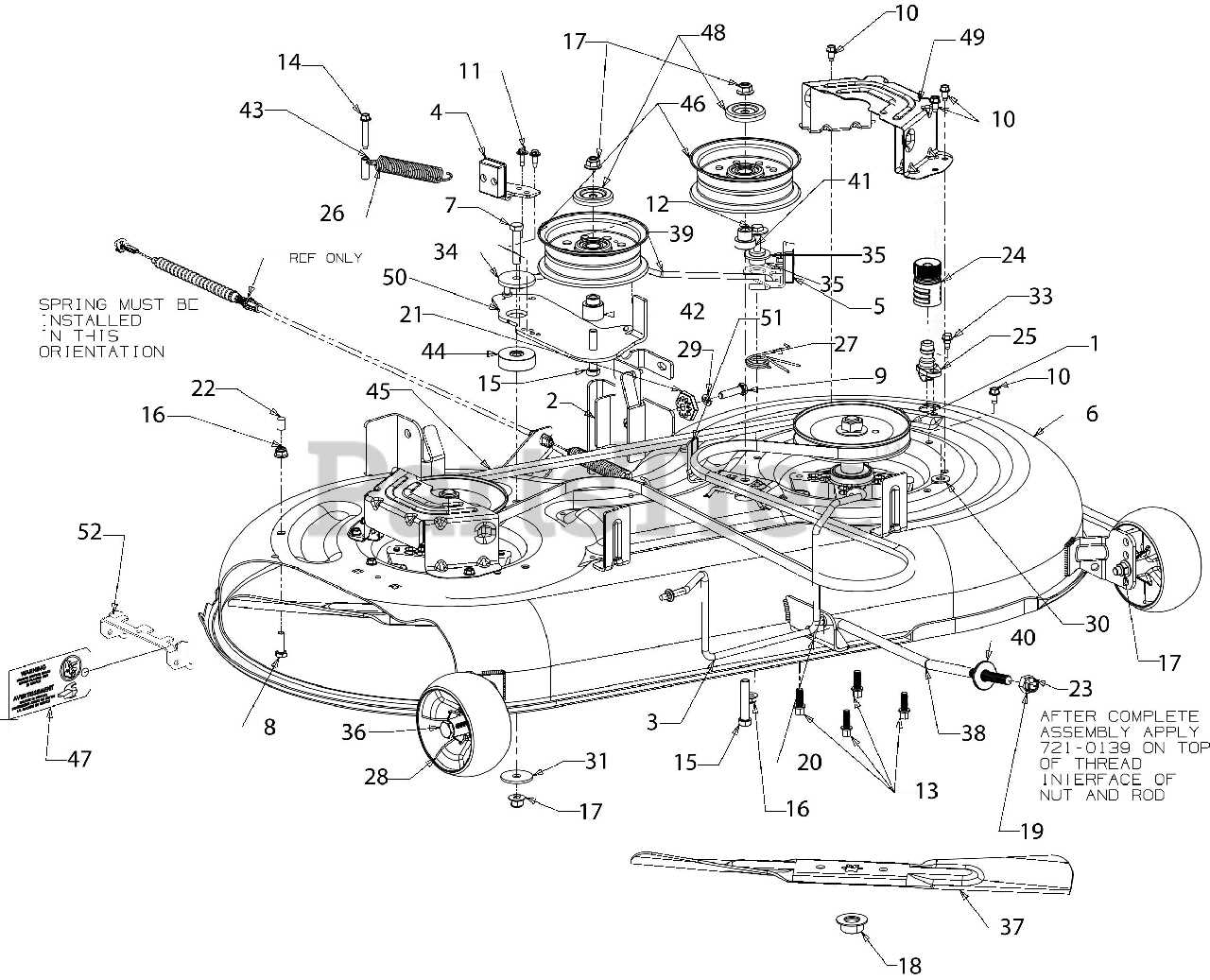

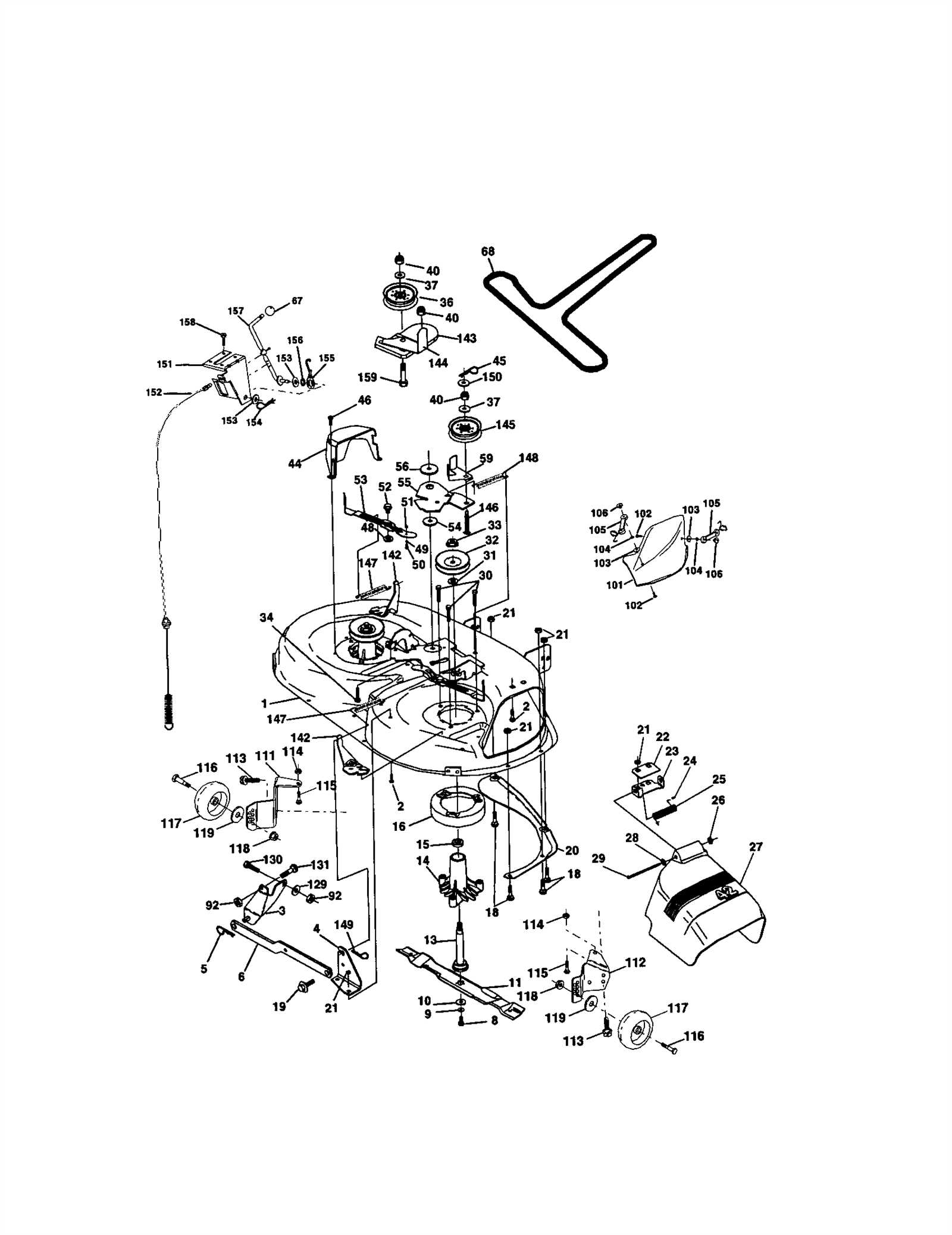

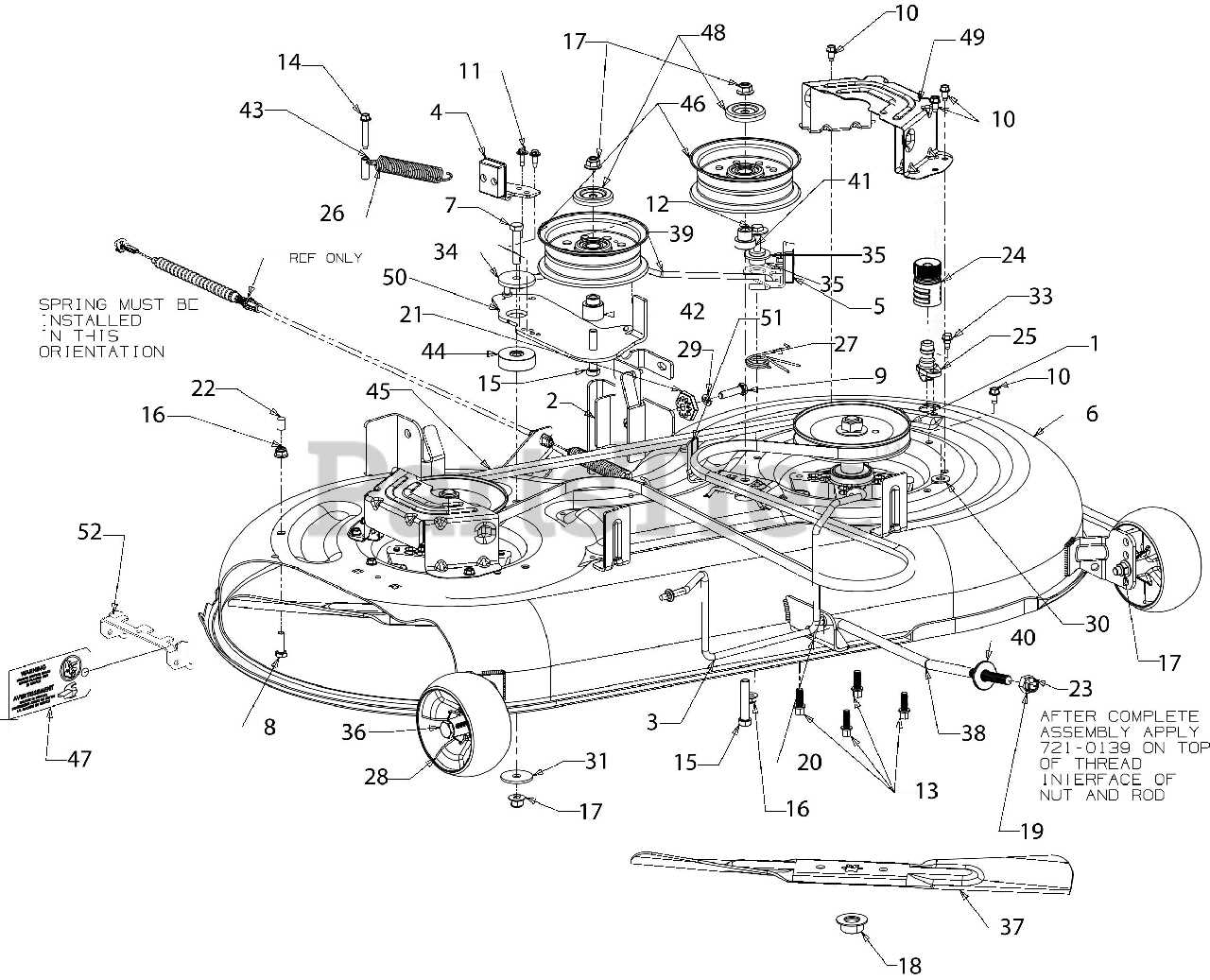

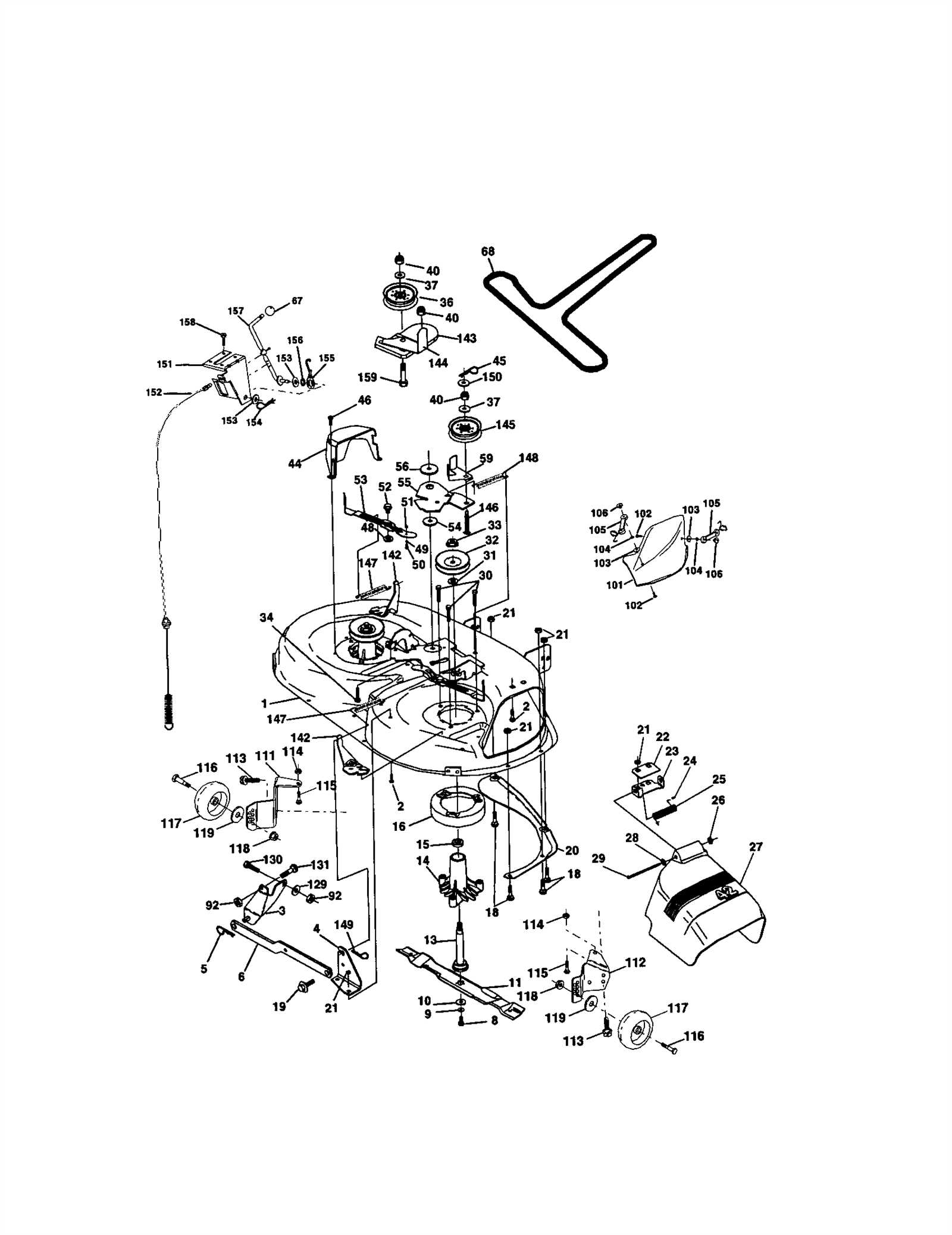

| Blade Assembly and Maintenance Guide

Ensuring optimal performance requires proper care and attention to the cutting components. Regular checks and adjustments are necessary to keep the system running efficiently and safely. Understanding how to maintain the blades will extend the life of your equipment and improve overall functionality.

Follow these simple steps for upkeep:

- Inspect the sharpness regularly to prevent dullness and uneven cuts.

- Remove debris and grass clippings after each use to avoid buildup.

- Tighten bolts and fasteners to secure the blade mechanism properly.

When replacing the blades:

- Ensure the machine is turned off and disconnect any power sources.

- Use the appropriate tools to loosen and remove the old blade.

- Install the new blade, ensuring it is aligned and balanced correctly.

- Tighten the fasteners securely, but avoid over-tightening.

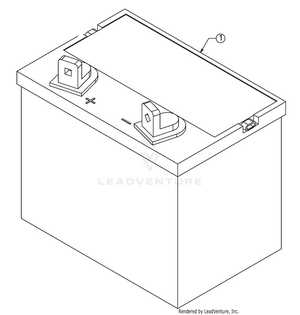

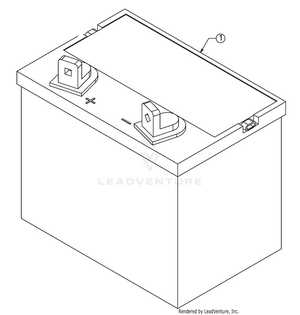

Electrical Wiring and Connections Explained

Understanding the wiring and connections is essential for ensuring that all components work in harmony. Properly organized electrical systems contribute to both functionality and safety. By following structured guidelines, one can ensure that circuits operate efficiently, minimizing the risk of malfunctions.

Main Electrical Components

Electrical systems are composed of various elements that need to be connected correctly. From power sources to control units, every part must be linked in a logical sequence. Ensuring these connections are firm and well-insulated will prevent potential issues like short circuits or overheating.

Wire Types and Functions

Different types of wires are used depending on the specific function they perform. For example, some are designed for carrying high voltage, while others handle smaller signals. It’s crucial to use the appropriate wire type to ensure both performance and safety.

| Wire Type |

Usage |

Insulation |

| Copper Wire |

General electrical connections |

High durability |

Fuel System Parts and Functions

The fuel system plays a crucial role in ensuring the smooth operation of the engine. Its components work together to manage the flow of fuel, ensuring the engine receives the right amount of energy at the right time. Understanding how each element functions is key to maintaining a well-performing machine.

- Fuel Tank: This component stores the liquid, acting as the main reservoir from which the engine draws energy.

- Fuel Line: A channel responsible for delivering the liquid from the tank to the rest of the system, ensuring a steady supply.

- Fuel Filter: Its primary task is to remove impurities, preventing debris from entering the engine and causing damage.

- Carburetor: This device mixes air with fuel, creating a fine mist that is ignited in the engine for combustion.

- Fuel Pump: An essential mechanism that moves the fuel from the tank to the carburetor, ensuring consistent pressure.

These components work in harmony, providing the engine with a precise mixture of air and fuel for efficient performance. Proper maintenance of these elements can signi

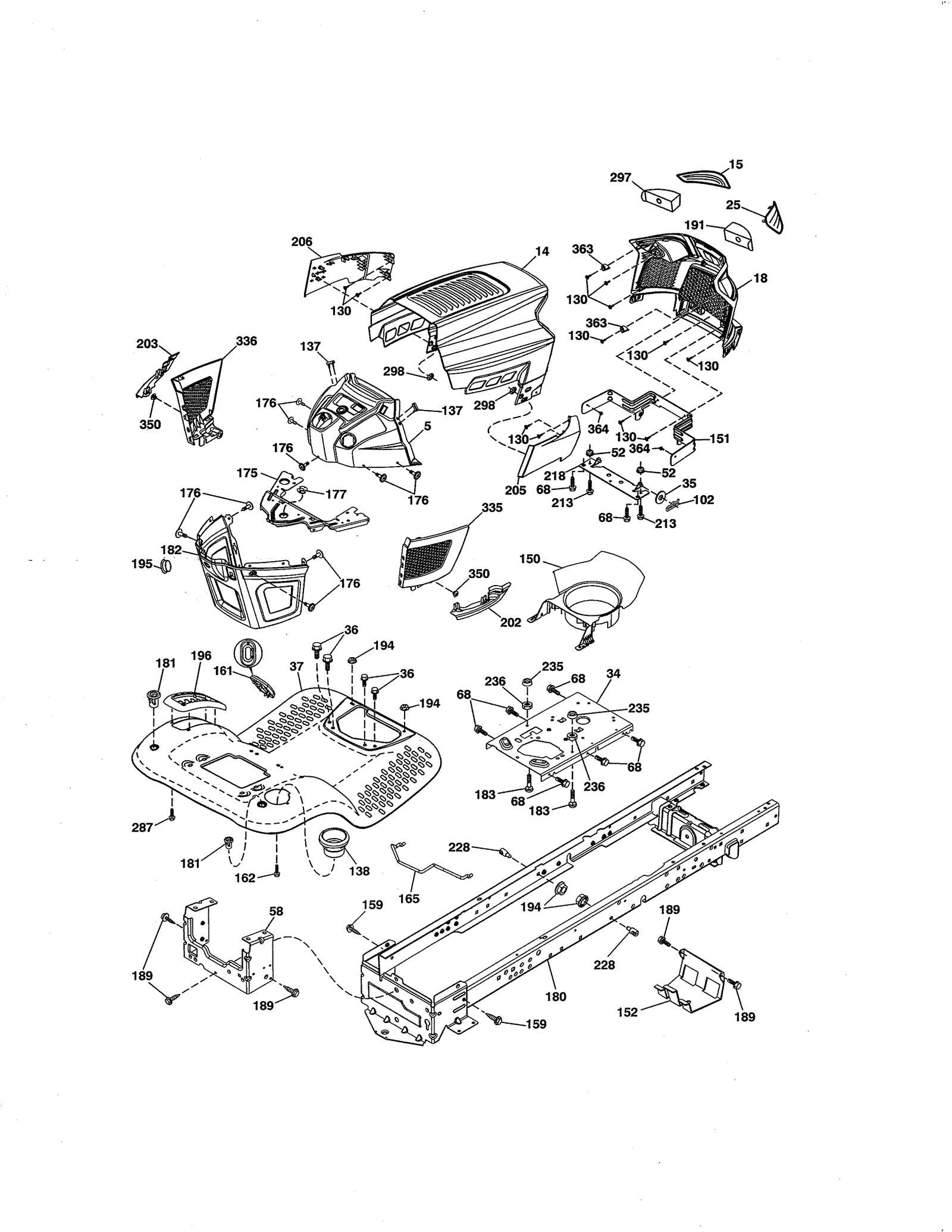

Steering Mechanism and Control Layout

The steering system plays a crucial role in ensuring smooth and precise control over the machine’s movements. By understanding its structure, users can achieve better maneuverability, enhancing overall operational efficiency. This section explores the components and the layout responsible for guiding direction and ease of handling.

Steering Wheel and Linkage System

The steering wheel is the primary interface for directing the vehicle, transmitting the user’s input to a system of linkages. These linkages are designed to convert rotational movement into the necessary adjustments, allowing the machine to turn and navigate efficiently. Proper alignment of these linkages ensures stability and predictable control.

Control Levers and Pedals

In addition to steering, control levers and pedals provide further management of the machine’s speed and direction. These elements are ergonomically positioned to enhance ease of use and reduce fatigue during

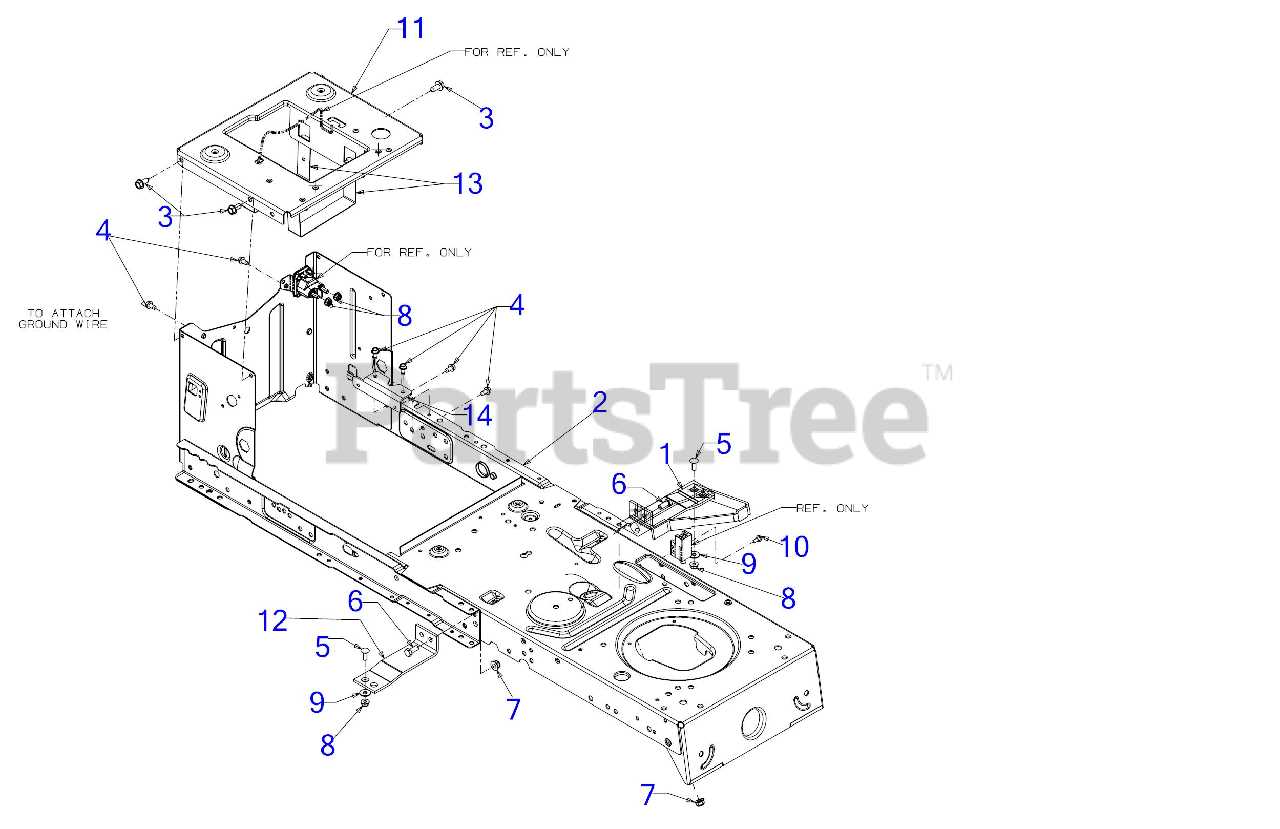

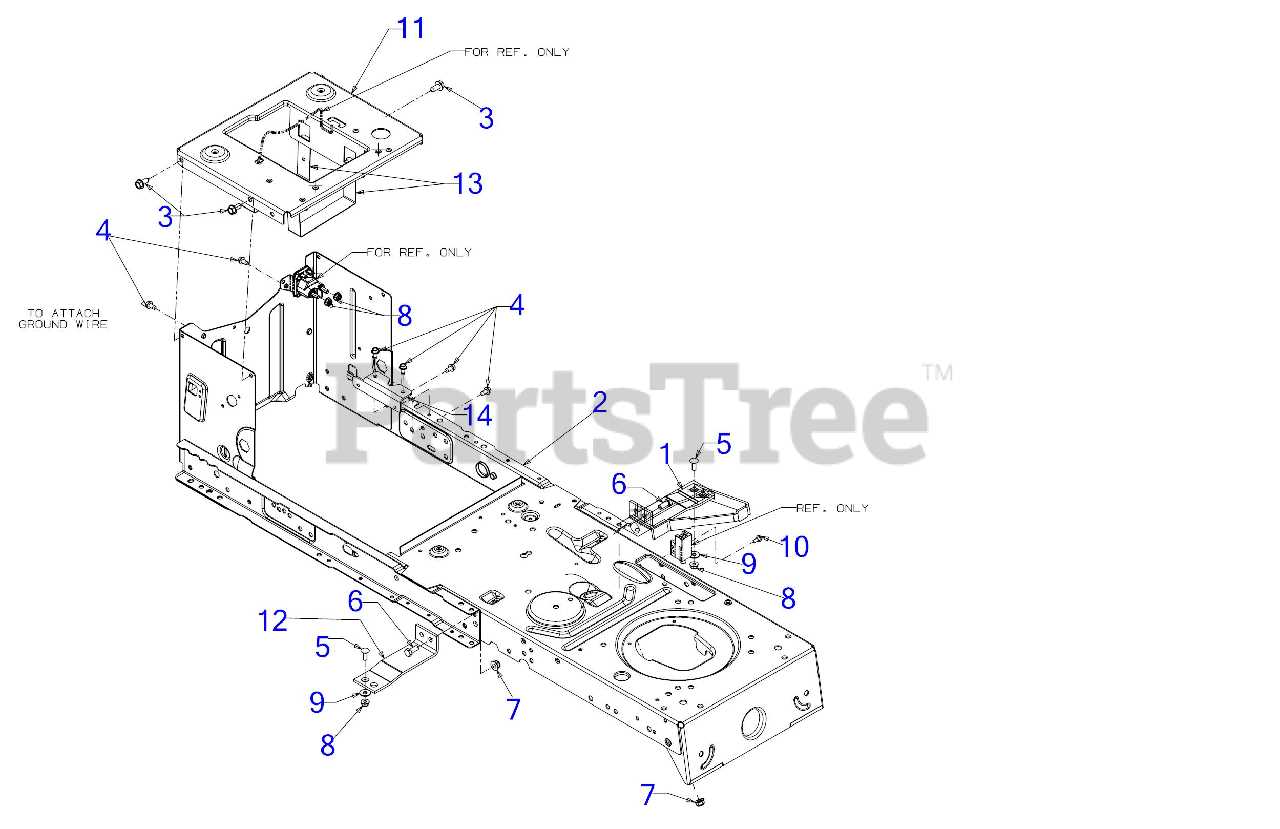

Chassis and Frame Structure Insights

The underlying structure of any machinery plays a crucial role in its overall functionality and stability. Understanding the framework that supports various components is essential for ensuring optimal performance. This section delves into the critical aspects of chassis design and its significance in maintaining structural integrity during operation.

| Component |

Description |

Function |

| Main Frame |

The primary structure that holds all components together. |

Provides support and stability to the entire assembly. |

| Crossmembers |

Horizontal supports that connect different sections of the frame. |

Enhances rigidity and distributes loads evenly. |

| Mounting Points |

Specific locations for securing various components. |

Ensures components are securely attached, preventing movement. |

| Suspension System |

System that absorbs shocks and maintains contact with the ground. |

Improves stability and comfort during operation. |

A well-designed framework not only supports weight but also absorbs vibrations and impacts, thereby extending the lifespan of the equipment. By examining the structural elements and their interrelations, users can gain insights into the design philosophy that enhances operational efficiency and reliability.

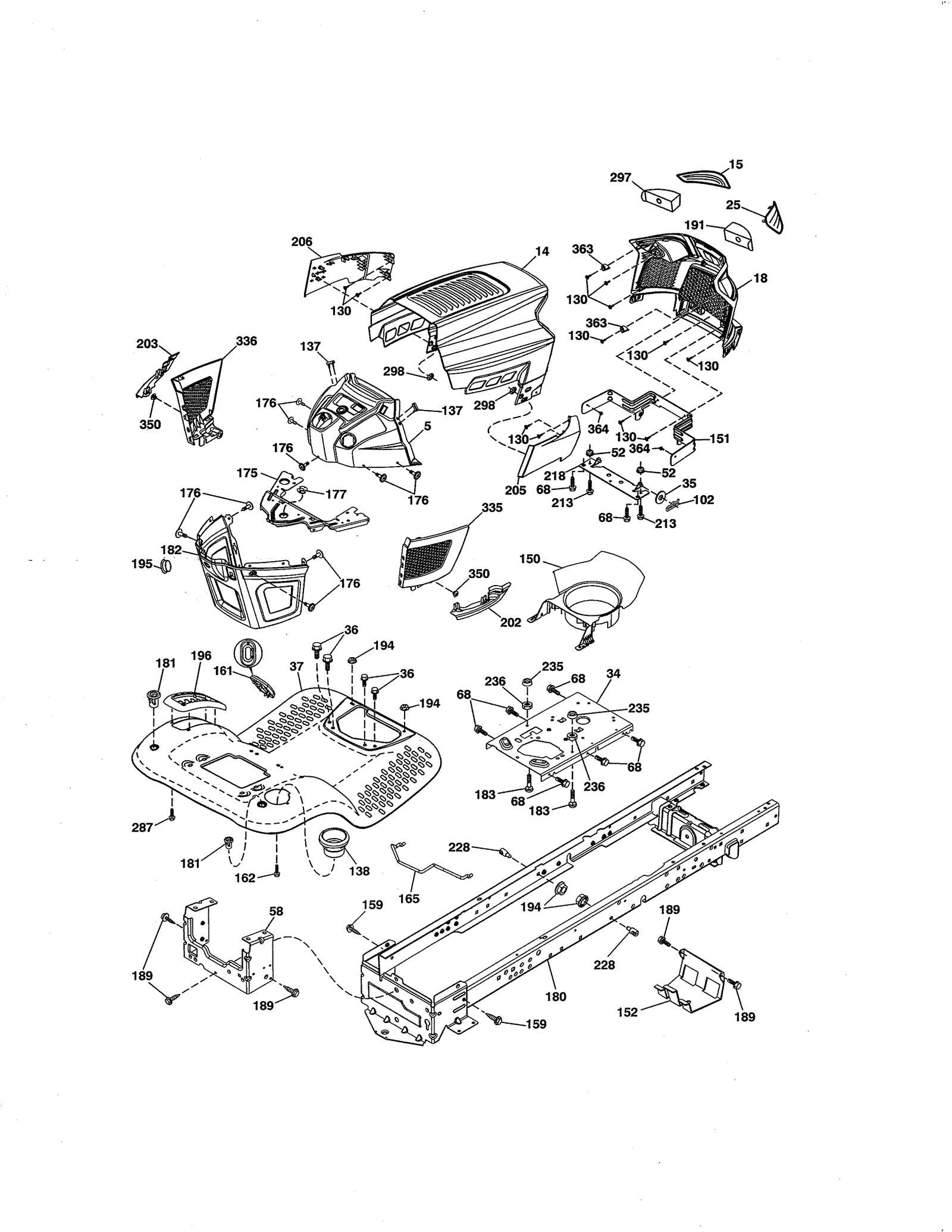

Seat and Operator Comfort Enhancements

Creating a comfortable working environment is essential for enhancing the overall experience of operators. Thoughtful design features can significantly reduce fatigue during extended use and improve productivity. This section focuses on various improvements that can be made to seating arrangements and operational ergonomics.

Advanced seating options include ergonomic designs that provide adequate lumbar support, promoting proper posture. Adjustable seating height and tilt mechanisms allow users to find their optimal position, catering to individual preferences. Furthermore, high-quality cushioning materials can enhance comfort, reducing pressure points and enhancing overall satisfaction during operation.

In addition to seating, the layout of controls and footrests plays a crucial role in operator comfort. Strategically placed controls within easy reach can minimize strain and improve efficiency. Incorporating adjustable footrests can also provide additional support, allowing operators to maintain a relaxed posture throughout their tasks. These enhancements contribute to a more enjoyable and efficient working experience.

Troubleshooting Common Part Failures

When working with machinery, identifying issues with components can significantly enhance performance and longevity. Understanding the typical malfunctions that can occur is essential for effective maintenance. This section outlines common problems and their solutions to help ensure smooth operation.

Signs of Component Malfunctions

Recognizing the signs of failure is crucial. Look for the following indicators:

- Unusual noises during operation

- Decreased efficiency or power

- Visible damage or wear on parts

- Inconsistent performance or erratic behavior

Troubleshooting Steps

To address these issues, follow these steps:

- Inspect the components for any obvious signs of wear or damage.

- Check all connections and ensure they are secure.

- Test the functionality of each part individually.

- Replace any defective components with high-quality alternatives.

Regular maintenance and prompt attention to these signs can prevent minor issues from becoming major problems.

|