When working with any complex outdoor equipment, it is essential to familiarize yourself with the internal setup. Recognizing the different elements and their arrangement ensures proper maintenance and troubleshooting. Whether you are maintaining your lawn or engaging in repairs, knowing how every element fits together can save time and effort.

Comprehending the design and layout of mechanical equipment is key to keeping it in top condition. Each segment plays a vital role, and understanding the connections between these elements helps ensure smooth operation. For those who use these machines regularly, having a solid grasp of its setup is incredibly valuable.

Additionally, paying attention to small details can prevent larger issues down the road. Understanding the core mechanisms behind the machine’s functionality aids in maintaining performance and extending its lifespan.

Understanding the LT Series Lawn Tractor Components

The lawn tractor series is built with a variety of mechanical and structural elements, each serving a specific role in ensuring efficient operation. Familiarity with the essential parts can help maintain the machine’s performance and longevity.

Engine and Transmission

The engine is the core of the machine, providing the power needed to drive the tractor and operate attachments. The transmission system transfers this power to the wheels, allowing the vehicle to move smoothly over different types of terrain. It’s crucial to keep these components well-maintained for consistent and effective performance.

Cutting System

The mowing system is designed to deliver precise grass trimming. This includes a cutting deck and sharp blades that rotate to slice through grass with ease. Regular inspections and upkeep of these components will ensure a clean, uniform cut, and prevent wear and tear over time.

Main Features of the LT1000 Model

This section highlights the key attributes of the well-known garden machine, focusing on the design and technical elements that make it effective for various tasks. The model is built to offer a balance between functionality and ease of use, ensuring optimal performance across different environments.

Engine and Performance

The engine is designed to provide reliable power, ensuring that the machine can handle both light and moderate workloads efficiently. It operates smoothly, allowing for consistent speed and control during use.

Design and Durability

The sturdy frame and well-structured components contribute to the overall durability of this model. Its compact design allows for easy maneuverability, making it suitable for navigating through tight spaces and uneven terrain.

- Powerful engine ensures consistent performance.

- Compact design for enhanced maneuverability.

- Durable frame, built to withstand regular use.

- Adjustable settings to accommodate various tasks.

Overall, this model

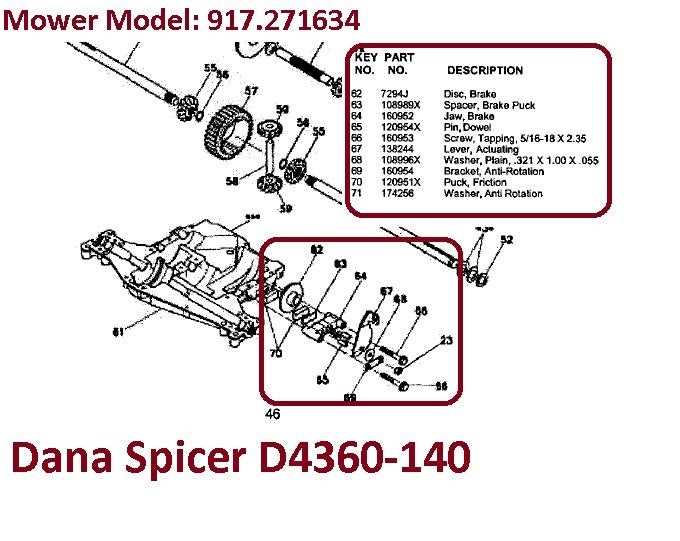

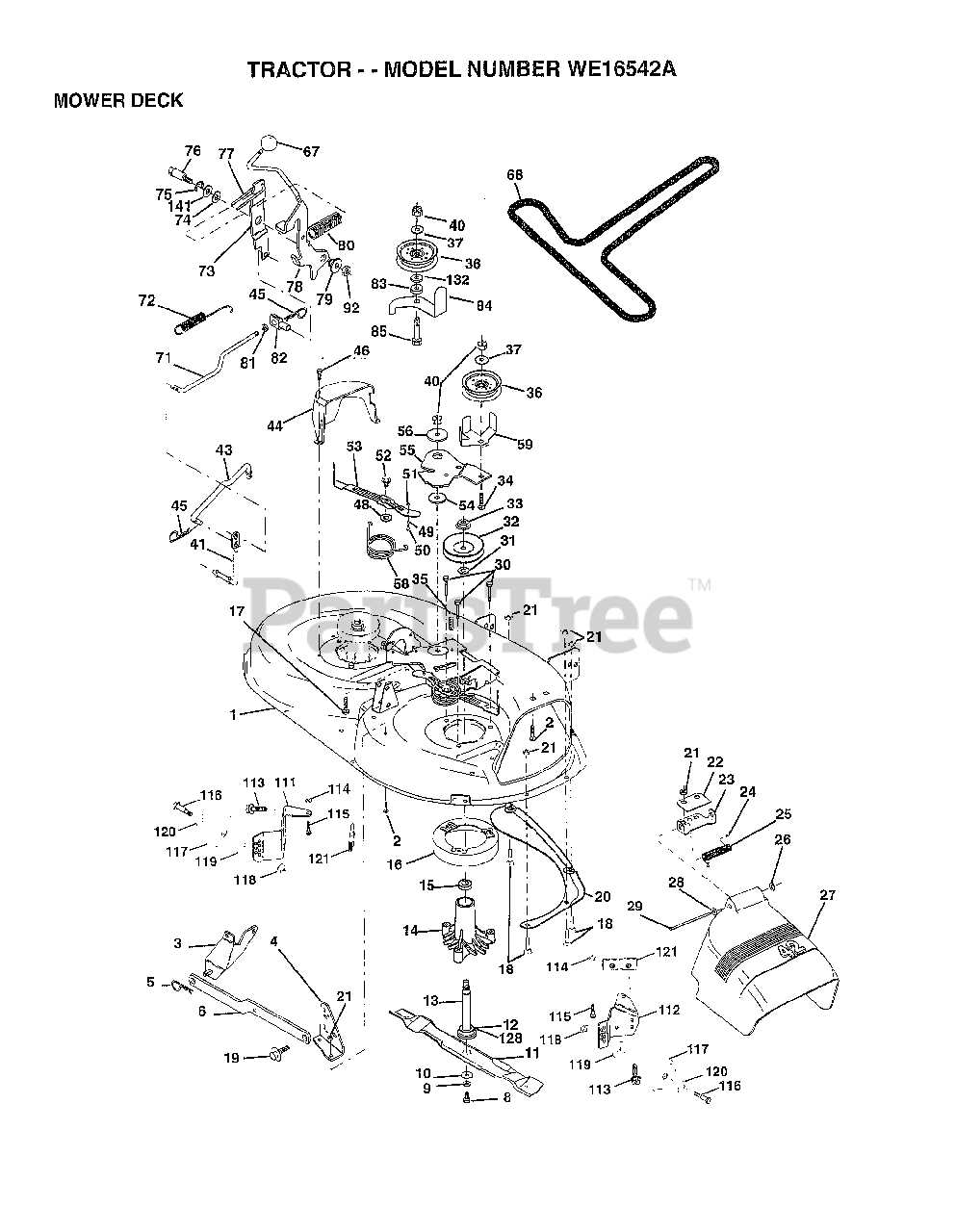

Diagram Overview of Essential Parts

The purpose of this section is to provide a clear visual representation of key components that are crucial for the functionality of various mechanical systems. Understanding the arrangement and interaction of these elements can help ensure smoother operations and maintenance.

Key Structural Components

In any mechanical system, the structural elements form the foundation that supports the entire mechanism. These components are typically designed to withstand stress and maintain the system’s integrity under different conditions.

- Frame – provides support and stability.

- Axles – ensure the movement of rotating parts.

- Fasteners – hold all elements securely in place.

Operational Mechanisms

The functional mechanisms enable the system to perform its intended tasks. These elements are interconnected and work together to achieve efficient operation.

- Drive mechanism – transfers energy to power the system.

- Control system – manages speed, direction, and precision.

- Safety components – ensure secure operation and prevent malfunctions.

Key Engine Components and Their Functions

The engine is comprised of multiple essential elements that work together to ensure smooth operation and reliable performance. Each part has a specific role that contributes to the overall function of the motor, enabling the machinery to operate efficiently and consistently.

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pistons | Responsible for transferring the energy created by combustion into mechanical power by moving up and down within the cylinders. | ||||||||

| Cylinders | Houses the pistons and is where the combustion process takes place, generating the necessary power for engine operation. | ||||||||

| Crankshaft | Converts the up-and-down motion of the pistons into rotational motion, which is then used to drive other mechanical components. | ||||||||

| Valves | Transmission and Drive Mechanism Breakdown

The transmission system and drive mechanism are critical components that ensure smooth power delivery and motion control. This section will explore the key elements that contribute to the overall function and durability of these systems, offering insights into how they work together to maintain the performance of the machine. Main Components OverviewThe drive mechanism consists of multiple interconnected parts that work in unison to transfer power from the engine to the wheels. Understanding the function of each component is essential for maintaining and repairing the system. Below is a breakdown of the main elements involved.

|