Every machine has its own intricate design, with various elements working together to ensure optimal performance. Knowing the specifics of these components can significantly enhance your ability to troubleshoot and maintain your tools effectively. This understanding can lead to a more efficient workflow and prolonged lifespan of your equipment.

In this section, we will explore the essential building blocks that contribute to the functionality of your device. By gaining insights into how each piece interacts with others, you will be better equipped to identify issues and implement solutions. Recognizing these elements can empower you as a user, fostering confidence in your repair and maintenance skills.

Additionally, a thorough examination of the structure can reveal opportunities for upgrades or modifications that might enhance performance. By delving into the various aspects of your machine, you can not only preserve its current state but also optimize it for future tasks. Let’s embark on this journey to demystify the components that make your equipment tick.

Understanding the LT2000 Model

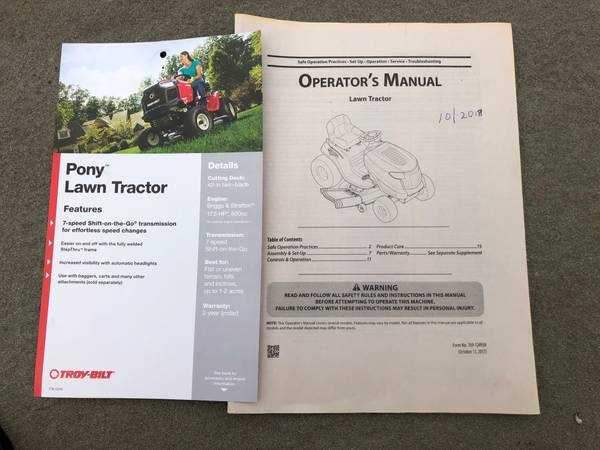

The LT2000 series represents a unique blend of innovation and practicality in its design, aimed at enhancing user experience while providing reliable performance. This model is well-regarded for its efficiency and versatility, making it a popular choice among enthusiasts and professionals alike.

At the heart of this model lies a robust framework that supports a variety of tasks, allowing users to tackle both simple and complex projects with ease. Its components work harmoniously, contributing to a smooth operation that stands the test of time. Understanding the intricacies of its design can greatly enhance maintenance and troubleshooting efforts.

Furthermore, the accessibility of resources related to this model enables users to easily locate information about its functionality and upkeep. Familiarity with its structure not only aids in effective usage but also ensures longevity, maximizing the value derived from the investment.

Key Features of Manual Craftsman Tools

When it comes to reliable hand tools, several characteristics set them apart from the rest. These attributes enhance usability, durability, and overall performance, making them essential for both professionals and DIY enthusiasts.

- Durability: Designed to withstand rigorous use, these tools are often made from high-quality materials that resist wear and tear.

- Ergonomic Design: Comfort is crucial during extended use. Many of these implements feature grips and handles that reduce strain on the hands.

- Precision: High levels of accuracy are a hallmark of these tools, allowing users to achieve precise results in various tasks.

- Versatility: A wide range of functions is available, catering to numerous applications, from simple repairs to complex projects.

- Ease of Use: Intuitive designs ensure that even beginners can handle these tools with confidence and efficiency.

In summary, these essential characteristics contribute to the effectiveness and satisfaction users experience, making them a preferred choice for many tasks.

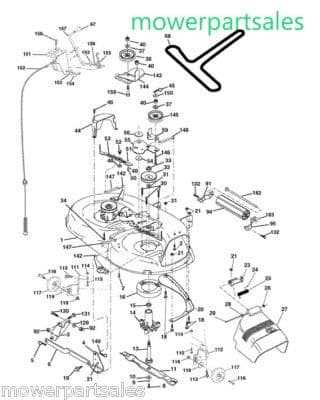

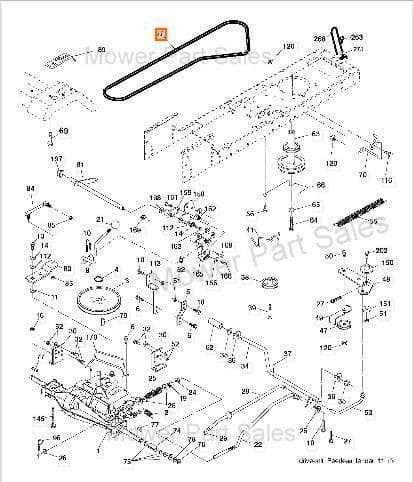

Importance of Parts Diagrams

Understanding the various components of machinery is essential for effective maintenance and repair. Visual representations play a crucial role in simplifying complex systems, enabling users to identify each element and its function within the whole. This clarity not only aids in troubleshooting but also enhances the overall efficiency of repair processes.

These illustrations serve multiple purposes, from guiding technicians during assembly to helping users order the correct replacements. A well-organized visual reference can save time and reduce the risk of errors, ultimately leading to improved performance and longevity of equipment.

| Benefits | Description |

|---|---|

| Clarity | Provides a clear view of each component’s position and function. |

| Efficiency | Streamlines the repair process by reducing the time spent searching for parts. |

| Accuracy | Helps ensure the correct components are identified and ordered. |

| Training | Acts as a valuable resource for educating new technicians on equipment assembly and maintenance. |

Common Issues with LT2000 Components

When working with a particular model of outdoor equipment, users may encounter various challenges related to its individual elements. Understanding these common complications can greatly enhance maintenance and longevity, ensuring optimal performance during operation.

Frequent Problems

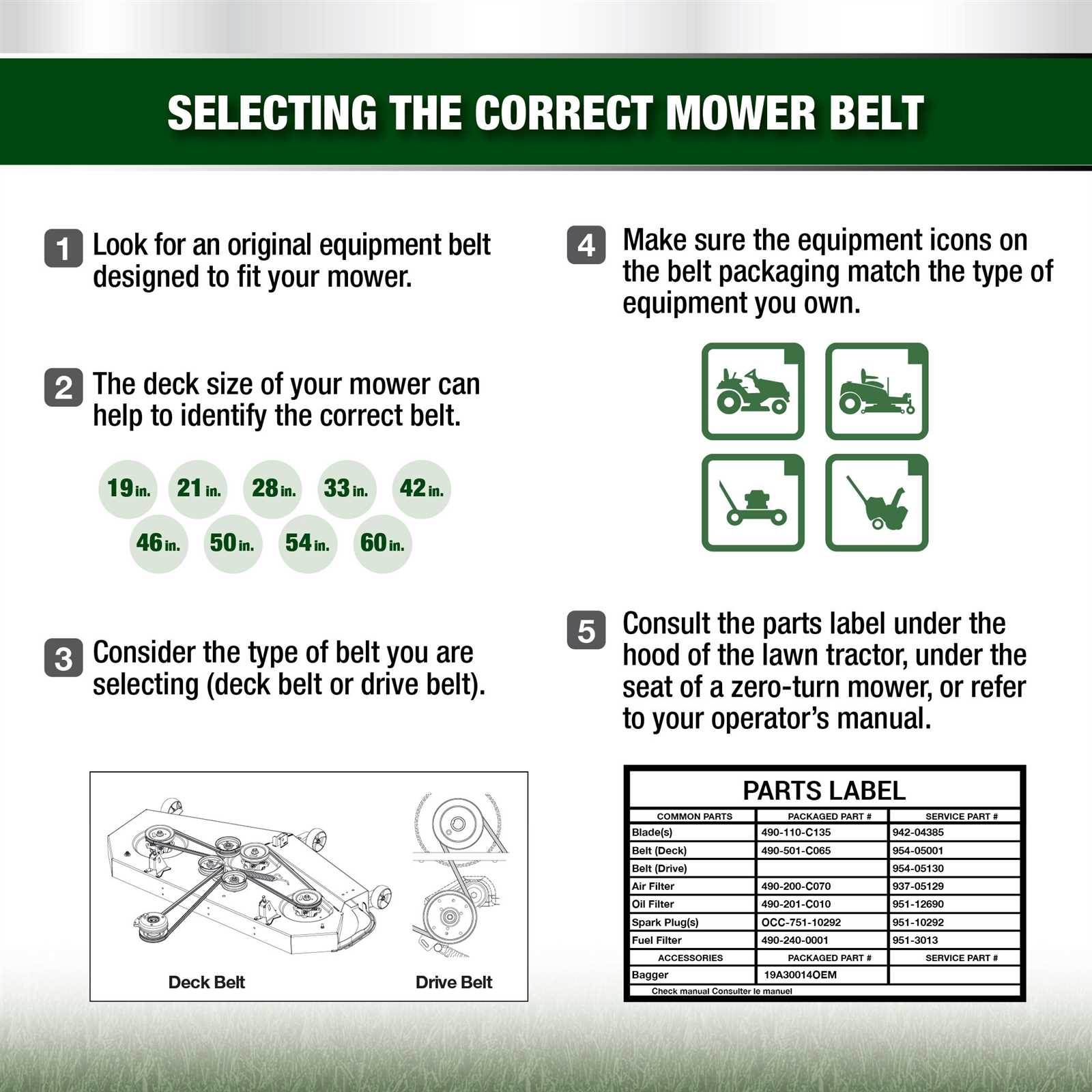

- Worn or damaged belts that can affect efficiency and power transfer.

- Faulty electrical connections leading to intermittent power issues.

- Clogged air filters which can hinder airflow and engine performance.

- Leaky fuel lines resulting in decreased fuel efficiency.

Symptoms to Look For

- Unusual noises during operation indicating potential mechanical failures.

- Inconsistent starting, which may point to ignition system failures.

- Excessive vibration, often a sign of unbalanced components.

- Poor cutting performance, indicating dull blades or misalignment.

Where to Find Replacement Parts

Finding the right components for your equipment can be a straightforward process if you know where to look. There are several reliable sources that cater to your needs, whether you are searching for original items or compatible alternatives.

Online Retailers: Many dedicated websites offer a vast selection of replacement items. These platforms often provide detailed descriptions, user reviews, and sometimes diagrams to help you identify the correct components for your specific model.

Local Hardware Stores: Brick-and-mortar establishments can be a great resource. Many local shops carry a variety of supplies and may even assist you in locating the precise pieces you need. Don’t hesitate to ask for help from knowledgeable staff.

Manufacturer’s Website: Visiting the official website of your equipment’s manufacturer can yield valuable information. Often, they have a dedicated section for replacement components, along with recommendations for authorized dealers.

Online Marketplaces: Websites such as eBay or Amazon can also be useful for finding both new and used components. Be sure to check seller ratings and reviews to ensure quality before making a purchase.

Community Forums: Engaging with online communities or forums can provide insights from other users. Members often share their experiences and may point you to specific retailers or sources where they found what they needed.

Utilizing these various avenues will help you efficiently locate the necessary items to keep your equipment functioning optimally.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to putting together your equipment efficiently. By following these clear instructions, you can ensure that each component is properly fitted and functions optimally. The process is designed to be straightforward, catering to both beginners and experienced users alike.

Step 1: Begin by gathering all the necessary components and tools. Having everything at hand will streamline the assembly process and prevent delays.

Step 2: Familiarize yourself with the assembly layout. Reviewing the configuration will give you a clearer understanding of how each part interacts with others.

Step 3: Start with the base unit. Ensure it is placed on a stable surface and secure any essential fixtures to maintain balance and support.

Step 4: Attach the primary components one by one. Follow the sequence recommended in the guide to avoid confusion and ensure a smooth integration.

Step 5: After all main elements are connected, check each connection for firmness. Tighten screws or bolts where necessary, making sure everything is securely fastened.

Step 6: Perform a final inspection of the assembled unit. Ensure that there are no loose parts and that everything is aligned correctly for optimal performance.

Step 7: Once satisfied with the assembly, proceed to test the functionality of your unit. This will confirm that all components are working as intended.

By following these structured steps, you can confidently assemble your equipment, paving the way for effective use in your projects.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of your equipment. Regular care not only prevents premature wear but also enhances efficiency and reliability. Here are some valuable practices to keep your tools in peak condition.

Regular Cleaning

Keeping your equipment clean is vital. Dust, debris, and moisture can accumulate over time, leading to corrosion and damage. Make it a habit to wipe down surfaces after each use and perform a deep cleaning periodically. Use appropriate cleaning agents that are safe for the materials involved.

Routine Inspections

Conducting frequent inspections helps identify wear and tear before it escalates into major issues. Check for loose components, signs of rust, or any irregularities in performance. Addressing minor problems promptly can save time and money in the long run. Always consult the user manual for specific areas to inspect.

Remember: Investing time in maintenance today will pay off with improved functionality and durability in the future. Prioritize care to keep your tools working efficiently.

Customer Reviews and Experiences

This section explores the insights and feedback from users who have interacted with various components and accessories for their tools. Understanding customer experiences can provide valuable information for potential buyers, helping them make informed decisions based on real-life usage and performance.

Users have shared a range of opinions regarding quality, durability, and ease of installation. Below is a summary of feedback collected from various sources:

| Feature | Positive Feedback | Negative Feedback |

|---|---|---|

| Quality | Many customers appreciate the robust build and reliability. | Some users reported issues with parts wearing out faster than expected. |

| Installation | Numerous reviews highlight the straightforward assembly process. | A few individuals encountered difficulties due to unclear instructions. |

| Performance | Users often note improved efficiency and functionality. | Occasional complaints about compatibility with certain models. |

Overall, feedback tends to emphasize both strengths and weaknesses, allowing prospective users to weigh their options based on comprehensive experiences shared by the community.