Maintaining your outdoor machinery is essential for ensuring optimal performance and longevity. An intricate system of various elements works together to achieve the ultimate efficiency in your tasks. Recognizing these components can significantly enhance your repair and maintenance efforts.

In this guide, we will explore the layout of essential elements that contribute to the effective functioning of your equipment. By delving into the specifics of each segment, you will gain valuable insights that aid in troubleshooting and repairs.

Whether you are a novice or an experienced user, having a clear visual representation of the assembly is crucial. This resource serves to empower you with knowledge, making the maintenance process less daunting and more manageable.

Understanding Scotts Lawn Mower Components

Maintaining a well-functioning machine requires familiarity with its various elements. Each component plays a vital role in ensuring optimal performance and efficiency. By grasping the significance of these parts, users can enhance their maintenance practices and troubleshoot issues effectively.

Engine: The heart of the system, responsible for powering the entire unit. Understanding its specifications and care requirements is essential for longevity.

Transmission: This component facilitates the transfer of power from the engine to the wheels, allowing for smooth movement. Regular checks can prevent operational hiccups.

Deck: The housing that protects and supports the cutting mechanism. Knowledge of its design can aid in identifying wear and tear that may affect performance.

Blades: These are crucial for achieving a clean cut. Familiarity with blade types and maintenance can significantly influence the quality of the outcome.

Fuel System: Comprising the tank, lines, and filter, this assembly is vital for proper operation. Understanding how to maintain it ensures reliability and efficiency.

Electrical System: Encompassing the battery and wiring, this system powers essential functions. Awareness of its components aids in troubleshooting electrical issues.

By developing a comprehensive understanding of these elements, operators can not only improve the efficiency of their equipment but also extend its lifespan. Regular inspection and maintenance are key to achieving optimal results.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended life and efficient performance of any machinery. Neglecting routine care can lead to wear and tear, ultimately resulting in costly repairs or premature replacement. By committing to consistent maintenance, owners can maximize the lifespan of their equipment while enhancing reliability and functionality.

Benefits of Routine Care

Conducting periodic inspections and performing necessary adjustments helps identify potential issues before they escalate. This proactive approach not only preserves the integrity of the equipment but also enhances its overall efficiency. Well-maintained machinery operates smoother and consumes less energy, translating into lower operational costs.

Best Practices for Upkeep

Establishing a maintenance schedule is essential. Key practices include checking fluid levels, replacing worn components, and cleaning filters. Additionally, ensuring proper storage conditions can protect against environmental factors that may cause damage. By following these guidelines, users can enjoy reliable performance and prolong the life of their investments.

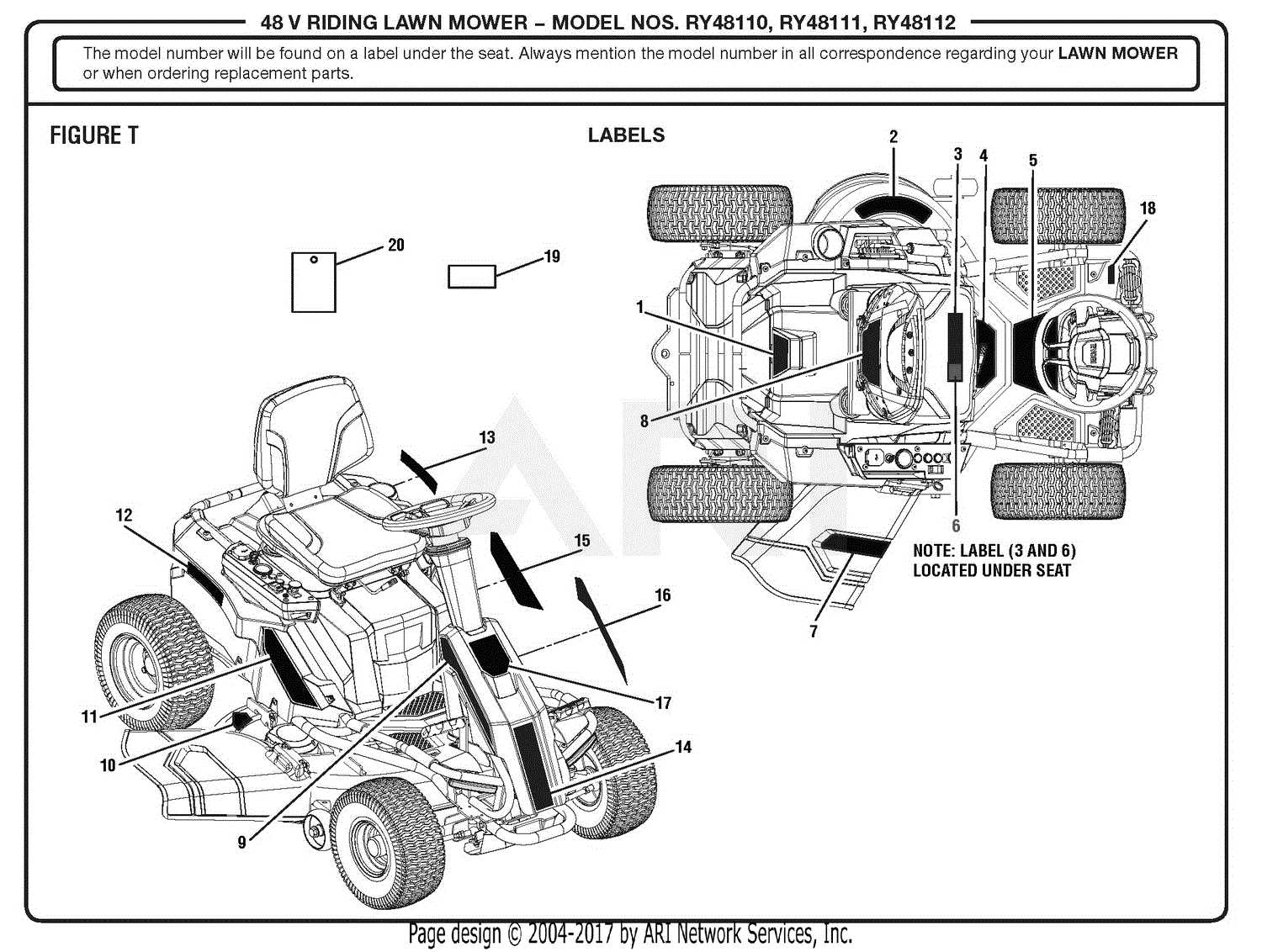

Identifying Parts in the Diagram

Understanding the components of machinery can significantly enhance your maintenance and repair experience. Familiarity with the layout and function of each element is essential for efficient troubleshooting and replacement. This section will guide you in recognizing the various segments illustrated in the schematic.

When analyzing the visual representation, consider the following categories:

- Engine Components: Key parts that drive the entire system, including the crankshaft, carburetor, and ignition coil.

- Transmission Elements: These parts enable the transfer of power, such as belts, pulleys, and gears.

- Cutting Mechanism: The elements responsible for the cutting action, including blades and spindles.

- Chassis and Frame: The structural components that support and protect other parts, like the body and wheels.

- Electrical System: Components that manage the electrical functions, including wiring, switches, and batteries.

By familiarizing yourself with these categories, you can more easily locate and identify specific components within the visual representation, facilitating efficient repairs and maintenance.

Common Issues and Solutions

Maintaining outdoor equipment can often lead to various challenges that users encounter. Understanding these common problems and their respective solutions can enhance performance and prolong the lifespan of the machinery. Below, we explore frequent difficulties and effective remedies that can be applied.

Engine Starts but Stalls

One prevalent issue is when the engine starts but quickly stalls. This can be caused by a clogged fuel filter or an empty tank. Regularly checking the fuel levels and replacing the filter as needed can resolve this issue. Additionally, ensuring that the air filter is clean can improve airflow and engine performance.

Uneven Cutting

Another common challenge is uneven cutting of the grass. This may stem from dull blades or an improperly leveled cutting deck. Sharpening the blades routinely and adjusting the deck height can ensure a uniform cut. Keeping the equipment clean from debris also contributes to better performance.

Where to Find Replacement Parts

Locating components for your outdoor machinery can be straightforward if you know where to search. Various resources are available, providing options to suit different needs and preferences.

Online Retailers

- Major e-commerce platforms offer a vast selection.

- Specialty websites focus on outdoor equipment.

- Manufacturer’s official sites often have specific components.

Local Stores

- Home improvement centers typically stock common items.

- Authorized dealers can provide expert advice and genuine components.

- Small engine repair shops might have unique options or used components.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is crucial for efficiency and effectiveness. A well-equipped toolkit not only facilitates smooth operations but also ensures safety throughout the process.

Essential Tools

Start with basic hand tools such as wrenches, screwdrivers, and pliers. These will cover most disassembly and reassembly needs. Additionally, consider a socket set for tackling stubborn fasteners.

Specialized Equipment

For more complex issues, a multimeter can be invaluable for electrical diagnostics, while a jack and jack stands are essential for safely lifting machinery. Always ensure your toolkit is comprehensive to address various challenges effectively.

Step-by-Step Repair Process

Undertaking repairs on garden machinery can seem daunting, but a methodical approach makes it manageable. This guide will provide a structured pathway to help you address common issues effectively, ensuring your equipment runs smoothly and efficiently.

Step 1: Identify the Problem

Begin by observing the machine’s performance. Note any unusual sounds, vibrations, or operational failures. Understanding the symptoms is crucial for diagnosing the underlying issue accurately.

Step 2: Gather Necessary Tools

Before diving into repairs, collect all the tools you’ll need. This might include wrenches, screwdrivers, pliers, and any specific instruments recommended for the task. Having everything at hand will streamline the process.

Step 3: Consult the Manual

Refer to the user manual for guidance specific to your model. Manuals typically provide valuable insights into common issues, troubleshooting tips, and detailed instructions for disassembly and reassembly.

Step 4: Disassemble with Care

Start disassembling the necessary components carefully. Keep track of screws and small parts to avoid losing them. It may help to take pictures during this step to reference during reassembly.

Step 5: Inspect Components

Once disassembled, thoroughly inspect each component for wear and tear. Look for signs of damage, such as cracks or rust, and replace any faulty parts as needed. Clean parts where necessary to enhance performance.

Step 6: Reassemble and Test

After replacing any damaged components and cleaning everything, carefully reassemble the machine. Ensure all parts fit snugly and securely. Once reassembled, conduct a test run to verify that the repairs were successful.

Step 7: Regular Maintenance

To prevent future issues, establish a regular maintenance routine. This includes checking fluid levels, cleaning filters, and inspecting components periodically to ensure long-lasting performance.

Tips for Safe Operation and Use

Ensuring safe operation of outdoor machinery is essential for both the user and the surrounding environment. Following proper guidelines can help prevent accidents and promote a more enjoyable experience while maintaining your green spaces.

Before starting the equipment, always inspect it for any signs of wear or damage. This includes checking the blades, tires, and fuel system. Make sure that all safety features are functioning correctly, as they are designed to protect you during use.

Wear appropriate protective gear, such as sturdy footwear, gloves, and eye protection. This minimizes the risk of injury from debris and moving parts. Additionally, avoid wearing loose clothing that could become entangled in the machinery.

Always operate the equipment in a well-lit area, ensuring clear visibility of your surroundings. Be mindful of children, pets, and obstacles in the vicinity. Establish a safe zone and communicate with others to avoid unexpected interactions while you are engaged in your task.

Finally, familiarize yourself with the operator’s manual to understand the specific controls and safety features of your machine. Following these tips will enhance safety and ensure a smooth and efficient experience when tending to your outdoor spaces.