When it comes to managing icy conditions, having a clear understanding of the machinery involved is crucial for optimal performance. This section delves into the intricate structures that play a vital role in winter maintenance. Familiarity with each element not only aids in efficient operation but also enhances safety and reliability.

Visual aids are essential tools in grasping the arrangement and function of various components. By exploring these illustrations, users can pinpoint essential features, ensuring proper upkeep and functionality. Recognizing how each segment interacts within the system fosters a deeper appreciation for the technology at work.

Moreover, comprehending the layout allows operators to address potential issues proactively. Whether for routine maintenance or troubleshooting, a thorough knowledge of the equipment’s assembly will empower individuals to tackle challenges with confidence. Engaging with these resources ultimately leads to improved performance and extended longevity of the machinery.

Understanding the Fisher Snow Plow System

This section aims to provide an overview of the components and mechanics involved in a specific winter maintenance apparatus designed for clearing surfaces. By exploring the interplay between various elements, we can gain insights into its functionality and maintenance requirements.

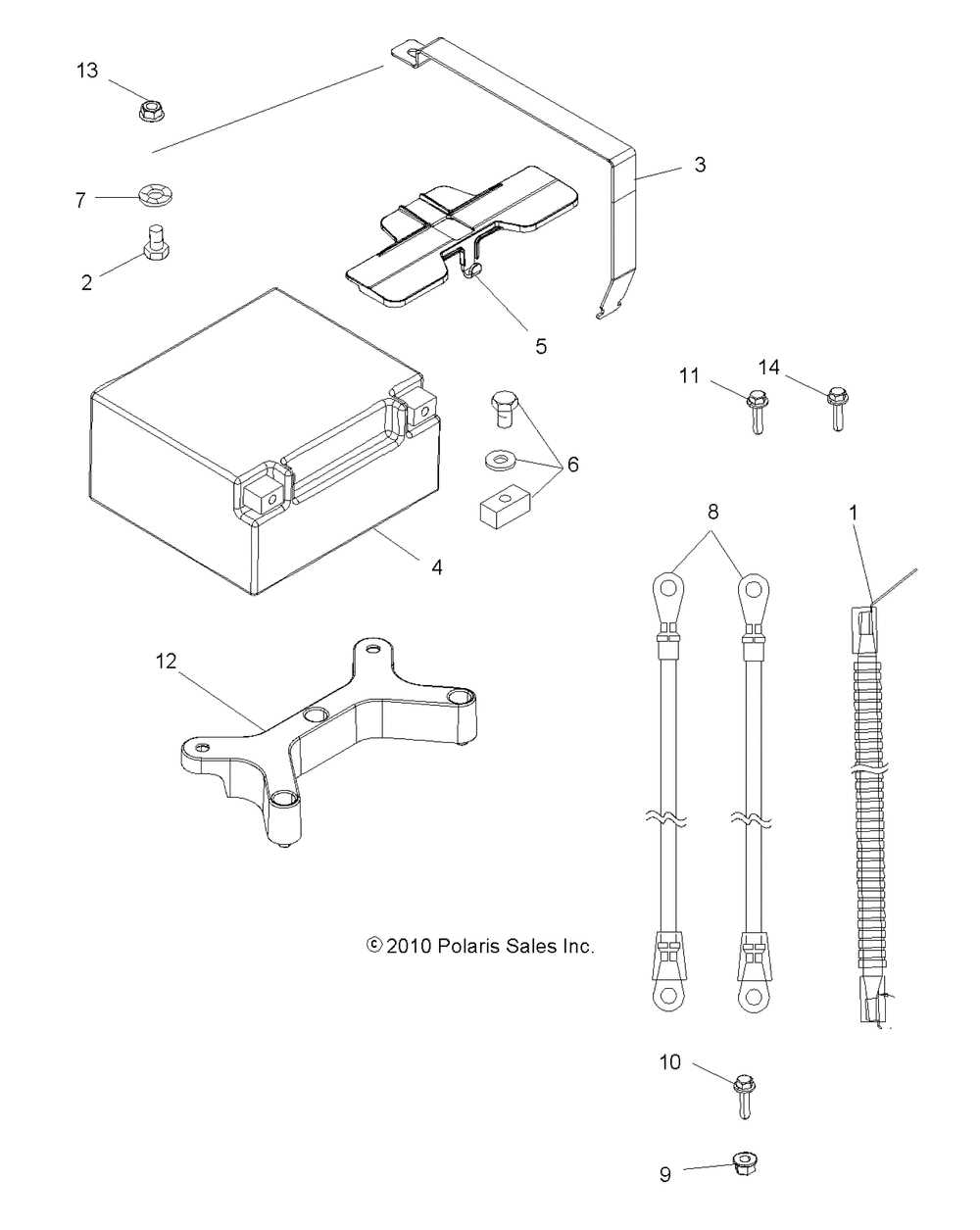

At the core of this system lies an assembly of essential components that work together to ensure efficient operation. These elements include hydraulic mechanisms, mounting structures, and control systems, each contributing to the overall effectiveness of the setup.

| Component | Description |

|---|---|

| Hydraulic Unit | Powers the lifting and angling functions for optimal maneuverability. |

| Mounting Frame | Secures the apparatus to the vehicle, providing stability during operation. |

| Control System | Allows the operator to manage the various functions with precision. |

| Blade Assembly | The primary element that interacts with the surface, removing debris efficiently. |

| Electrical Components | Facilitate communication between the controls and the hydraulic unit. |

Understanding these components is crucial for effective troubleshooting and maintenance, ensuring the apparatus remains reliable throughout its operational life.

Key Components of Snow Plows

The efficiency of a snow-clearing machine hinges on its essential elements, which work harmoniously to tackle winter challenges. Understanding these components is crucial for optimal performance and maintenance.

Blade: This is the primary tool responsible for pushing away accumulated ice and frost. Its design and material greatly influence effectiveness and durability.

Mounting System: A robust mounting framework secures the blade to the vehicle, ensuring stability during operation. Proper installation is vital for safe maneuverability.

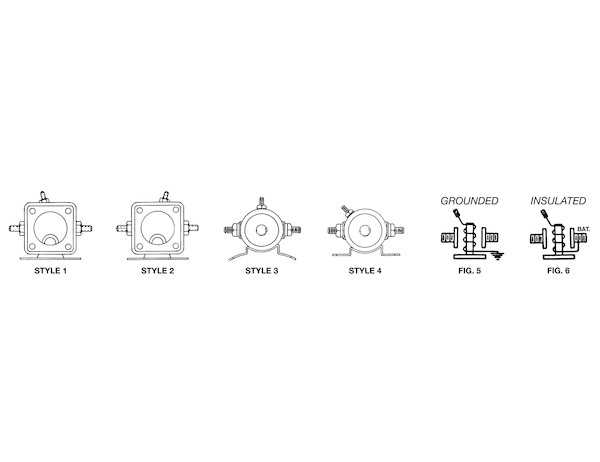

Hydraulic System: This mechanism controls the angle and height of the blade, allowing for precise adjustments while clearing surfaces. Hydraulic efficiency directly affects response time and ease of use.

Control Mechanism: Operators utilize this interface to manage the blade’s functions. Intuitive controls enhance the user experience and operational speed.

Deflector: Attached to the top of the blade, this component prevents snow from spilling over during movement, enhancing effectiveness in various conditions.

Skid Shoes: Positioned at the blade’s bottom, these wear items protect the blade and the surface beneath it, helping maintain optimal scraping performance.

By delving into these fundamental elements, users can achieve the ultimate efficiency in winter maintenance tasks.

Benefits of Regular Maintenance

Consistent upkeep of equipment is crucial for ensuring optimal performance and longevity. By adhering to a regular maintenance schedule, owners can significantly reduce the likelihood of unexpected failures and enhance overall efficiency. This proactive approach not only safeguards the investment but also promotes safety and reliability.

Enhanced Performance

Routine care leads to improved functionality and effectiveness. Regular checks and servicing can result in:

- Better efficiency in operation

- Increased power and responsiveness

- Minimized wear and tear

Cost Savings

Investing in regular maintenance can lead to substantial financial benefits:

- Reduction in repair costs due to early detection of issues

- Extended lifespan of equipment, delaying replacement expenses

- Improved fuel efficiency, lowering operating costs

Overall, maintaining equipment not only ensures optimal performance but also provides significant savings, making it a wise choice for any owner. Emphasizing regular upkeep is key to achieving long-term success.

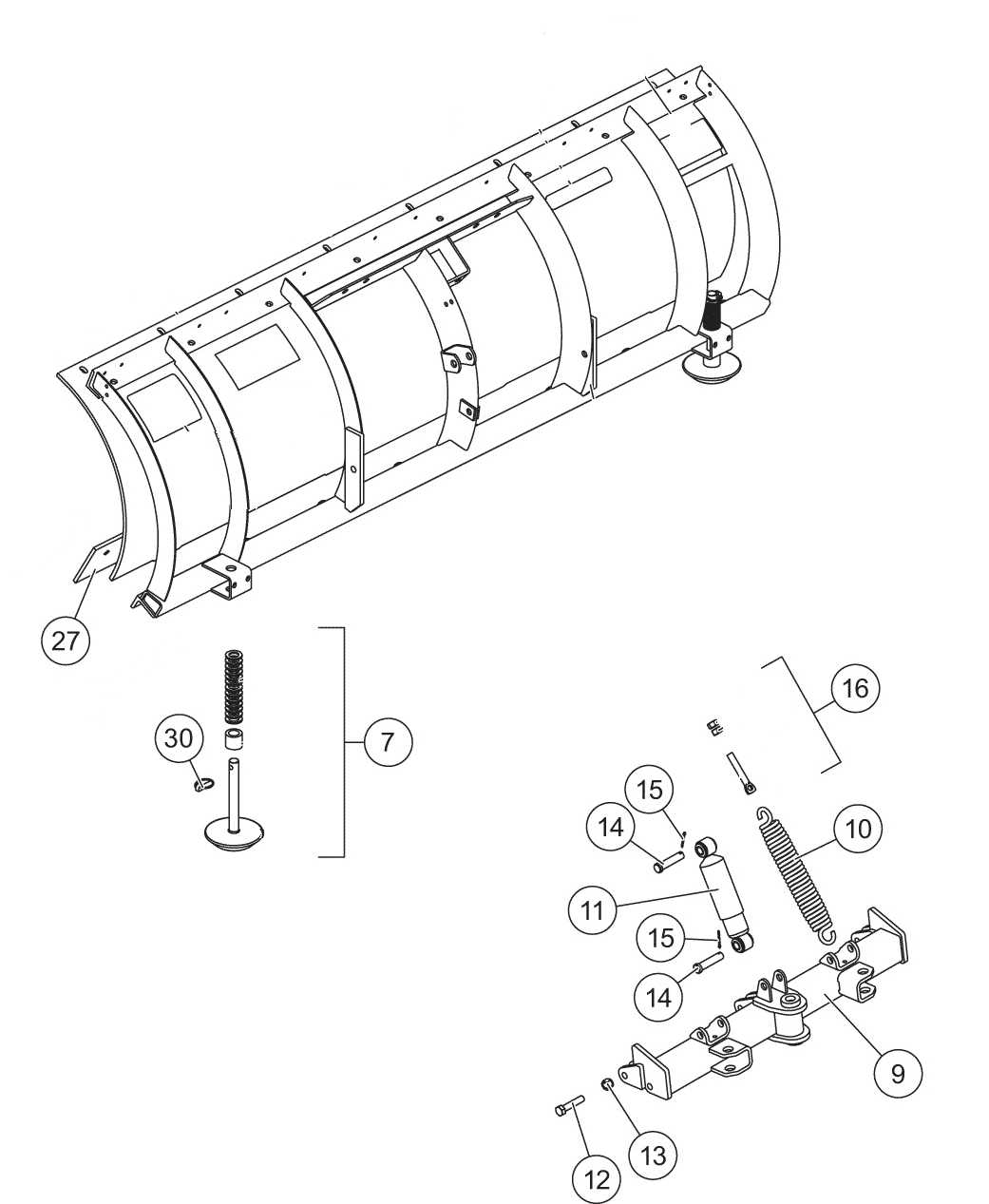

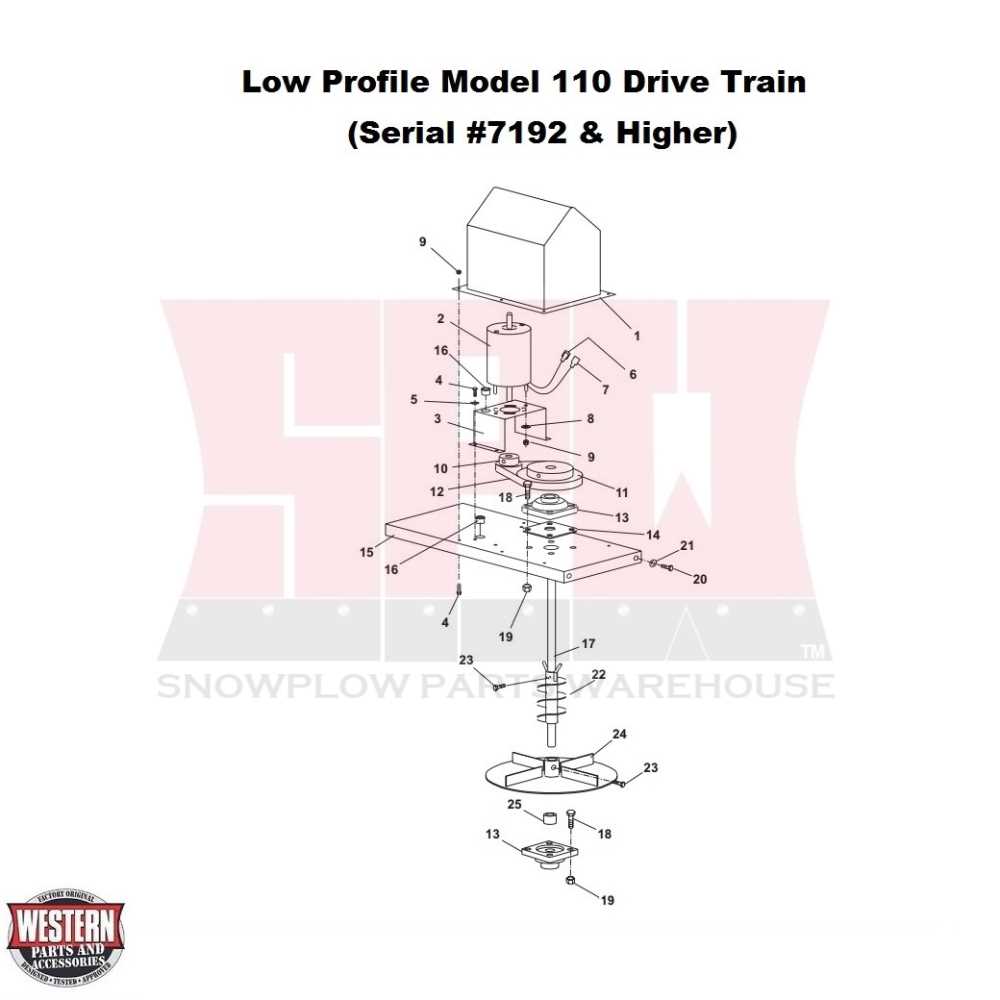

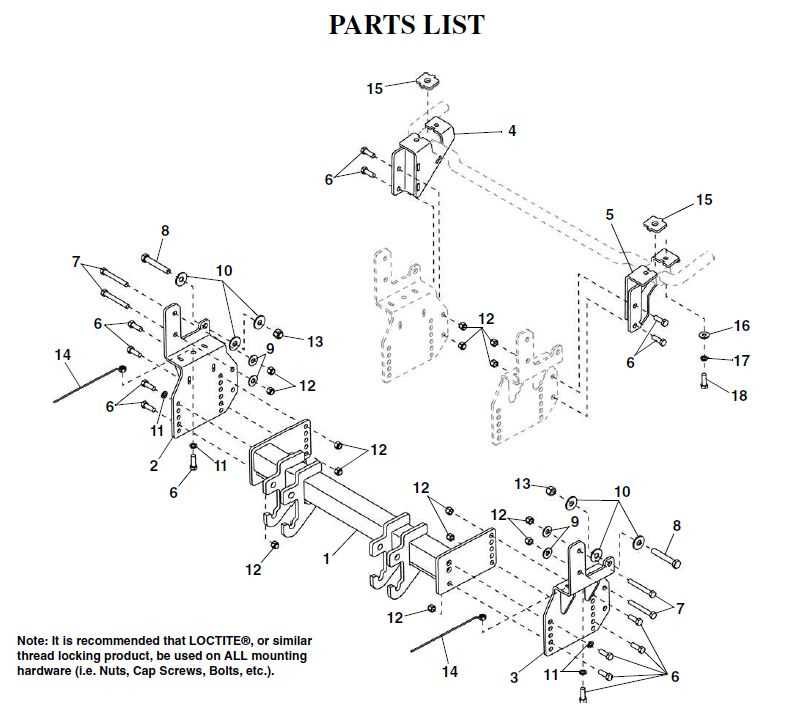

How to Identify Parts in Diagrams

Understanding the components of a mechanical layout can greatly enhance your ability to perform maintenance or repairs. Recognizing various elements and their functions is essential for efficient troubleshooting and replacement.

First, familiarize yourself with the overall structure of the layout. Look for labels or numbers that correspond to specific items. These identifiers often serve as guides to understanding the relationship between components.

Next, pay attention to symbols and shapes. Different forms often represent various functionalities, so knowing what each shape signifies can aid in pinpointing the correct elements. Additionally, cross-referencing with manuals or guides can provide further clarification.

Finally, practice makes perfect. The more you delve into these layouts, the easier it becomes to identify each piece swiftly and accurately. This skill is ultimately invaluable for anyone involved in mechanical work.

Common Issues with Snow Plow Parts

When operating winter equipment, various components may encounter issues that can hinder performance and efficiency. Understanding these common challenges is essential for timely maintenance and repair, ensuring smooth operation during the cold season. Below are some frequent problems that can arise with different elements of such machinery.

Mechanical Failures

Mechanical components can wear out or become damaged due to prolonged use or harsh conditions. These failures can manifest in several ways, including unusual noises, reduced responsiveness, or complete system failure. Regular inspections and timely replacements are crucial to prevent these issues from escalating.

Hydraulic System Problems

The hydraulic system is vital for the operation of winter equipment. Common issues include leaks, pressure loss, and contamination of fluid. These problems can lead to inefficient operation and increased wear on components. Monitoring fluid levels and performing regular maintenance can help mitigate these risks.

| Issue | Symptoms | Solutions |

|---|---|---|

| Mechanical Failure | Unusual noises, lack of movement | Regular inspection, component replacement |

| Hydraulic Leak | Fluid puddles, decreased pressure | Seal replacement, fluid check |

| Electrical Malfunction | Inconsistent operation, warning lights | Wiring inspection, component testing |

| Corrosion | Visible rust, weakened structure | Regular cleaning, protective coatings |

Upgrading Your Fisher Plow Components

Enhancing the functionality of your equipment can significantly improve performance and efficiency. By focusing on specific components, you can achieve better results during winter operations. Upgrades not only extend the lifespan of your machinery but also contribute to a more seamless experience on the job.

Identifying Key Components for Enhancement

Before proceeding with modifications, it’s essential to identify which elements can benefit from an upgrade. Commonly, aspects such as hydraulic systems, cutting edges, and electrical components are prime candidates. Upgrading these areas can lead to improved response times and greater durability, ultimately making your work easier and more effective.

Selecting Quality Upgrades

When considering enhancements, choosing high-quality alternatives is crucial. Look for reputable brands that offer reliable options tailored for your equipment. Investing in superior components may require a higher initial expenditure but can result in significant long-term savings through reduced maintenance and increased productivity.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process if you know where to look. Various resources are available to help you find what you need, whether it’s for maintenance or repairs.

- Authorized Dealers: Visiting a certified distributor ensures that you receive high-quality components that meet manufacturer standards.

- Online Retailers: Numerous websites specialize in equipment components, providing detailed catalogs and often user reviews to aid in your selection.

- Local Hardware Stores: Many community stores carry essential items that can be useful for basic repairs or replacements.

- Forums and Online Communities: Engaging with fellow enthusiasts can provide recommendations on where to source components and share personal experiences.

By exploring these options, you can efficiently locate the necessary items to keep your equipment functioning smoothly.

Assembly and Installation Guide

This section provides a comprehensive overview of the procedures necessary for the proper assembly and setup of your equipment. By following these guidelines, you can ensure optimal performance and longevity.

Before beginning, gather all necessary tools and components. Review the components list and familiarize yourself with each item’s function and placement within the system.

| Step | Description |

|---|---|

| 1 | Prepare your workspace by clearing any debris and ensuring you have ample room to maneuver. |

| 2 | Begin with the base assembly, aligning all parts according to the provided specifications. |

| 3 | Secure all connections using the appropriate fasteners, ensuring each is tightened to the recommended torque. |

| 4 | Install additional components, following the sequence outlined in the instructions to avoid conflicts. |

| 5 | Once assembled, conduct a thorough inspection to confirm that all parts are correctly installed and secure. |

Finally, perform a test run to verify that the system operates as intended, making adjustments as necessary for the ultimate efficiency.

Safety Tips for Plow Operators

Operating heavy equipment in adverse weather conditions demands a high level of caution. Ensuring personal safety and the safety of others is paramount. Here are essential practices to follow while managing such machinery.

- Always wear appropriate protective gear, including gloves, helmets, and high-visibility clothing.

- Conduct a thorough pre-operation inspection of the equipment to identify any potential issues.

- Stay aware of your surroundings and avoid distractions while driving.

- Maintain a safe distance from pedestrians and other vehicles.

Additionally, it’s vital to:

- Familiarize yourself with emergency procedures in case of an accident.

- Keep your equipment well-maintained and serviced regularly.

- Stay hydrated and take regular breaks to remain alert.

- Utilize mirrors and cameras effectively for better visibility.

By adhering to these guidelines, operators can significantly reduce risks associated with their responsibilities.