In the world of outdoor equipment, the intricate assembly of a lawn mower plays a crucial role in its performance and longevity. Every part, from the engine to the blades, works in harmony to ensure optimal functionality. Gaining insight into how these elements fit together can enhance maintenance and repair efforts, leading to a more efficient machine.

Familiarizing oneself with the specific components of a mowing device can be immensely beneficial for both novice and experienced users. This knowledge not only empowers individuals to troubleshoot issues but also facilitates timely replacements and upgrades. A clear visualization of each piece allows for better comprehension of their individual roles and interactions.

Additionally, understanding the layout and connection of various elements can significantly reduce downtime during repairs. By referencing detailed illustrations, owners can pinpoint problems swiftly and accurately, ensuring that their equipment remains in peak condition. The ability to navigate these technical details can transform the mowing experience, making it smoother and more enjoyable.

Understanding Husqvarna HU700F Components

Grasping the intricacies of your lawn equipment is essential for optimal performance and maintenance. Every element plays a vital role in the overall functionality, influencing everything from efficiency to longevity. Recognizing these components allows users to troubleshoot issues effectively and ensure their machine operates at its best.

The engine serves as the heart of the equipment, providing the necessary power for operation. Regular maintenance of this critical part ensures reliability and efficiency.

The cutting deck is where the magic happens, responsible for delivering a clean and precise cut. Understanding its design can help users maintain sharpness and effectiveness.

Wheels and drive systems contribute significantly to maneuverability. Keeping these parts in good condition enhances overall ease of use, especially on uneven terrain.

Filters and fuel systems are crucial for maintaining the machine’s health. Regular checks and replacements can prevent potential failures and prolong the life of the equipment.

By delving into the specifics of each component, users can gain ultimate control over their lawn care experience, leading to a beautifully maintained outdoor space.

Essential Parts for Optimal Performance

Achieving peak efficiency in lawn maintenance equipment relies heavily on the quality and functionality of its components. Each element plays a vital role in ensuring smooth operation, enhancing durability, and providing a seamless user experience. Understanding these crucial elements can lead to improved performance and longevity of the machine.

Key Components

- Engine: The heart of the equipment, responsible for power generation and overall functionality.

- Blades: Essential for effective cutting, they need to be sharp and well-aligned.

- Wheels: Provide mobility; choosing the right type enhances maneuverability across different terrains.

- Fuel System: Ensures efficient fuel delivery for optimal engine performance.

- Air Filter: Maintains engine health by preventing dirt and debris from entering.

Maintenance Tips

- Regularly check and replace worn blades to maintain cutting efficiency.

- Inspect the air filter frequently and clean or replace as needed to ensure proper airflow.

- Keep the fuel system clean to prevent clogs and ensure smooth operation.

- Check wheel conditions and tire pressure to guarantee safe and effective movement.

- Perform routine engine maintenance to enhance performance and extend lifespan.

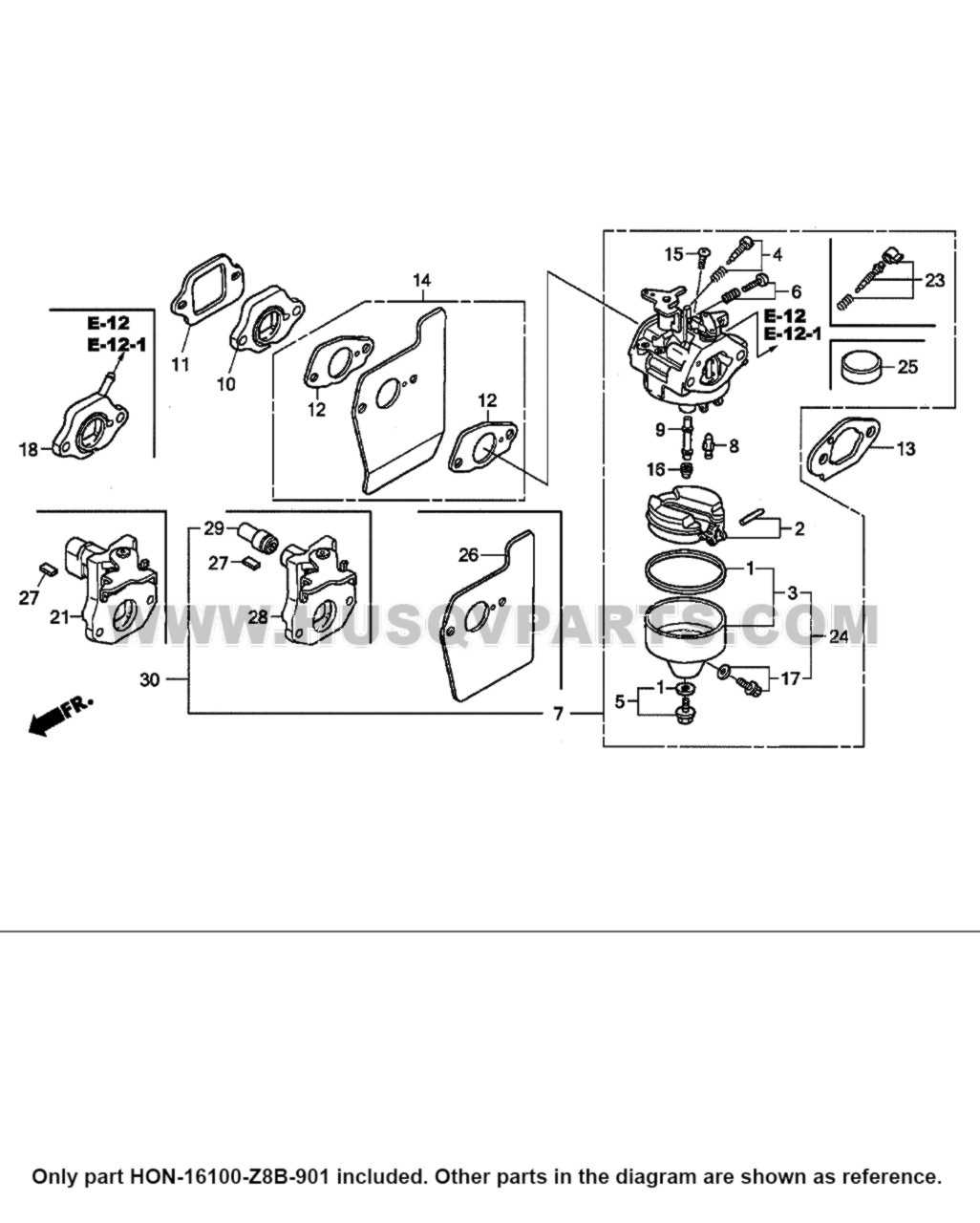

How to Read the Parts Diagram

Understanding a component illustration can significantly enhance your ability to maintain and repair equipment. This visual representation provides an organized overview of each element, making it easier to identify specific parts and their functions. By familiarizing yourself with this layout, you can streamline the process of ordering replacements and conducting repairs.

Start by identifying the key sections of the illustration. Each area typically corresponds to a specific part of the machine, which may be grouped by function or location. Look for labels or numbers that help in pinpointing each component, often accompanying a brief description.

Next, note the connections between various parts. Understanding how components interact with one another is crucial for diagnosing issues and ensuring proper assembly. Pay attention to arrows or lines that indicate relationships, as these can guide you in comprehending the overall structure.

Lastly, use a reference guide to translate the visual information into real-world applications. This guide will often include a list of components along with their corresponding numbers from the illustration, allowing you to find and order parts more efficiently. By mastering this process, you’ll be better equipped to handle repairs and maintenance tasks effectively.

Common Issues and Replacement Solutions

Every mechanical device can encounter problems over time, and lawn mowers are no exception. Understanding these common issues and knowing the appropriate solutions can enhance the lifespan of your equipment and improve its performance. Below are some frequent complications that users might face, along with recommended replacement options.

-

Engine Not Starting:

- Check the fuel level and quality. Replace old fuel with fresh gasoline.

- Inspect the spark plug for wear and replace if necessary.

- Examine the battery connections for corrosion or looseness.

-

Uneven Cutting:

- Ensure the blades are sharp. Dull blades can be replaced to improve cutting efficiency.

- Check the height adjustment settings and ensure they are uniform.

- Inspect the wheel alignment to ensure they are all at the same height.

-

Excessive Vibration:

- Examine the blades for damage or bending and replace if necessary.

- Ensure all bolts and fasteners are tightened securely.

- Check for any debris caught in the cutting deck and clean it out.

-

Overheating:

- Ensure proper airflow by cleaning the air filter and replacing it if it’s clogged.

- Check the oil level and replace old oil with fresh oil.

- Inspect the cooling fins for dirt buildup and clean as needed.

By identifying these common problems and taking appropriate measures, users can maintain their equipment effectively, ensuring a smoother and more efficient operation throughout the mowing season.

Maintenance Tips for Longevity

To ensure the prolonged performance of your outdoor equipment, regular upkeep is essential. Consistent maintenance not only enhances efficiency but also extends the lifespan of the machinery. Following a few simple practices can prevent costly repairs and keep your tools running smoothly.

Regular Cleaning

After each use, take the time to clean the exterior and any components that may have accumulated debris. Dirt and grass clippings can obstruct airflow and cause overheating. Use a brush or compressed air to remove buildup, ensuring that all parts function correctly.

Routine Inspections

Conduct periodic checks of essential components such as blades, belts, and filters. Look for signs of wear and replace any parts that appear damaged or excessively worn. Timely replacements can prevent further issues and ensure optimal operation.

Additionally, consult the owner’s manual for recommended maintenance intervals and follow the guidelines closely. Adhering to a regular schedule will help maintain peak performance and reliability throughout the equipment’s life.

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential for maintaining optimal performance and longevity. When seeking reliable sources, it’s crucial to ensure that the items you purchase meet high-quality standards and are designed specifically for your model.

Authorized dealers are often the best option, as they provide products that are guaranteed to fit and function properly. Additionally, reputable online retailers can offer a wide selection of genuine items, often with user reviews to assist in your decision-making process.

Local service centers can also be valuable resources, as they frequently stock essential components and may provide installation assistance. Always verify the authenticity of the seller and consider reaching out to customer service for any inquiries regarding compatibility.

Comparison of Aftermarket Options

When considering replacement components for lawn equipment, evaluating alternative choices is essential. Aftermarket products often present a range of benefits, including cost-effectiveness and availability, appealing to budget-conscious consumers. However, the quality and compatibility of these alternatives can vary significantly, making it crucial to research and compare various offerings.

One of the primary advantages of aftermarket selections is the potential for lower prices. Many manufacturers provide similar functionalities at a fraction of the cost of original equipment. This can be particularly attractive for those looking to maintain their machines without breaking the bank. Nevertheless, it’s important to assess the durability and performance of these substitutes to ensure they meet the required standards.

In addition to price, another aspect to consider is the range of options available. Aftermarket suppliers often offer a broader selection of components, which can be beneficial for customization or upgrades. Users can find unique features that might not be present in the original offerings. However, it is wise to consult reviews and ratings to gauge the reliability of these products before making a purchase.

Ultimately, balancing cost, quality, and compatibility will guide users in making informed decisions about aftermarket alternatives. Thorough research and comparisons will lead to optimal choices that enhance performance and longevity.

Assembly Instructions for DIY Repairs

Repairing lawn equipment can be a rewarding experience, allowing you to save money and gain a deeper understanding of how your machinery operates. Following clear assembly instructions ensures that you can efficiently tackle common repairs and keep your tools in top condition.

Before you begin, gather the necessary tools and materials:

- Screwdriver set

- Wrenches

- Pliers

- Replacement components

- Cleaning cloths

- Safety goggles

Follow these steps for successful reassembly:

- Preparation: Ensure the equipment is powered off and disconnected from any power source. Clear your workspace of clutter.

- Identify Components: Familiarize yourself with the parts you will be handling. Lay them out in the order they will be reassembled.

- Follow the Manual: If available, consult the owner’s manual for specific instructions related to the model you are repairing.

- Reassembly: Start reassembling from the bottom up or from the largest components to the smallest, securing each part with the appropriate fasteners.

- Test the Mechanism: Once reassembled, manually test the moving parts to ensure they operate smoothly before reconnecting to power.

- Final Inspection: Double-check that all components are secured properly, and there are no loose parts or tools left behind.

By following these instructions, you can confidently manage repairs and maintain your equipment effectively. Regular upkeep will not only enhance performance but also extend the lifespan of your machinery.

FAQs About Husqvarna HU700F Parts

This section addresses common inquiries regarding components for a specific lawn maintenance machine. Understanding these elements is essential for effective operation and maintenance, ensuring that users can keep their equipment running smoothly and efficiently.

What are the most commonly replaced components?

Users often find themselves needing to replace items such as the cutting blade, air filter, and spark plug. Regular maintenance of these essential elements can greatly enhance the machine’s performance and longevity.

Where can I find quality replacements?

Quality replacements can typically be sourced from authorized dealers, specialized online retailers, and local hardware stores. It’s crucial to ensure that the components match the specifications of the equipment to guarantee optimal functionality.