Every powerful tool consists of numerous intricate elements working in harmony to deliver exceptional performance. In the realm of forestry and landscaping, a specific machine is known for its reliability and efficiency, making it a favorite among professionals and hobbyists alike. Understanding these components is crucial for optimal operation and maintenance.

Exploring the structure of this remarkable machine reveals a variety of essential sections, each playing a vital role in its functionality. From the motor to the cutting mechanism, every part is designed to endure the demands of tough tasks. Familiarity with these components not only aids in troubleshooting but also enhances the overall user experience.

For those looking to delve deeper, examining a comprehensive representation of these elements can provide insights into their arrangement and interaction. This ultimate guide will equip you with the knowledge needed to ensure your machine remains in peak condition, ready to tackle any challenge that comes its way.

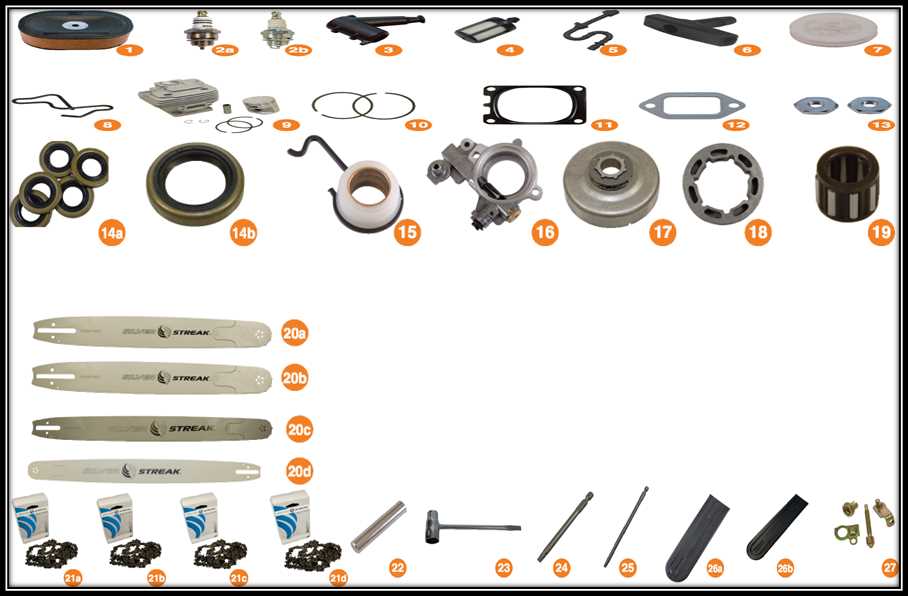

Understanding the Stihl MS441 Components

Grasping the intricacies of a chainsaw’s elements is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and longevity. Familiarity with these elements empowers users to troubleshoot issues and enhance their equipment’s efficiency.

| Component | Function |

|---|---|

| Engine | Provides power for cutting tasks. |

| Bar | Guides the chain during operation. |

| Chain | Engages in cutting through materials. |

| Clutch | Engages and disengages the chain. |

| Air Filter | Prevents debris from entering the engine. |

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for maintenance and repair tasks. Visual representations of components serve as crucial tools for both professionals and enthusiasts, enabling them to navigate the complexities of assembly and disassembly with ease.

These illustrations offer numerous benefits, including:

- Clarity: Clear depictions help identify each element, reducing confusion during repairs.

- Efficiency: Users can quickly locate necessary components, saving valuable time.

- Accuracy: Detailed visuals minimize the risk of errors, ensuring that parts are replaced correctly.

- Reference: They serve as a reliable guide for reassembly, especially for complex machinery.

Moreover, familiarity with these visual aids enhances one’s overall understanding of the equipment’s functionality, promoting better care and longevity. Properly utilizing such resources is a key factor in successful maintenance practices.

Common Issues with MS441 Chainsaw

When it comes to powerful cutting tools, users often encounter a variety of challenges that can affect performance and efficiency. Understanding these common problems can help in troubleshooting and maintenance, ensuring optimal operation for all tasks.

Frequent Problems

- Starting Difficulties: Many operators experience issues with ignition, leading to frustrating attempts to get the engine running.

- Chain Stalling: A stalled chain can be a sign of tension issues or insufficient lubrication, hindering productivity.

- Excessive Vibration: High levels of vibration during operation can indicate a need for balancing or a problem with the cutting attachment.

- Overheating: If the tool becomes excessively hot, it may result from clogged air filters or poor fuel mixture.

- Oil Leaks: Leaking oil can lead to decreased lubrication and potential damage to the unit.

Troubleshooting Tips

- Check the spark plug for wear and replace it if necessary.

- Ensure that the chain tension is correctly adjusted.

- Regularly clean the air filter to prevent clogging.

- Inspect the lubrication system for any blockages or leaks.

- Maintain proper fuel ratios to avoid overheating issues.

Where to Find Replacement Parts

Finding components for your equipment can seem daunting, but there are various reliable sources to consider. Whether you need specific items for maintenance or repairs, knowing where to look can simplify the process.

- Authorized Dealers: Official retailers often carry a comprehensive selection of components. They can also provide expert advice and guidance.

- Online Marketplaces: Websites such as eBay and Amazon offer a wide range of items. Ensure to check seller ratings and product reviews.

- Specialized Websites: Numerous online stores focus on outdoor equipment. They often have detailed catalogs and competitive pricing.

- Local Repair Shops: Independent mechanics and service centers may stock essential components or can order them for you.

Before making a purchase, always verify compatibility with your specific model to avoid any issues. Additionally, consider checking for warranties or return policies to ensure a satisfactory shopping experience.

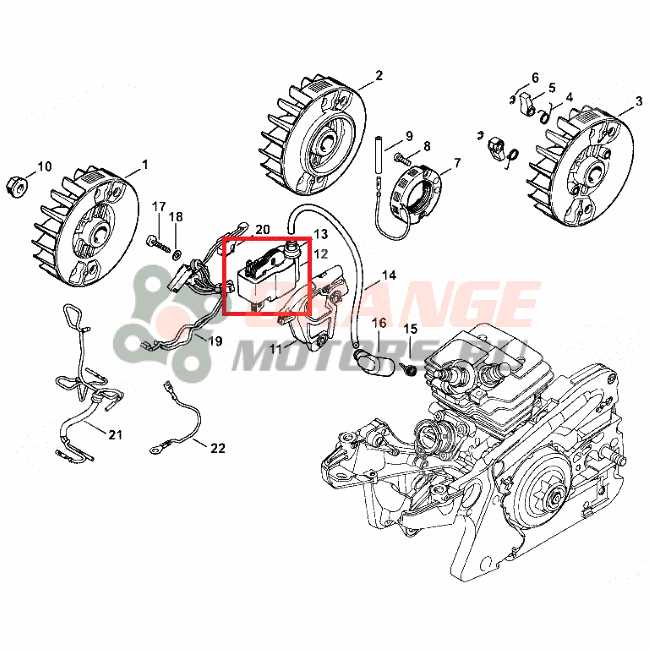

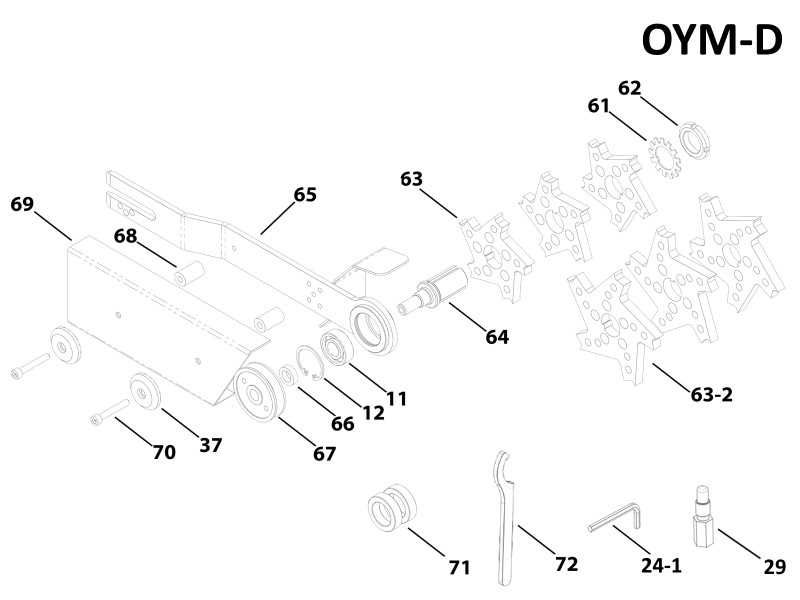

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as guides, allowing users to identify individual elements and their relationships within a system. Familiarizing yourself with these visuals can enhance your troubleshooting skills and improve overall efficiency in managing machinery.

Begin by examining the layout of the illustration. Components are typically arranged in a logical order, often reflecting their physical placement within the equipment. Look for labels that indicate each element; these can include numbers, letters, or specific terminology. Cross-referencing these labels with accompanying documentation can provide additional context and clarify any uncertainties.

Pay attention to the various lines and arrows that connect different parts. These often indicate how components interact or are assembled. Understanding these connections can be crucial for identifying potential issues or planning replacements. It’s also important to note any notes or legends that accompany the visual, as they often contain valuable information about specifications or installation procedures.

Lastly, practice is key. The more you engage with these representations, the more intuitive they will become. Over time, you’ll find it easier to visualize how each part contributes to the overall functionality, leading to more informed decisions during repairs or upgrades.

Maintenance Tips for MS441

Proper upkeep of your equipment ensures optimal performance and longevity. Regular attention to key components not only enhances efficiency but also prevents costly repairs down the line. Adopting a routine maintenance schedule can make a significant difference in the lifespan of your tools.

Here are some essential maintenance practices to consider:

| Task | Frequency | Description |

|---|---|---|

| Chain Lubrication | After every use | Ensure the chain is well-lubricated to reduce wear and improve cutting efficiency. |

| Air Filter Cleaning | Every 5 hours | Clean the air filter to prevent dirt buildup, which can affect engine performance. |

| Spark Plug Inspection | Every 10 hours | Check and replace the spark plug as necessary to ensure reliable starting and combustion. |

| Bar Maintenance | Every 5 hours | Inspect the guide bar for wear and flatten any burrs to maintain proper chain alignment. |

| Fuel System Check | Weekly | Inspect the fuel lines for leaks and replace stale fuel to ensure smooth operation. |

Implementing these practices will help keep your equipment in prime condition, allowing you to work more efficiently and safely.

Upgrades for Enhanced Performance

Improving the efficiency and effectiveness of your machinery can significantly enhance its overall performance. By incorporating various upgrades, users can optimize functionality, extend lifespan, and increase productivity. Below are some key enhancements that can lead to substantial improvements.

| Upgrade | Description | Benefits |

|---|---|---|

| High-Performance Air Filter | Replaces the standard filter to allow for better airflow. | Increased power and fuel efficiency. |

| Premium Spark Plug | Upgraded spark plug for more reliable ignition. | Smoother operation and improved starting. |

| Enhanced Fuel System | Modification of the fuel delivery system for optimal mixture. | Boosted power output and reduced emissions. |

| Vibration Dampening System | Installation of advanced dampeners to reduce vibration. | Increased operator comfort and reduced fatigue. |

| Durable Bar and Chain | Higher quality cutting equipment designed for longevity. | Improved cutting efficiency and reduced downtime. |

By investing in these enhancements, users can experience a noticeable difference in the performance and reliability of their equipment. Each upgrade contributes to a more effective and enjoyable experience, making it a worthwhile consideration for any operator.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment on hand is crucial for achieving effective results. This section outlines the essential tools required for successful repairs, ensuring that you can perform tasks efficiently and safely.

Essential Tools

- Wrenches: A variety of sizes to fit different bolts and nuts.

- Screwdrivers: Both flathead and Phillips for various screws.

- Socket Set: Ideal for loosening or tightening larger fasteners.

- Pliers: Useful for gripping and manipulating components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Additional Equipment

- Safety Gear: Goggles and gloves to protect yourself during repairs.

- Work Surface: A sturdy bench or table to hold parts securely.

- Lubricants: For reducing friction and ensuring smooth operation of moving parts.

- Cleaning Supplies: Brushes and cloths to keep components clean.

Equipping yourself with these tools will facilitate a smoother repair process, minimizing the chances of errors and enhancing your overall efficiency.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both the individual performing the repairs and the equipment itself. By following certain guidelines, one can minimize risks and enhance the overall repair experience.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment, such as gloves and goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Disconnect the power source before beginning any repairs to prevent accidental start-ups.

Additional Tips

- Keep your workspace organized to avoid hazards and ensure you can find tools easily.

- Read the manufacturer’s manual for specific safety instructions related to the equipment.

- Never rush through repairs; take your time to ensure everything is done correctly.