When it comes to maintaining outdoor machinery, having a clear understanding of its structure is essential. A detailed overview of each segment not only facilitates efficient repairs but also enhances the overall lifespan of the equipment. This guide delves into the intricacies of your device, providing valuable insights into its various components.

By familiarizing yourself with the configuration of the internal mechanisms, you can identify potential issues before they escalate. Whether you are a seasoned professional or a DIY enthusiast, knowing how to navigate through the assembly will empower you to tackle maintenance tasks with confidence. Each element plays a critical role in the machine’s functionality, and recognizing their interconnections can lead to more informed decisions during servicing.

Additionally, visual aids can significantly improve your comprehension of the layout. They serve as effective references, making it easier to locate specific elements and understand their purpose within the entire system. Embracing this knowledge not only simplifies repairs but also fosters a deeper appreciation for the engineering behind your equipment.

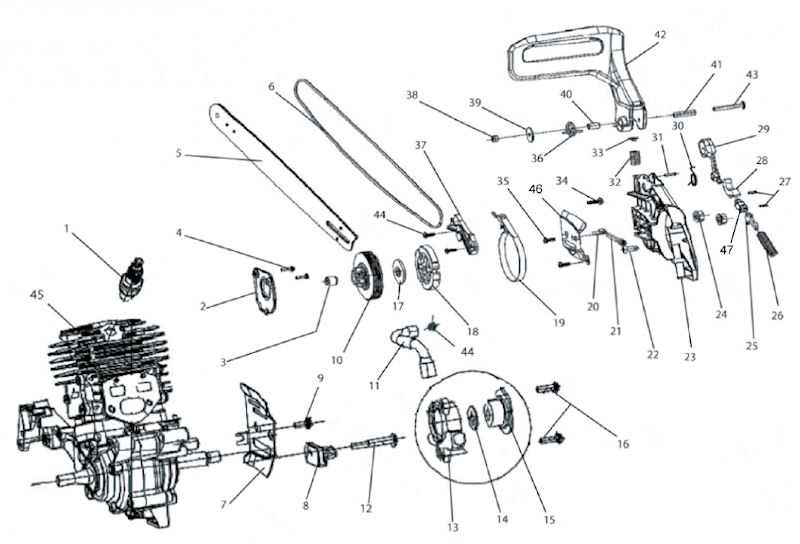

Understanding the Stihl 028 AV Super

This segment explores a well-regarded model in the realm of outdoor power equipment, focusing on its operational features and components. Renowned for its durability and efficiency, this machine has earned a loyal following among both professionals and enthusiasts. Understanding its construction and functionality is essential for effective maintenance and optimal performance.

One of the standout aspects of this model is its vibration reduction system, which enhances user comfort during prolonged use. This feature is particularly beneficial for those who rely on their tools for extended periods, as it minimizes fatigue and strain. Furthermore, the design facilitates easy access to key components, making routine maintenance more manageable.

The engine’s power output is another highlight, providing ample strength for various tasks. Users appreciate its ability to handle demanding jobs while maintaining efficiency. Additionally, the fuel system is designed for optimal performance, ensuring that the machine operates smoothly with minimal interruptions.

In summary, familiarity with this model’s features and mechanics not only aids in ensuring its longevity but also enhances the overall experience for users. Proper understanding contributes to effective troubleshooting and maintenance, ultimately leading to better performance and satisfaction.

Key Features of Stihl 028 AV Super

This section explores the essential characteristics of a renowned chainsaw model, highlighting its advantages and performance attributes. Understanding these features can help users appreciate its design and functionality, ensuring effective usage for various tasks.

Power and Efficiency

The engine delivers impressive power while maintaining fuel efficiency, making it suitable for both professional and personal use. Its robust design ensures reliability even during extended operation, enabling users to tackle challenging jobs with ease.

Vibration Reduction System

Equipped with an advanced vibration damping system, this model minimizes user fatigue during prolonged use. This feature enhances comfort and control, allowing for greater precision and safety in various cutting applications.

Importance of Parts Diagrams

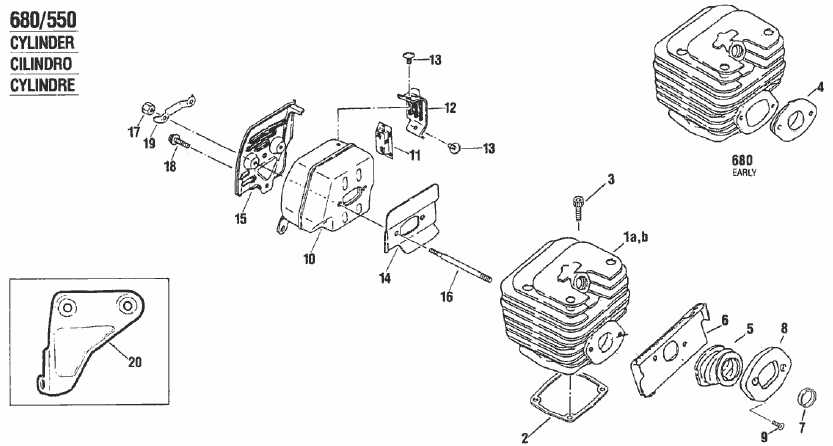

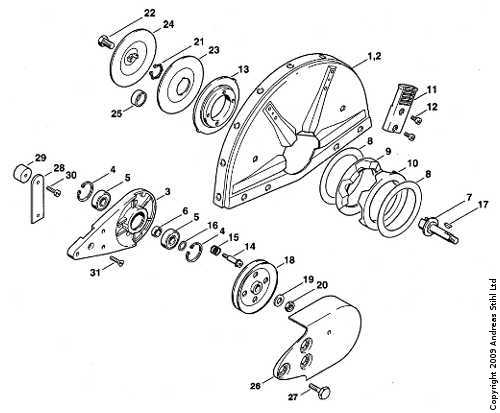

Understanding the intricate details of mechanical assemblies is essential for effective maintenance and repair. Visual representations of components not only simplify the identification of individual elements but also enhance the overall efficiency of restoration processes. Such resources serve as invaluable tools for both professionals and enthusiasts, ensuring accuracy in repairs and modifications.

Facilitating Accurate Repairs

One of the primary benefits of visual representations is their ability to provide clarity. By breaking down complex systems into manageable parts, users can locate specific components quickly. This clarity minimizes errors during assembly and disassembly, allowing for precise repairs that prolong the lifespan of equipment.

Enhancing Understanding of Mechanisms

Beyond practical repairs, these visual guides deepen the user’s comprehension of how different parts interact within a system. By illustrating relationships and functions, they empower users to troubleshoot issues more effectively. This understanding fosters a sense of confidence, enabling individuals to tackle challenges that may arise during maintenance.

Common Issues with Stihl 028 AV Super

Chainsaws are essential tools for many outdoor tasks, but like any machinery, they can encounter various problems over time. Understanding these common issues can help users maintain their equipment effectively and ensure longevity. Below is a summary of frequent challenges faced by users, along with potential solutions.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Problems | Difficulty in starting the engine, often due to fuel or ignition issues. | Check the fuel mixture, inspect the spark plug, and ensure the choke is functioning properly. |

| Overheating | The machine may overheat during use, which can lead to performance issues. | Ensure proper lubrication, clean air filters, and check for blockages in cooling fins. |

| Chain Tension Issues | The cutting chain may become loose or overly tight, affecting efficiency. | Regularly check and adjust the chain tension as needed, following manufacturer guidelines. |

| Fuel Leaks | Leaks can occur in fuel lines, causing safety hazards and performance drops. | Inspect all fuel lines for cracks or damage and replace them as necessary. |

| Excessive Vibration | Increased vibrations during operation can indicate issues with the machine’s components. | Check for loose parts and ensure that the anti-vibration system is functioning correctly. |

Identifying Replacement Parts Easily

Understanding the components of your equipment is crucial for effective maintenance and seamless operation. By familiarizing yourself with the essential elements, you can ensure that you select the correct replacements without unnecessary hassle. This knowledge empowers you to keep your machine in optimal condition for extended use.

Key Components to Recognize

Recognizing key elements can simplify the process of finding suitable replacements. Below is a table highlighting some fundamental components commonly found in various machinery.

| Component | Description |

|---|---|

| Cylinder | Houses the combustion process, integral for engine function. |

| Piston | Moves within the cylinder, converting fuel into mechanical energy. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean airflow. |

| Chain Brake | Enhances safety by stopping the chain quickly during operation. |

Tips for Efficient Identification

To effectively identify the necessary components, consult the user manual or reliable online resources. Familiarizing yourself with diagrams and descriptions can significantly streamline your search, making the replacement process much smoother.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the efficiency and longevity of your equipment. By following systematic care routines, you can enhance performance and minimize the likelihood of issues arising during operation.

Start with routine cleaning to remove debris and prevent buildup, especially in air filters and cooling systems. This not only maintains airflow but also helps the engine run cooler.

Periodic inspections of essential components, such as spark plugs and fuel lines, can identify wear before it leads to significant failures. Replacing these parts as needed will ensure optimal functionality.

Keep an eye on lubrication levels and use the appropriate oil for your machine. Proper lubrication reduces friction, extending the life of moving parts and maintaining efficiency.

Finally, always refer to the manufacturer’s guidelines for specific maintenance intervals and procedures. Adhering to these recommendations can dramatically improve your equipment’s overall performance.

Where to Find Parts Diagrams

Locating detailed schematics for your equipment can significantly streamline maintenance and repair tasks. Whether you’re seeking specific components or trying to understand the assembly of various parts, having access to reliable resources is crucial. There are numerous avenues to explore when searching for these valuable visual aids.

Online Resources

The internet is a treasure trove of information. Numerous websites specialize in offering schematics for a wide range of machinery. Manufacturer websites often provide downloadable manuals that include visual references. Additionally, forums and community websites can be helpful, as experienced users frequently share their insights and resources.

Local Dealerships and Repair Shops

Your local dealer or repair shop can be an excellent source of information. Many establishments keep hard copies of manuals and diagrams for the products they sell and service. Don’t hesitate to ask for assistance; knowledgeable staff can often provide the guidance you need to find the right resources for your equipment.

Benefits of Using Genuine Parts

Choosing authentic components for your equipment is crucial for ensuring optimal performance and longevity. While aftermarket alternatives may seem appealing due to their lower cost, they often fail to meet the same rigorous standards set by manufacturers. This section explores the advantages of utilizing original components, highlighting their impact on efficiency, safety, and overall value.

Quality Assurance

Original components are crafted with precision and undergo extensive testing to meet strict quality guidelines. This ensures a reliable fit and consistent performance, reducing the risk of malfunction. In contrast, counterfeit or generic options may lack the same level of quality control, leading to potential issues and increased maintenance costs.

Enhanced Performance and Longevity

Using genuine components not only enhances the efficiency of your machinery but also extends its operational life. Authentic parts are designed to work harmoniously with the entire system, providing better performance and minimizing wear and tear. Investing in original components ultimately translates to fewer breakdowns and a more dependable experience.

In summary, the benefits of utilizing authentic components significantly outweigh any initial savings offered by alternatives. Prioritizing quality ensures that your equipment remains reliable, safe, and efficient for years to come.