In the realm of outdoor equipment, comprehending the intricate assembly of a chainsaw can significantly enhance its maintenance and performance. This section delves into the essential elements that constitute a specific chainsaw model, providing insights into each component’s function and relevance. Mastery of these details not only aids in effective repairs but also extends the lifespan of the machine.

The visualization of component relationships and functionalities can demystify the inner workings of a chainsaw. Each piece plays a crucial role in ensuring optimal operation, and recognizing how they interconnect can empower users to tackle issues with confidence. By familiarizing oneself with these parts, one can enhance both safety and efficiency during use.

Furthermore, understanding the arrangement and specifications of these elements is invaluable for troubleshooting common problems. A well-informed operator is better equipped to recognize signs of wear and tear, leading to timely interventions. This proactive approach can prevent minor issues from escalating into significant repairs, thereby saving time and resources in the long run.

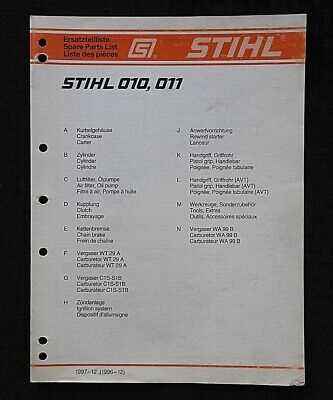

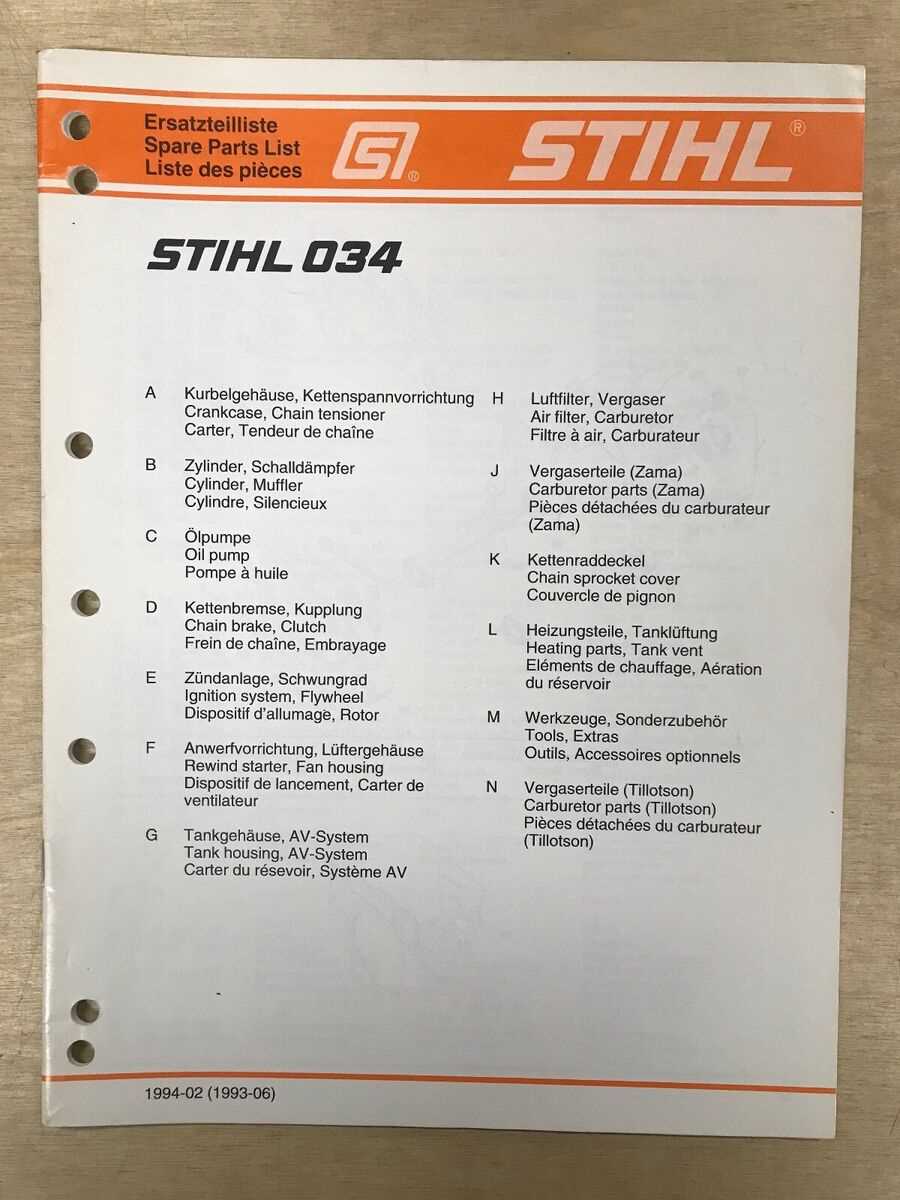

Understanding Stihl 034 AV Super

This section explores a well-regarded model in the world of power tools, known for its robust performance and reliability. Designed for efficiency, it caters to various tasks with ease and precision. Users appreciate its ergonomic design and user-friendly features, making it a preferred choice for both professionals and enthusiasts.

Key Features: The tool boasts a powerful engine, ensuring optimal functionality even in demanding conditions. Its innovative design minimizes vibration, enhancing comfort during prolonged use. The maintenance aspects are also simplified, allowing users to focus more on their work and less on upkeep.

Applications: Ideal for cutting, trimming, and various landscaping tasks, this equipment proves invaluable in both residential and commercial settings. Whether you’re tackling large projects or small jobs, its versatility makes it an essential addition to any toolkit.

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations play a crucial role in this process, allowing users to identify components and their relationships. These illustrations not only facilitate troubleshooting but also enhance the overall efficiency of servicing equipment.

Benefits of Visual Representations

- Streamlined repairs: Quick identification of faulty elements.

- Enhanced learning: Better grasp of machinery layout for beginners.

- Reduced errors: Fewer mistakes during reassembly.

Utilizing Visual Aids Effectively

- Refer to the illustrations regularly during maintenance tasks.

- Compare actual components with the visuals to ensure accuracy.

- Use alongside manuals for comprehensive understanding.

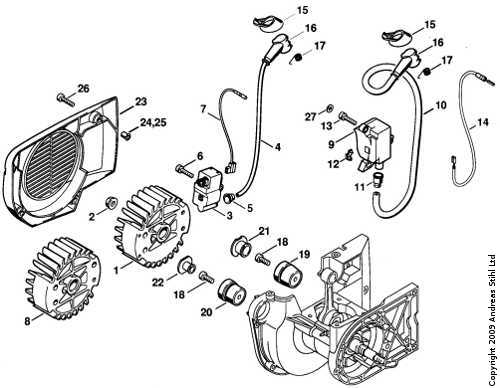

Common Issues with Stihl 034 AV

Various problems can arise with this model that may affect its performance and longevity. Understanding these common concerns is crucial for maintaining optimal functionality and ensuring safe operation.

Fuel Delivery Problems: Clogs in the fuel lines or a faulty filter can lead to insufficient fuel reaching the engine, resulting in poor performance.

Ignition Failures: Defective spark plugs or ignition coils often cause starting issues, making it difficult to ignite the engine.

Chain Tension Issues: Incorrect chain tension can lead to excessive wear, affecting both cutting efficiency and safety.

Vibration and Noise: Excessive vibration during operation may indicate loose components or worn-out parts, which can lead to further damage if not addressed.

Overheating: Inadequate cooling due to blocked air filters or failing cooling fins can result in overheating, posing a risk to the engine’s integrity.

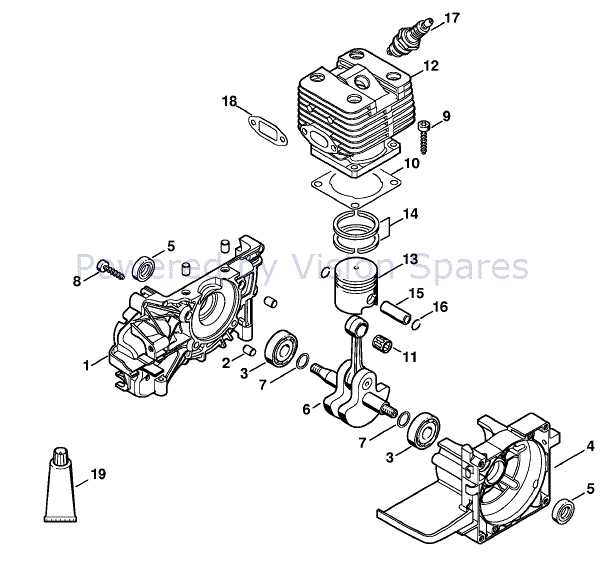

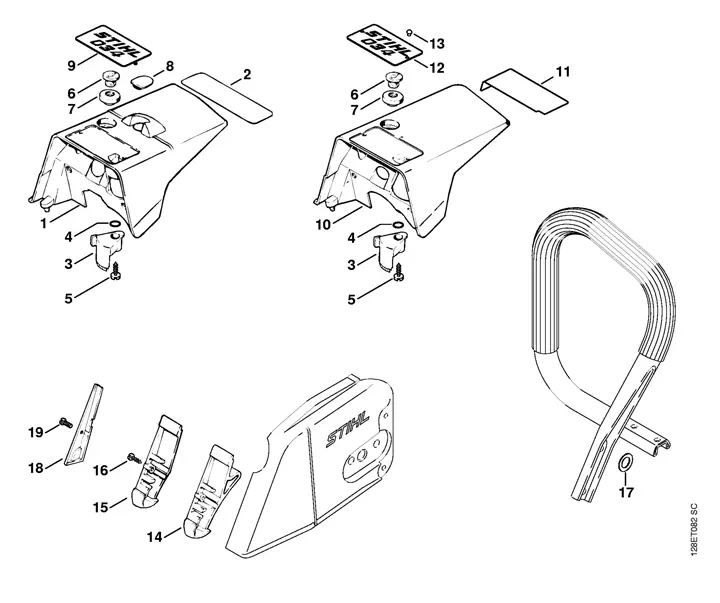

Key Components of the Chainsaw

Understanding the essential elements of a chainsaw is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance, safety, and longevity of the tool. Below are the primary parts that contribute to the functionality of this powerful device.

Essential Elements

- Engine: Provides the necessary power to drive the cutting mechanism.

- Bar: The long metal piece that holds the chain in place.

- Chain: The sharp, linked loop that performs the cutting action.

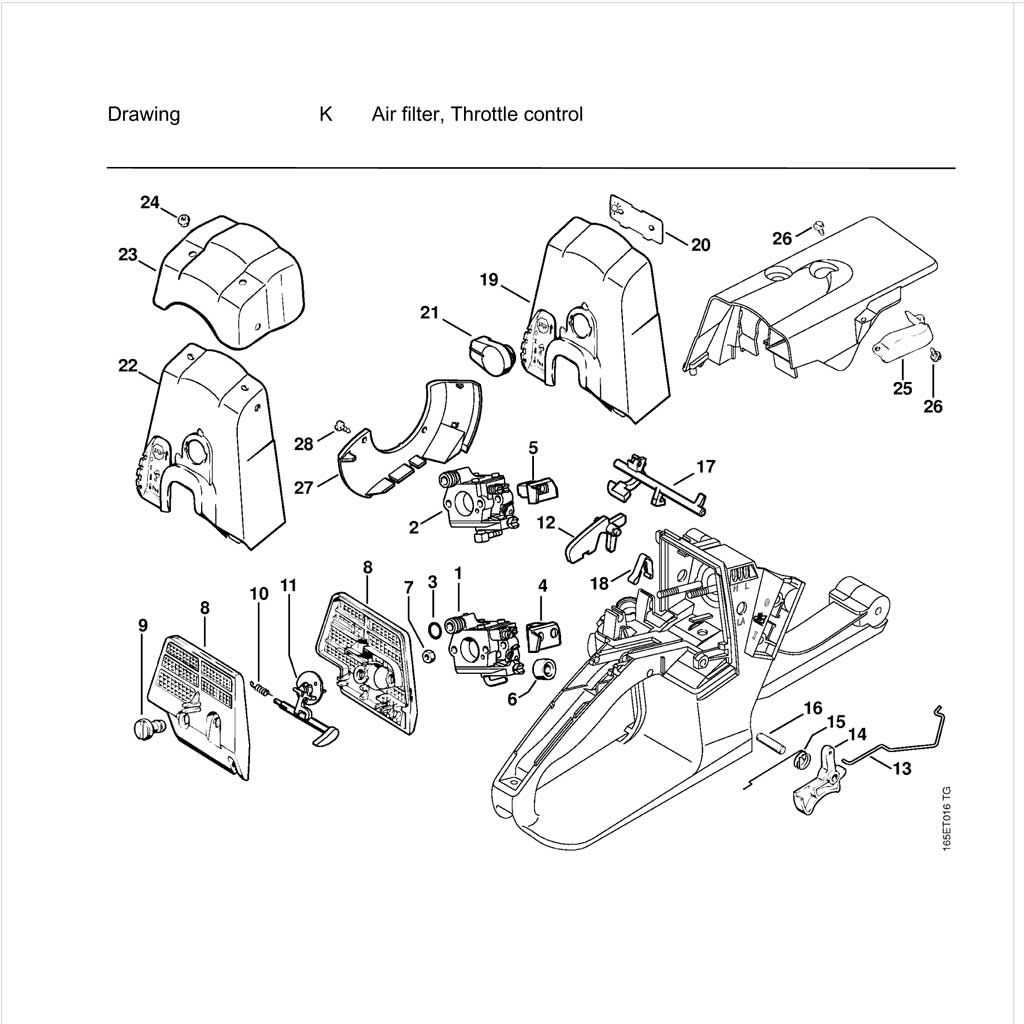

- Throttle: Controls the speed of the engine, allowing for adjustable cutting power.

- Handle: Offers grip and control during operation, ensuring user safety.

Additional Components

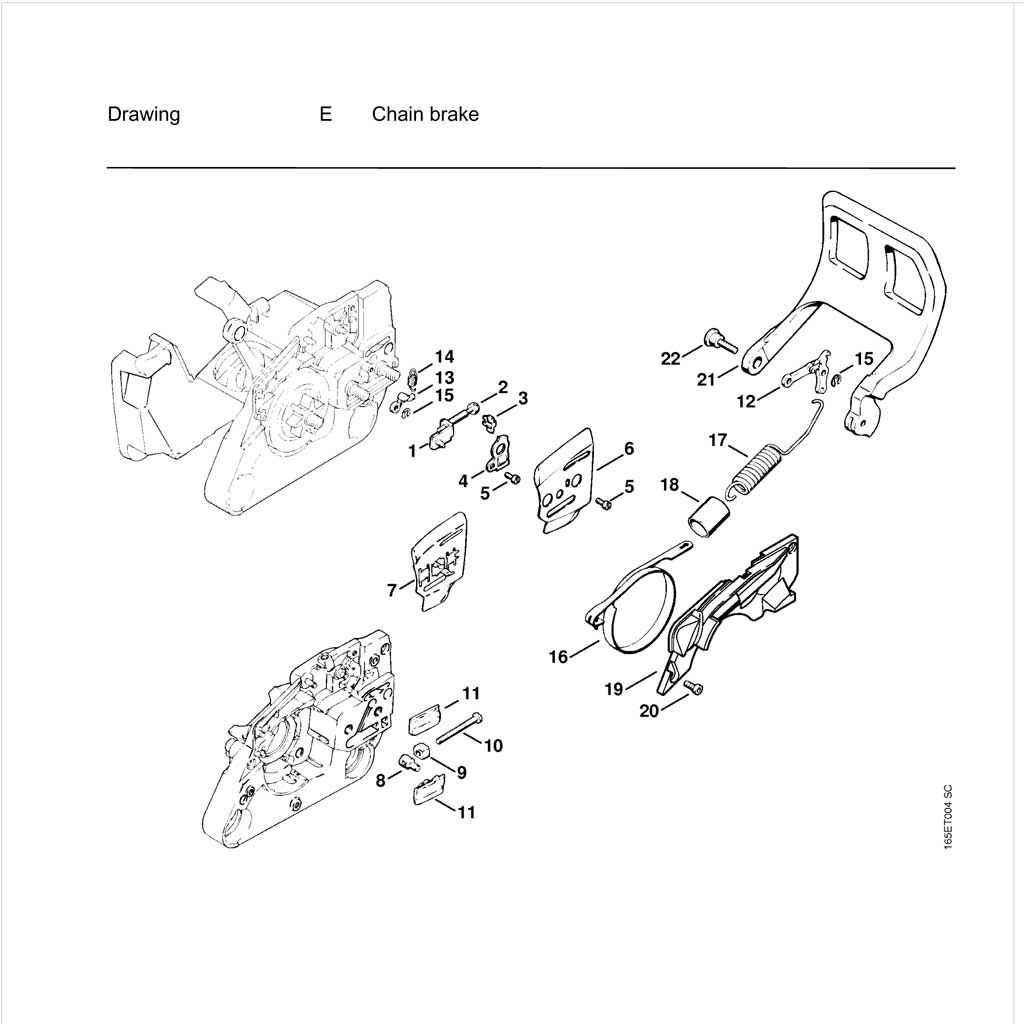

- Chain Brake: A safety feature that stops the chain’s movement in emergencies.

- Fuel Tank: Stores the mixture required to power the engine.

- Air Filter: Keeps debris from entering the engine, ensuring efficient operation.

- Clutch: Engages and disengages the chain from the engine based on throttle input.

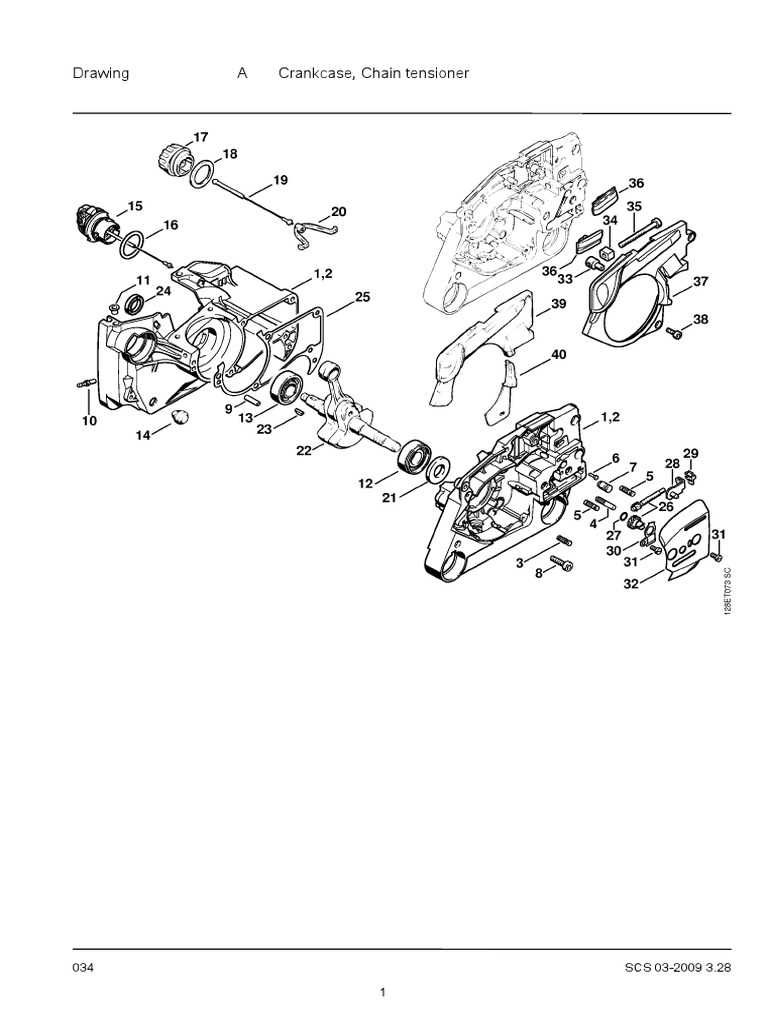

How to Interpret the Diagram

Understanding a technical illustration is essential for effective maintenance and repair of machinery. These visual representations provide a detailed view of components and their relationships, allowing users to identify parts and comprehend assembly processes. By interpreting the layout accurately, one can ensure proper functioning and longevity of the equipment.

Start by familiarizing yourself with the overall layout. Each section is usually organized logically, often grouped by function or location within the device. Look for labels and numbers that indicate specific items, as these often correlate with a corresponding list or key, making it easier to identify the components.

Next, pay attention to the connections between parts. Arrows or lines may illustrate how pieces interact or fit together. This information is crucial for understanding assembly order and ensuring that everything is correctly aligned during reassembly.

Lastly, consult the accompanying documentation for additional details on each component’s specifications and maintenance recommendations. This context can provide insights into how to troubleshoot issues and perform repairs efficiently.

Finding Replacement Parts

When maintaining outdoor power equipment, sourcing components can be a crucial task. Identifying suitable substitutes not only ensures optimal performance but also extends the lifespan of the machine. Whether you’re a seasoned professional or a DIY enthusiast, understanding where to find reliable replacements can make a significant difference.

Authorized Dealers often provide the most dependable options. These retailers specialize in specific brands and are more likely to have authentic components that meet the manufacturer’s standards. Visiting a local dealer allows you to consult with knowledgeable staff who can guide you in selecting the right items.

Online Retailers have become increasingly popular for finding essential components. Various e-commerce platforms offer extensive catalogs, allowing users to compare prices and availability. Ensure that you check the credibility of the seller and read customer reviews to guarantee the quality of the items.

Aftermarket Suppliers can also be a viable option. They produce alternatives that may offer similar functionality at a lower cost. However, it’s essential to evaluate the quality and compatibility of these components with your equipment to avoid potential issues.

Lastly, joining Community Forums or groups dedicated to outdoor equipment can provide invaluable insights. Enthusiasts often share their experiences and recommendations, helping others find reliable sources for their replacement needs.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its long-lasting performance and reliability. Regular maintenance not only enhances functionality but also prevents costly repairs and extends the overall lifespan. By following a few simple guidelines, you can keep your machine operating efficiently for years to come.

Regular Cleaning

Keep your tools free from debris and dirt. After each use, take the time to clean any buildup of dust, grass, or other materials. This practice helps prevent overheating and maintains optimal performance. Use a soft brush or cloth to gently wipe down surfaces, paying close attention to air filters and vents.

Routine Inspections and Lubrication

Conduct regular inspections to identify any signs of wear or damage. Check components such as the chain, guide bar, and spark plug. Replacing worn parts promptly can prevent further issues. Additionally, ensure that all moving parts are properly lubricated; this reduces friction and prolongs the life of your machinery. Following the manufacturer’s recommendations for lubricants and maintenance schedules is crucial for achieving the best results.

DIY Repair Steps Explained

Repairing outdoor equipment can be a rewarding challenge that enhances both your skills and understanding of the machinery. This guide outlines essential steps to troubleshoot and fix common issues, empowering you to tackle repairs confidently and efficiently.

Assessment and Preparation

Begin by evaluating the device to identify the problem. Gather the necessary tools and safety gear to ensure a smooth repair process. Taking notes on the initial condition and symptoms will aid in diagnosing the issue accurately.

Disassembly and Inspection

Carefully disassemble the components, keeping track of screws and small parts. Inspect each element for wear, damage, or blockages. This detailed examination will help you determine the ultimate solution for restoring functionality.

Where to Purchase Authentic Parts

Finding reliable components for your equipment is essential for maintaining optimal performance and longevity. Numerous sources offer genuine items that ensure compatibility and durability, preventing potential issues from substandard alternatives.

Authorized Dealers: Visiting an official retailer guarantees access to original items and expert advice tailored to your needs. These dealers often have comprehensive inventories and can assist with specific queries.

Online Marketplaces: Reputable e-commerce platforms provide a wide selection of components. Always check for verified sellers to ensure authenticity and read reviews to gauge reliability.

Manufacturer’s Website: The best place to obtain original components directly from the source. Many manufacturers feature online shops or provide lists of certified distributors for easy access.

Local Repair Shops: Connecting with nearby service providers can also yield authentic components. Many shops maintain partnerships with manufacturers, ensuring they can source genuine items quickly.