When it comes to maintaining your garden, having a reliable tool is essential. A telescopic pruner is designed to help you reach those hard-to-access branches with ease. Understanding the intricate layout of its components can greatly enhance your experience and efficiency in the garden.

Each segment of this versatile tool plays a crucial role in its overall functionality. From the handle to the cutting mechanism, every part is engineered to work seamlessly together. Familiarizing yourself with these elements not only aids in effective usage but also simplifies the process of troubleshooting and maintenance.

In this section, we will explore the various elements of a telescopic pruner, providing insight into their arrangement and function. By gaining a deeper understanding of how these components interact, you can ensure optimal performance and longevity of your gardening equipment.

Understanding the Stihl HT 135

This section delves into the essential features and functionality of a popular tool designed for elevated pruning tasks. Its design emphasizes user comfort and operational efficiency, making it a preferred choice among both professionals and enthusiasts.

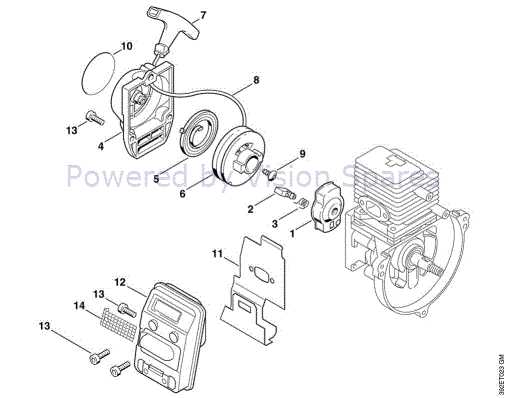

One of the key aspects of this equipment is its robust engine, which ensures reliable power output for various cutting applications. The combination of lightweight construction and ergonomic design allows users to handle the tool with ease, even during extended use.

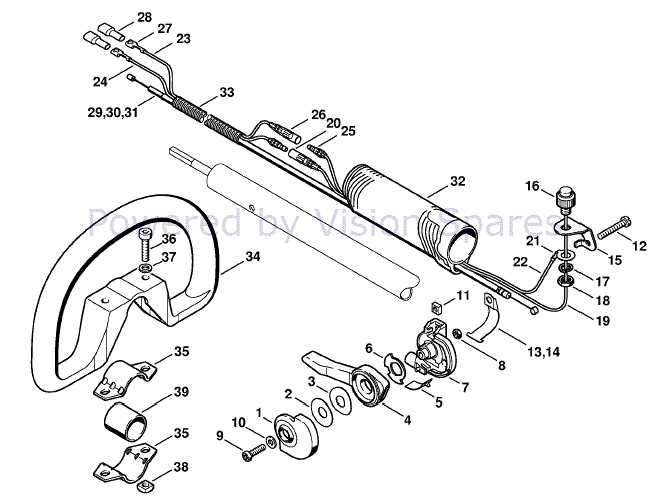

Another significant feature is the adjustable telescoping pole, which enables users to reach greater heights without compromising stability. This functionality is particularly beneficial for accessing hard-to-reach branches, ensuring that tree maintenance can be performed safely and effectively.

In terms of maintenance, understanding the individual components and their functions is crucial for optimal performance. Regular inspections and servicing can prolong the lifespan of the equipment, ensuring it remains a reliable asset for any outdoor project.

Overall, grasping the nuances of this specific tool enhances the user experience, promoting both efficiency and safety while tackling various gardening and landscaping tasks.

Components Overview of HT 135

This section provides a detailed look at the essential elements that contribute to the functionality of the pruning tool. Understanding these components is vital for effective maintenance and optimal performance, ensuring the device operates smoothly during use.

Main Components

The primary parts of this device are designed to enhance efficiency and user comfort. Key elements include the power unit, cutting attachment, and control mechanisms, each playing a crucial role in the overall operation.

Technical Specifications

Below is a summary of the main technical specifications relevant to the functioning of the device:

| Component | Description |

|---|---|

| Engine | Provides the necessary power for cutting operations. |

| Bar | Guides the cutting tool, ensuring precision and stability. |

| Cutting Head | Houses the cutting blade, essential for pruning tasks. |

| Handle | Ergonomically designed for comfort and control during operation. |

| Fuel Tank | Stores the fuel necessary for the engine to operate. |

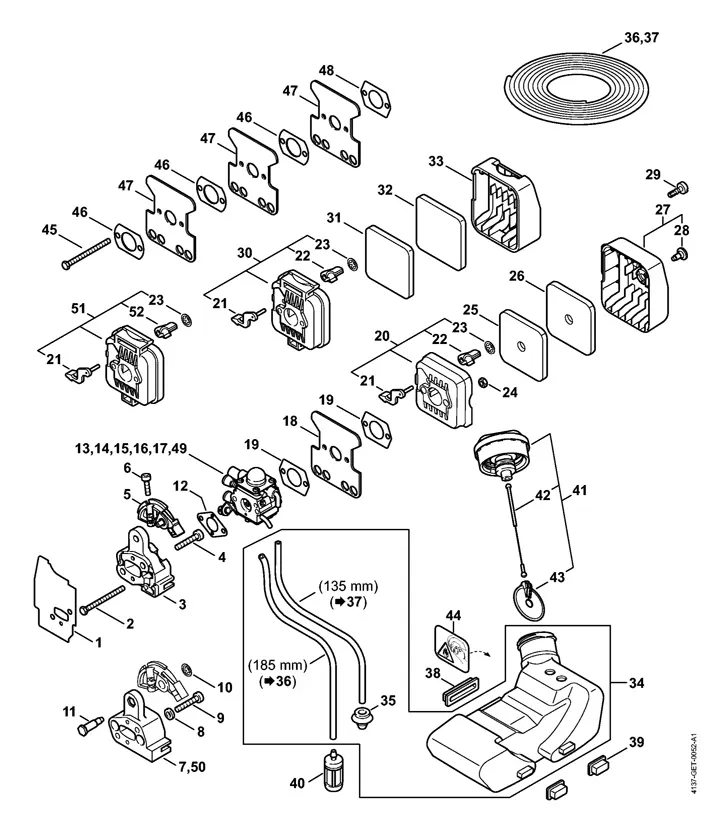

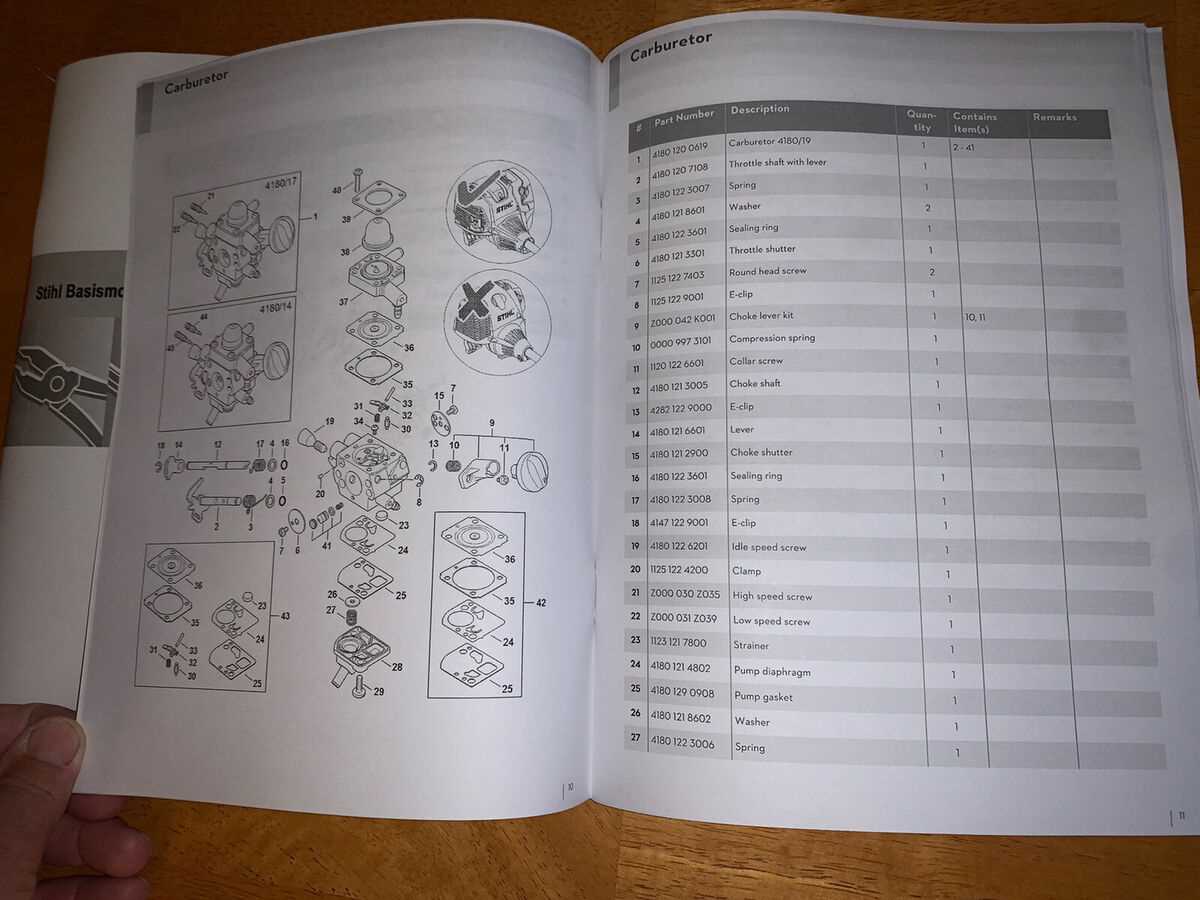

Importance of Parts Diagrams

Visual representations of component layouts play a crucial role in understanding machinery. They provide an organized view that helps users identify individual elements, facilitating both maintenance and repair processes. By simplifying complex assemblies into comprehensible formats, these illustrations enhance efficiency and reduce the likelihood of errors.

Benefits of Visual Guides

- Enhanced Understanding: Clear depictions allow users to quickly grasp the structure and function of various elements.

- Efficient Repairs: Knowing the exact placement and relationship of components streamlines troubleshooting efforts.

- Reduced Downtime: Quick access to necessary information minimizes the time spent searching for solutions.

- Improved Safety: Understanding how parts fit together helps prevent accidents during assembly or disassembly.

Applications in Maintenance

- Routine Checkups: Regular inspections become easier when users can identify key components at a glance.

- Replacement Procedures: Knowing which parts to remove and replace ensures a smooth workflow during maintenance tasks.

- Upgrades: Visual aids assist in determining compatibility and positioning for new components.

In conclusion, these visual tools are indispensable for anyone involved in the upkeep or modification of machinery, providing clarity and guidance throughout the entire process.

How to Read Parts Diagrams

Understanding component illustrations is essential for efficient maintenance and repairs. These visual aids provide a clear overview of how various elements fit together and operate within a machine. By mastering the art of reading these representations, you can streamline your repair process and ensure accuracy in part identification.

Key Elements to Observe

- Labels: Pay attention to the annotations that identify each element.

- Numbering: Components are often numbered for easy reference in accompanying manuals.

- Connections: Look for lines that indicate how parts interact or connect with one another.

Steps for Effective Reading

- Start by familiarizing yourself with the overall layout of the illustration.

- Identify the main components and their corresponding labels.

- Cross-reference the illustration with the parts list to verify details.

- Make notes on any parts that require replacement or maintenance.

Common Issues and Solutions

When operating a cutting tool, users often encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their remedies can enhance the overall experience and prolong the equipment’s lifespan.

One frequent issue is the tool’s difficulty in starting. This may result from stale fuel or a clogged air filter. Regular maintenance, including replacing fuel and cleaning filters, can significantly improve ignition reliability.

Another common concern involves the cutting mechanism not functioning effectively. Dull blades or improper tension can lead to subpar cutting performance. Ensuring blades are sharp and correctly adjusted can help restore optimal operation.

Users might also experience overheating, often caused by prolonged use without adequate breaks. Allowing the tool to cool down during operation intervals can prevent damage and enhance performance.

Finally, frequent vibrations can indicate loose components or worn parts. Regular inspections and timely replacements are essential to maintain stability and ensure safe usage.

Maintenance Tips for HT 135

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. Regular maintenance not only enhances performance but also prevents potential issues that can arise from neglect. Following a structured maintenance routine can save time and money in the long run.

Here are some key maintenance practices to keep your tool in top condition:

- Regular Cleaning:

Remove debris and dirt after each use. Pay special attention to air filters and cutting components.

- Inspect the Cutting Head:

Check for wear and damage. Replace any worn or damaged parts to maintain cutting efficiency.

- Lubrication:

Apply appropriate lubricants to moving parts as recommended by the manufacturer. This helps reduce friction and wear.

- Fuel Quality:

Use fresh, high-quality fuel. Stale or contaminated fuel can cause performance issues and engine damage.

- Regularly Check Spark Plug:

Inspect for signs of wear or fouling. Replace it if necessary to ensure reliable ignition.

- Storage Practices:

Store in a dry, cool place. Before long-term storage, empty the fuel tank and clean the unit thoroughly.

By adhering to these maintenance tips, you can significantly extend the lifespan of your equipment and enhance its performance, ensuring that it operates smoothly whenever needed.

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing quality components is essential for optimal performance. There are several avenues to explore when looking for reliable replacements, ensuring that your tools remain in top condition.

Authorized Dealers

One of the most dependable options is to visit authorized retailers. They offer:

- Genuine components that meet manufacturer specifications

- Expert advice from knowledgeable staff

- Warranty coverage on items purchased

Online Marketplaces

The internet provides a wealth of resources for obtaining necessary items. Consider the following:

- Specialized websites dedicated to outdoor equipment

- Major e-commerce platforms with extensive inventories

- Forums and community groups where users sell or trade components

By exploring these options, you can find the right replacements to keep your machinery running smoothly.

Comparing HT 135 with Other Models

This section explores the key distinctions between a specific model and its contemporaries in the same category. By examining various features, performance metrics, and user experiences, we aim to provide a clearer understanding of how these tools stack up against each other.

Performance Comparison

- Power Output: Assessing engine strength across models.

- Cutting Efficiency: Evaluating the ability to handle different vegetation types.

- Weight and Balance: Understanding how ergonomics influence user experience.

Feature Analysis

- Adjustability: Examining how various options cater to different user needs.

- Maintenance Requirements: Comparing upkeep demands for longevity.

- Accessories Compatibility: Identifying which tools enhance functionality.

User Experiences and Reviews

This section delves into the feedback and insights shared by individuals who have utilized the tool, focusing on their personal encounters, satisfaction levels, and suggestions for improvement. These testimonials provide valuable information for prospective users, helping them make informed decisions based on real-life experiences.

Positive Feedback

- Performance: Many users highlight the exceptional performance, noting its efficiency in handling various tasks.

- Ease of Use: Several reviews commend the user-friendly design, making it accessible for both beginners and experienced operators.

- Durability: Customers often mention the robust construction, stating that it withstands rigorous use without compromising quality.

Areas for Improvement

- Weight: Some individuals find the tool a bit heavy for extended use, suggesting a need for a lighter model.

- Noise Level: A few users express concerns about the noise produced during operation, recommending quieter alternatives.

- Maintenance: While generally satisfied, some have noted that regular upkeep can be cumbersome, urging for more user-friendly maintenance options.

Overall, the feedback illustrates a well-rounded perspective, emphasizing both strengths and potential enhancements, making it a helpful resource for those considering a purchase.