The efficiency of agricultural machinery plays a crucial role in modern farming practices. A thorough understanding of the various elements that comprise these machines is essential for optimal performance and maintenance. This section delves into the intricate details of a specific model that exemplifies this type of equipment, focusing on its essential components and their functions.

Farmers and technicians alike benefit from a comprehensive overview of the internal mechanisms and attachments of this equipment. By exploring the assembly and arrangement of its elements, users can enhance their operational knowledge, ensuring that the machinery operates smoothly and effectively. This understanding is vital for troubleshooting and making informed decisions regarding repairs and upgrades.

In this discussion, we will examine the various sections and features that make up this agricultural device. A detailed breakdown of its individual components will provide clarity on their roles and significance in the overall functionality of the machine. By familiarizing oneself with these aspects, one can achieve better results and maintain productivity in agricultural endeavors.

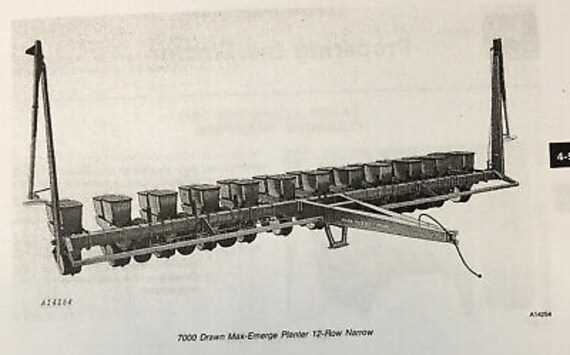

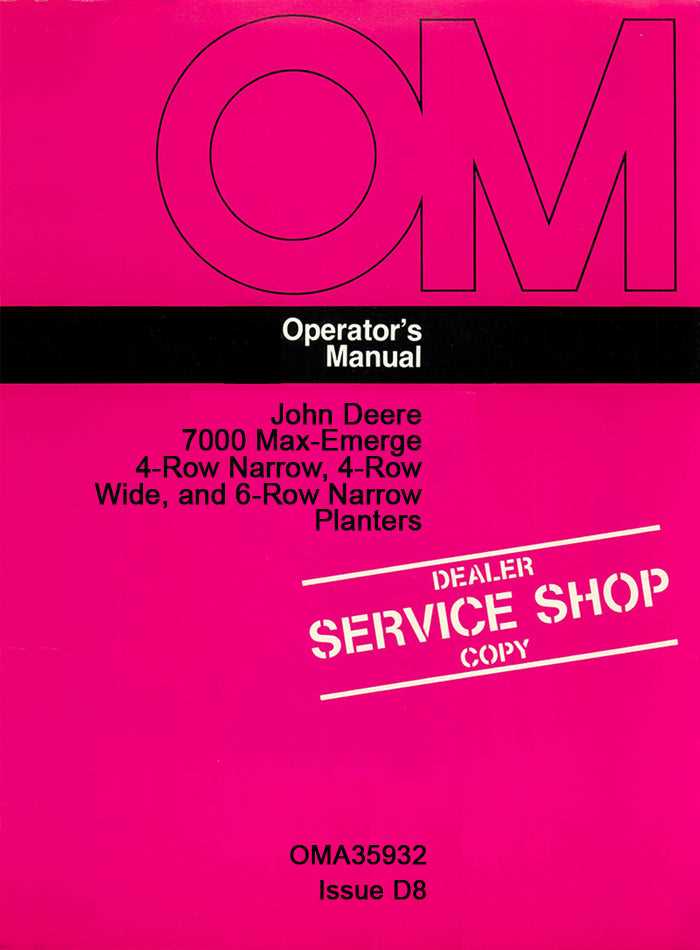

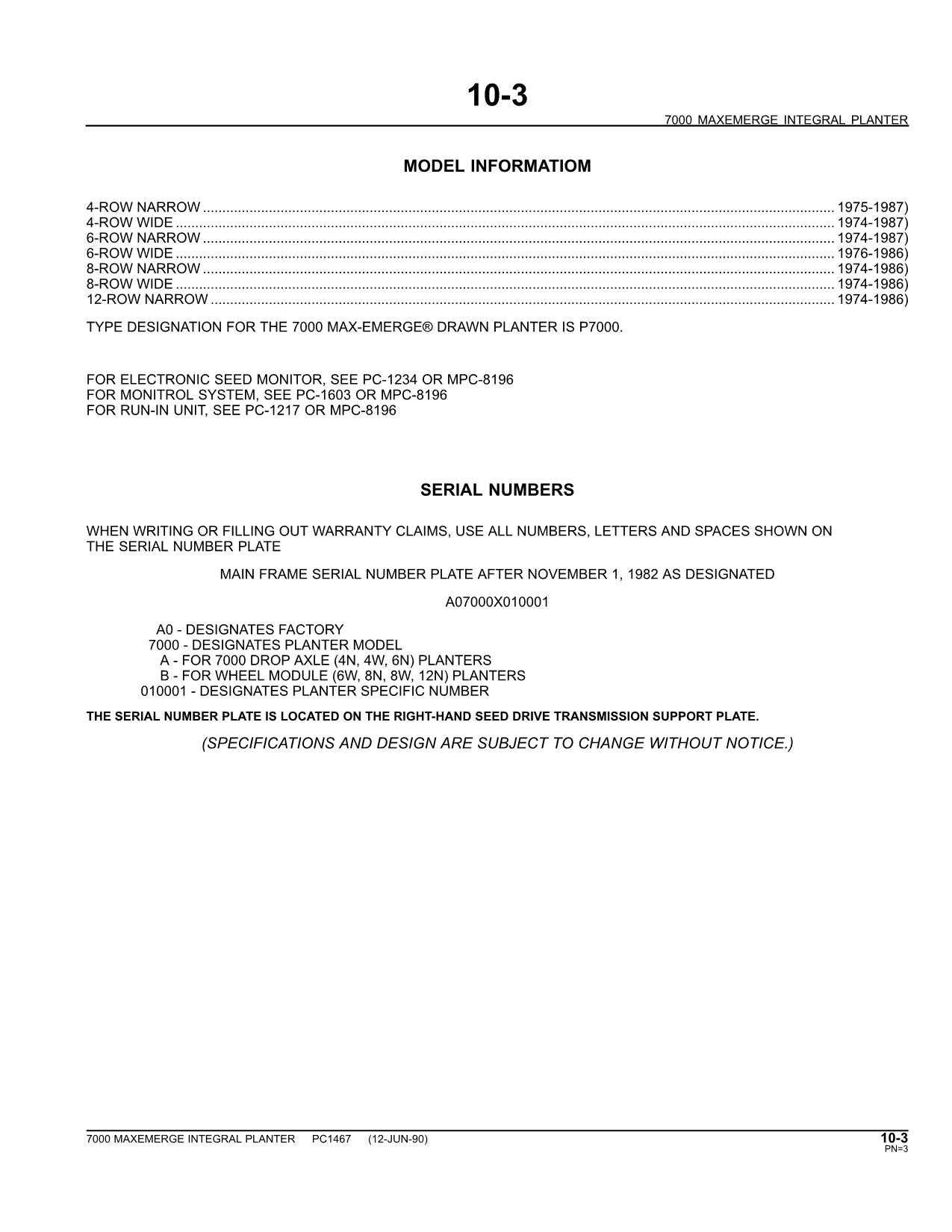

Overview of John Deere 7000 Planter

This section provides a comprehensive look at a well-regarded agricultural machine designed for efficient seed planting. It highlights the essential features, functionality, and benefits that contribute to its popularity among farmers. With its robust construction and innovative design, this equipment ensures effective planting across various field conditions.

Key Features

The machinery is known for its reliability and adaptability, making it suitable for diverse farming practices. It offers advanced features that enhance performance and ease of use, catering to the needs of modern agriculture.

| Feature | Description |

|---|---|

| Durability | Constructed with high-quality materials to withstand tough field conditions. |

| Precision | Equipped with technology that ensures accurate seed placement. |

| Versatility | Compatible with various crops, adapting to different planting requirements. |

| User-friendly | Designed for ease of operation, reducing the learning curve for new users. |

Benefits of Using This Equipment

Employing this agricultural machine leads to improved efficiency in planting processes, resulting in higher yields. Farmers appreciate the reduction in labor costs and the enhancement in crop management capabilities, making it a valuable asset in any farming operation.

Key Features of the 7000 Series

The 7000 Series is renowned for its exceptional design and functionality, making it a standout in the agricultural sector. This lineup incorporates advanced technology and innovative features that enhance efficiency and productivity in crop management.

Precision Engineering: Each model is crafted with meticulous attention to detail, ensuring reliable performance and longevity in various field conditions.

Versatile Adjustability: The equipment offers a range of settings that allow users to customize operations according to specific crop needs and soil types.

User-Friendly Interface: Operators benefit from intuitive controls and clear displays, making it easier to monitor and manage planting activities.

Durability: Built with robust materials, the series withstands harsh environments, ensuring sustained performance over time.

Enhanced Seed Placement: Innovative mechanisms allow for precise seed distribution, optimizing germination rates and crop yields.

Understanding Planter Parts and Functions

Grasping the components and their roles in agricultural machinery is essential for optimizing performance and efficiency. Each element contributes uniquely to the overall process, ensuring effective planting and cultivation. A clear comprehension of these mechanisms enables better maintenance and improved productivity.

The primary mechanism responsible for soil engagement allows for precise seed placement at optimal depths. This ensures that seeds are adequately covered and receive the necessary moisture and nutrients for germination. Additionally, the structure that facilitates seed delivery plays a crucial role in maintaining consistent spacing, which is vital for crop development.

Another important feature is the adjustable element that controls downforce, which ensures that the machinery operates effectively across varying soil types and conditions. Proper adjustment is key to achieving the desired planting depth while minimizing soil disturbance.

Lastly, understanding the role of the monitoring systems is crucial, as they provide real-time feedback on seed flow and overall operation, allowing for timely adjustments. This integration of technology enhances the capability of modern agricultural tools, paving the way for more efficient farming practices.

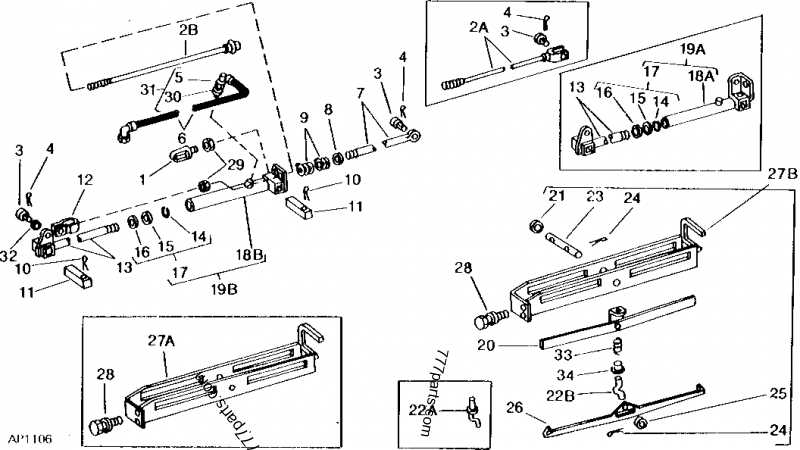

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements provide invaluable insights into their arrangement and function. They enable users to identify specific segments, understand their roles, and ensure that everything operates efficiently. By utilizing these illustrations, operators can streamline troubleshooting processes and enhance the longevity of their equipment.

These schematics serve as essential references during repairs and upgrades. They break down complex systems into manageable sections, allowing users to grasp intricate details that may not be immediately apparent. Furthermore, they facilitate communication between technicians and engineers, ensuring that everyone involved has a clear understanding of the machine’s structure.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids simplify complex systems, making it easier to locate and understand various components. |

| Efficient Troubleshooting | Quick identification of faulty parts allows for faster repairs, minimizing downtime. |

| Improved Communication | Shared visual references foster better dialogue among team members during repairs. |

| Long-Term Maintenance | Understanding component roles helps in planning regular upkeep, extending the machine’s lifespan. |

In summary, these visual representations are vital tools for anyone involved in the upkeep of machinery. They not only enhance understanding but also contribute to more efficient and effective maintenance practices.

Common Issues with 7000 Planters

Farm machinery is essential for efficient agricultural practices, but it can encounter various challenges that affect performance and productivity. Understanding these issues helps in identifying solutions and ensuring optimal operation. Common problems arise from mechanical failures, wear and tear, and improper adjustments, leading to decreased planting accuracy and efficiency.

Mechanical Failures

One of the primary concerns is mechanical breakdowns, which can stem from numerous factors, including inadequate maintenance and faulty components. For instance, worn-out bearings or defective seed meters can significantly impact planting precision. Regular inspections and timely replacements are vital in mitigating these issues and enhancing overall functionality.

Calibration and Adjustment Issues

Improper calibration is another frequent problem that can lead to uneven seed distribution. If the equipment settings are not aligned with the specific crop requirements, it may result in over-planting or under-planting. Regular adjustments based on field conditions and thorough calibration checks are crucial to achieving desired planting outcomes.

Where to Find Replacement Parts

When it comes to maintaining agricultural machinery, sourcing the right components is essential for ensuring optimal performance. Finding suitable replacements can significantly enhance the lifespan and efficiency of your equipment, leading to better yields and reduced downtime.

Online Marketplaces are a great resource for locating various components. Websites specializing in agricultural equipment often have extensive catalogs, making it easier to compare prices and availability. Additionally, some platforms allow users to connect directly with suppliers, facilitating negotiations and bulk purchases.

Local Dealerships should not be overlooked. These establishments typically stock genuine items and can provide valuable insights into compatibility and performance. Building a relationship with local dealers can also lead to personalized service and support when navigating through replacement options.

Salvage Yards can be an excellent alternative for those seeking cost-effective solutions. Many yards specialize in used machinery, offering a variety of components at reduced prices. Although quality may vary, with some diligence, you can often find high-quality items that have plenty of life left in them.

Manufacturer Websites are another reliable source. They often provide detailed information about available components, including specifications and installation guidelines. Directly purchasing from the manufacturer ensures that you are acquiring authentic products that meet the necessary standards for your equipment.

Online Forums and Communities can also be helpful. Engaging with fellow enthusiasts and professionals allows you to gather recommendations and insights on where to find specific components. Often, community members share links to reputable suppliers or even post about surplus items they are willing to sell.

In summary, a combination of online resources, local suppliers, and community engagement can effectively guide you in your search for replacement components, ensuring your machinery continues to operate efficiently.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of agricultural equipment requires regular attention and care. Proper upkeep not only enhances performance but also prevents costly repairs and downtime during critical periods. By following a few key strategies, operators can maintain their machinery in peak condition and achieve the best possible results in their operations.

Firstly, it is essential to conduct routine inspections. Regularly check all components for wear and tear, including seals, bearings, and hydraulic systems. Identifying issues early can prevent more significant problems from developing. Additionally, maintaining cleanliness is crucial; dirt and debris can lead to premature wear and malfunctions.

Another vital aspect is lubrication. Ensuring that all moving parts are adequately lubricated reduces friction and wear, extending the life of the machinery. Always use the recommended lubricants and follow the manufacturer’s guidelines regarding intervals and quantities.

Moreover, calibration of the equipment should not be overlooked. Regularly adjusting settings based on specific crop requirements ensures optimal planting depth and spacing. This practice not only improves yield but also enhances overall efficiency.

Lastly, keeping accurate records of maintenance activities and any repairs performed helps in tracking performance trends and anticipating future needs. This proactive approach can significantly reduce unexpected failures and improve operational reliability.

Comparing 7000 with Other Models

When evaluating agricultural equipment, it’s essential to understand how various models stack up against each other. This section delves into the features and functionalities of a specific model in comparison to its contemporaries, highlighting their strengths and weaknesses.

Performance: The examined machine is known for its reliability and efficiency in the field. When contrasted with alternative options, its design often allows for greater ease of use and reduced maintenance requirements. Other models may offer advanced technology but can fall short in overall dependability.

Capacity: While some alternatives boast higher planting capacities, this particular model excels in versatility, making it suitable for a wider range of crops. Its adaptability is often favored by farmers who manage diverse agricultural practices.

Cost-effectiveness: Pricing can significantly influence the decision-making process. The analyzed machine typically presents a competitive price point, especially when considering its longevity and low operational costs. In contrast, some rival products, though initially appealing, may incur higher expenses over time.

User Experience: Operators frequently praise the intuitive design of this model, which facilitates a more straightforward setup and operation. While some competing devices may feature more complex interfaces, this simplicity can lead to improved productivity in the field.

In summary, while there are various options available, this model stands out in terms of reliability, versatility, and user-friendliness, making it a valuable choice for many agricultural professionals.