When it comes to maintaining and repairing machinery, having a clear understanding of the individual elements is crucial. A detailed overview of all the key components can help ensure smooth operation and longevity of the equipment. This information is essential for both troubleshooting and effective repairs.

Knowing how each part works in relation to others allows for efficient diagnostics. A clear representation of the assembly helps in identifying potential issues before they become major problems. Whether you’re a professional or a DIY enthusiast, visualizing the internal layout aids in quicker, more accurate fixes.

Having a visual guide to follow while working on your machine can significantly reduce the complexity of repairs. It simplifies the process of locating parts and understanding their functions, making your maintenance tasks more efficient and manageable.

Overview of Components for the John Deere 325

In this section, we delve into the essential elements that compose the machinery known as the John Deere 325. Explore the fundamental constituents that form the operational framework of this equipment, offering a comprehensive understanding of its structural composition.

- Key components that contribute to the operational efficiency and durability of the machinery.

- Primary elements crucial for the proper functioning and performance of the equipment.

- Integral parts essential for the seamless integration and cohesive operation of the system.

- Vital elements that sustain the reliability and longevity of the machinery over extended periods.

- Essential modules that facilitate the effective execution of tasks and operations within various environments.

This overview provides insight into the core components that define the functionality and reliability of the John Deere 325, offering a foundational understanding of its mechanical framework.

Key Components of the John Deere 325

In this section, we explore the essential elements that comprise the core functionality of the John Deere 325.

We delve into the fundamental components that contribute to the operational prowess of this machinery, focusing on its integral parts that ensure optimal performance and reliability.

These critical elements form the backbone of the John Deere 325, supporting its ability to tackle diverse tasks with efficiency and precision.

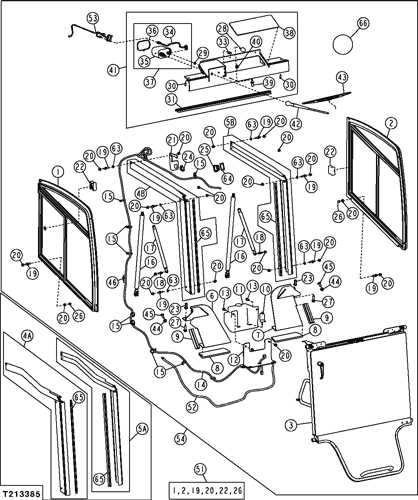

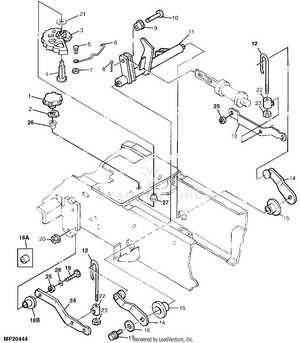

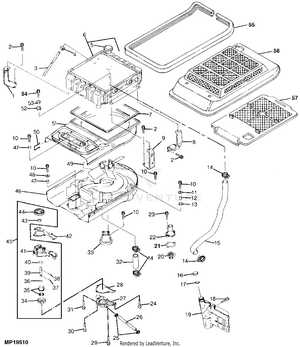

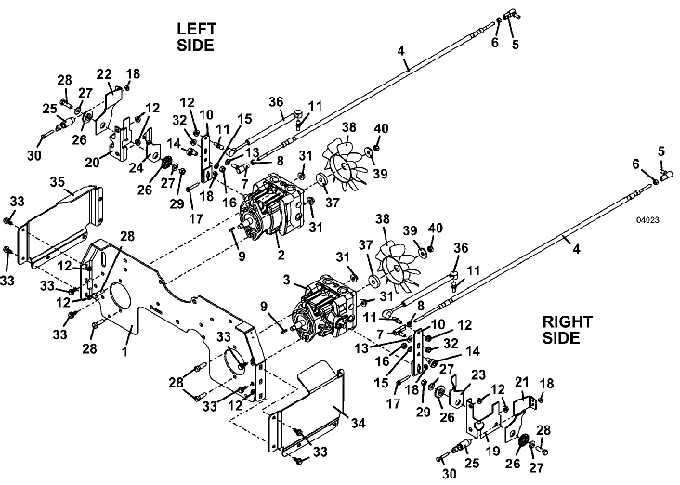

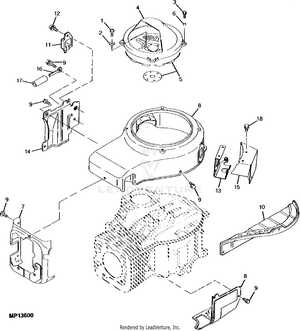

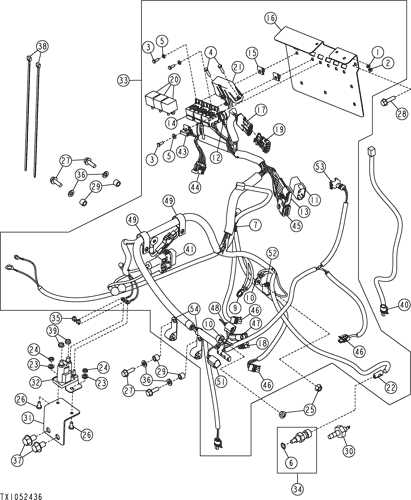

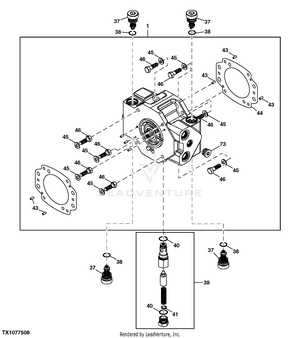

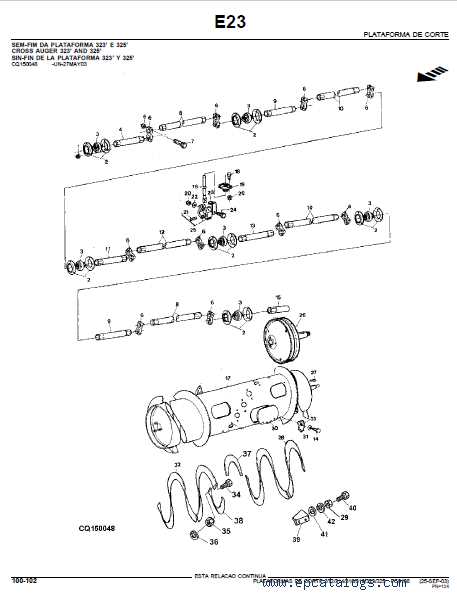

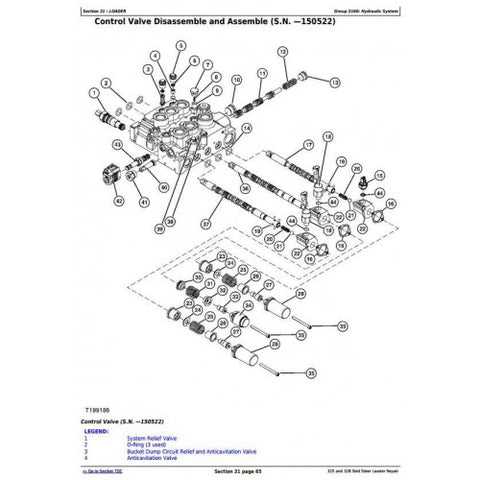

How to Interpret a Parts Diagram

Understanding technical illustrations that depict the components of a machine is crucial for efficient repair and maintenance. These visual guides provide an organized view of the individual elements, helping users identify specific pieces and their relationships within the assembly. The key is to recognize how these visual representations translate into physical parts and the steps required to service them properly.

Key Features to Focus On

- Labels and Numbers: Each part is typically numbered, with corresponding references to help you identify specific components.

- Symmetry and Groupings: Parts are often grouped to show how they interact or are mounted together, offering a clearer view of their function.

- Color Coding: In some diagrams, different colors indicate various part categories, such as electrical or mechanical components.

Steps to Use the Diagram Effectively

- Start by identifying the area of interest in the illustration. Focus on the section that corresponds to the issue you’re addressing.

- Match the numbers or labels in the diagram to the parts in your inventory or on the machine.

- Check for additional details, such as connections or dependencies between the parts, to ensure the assembly process is clear.

Essential Tools for John Deere Repairs

Having the right tools is crucial for maintaining and fixing heavy-duty equipment. Properly equipped, you can ensure smooth repairs, extend the lifespan of your machine, and minimize downtime. Whether you are working on a lawn tractor, a compact utility vehicle, or any similar machinery, the correct set of tools can make all the difference.

Basic Hand Tools are essential for any repair job. A set of wrenches, screwdrivers, and pliers will cover most small adjustments and maintenance tasks. For larger tasks, impact tools or ratchet sets can provide the necessary force to loosen tight bolts or screws.

For more advanced repairs, specialized equipment such as hydraulic jacks or engine diagnostic tools can be invaluable. These tools help ensure precision and efficiency when dealing with intricate mechanical issues.

Where to Find John Deere Parts

For those seeking essential components to maintain or repair their machinery, numerous reliable sources are available. Whether you’re looking for specific items or need a full set of replacements, it’s important to choose the right supplier for quality and authenticity.

Authorized retailers often offer the best selection of original equipment and accessories. These suppliers provide items directly from the manufacturer, ensuring compatibility and durability.

Online marketplaces can also be a useful option, with many platforms offering both new and used items. This option allows you to compare prices, read reviews, and select from various sellers.

Another avenue includes local dealers and service centers, which may carry both the original and aftermarket options. These centers can often provide expert advice on installation and maintenance.

Maintenance Tips for John Deere 325

Proper upkeep is essential for maximizing the longevity and performance of your lawn equipment. Regular maintenance ensures smooth operation and prevents unnecessary wear and tear. Following a few key steps can help keep your machine in optimal condition throughout its life.

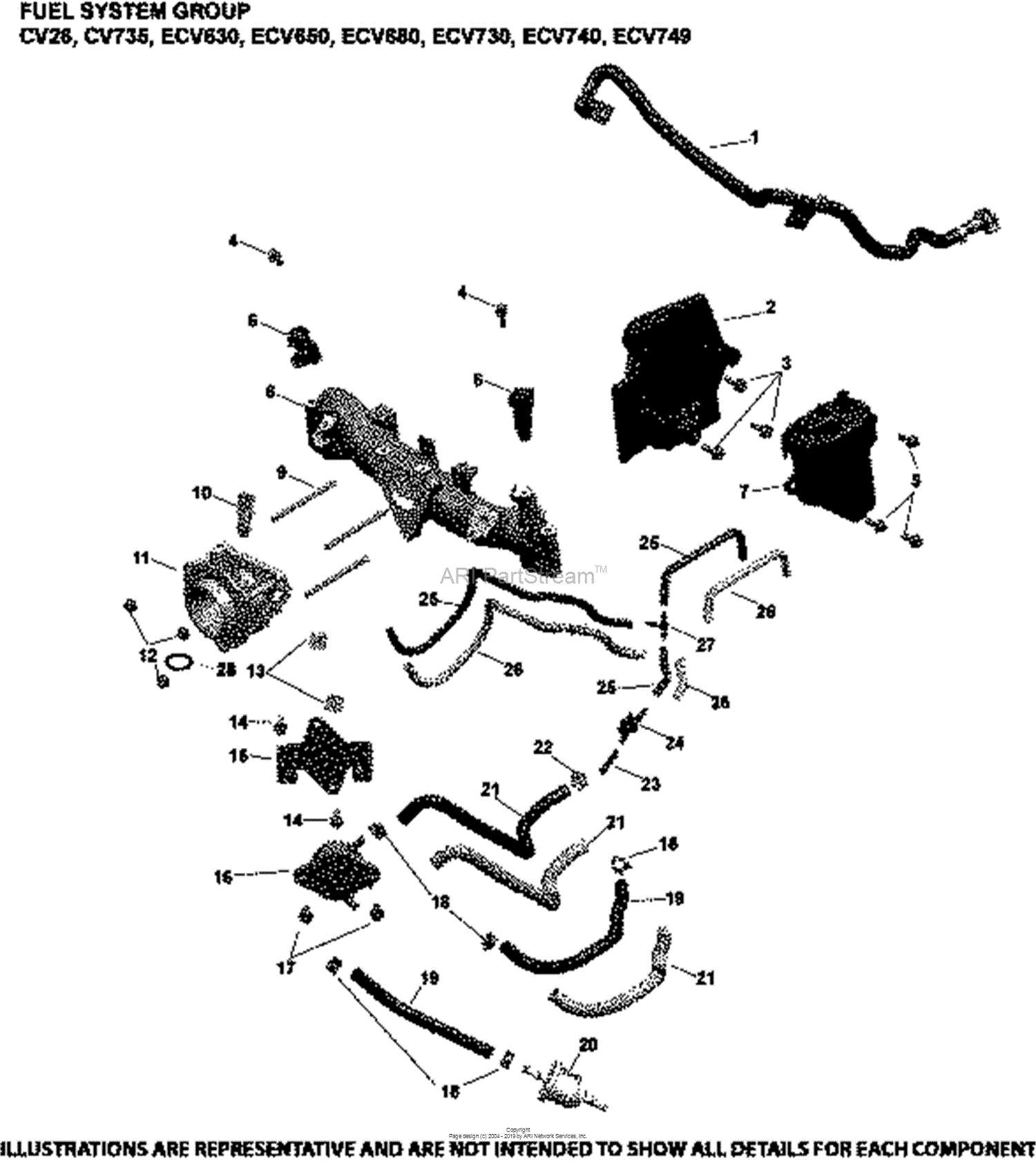

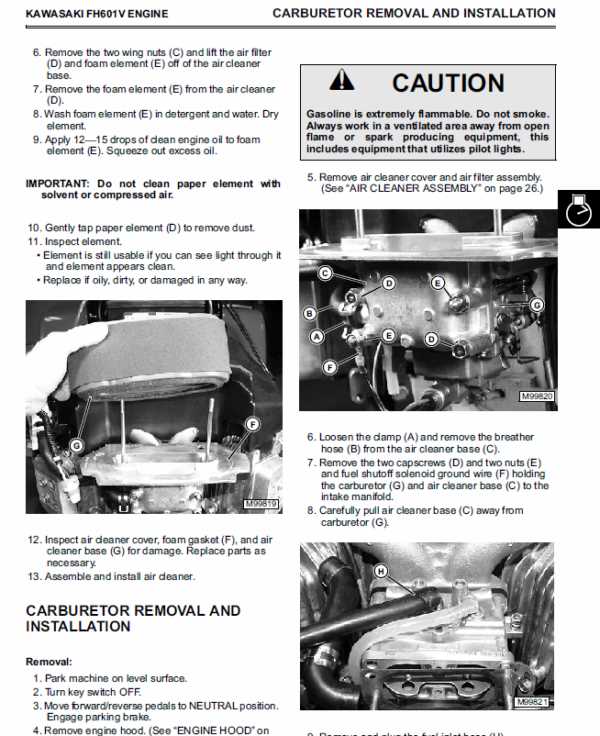

Check fluid levels regularly, including oil, fuel, and coolant. Keeping these at proper levels ensures efficient operation and protects internal components from damage.

Inspect and replace filters periodically. Clean air and fuel filters help maintain proper engine function, while a clean oil filter ensures the engine remains lubricated without contaminants.

Sharpen the blades as needed to ensure a clean cut. Dull blades can damage the grass and strain the engine, leading to decreased performance and potential issues.

Examine the tires for proper inflation and tread wear. Well-maintained tires improve traction, which is crucial for safe operation on uneven or slippery surfaces.

Finally, keep an eye on the overall condition of the frame and components, tightening loose parts and addressing any signs of wear to avoid bigger problems down the road.

Common Issues and Replacement Parts

When operating machinery, it is common to encounter wear and tear over time. Recognizing the typical problems that arise and knowing the components that may need to be replaced ensures optimal performance. Addressing these issues promptly can prevent further damage and improve the longevity of the equipment.

Frequent Problems

- Engine starting difficulties

- Reduced power output

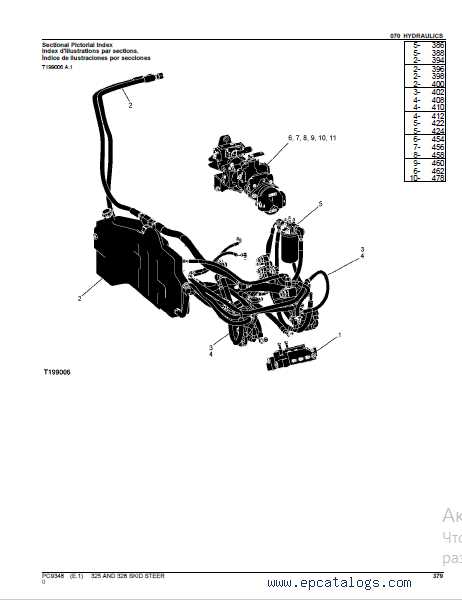

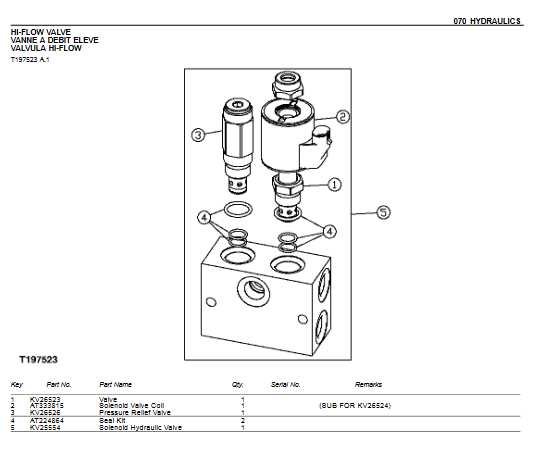

- Hydraulic system malfunctions

- Excessive vibration or noise

- Unresponsive steering

Essential Replacements

- Air filter

- Oil filter and fluids

- Hydraulic hoses and pumps

- Belts and pulleys

- Wheel bearings

Understanding Service Manuals

Service manuals play a critical role in maintaining and repairing machinery. These documents provide detailed instructions and technical information, helping users to perform tasks accurately. Whether for routine maintenance or troubleshooting complex issues, they are essential for keeping equipment running smoothly and efficiently.

Key Features of Service Manuals

These manuals typically include a variety of useful sections, such as maintenance schedules, step-by-step repair procedures, and safety guidelines. They are designed to help both professional technicians and everyday users understand the inner workings of the machine. Clear illustrations, as well as parts lists, ensure that users can identify and replace components with precision.

Benefits of Using a Service Manual

By following the guidelines in these manuals, users can extend the lifespan of their equipment and reduce the risk of costly mistakes. Manuals also empower users to perform maintenance themselves, saving time and money while ensuring that the equipment remains in peak condition.

Benefits of Accurate Parts Diagrams

Having detailed visual guides for components and their arrangement is crucial for efficient maintenance and repair tasks. Such illustrations help ensure proper assembly and disassembly, reducing the likelihood of errors and streamlining the repair process. With precise reference materials, identifying and sourcing the correct elements becomes straightforward, saving time and preventing unnecessary delays.

Enhanced Repair Efficiency

Clear, well-organized reference visuals allow technicians to quickly pinpoint the required elements. This efficiency translates to faster repairs, fewer mistakes, and ultimately, a reduced risk of operational disruptions.

Cost Savings

Accurate visual references help prevent the unnecessary purchase of incorrect or incompatible components. This not only reduces costs but also minimizes downtime by ensuring the right parts are used the first time.

| Component | Purpose | Common Issues |

|---|---|---|

| Engine Gasket | Seals engine parts for optimal performance | Worn or cracked seals leading to leaks |

| Transmission Shaft | Transfers power from the engine to wheels | Misalignment or wear causing operational issues |

| Hydraulic Hose | Transfers hydraulic fluid for movement | Cracks or leaks causing fluid loss |