The efficient operation of any garden machine relies heavily on its intricate elements. A comprehensive grasp of these components not only ensures optimal performance but also enhances the overall lifespan of the equipment. By familiarizing oneself with each segment, users can address issues more effectively and undertake necessary maintenance with confidence.

Visual aids play a crucial role in this understanding, offering a clear representation of how various parts interact within the machinery. Whether you’re a seasoned operator or a novice, having access to detailed illustrations can significantly aid in troubleshooting and repairs. These resources empower individuals to delve deeper into their machinery’s inner workings.

Ultimately, cultivating a thorough knowledge of your equipment can transform your maintenance practices, leading to a more reliable and efficient gardening experience. By investing time in understanding each aspect, you set the foundation for long-term success in managing your outdoor tasks.

Understanding John Deere LX279 Components

Gaining insight into the individual elements of a lawn care machine is essential for effective maintenance and optimal performance. Each component plays a pivotal role in ensuring the device operates smoothly and efficiently. Familiarity with these parts enables users to troubleshoot issues and make informed decisions regarding repairs or replacements.

Key components include the engine, which provides the necessary power, and the transmission system, responsible for speed regulation and maneuverability. The cutting deck is vital for achieving a precise and even cut, while the wheels and tires affect traction and stability. Additionally, the electrical system ensures proper operation of lights and ignition.

Understanding the interconnectedness of these elements can enhance the user’s ability to maintain their equipment effectively. Regular checks and maintenance on each part not only prolong the life of the machine but also improve overall functionality, making lawn care tasks more efficient and enjoyable.

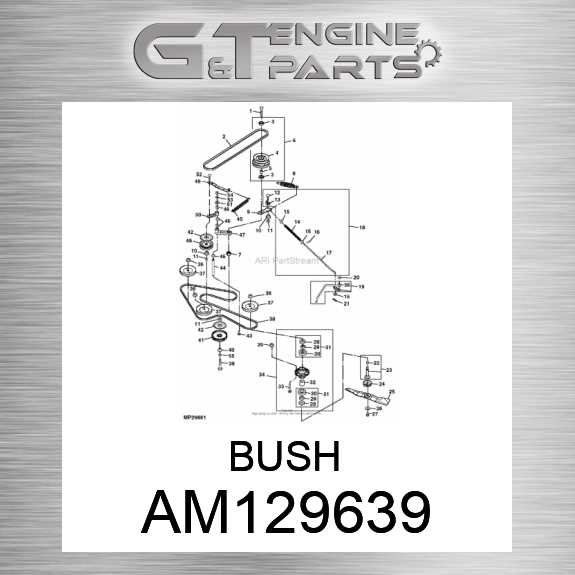

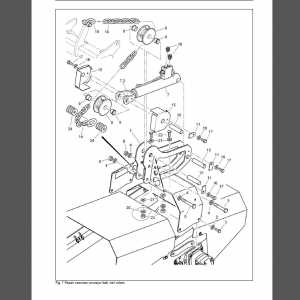

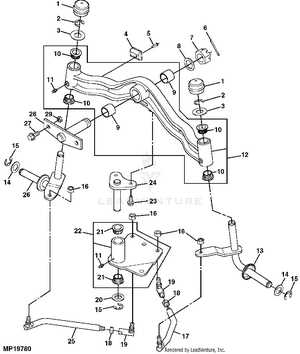

Parts Diagram Overview for LX279

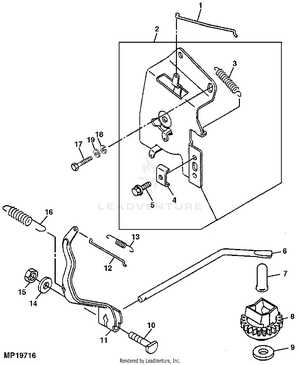

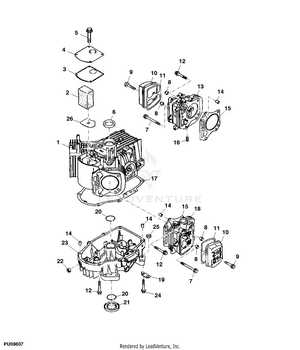

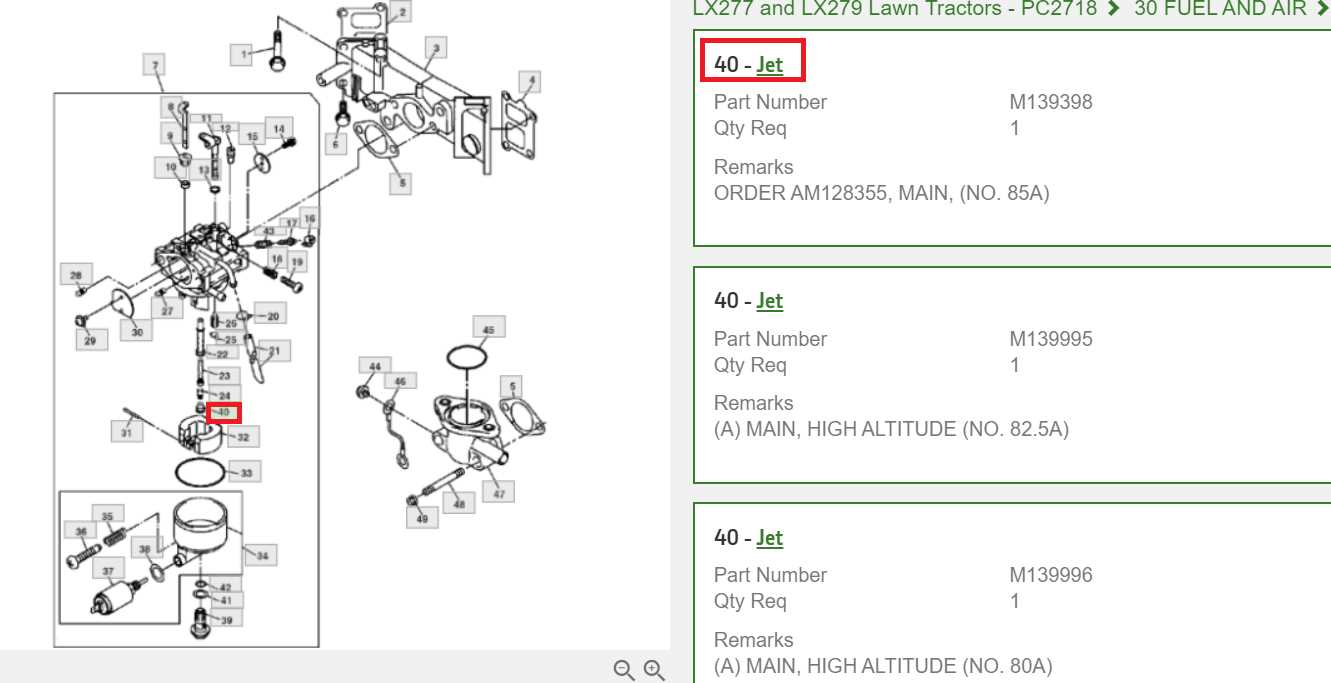

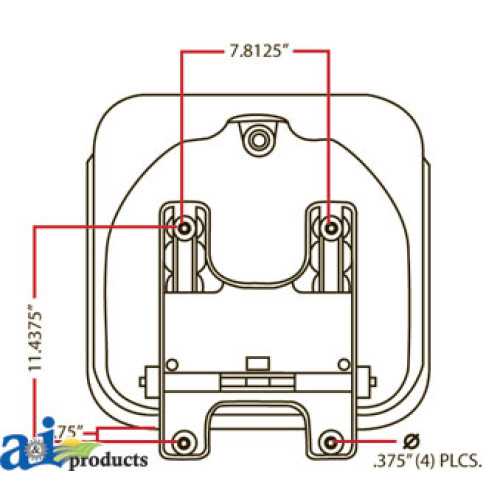

This section provides an insightful exploration of the components associated with the LX279 model. Understanding the layout and relationships among these elements is crucial for effective maintenance and repairs. The visual representation serves as a valuable tool for identifying individual parts and their functions within the assembly.

Key Components Breakdown

To facilitate a better grasp of the structure, we categorize the essential elements into several groups. Each category highlights specific areas that users often interact with, ensuring that all necessary information is readily available.

| Component Category | Description |

|---|---|

| Engine | The heart of the machine, responsible for powering all operations. |

| Transmission | Transfers power from the engine to the wheels, affecting speed and performance. |

| Chassis | The frame that supports the entire assembly and provides stability. |

| Electrical System | Encompasses wiring and components essential for operation and control. |

| Hydraulic Components | Facilitate the movement and operation of various attachments and implements. |

Importance of Accurate Identification

Accurate identification of each part is paramount for troubleshooting and repairs. A well-organized visual layout aids technicians and enthusiasts alike in ensuring that replacements are done efficiently, ultimately prolonging the lifespan of the machinery.

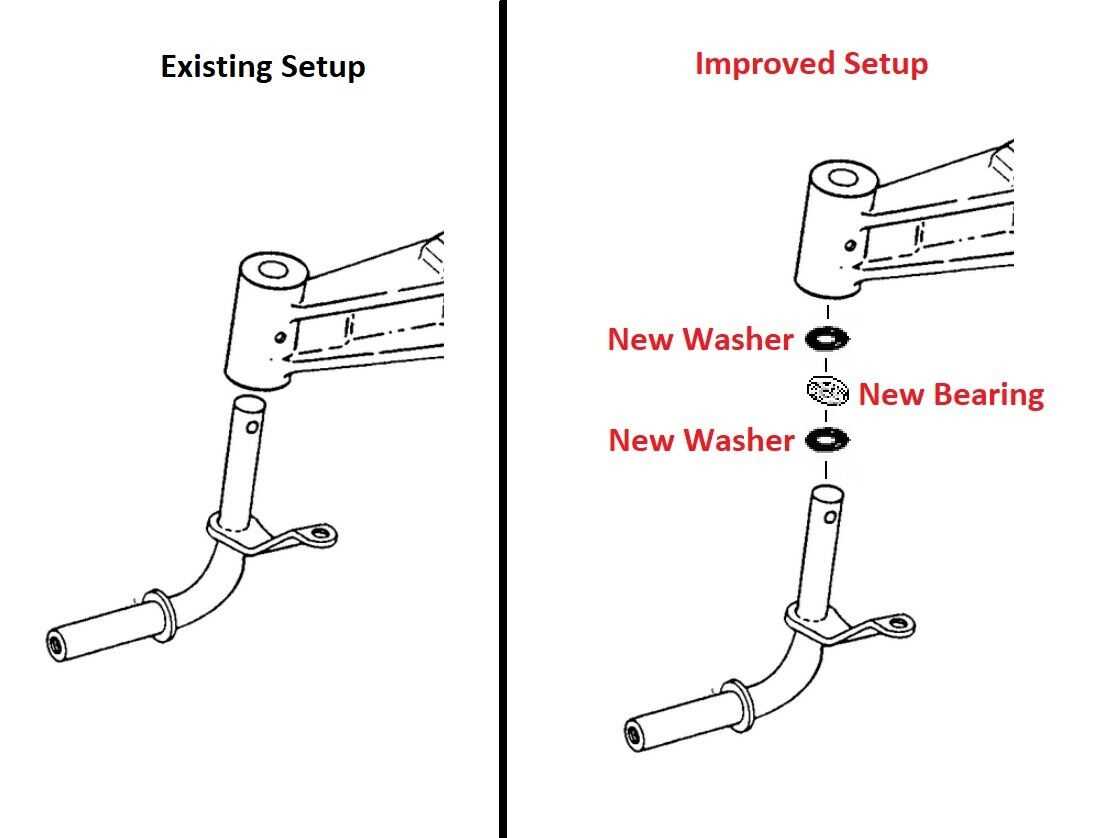

Common Issues with LX279 Parts

When dealing with outdoor machinery, users often encounter various challenges related to components. Understanding these common issues can greatly enhance maintenance efforts and prolong the lifespan of the equipment.

Wear and Tear

One of the most prevalent problems involves the natural deterioration of components over time. Factors such as frequent use, exposure to harsh weather, and inadequate maintenance can lead to reduced efficiency and performance. Regular inspections and timely replacements are essential to mitigate these effects.

Compatibility Problems

Another issue arises when seeking replacements or upgrades. Users might struggle with finding suitable alternatives that fit properly and function as intended. It’s crucial to verify specifications and compatibility to avoid further complications and ensure optimal operation.

Addressing these common issues through proactive maintenance and careful selection of replacements can help maintain performance and reliability. Awareness of these factors will empower users to make informed decisions regarding their machinery’s upkeep.

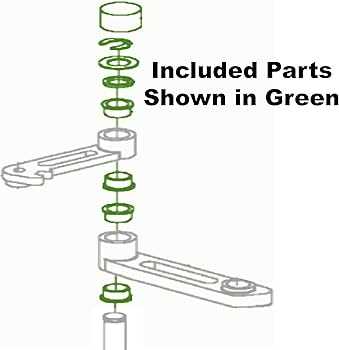

How to Interpret Parts Diagrams

Understanding assembly visuals is crucial for effective maintenance and repair tasks. These illustrations provide a visual representation of components, enabling users to identify and organize each element efficiently.

Key Elements to Consider

- Labels: Each component is often labeled for easy identification.

- Connections: Pay attention to how parts connect, as this affects assembly and disassembly.

- Legend: A legend usually explains symbols and numbers used throughout the visual.

Steps for Effective Interpretation

- Start by examining the overall layout.

- Identify and locate each labeled item.

- Refer to the legend for clarity on symbols.

- Understand the sequence of assembly based on connections.

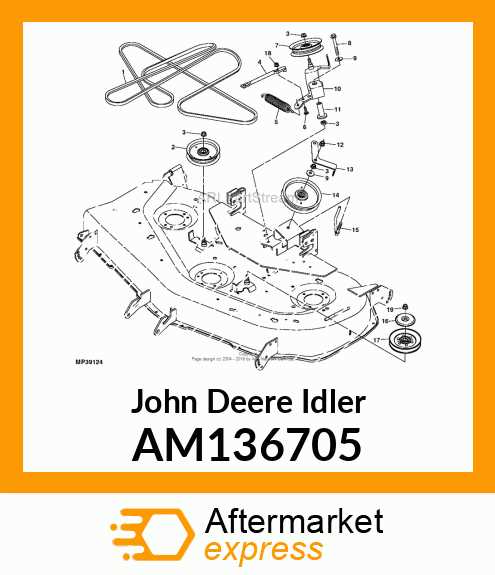

Finding Replacement Parts for LX279

Locating suitable components for your equipment can be a crucial task for maintaining optimal performance. Whether you’re repairing or upgrading, understanding how to navigate the available resources can make all the difference. Here are some effective strategies for sourcing the necessary items.

Online Resources

- Manufacturer’s Website: Start by visiting the official site where you can find a range of items specifically designed for your model.

- Online Retailers: Websites like Amazon and eBay often have a selection of aftermarket and OEM components.

- Forums and Communities: Engaging with online groups dedicated to equipment can provide valuable insights and recommendations.

Local Options

- Authorized Dealers: Local dealerships can offer original items along with expert advice on installation.

- Repair Shops: Consider contacting local repair services that may have spare components available.

- Salvage Yards: Sometimes, used components can be found at salvage yards, which can be a cost-effective solution.

Maintenance Tips for LX279 Owners

Proper upkeep is essential for ensuring optimal performance and longevity of your lawn equipment. By adhering to a regular maintenance routine, you can prevent costly repairs and enhance the efficiency of your machine. Below are some key recommendations that every owner should consider.

Regular Oil Changes: Changing the oil at recommended intervals is vital. Fresh oil keeps the engine running smoothly and helps prevent wear. Always use the specified type for your model.

Blade Sharpening: Keeping the cutting blades sharp is crucial for achieving a clean cut. Dull blades can stress the engine and lead to uneven mowing. Sharpen or replace them as needed.

Air Filter Maintenance: A clean air filter ensures optimal airflow to the engine. Inspect and replace the filter periodically, especially if operating in dusty conditions.

Tire Pressure Checks: Maintaining proper tire pressure improves traction and reduces uneven wear. Check the pressure regularly and inflate as necessary to the manufacturer’s specifications.

Battery Care: For electric-start models, a well-maintained battery is essential. Keep terminals clean and ensure connections are secure. Consider using a trickle charger during off-seasons.

Inspect Belts and Cables: Regularly examine belts and cables for signs of wear or fraying. Replacing these components promptly can prevent breakdowns during operation.

By implementing these maintenance practices, you can extend the lifespan of your equipment and enjoy a more efficient mowing experience.

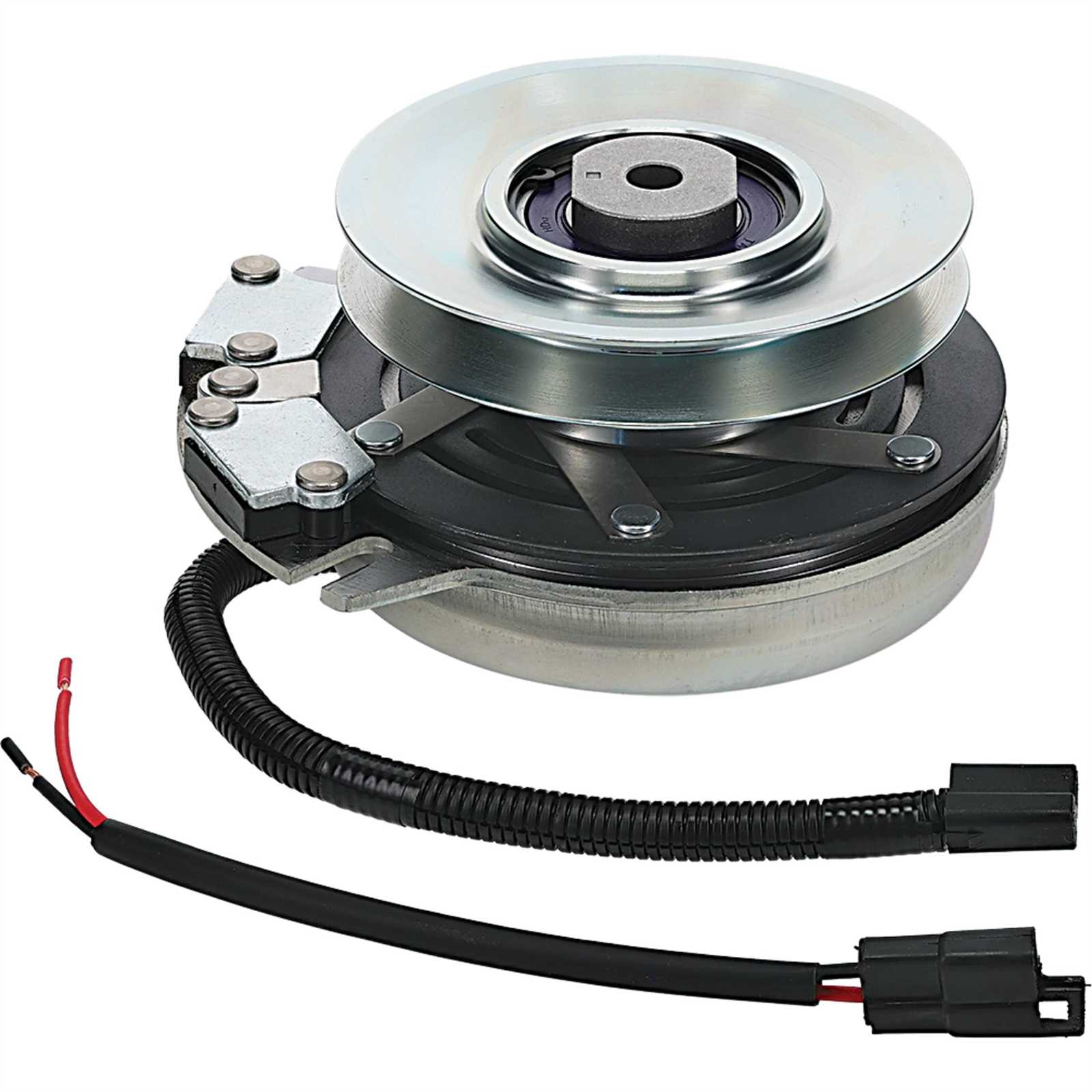

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. These high-quality replacements are designed specifically to fit and function seamlessly within the equipment, providing numerous advantages that enhance overall efficiency and reliability.

Enhanced Performance

Genuine components are crafted to meet precise specifications, which means they operate more effectively than generic alternatives. This tailored fit allows for smoother operation and minimizes the risk of mechanical failures.

Cost-Effectiveness in the Long Run

While the initial investment for original components may be higher, they often result in lower maintenance costs over time. Authentic parts are less likely to wear out quickly, reducing the frequency of replacements and repairs.

| Benefits | Description |

|---|---|

| Quality Assurance | Manufactured to meet strict industry standards. |

| Compatibility | Engineered to fit perfectly with existing machinery. |

| Warranty Protection | Often backed by manufacturer warranties for added peace of mind. |

| Resale Value | Maintains higher resale value due to quality components. |

Comparing Aftermarket vs. OEM Parts

When it comes to maintenance and repairs, the choice between original equipment manufacturer (OEM) components and aftermarket alternatives can significantly impact performance, longevity, and cost. Understanding the differences between these options is essential for making informed decisions that suit both budget and quality needs.

OEM components are made by the original manufacturer and are designed to meet specific standards. In contrast, aftermarket options are produced by third-party companies, often at a lower cost. Each type has its advantages and drawbacks.

- Quality: OEM products typically guarantee higher quality due to strict manufacturing guidelines.

- Cost: Aftermarket items are generally more affordable, providing budget-friendly solutions.

- Availability: Aftermarket options may offer a wider selection, making it easier to find specific components.

- Compatibility: OEM parts ensure a perfect fit, whereas aftermarket items may vary in compatibility.

- Warranty: OEM parts usually come with a warranty, offering protection against defects.

Ultimately, the choice hinges on individual preferences and specific requirements. It’s crucial to weigh the benefits and challenges of each option to determine the best path for your needs.

Resources for LX279 Repair Guides

When it comes to maintaining and repairing your equipment, having access to reliable resources can make all the difference. This section provides various materials to help you navigate the repair process efficiently and effectively. From manuals to online forums, these tools will guide you through troubleshooting and fixing your machinery.

Essential Manuals and Guides

- User manuals that detail specifications and maintenance procedures.

- Service manuals offering in-depth repair instructions and troubleshooting tips.

- Parts catalogs for identifying compatible components and accessories.

Online Resources and Communities

- Dedicated forums where enthusiasts share advice and experiences.

- Video tutorials that visually demonstrate repair techniques.

- Official websites providing downloadable resources and support options.

Utilizing these resources will empower you to take on repairs with confidence, ensuring your equipment remains in optimal condition.