The intricacies of agricultural machinery can often be daunting for users and enthusiasts alike. A comprehensive understanding of the essential elements that make up these machines is crucial for maintenance and optimal performance. This section aims to clarify the relationships between various components and their functions, offering insights that can enhance your operational knowledge.

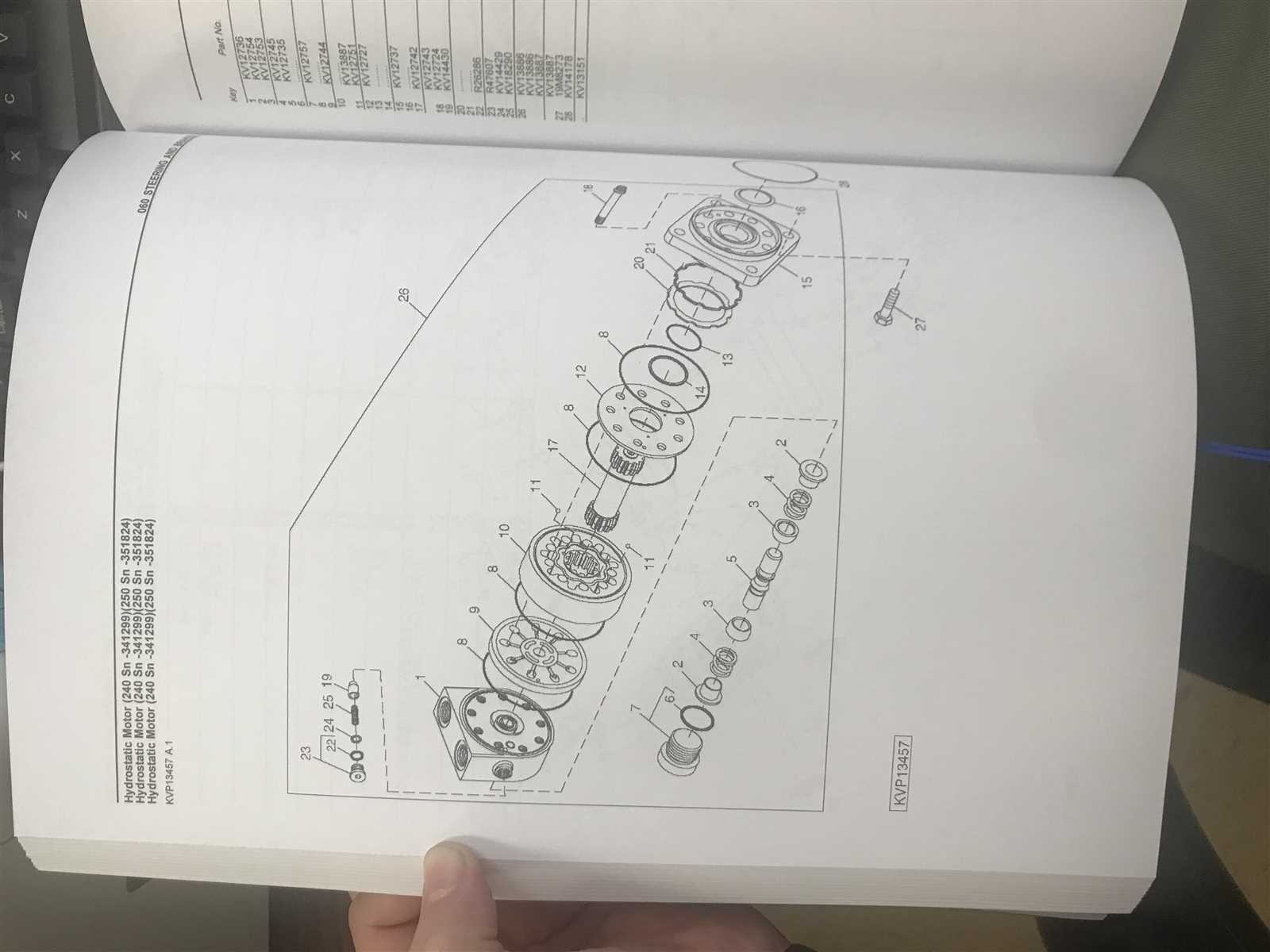

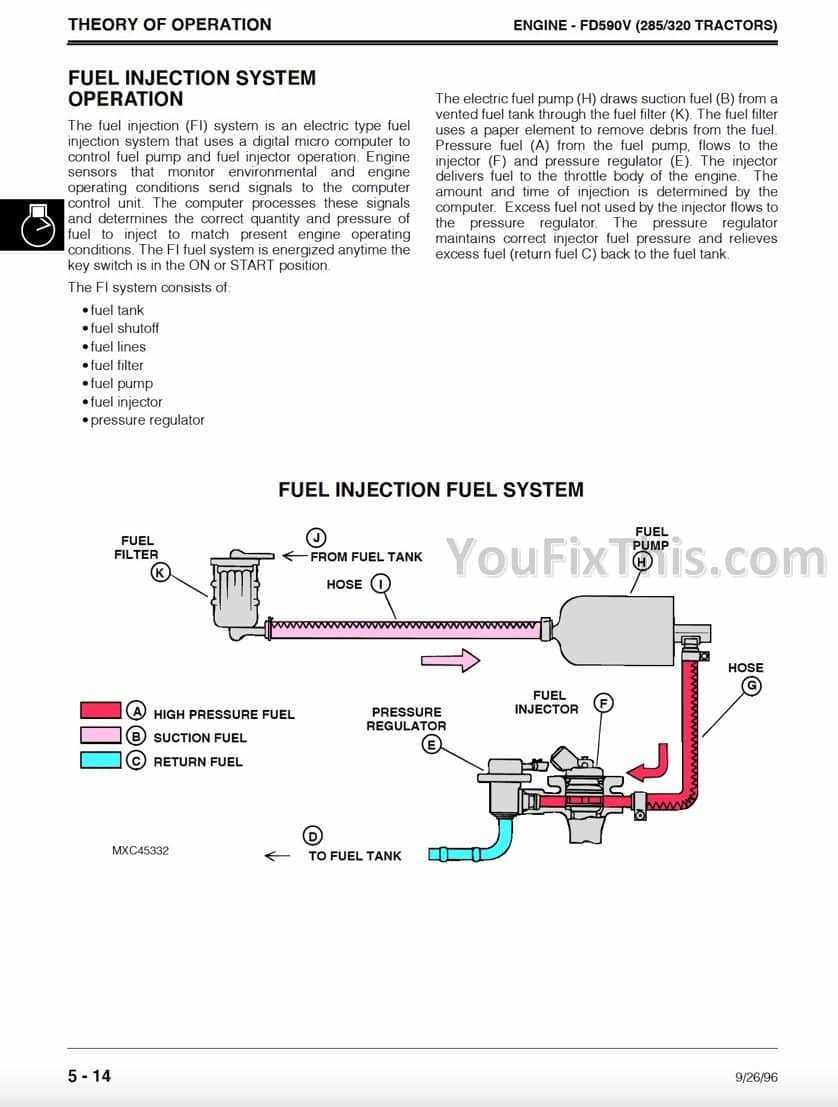

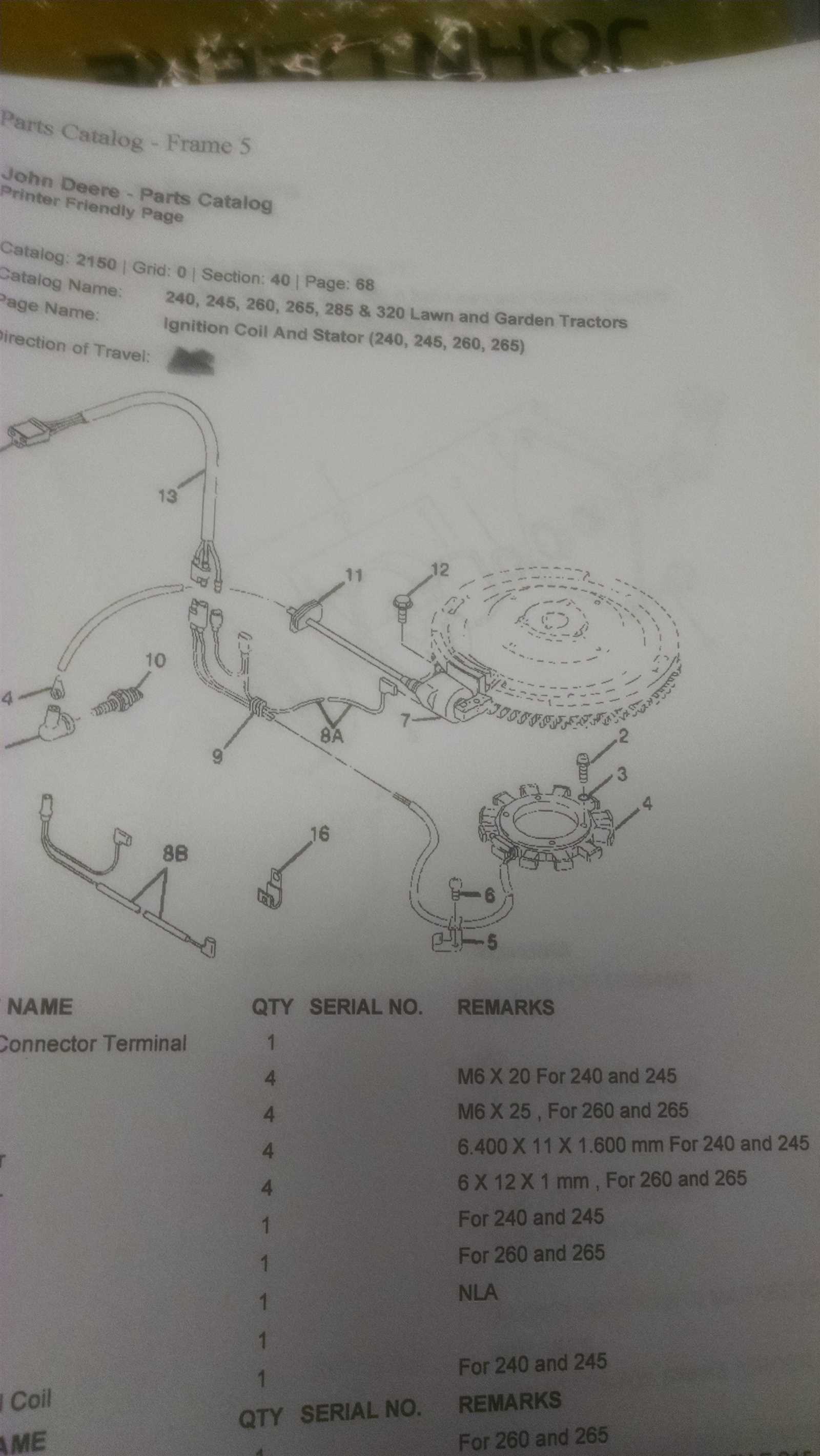

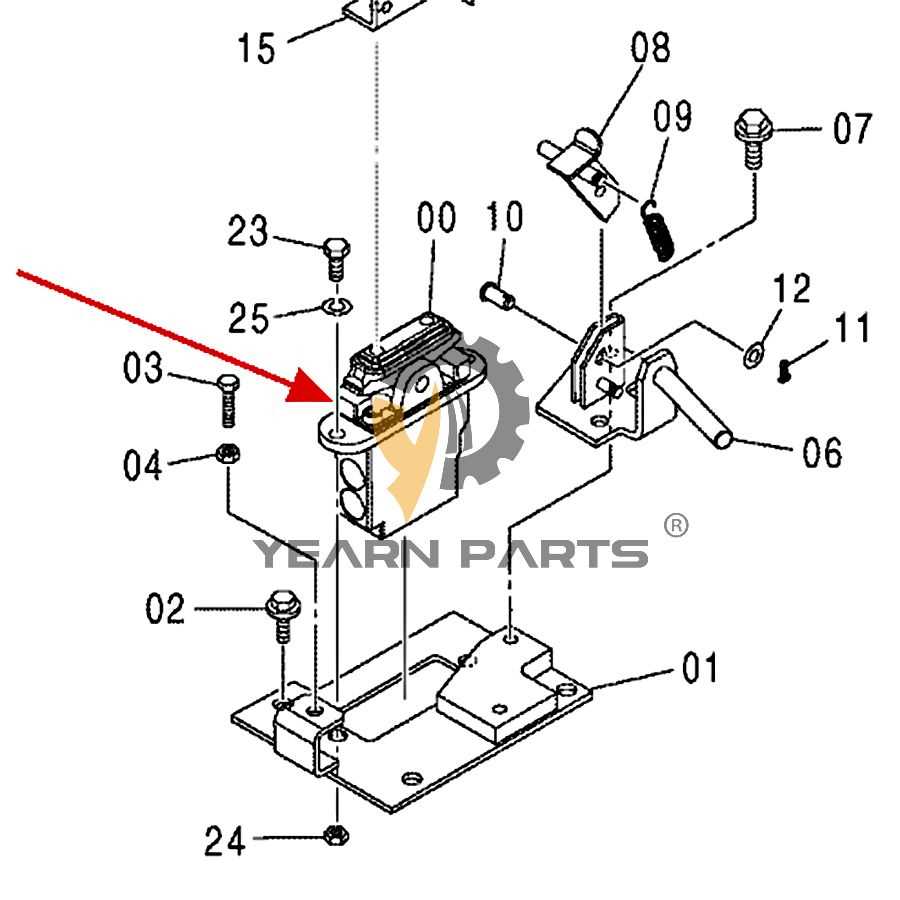

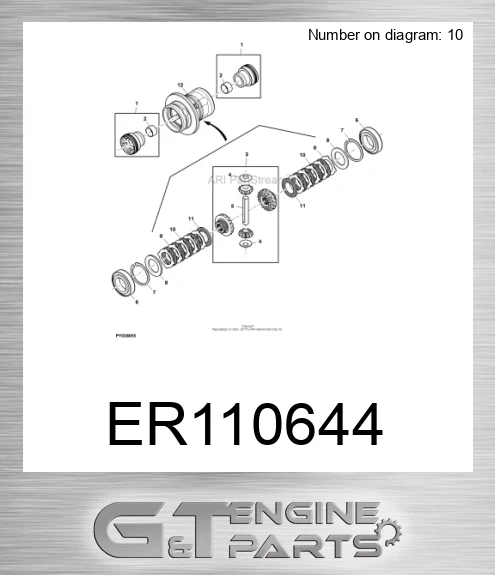

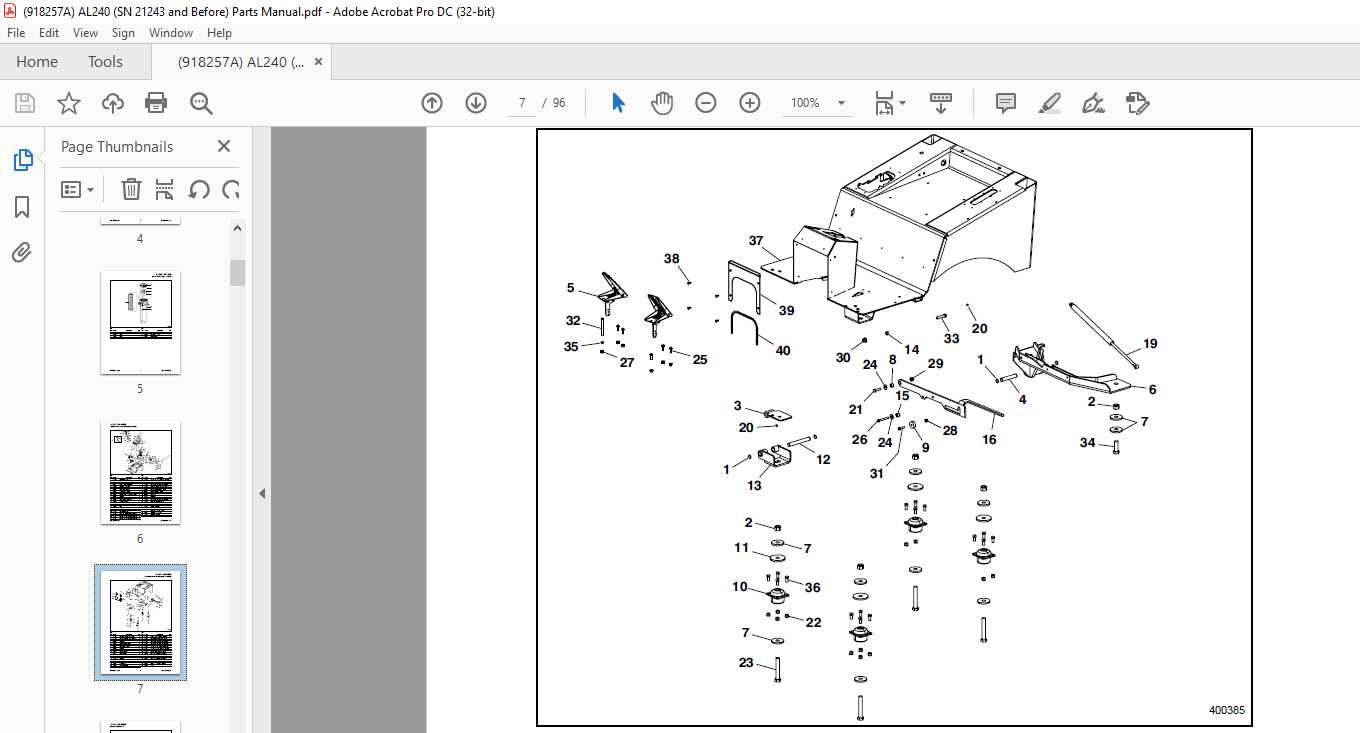

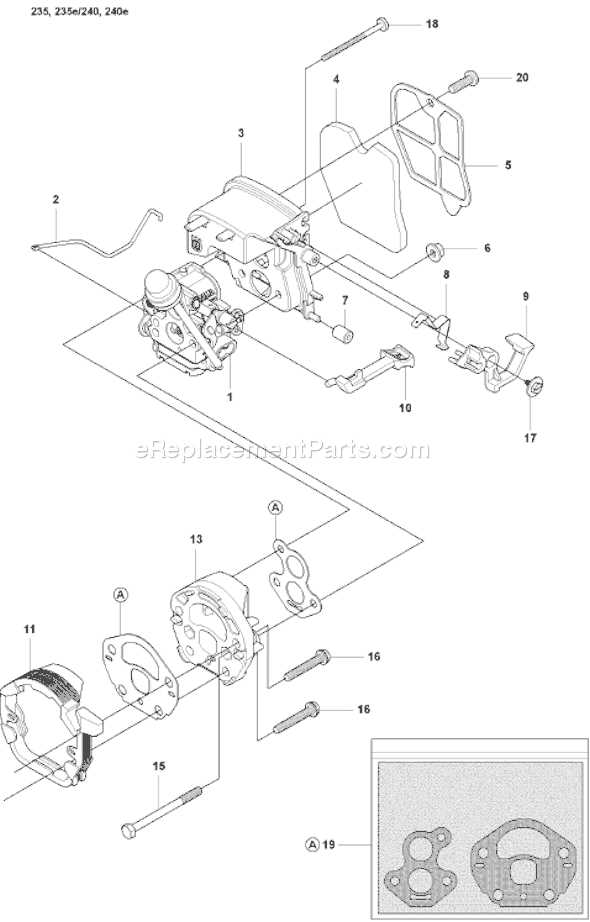

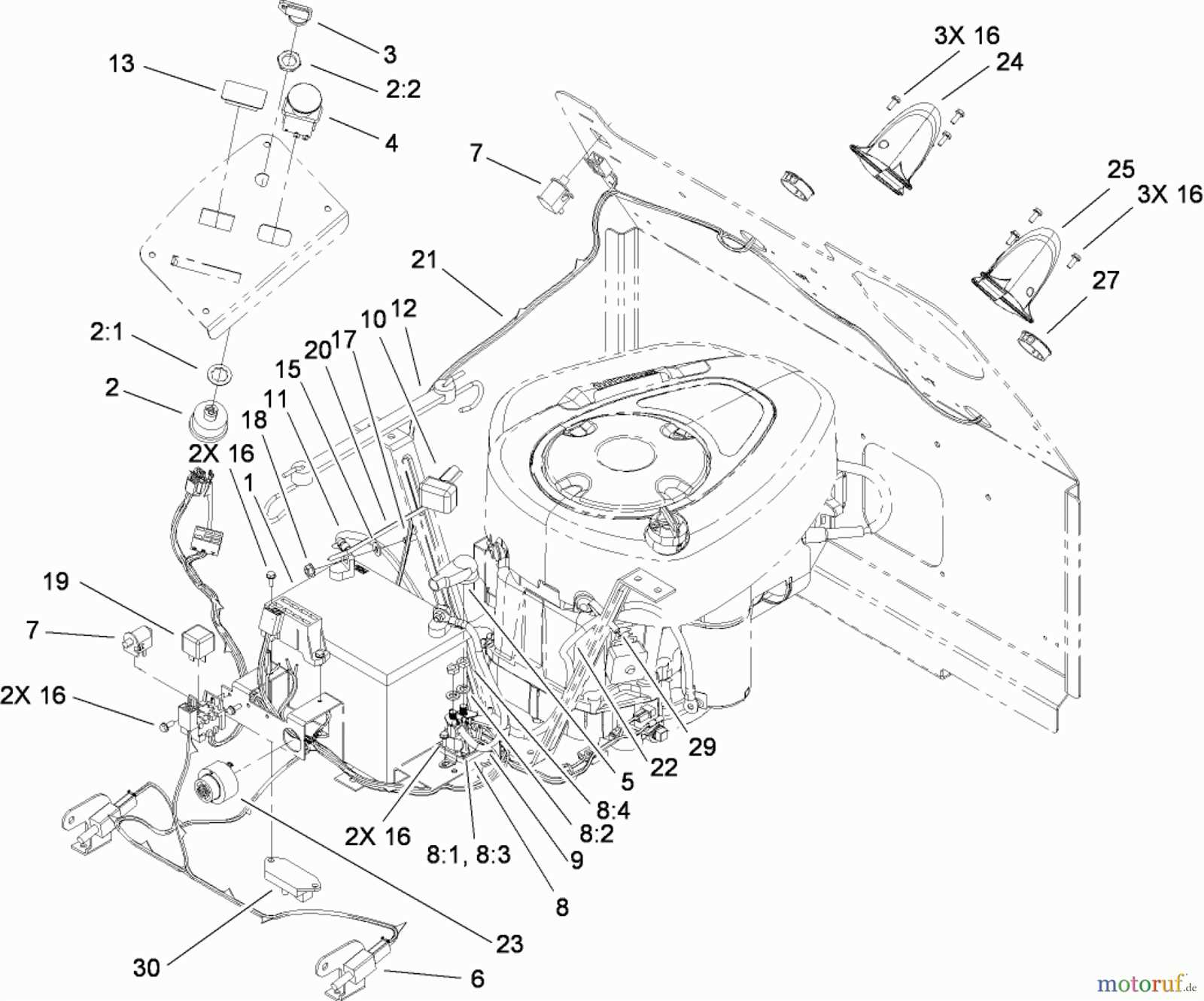

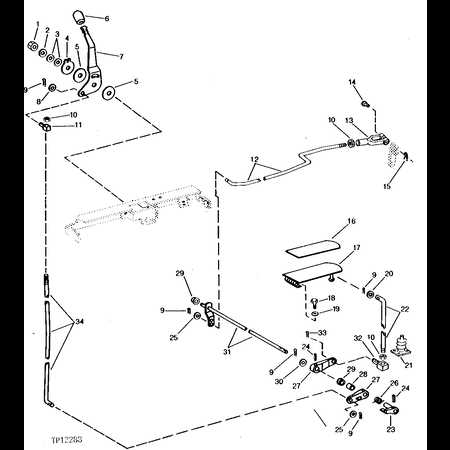

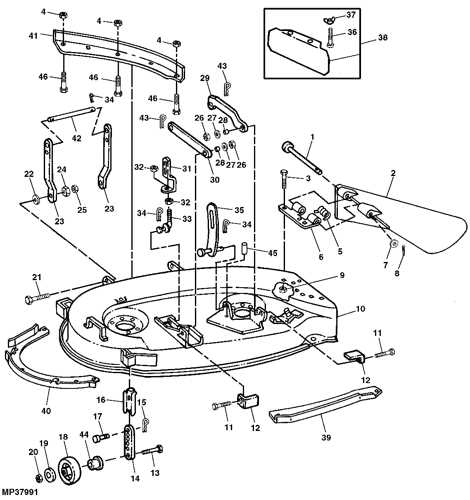

Utilizing visual aids is an effective method for grasping complex information. Diagrams serve as invaluable tools, providing a clear representation of how different pieces interact and contribute to the overall efficiency of the machinery. By examining these illustrations, one can gain a deeper appreciation for the engineering behind these powerful machines.

Whether you are a seasoned professional or a novice, delving into the specifics of machinery construction can lead to the ultimate understanding of its capabilities. This exploration not only improves your technical skills but also empowers you to troubleshoot issues with confidence, ensuring that your equipment runs smoothly and effectively.

Understanding John Deere 240 Components

Exploring the intricate elements of a well-known agricultural machine enhances the user’s comprehension of its functionality and maintenance. Each segment plays a pivotal role in ensuring optimal performance and efficiency.

Key Elements

- Engine: Powers the entire system, vital for operation.

- Transmission: Transmits power from the engine to the wheels.

- Hydraulics: Facilitates various movements and functions of attachments.

- Chassis: Provides the framework and supports other components.

- Electrical System: Powers lights, ignition, and various controls.

Maintenance Tips

- Regularly check and change the oil to ensure engine health.

- Inspect the hydraulic fluid levels frequently.

- Keep the electrical connections clean and secure.

- Monitor tire pressure for optimal traction and handling.

Overview of John Deere 240 Model

This section provides a comprehensive look at a renowned model from a well-established agricultural equipment manufacturer. Designed for versatility and efficiency, this machine has become a favorite among both hobbyists and professionals in the farming community.

The machine boasts a range of features that enhance its performance and usability. Its robust construction ensures durability in various working conditions, while the advanced engineering provides excellent maneuverability. Users appreciate the ergonomic design, which facilitates ease of operation during extended periods of use.

Furthermore, this model is equipped with a variety of attachments, making it adaptable for different tasks. From mowing to tilling, the equipment is capable of handling diverse agricultural needs. Maintenance and servicing are straightforward, allowing operators to keep the machine in peak condition with minimal effort.

Importance of Parts Diagrams

Understanding the components of machinery and their correct arrangement is crucial for proper maintenance and efficient operation. These visual aids provide clear depictions of how different elements interact, making it easier to identify issues, replace faulty parts, or perform upgrades. Without these references, workers would struggle to determine the correct parts or understand the reassembly process after disassembly.

Precise identification is one of the most significant advantages of these reference tools. They help technicians quickly locate and identify the exact components needed, preventing errors and ensuring that the right replacements are used. This not only saves time but also reduces the risk of damaging other interconnected systems.

Efficiency in repair is enhanced when workers can see where each component fits into the larger machine. A clear layout of the system helps avoid unnecessary steps or confusion during the repair process. Technicians can address problems swiftly and confidently, leading to faster turnaround times and minimized downtime.

In addition, preventative maintenance becomes easier with these resources. Regular checks and repairs are more manageable when operators have a visual guide to the machine’s structure. By following the diagram’s instructions, they can keep track of potential wear points and perform necessary checks before minor issues escalate into major failures.

Ultimately, these references promote consistency and standardization in repairs, ensuring that each operation is carried out correctly, regardless of who is performing the task. With a reliable guide, users can work with greater confidence and accuracy, fostering an overall increase in productivity and safety.

Common Replacement Parts Explained

Understanding the components that may need replacement is crucial for maintaining machinery efficiency. Several elements play a significant role in ensuring optimal performance, and recognizing their function can help in timely interventions. Here, we delve into the most frequently needed items and their importance in the upkeep of equipment.

Critical Components for Maintenance

Among the various elements, some are more prone to wear and tear due to their constant use. For example, filters are essential for keeping fluids clean and preventing contaminants from causing damage. Regular replacement can prolong the life of your machinery and enhance its efficiency.

Wear Parts to Monitor

Another category includes wear components such as belts and blades. These parts endure significant stress and can degrade over time, impacting overall functionality. Keeping an eye on their condition and replacing them when necessary ensures uninterrupted operation and prevents costly repairs.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components is essential for proper maintenance and repair. These visual guides offer a clear understanding of the assembly and individual parts, making it easier to identify replacements and troubleshoot issues. Whether you are a technician, mechanic, or DIY enthusiast, having access to such resources can save time and ensure accuracy during repairs.

There are several reliable sources to obtain these guides. Official manufacturer websites typically provide digital catalogs for registered users or customers. Additionally, specialized online platforms often host databases with comprehensive charts for a wide range of machinery models. For physical copies, parts suppliers and authorized dealerships may offer printed manuals or direct you to trusted sources.

Online forums and community groups dedicated to specific equipment brands are another valuable resource. Users often share digital copies of schematics or direct others to sites where they can be found. Many of these platforms also allow for discussions, where users can offer tips or clarify uncertainties regarding the assembly and functionality of particular components.

Finally, third-party websites and aftermarket retailers may also have parts catalogs available, but it’s important to ensure the accuracy of the information provided. Always cross-reference with the original manufacturer’s specifications to ensure compatibility and quality when purchasing replacements.

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to maintain and repair machinery. These illustrations provide detailed insights into the relationships and functions of various elements, making it easier to identify what you need for repairs or upgrades.

To effectively interpret these illustrations, consider the following steps:

- Familiarize Yourself with the Layout: Most illustrations follow a standard format. Take note of sections, labels, and how items are grouped.

- Identify Key Components: Look for the main parts that are essential for the operation. These are often highlighted or indicated with different colors.

- Understand the Numbering System: Many visuals include a numbering or lettering scheme that corresponds to a list of items. Ensure you can match the numbers to their descriptions.

- Check for Additional Information: There may be notes or legends explaining specific features, which can provide further clarity on the components’ functions.

With practice, you’ll find that these illustrations become invaluable tools in troubleshooting and enhancing your machinery’s performance.

Maintenance Tips for John Deere 240

Regular upkeep is essential to ensure optimal performance and longevity of your machinery. Implementing a consistent maintenance routine can prevent costly repairs and enhance efficiency. Here are some practical suggestions to keep your equipment in top shape.

| Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 50 hours | Use recommended oil type and check filters. |

| Check Tires | Weekly | Inspect for wear and maintain proper pressure. |

| Clean Air Filter | Every 100 hours | Ensure maximum airflow; replace if damaged. |

| Inspect Belts | Monthly | Look for cracks or wear; adjust tension as needed. |

| Grease Fittings | Every 50 hours | Use high-quality grease to reduce friction. |

Frequently Asked Questions About Parts

This section addresses common inquiries related to components and accessories, providing clarity for those seeking information on maintenance and replacements. Understanding these aspects can enhance your experience and ensure optimal performance of your machinery.

What Should I Consider When Choosing Components?

When selecting replacements, it’s crucial to evaluate compatibility, durability, and manufacturer recommendations. Quality is paramount, as it affects the longevity and efficiency of your equipment. Always consult your manual for specifications to ensure a proper fit.

Where Can I Find Reliable Information?

For trustworthy details, refer to official sources such as manufacturer websites and authorized dealers. Online forums and communities can also provide valuable insights from other users. Always verify information with credible references to avoid potential issues.

Resources for John Deere Enthusiasts

For those passionate about agricultural machinery, having access to reliable information and tools is essential. This section highlights various resources that can enhance the experience for enthusiasts and owners alike, ensuring that they have everything they need to maintain and understand their equipment effectively.

Online Forums and Communities

Connecting with fellow aficionados can provide valuable insights and shared experiences. Online forums and social media groups offer platforms for discussions, troubleshooting tips, and advice on maintenance and upgrades.

Manuals and Guides

Access to manuals and instructional guides is crucial for anyone looking to delve deeper into machinery specifics. These documents often contain essential information about operation, maintenance, and troubleshooting.

| Resource Type | Description | Link |

|---|---|---|

| Forums | Community-driven platforms for discussions and advice. | Visit Forum |

| Manuals | Official documentation for operation and maintenance. | Access Manuals |

| Videos | Tutorials and guides available on various platforms. | Watch Tutorials |