In the realm of heavy machinery, comprehending the intricate workings of components is essential for effective maintenance and operation. A thorough exploration of mechanical systems can significantly enhance performance and longevity. By examining various elements involved in these systems, users can ensure optimal functionality.

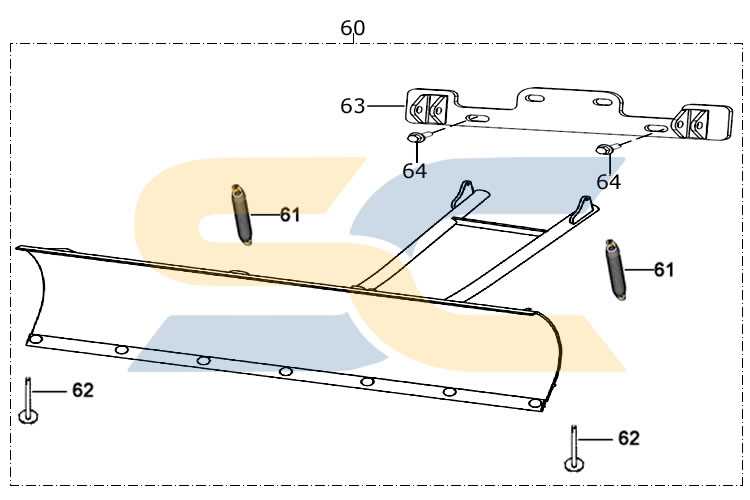

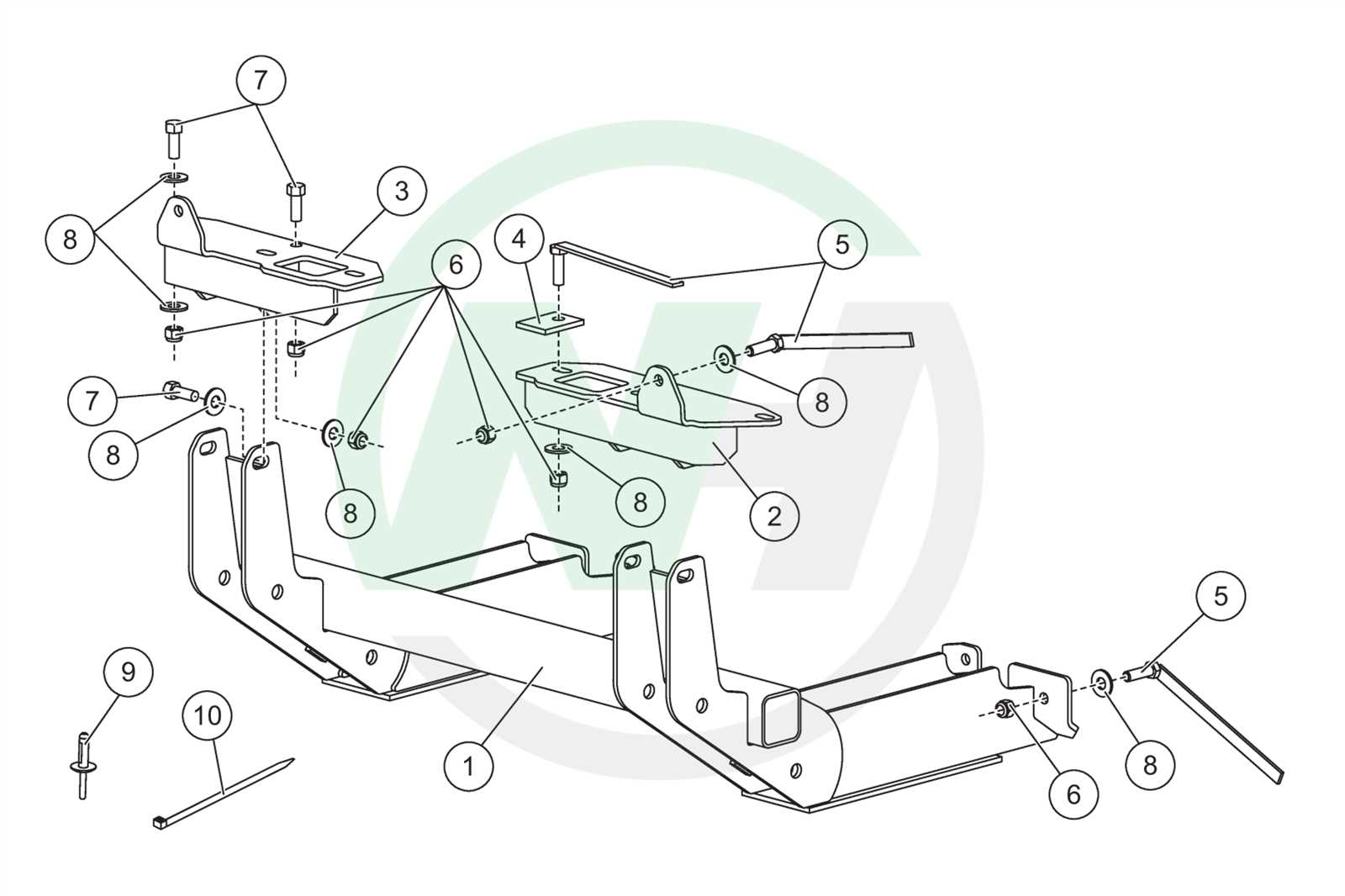

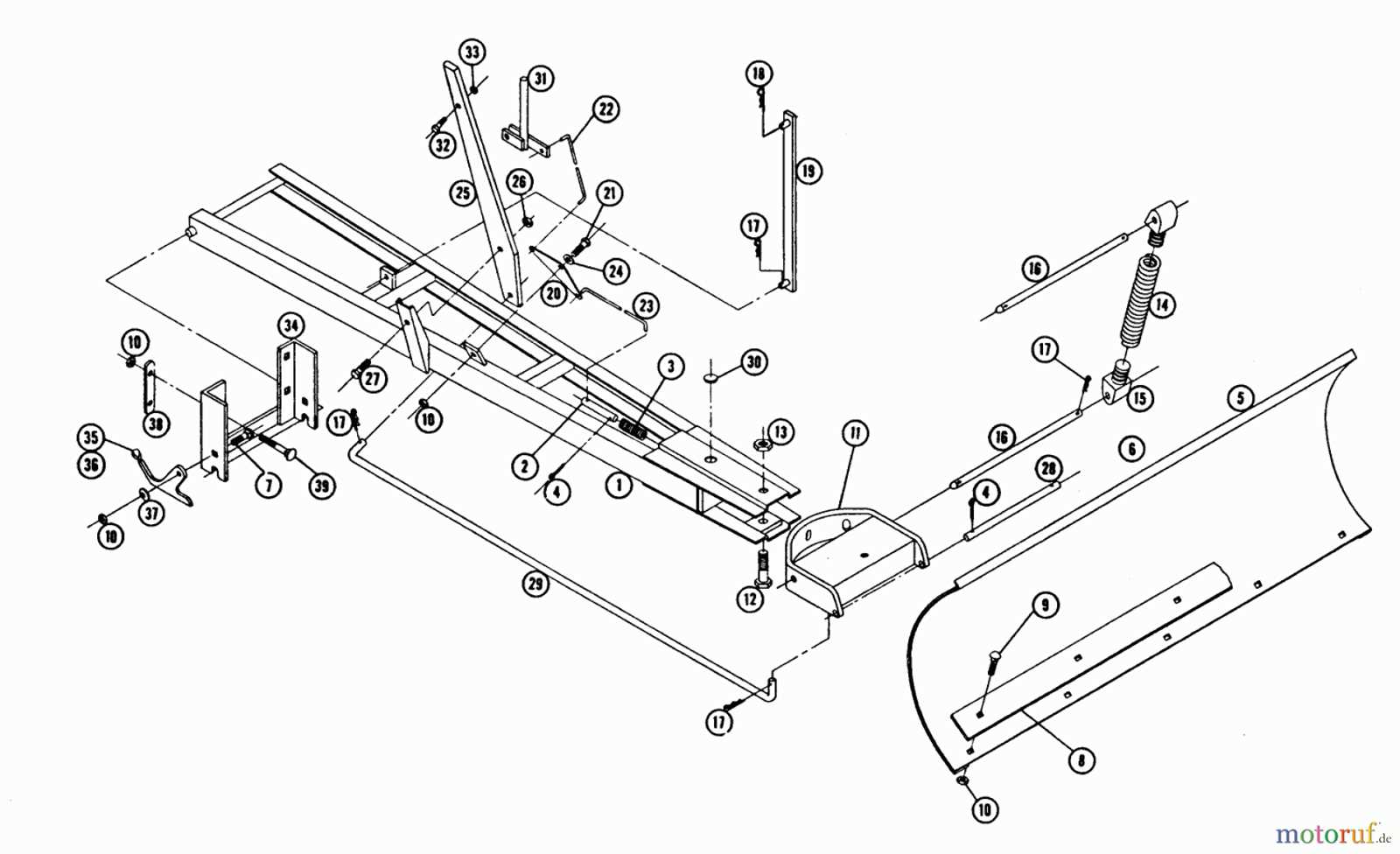

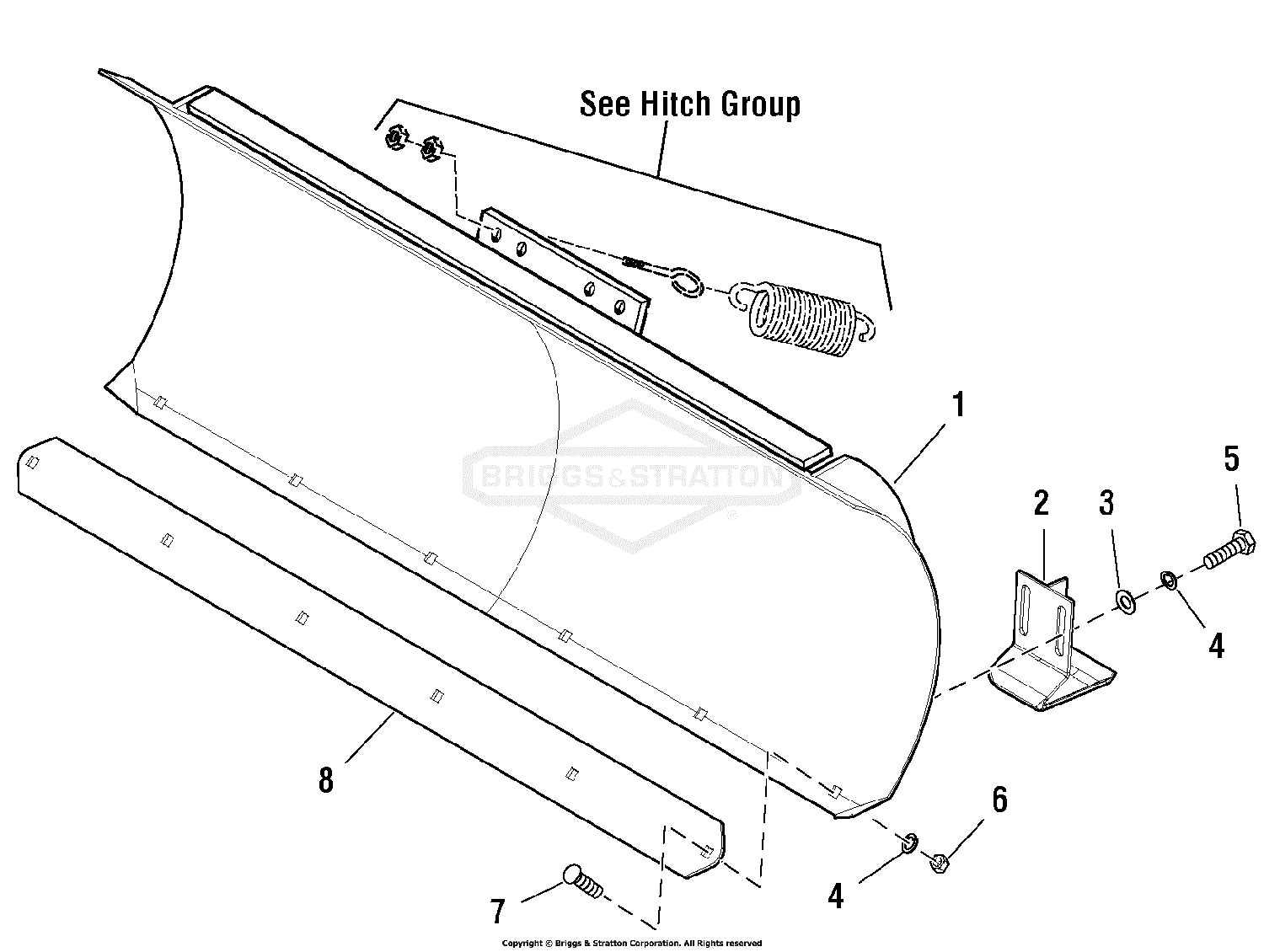

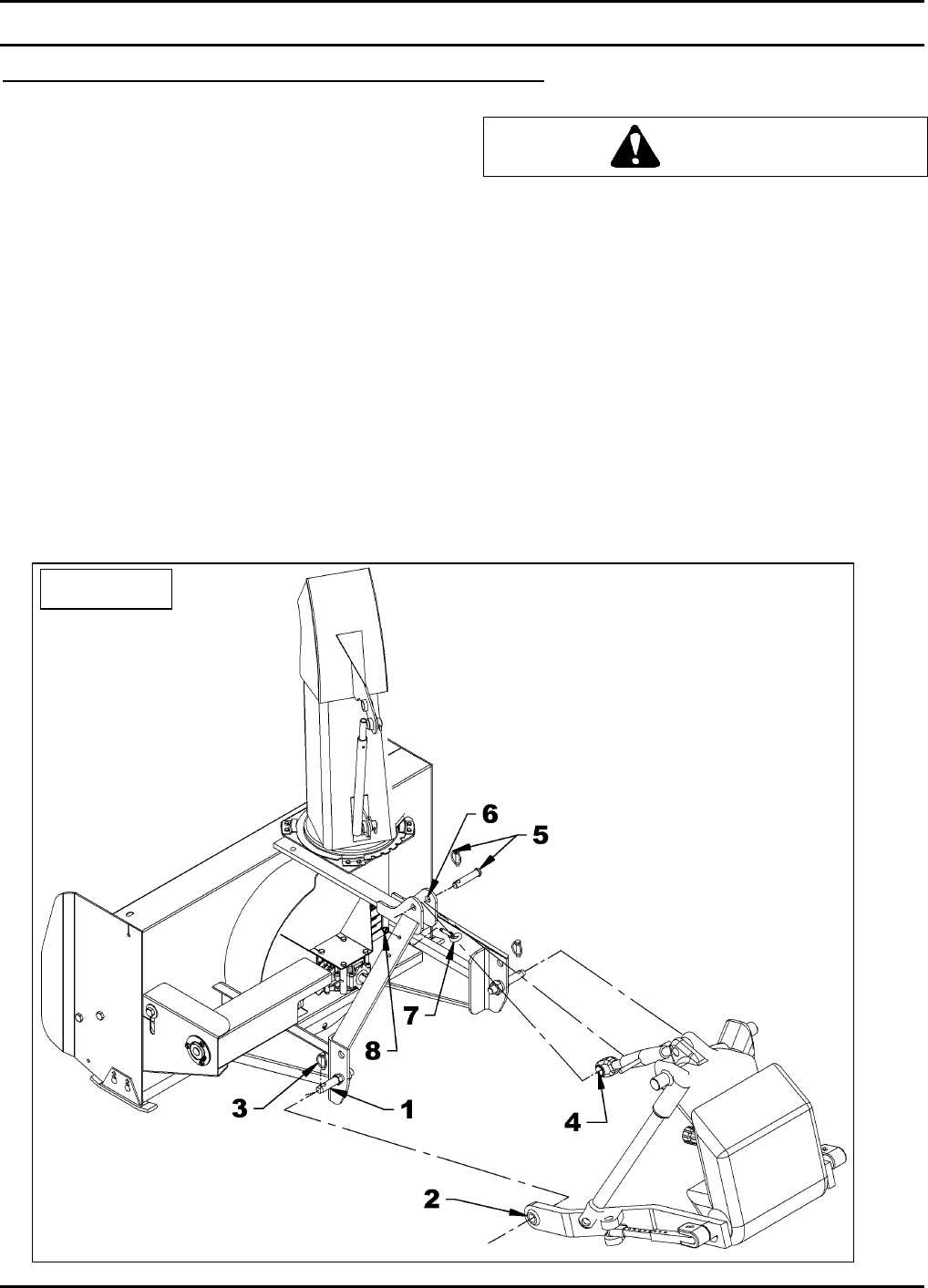

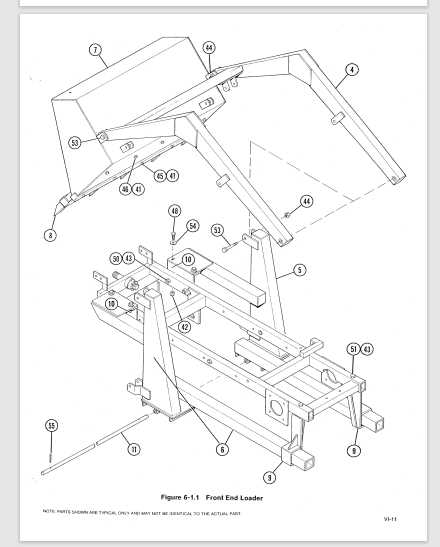

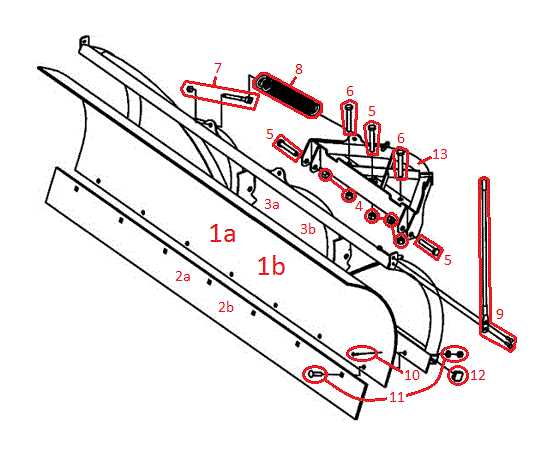

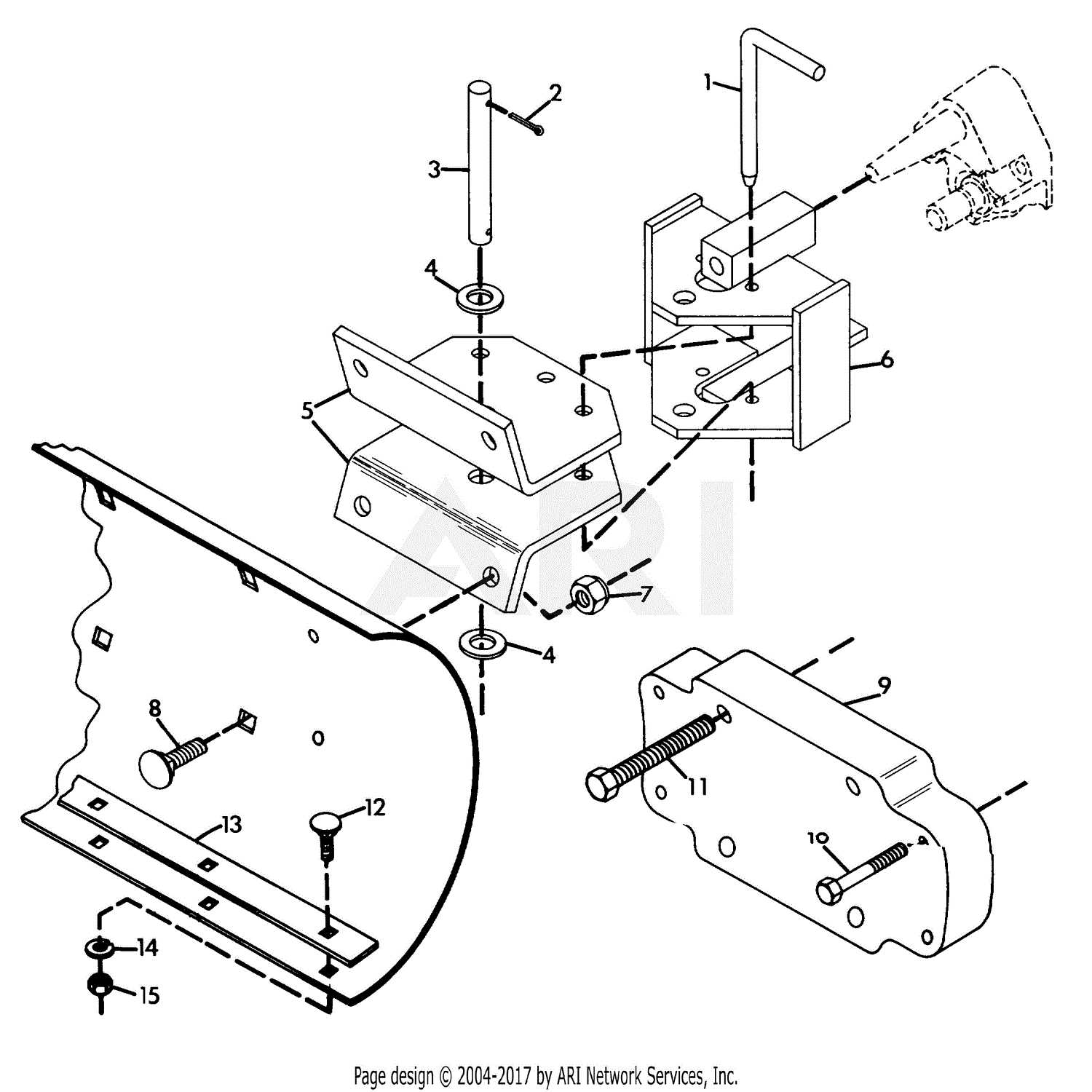

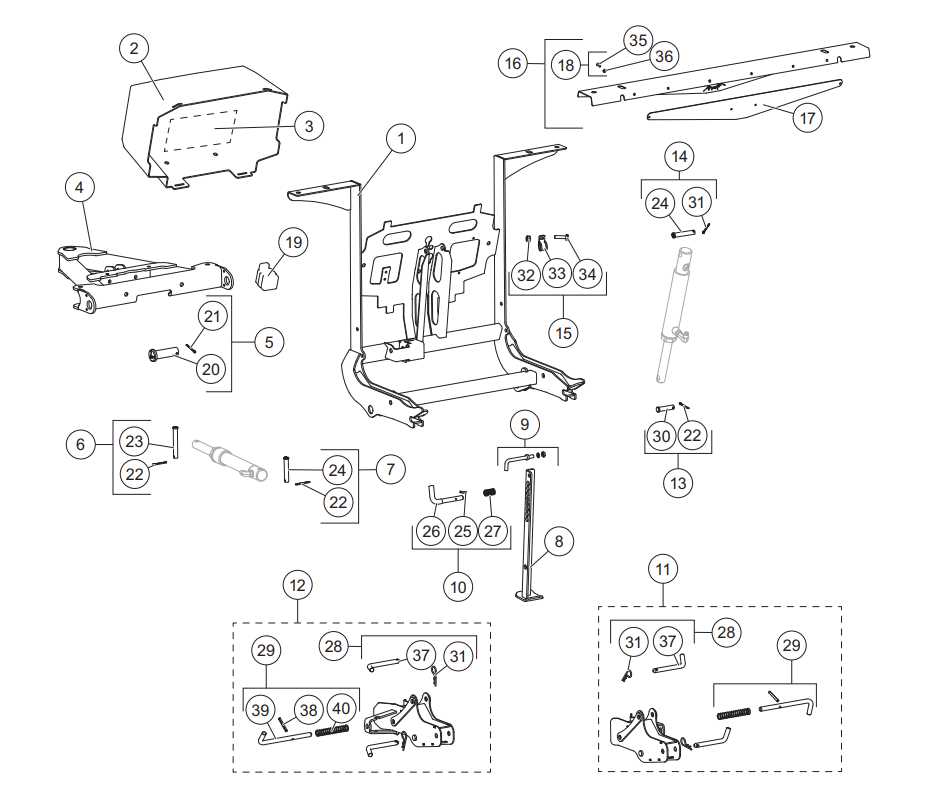

Visual representations of equipment layouts provide invaluable insight into the arrangement and interaction of different elements. These illustrations serve as a roadmap for users, facilitating a deeper understanding of how each component contributes to the overall efficiency of the machinery. Emphasizing clarity and detail, such depictions can ultimately streamline troubleshooting and repairs.

For those seeking to maximize their equipment’s potential, delving into these visuals is a crucial step. A comprehensive grasp of assembly and organization can lead to informed decisions, ensuring that every operation runs smoothly and effectively. Engaging with this information empowers users to tackle any challenges that may arise with confidence.

Understanding John Deere Snow Plows

This section explores the essential elements and functionalities of various clearing tools, designed to enhance winter operations. By grasping the intricacies of these implements, users can maximize their efficiency and performance in adverse weather conditions.

Key Components

Familiarity with the primary components is crucial for effective maintenance and operation. Each element plays a significant role in ensuring optimal performance.

| Component | Description |

|---|---|

| Blade | The main tool for moving and displacing material. |

| Mounting Kit | Secures the implement to the vehicle for stability. |

| Hydraulic System | Enables the adjustment of the blade position. |

Maintenance Tips

Regular upkeep is essential for prolonging the life of these implements. Ensure all components are inspected and lubricated periodically to maintain functionality.

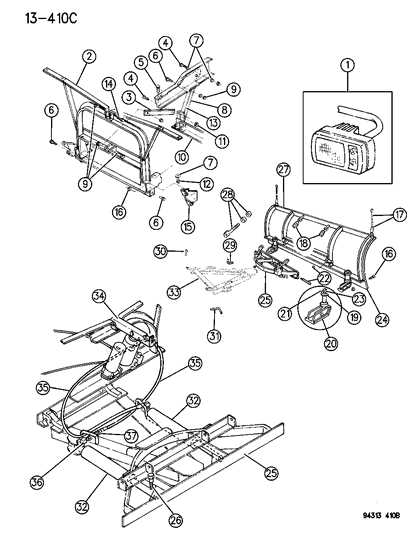

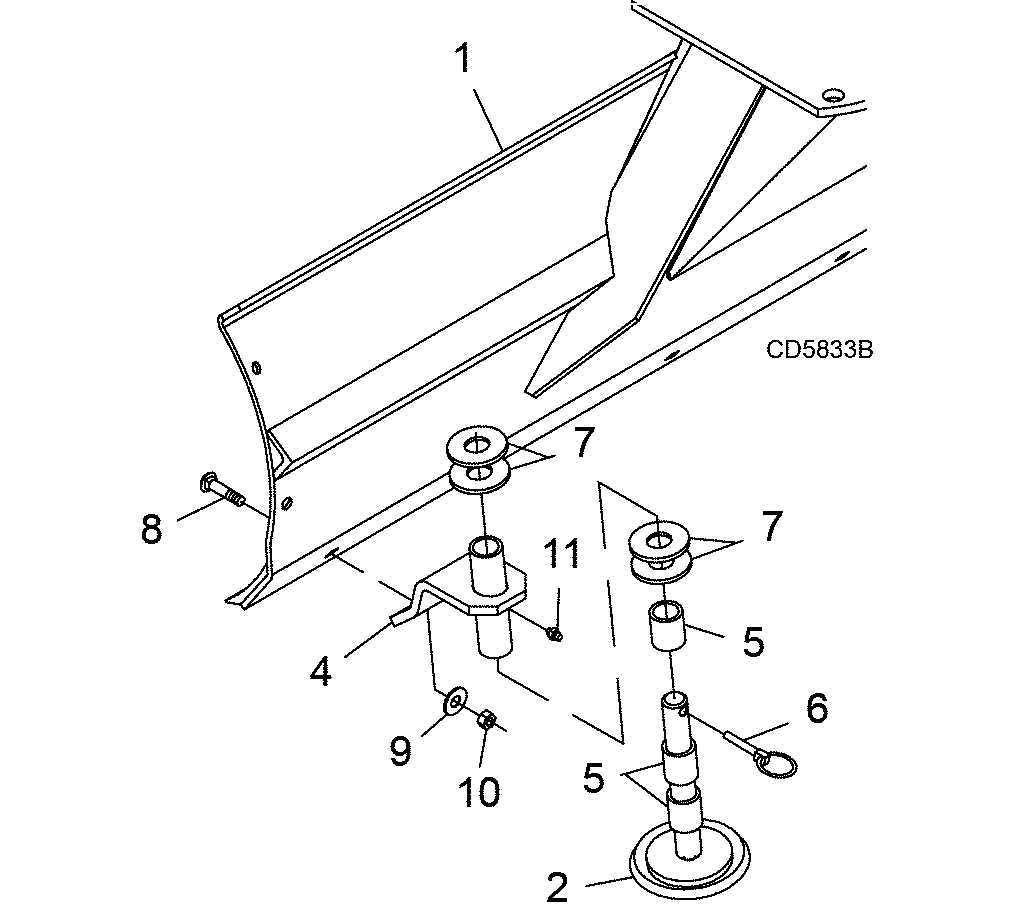

Key Components of Snow Plow Systems

Understanding the essential elements of a clearing apparatus is crucial for effective operation and maintenance. These components work together to ensure optimal performance during winter conditions.

- Mounting Frame: This structure connects the equipment to the vehicle, providing stability and support.

- Blade: The main component for moving snow, available in various shapes and sizes to suit different tasks.

- Lift Mechanism: Enables the operator to raise and lower the blade efficiently, enhancing maneuverability.

- Control System: Provides the operator with the ability to adjust settings and monitor performance in real-time.

- Hydraulic System: Powers the lift and angle functions, allowing for smooth adjustments during operation.

Each of these components plays a vital role in the ultimate efficiency and reliability of the system, ensuring effective clearing of surfaces in adverse weather.

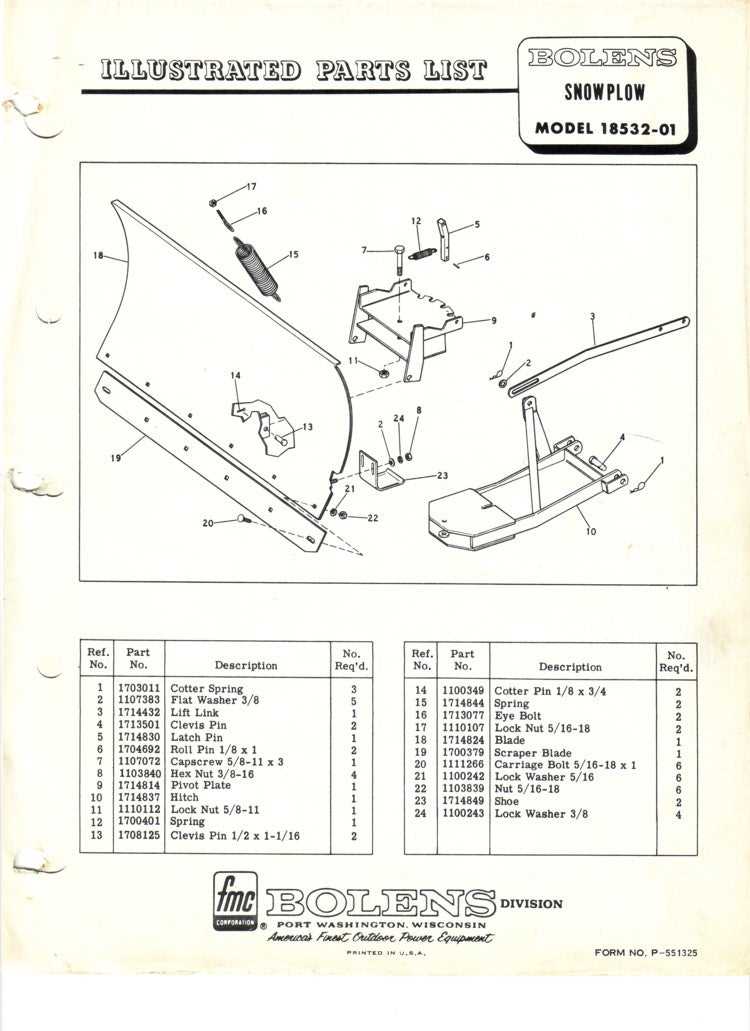

How to Interpret Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations offer a simplified view of various elements, helping users identify and locate each piece in a system. Familiarity with symbols and notation used can greatly enhance your ability to interpret these visuals.

Start by examining the overall layout, noting how components are organized. Look for numbered or labeled sections that indicate specific items, as these references guide you through the assembly or disassembly process. Pay attention to any color coding or grouping, as these can signify different categories or functions within the system.

When analyzing a visual guide, it’s beneficial to cross-reference with the accompanying text or legend. This additional information often clarifies the function of each item, providing context that enhances understanding. By taking the time to study these materials, you will ultimately gain a clearer picture of how everything fits together.

Practice makes perfect; the more you engage with these visuals, the more intuitive the process becomes. As you delve deeper into the intricacies of the components, you’ll find yourself more confident in tackling repairs and upgrades. Remember, each illustration serves as a valuable tool in mastering the mechanics at play.

Maintenance Tips for Snow Plow Parts

Ensuring optimal performance during the winter season requires regular upkeep of essential components. Proper care not only enhances efficiency but also extends the lifespan of the equipment. By following a few straightforward maintenance practices, operators can avoid common issues and ensure reliable operation.

Regular Inspections

Conducting thorough evaluations of your equipment before each use is crucial. Check for signs of wear, rust, or damage, focusing on key areas such as blades and hydraulic systems. Addressing minor problems early can prevent more significant repairs later on.

Lubrication and Cleaning

Keep all moving parts well-lubricated to reduce friction and prevent wear. Cleaning the surfaces after each use removes debris and prevents buildup, which can hinder functionality. Make sure to use appropriate cleaning agents that won’t harm the materials.

Common Issues with Snow Plow Mechanisms

When it comes to winter equipment, various challenges can arise that hinder performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and ensuring safe operation during harsh weather conditions. This section explores typical complications encountered in such machinery.

Mechanical Failures

Mechanical failures can significantly impact the operation of winter clearing equipment. These issues may stem from wear and tear, lack of maintenance, or component incompatibility. Regular inspections and timely replacements can mitigate these risks.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Hydraulic leaks | Reduced lifting capability | Inspect hoses and fittings; replace damaged components. |

| Worn blades | Poor clearing performance | Sharpen or replace blades as needed. |

| Electrical malfunctions | Inconsistent operation | Check wiring connections and replace faulty switches. |

Environmental Effects

Environmental factors can also play a significant role in the efficiency of winter equipment. Extreme temperatures, ice buildup, and heavy snowfall can exacerbate existing issues, leading to further complications.

Where to Find Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its efficiency and performance. There are several reliable sources where you can search for these essential items, ensuring you get the right fit and quality for your machinery.

Online Retailers

Many websites specialize in providing a vast array of components for various machines. These platforms often feature detailed descriptions and user reviews, aiding in making informed decisions.

Local Dealerships

Your local dealerships can be a valuable resource for acquiring original components. They usually have knowledgeable staff who can assist in identifying the right items for your needs.

| Source Type | Advantages |

|---|---|

| Online Retailers | Wide selection, competitive pricing |

| Local Dealerships | Expert assistance, guaranteed compatibility |

| Salvage Yards | Cost-effective options, unique finds |

Upgrading Your Snow Plow Setup

Enhancing your winter preparation equipment can significantly improve efficiency and effectiveness during harsh weather conditions. By considering various upgrades, you can optimize performance, increase durability, and make your tasks easier. Here are some essential components to consider when looking to elevate your setup.

- Blade Width: A wider blade can cover more ground, reducing the number of passes needed.

- Material Quality: Upgrading to high-grade materials can enhance longevity and resistance to wear and tear.

- Attachment Systems: Investing in advanced attachment systems can simplify the process of switching tools.

- Hydraulic Features: Hydraulic lifts and angling systems allow for better maneuverability and precision.

When considering upgrades, it’s essential to evaluate the compatibility with existing equipment. Ensure that any new components align with your current setup to avoid unnecessary complications.

- Assess current equipment condition and performance.

- Research available enhancements that meet your specific needs.

- Consult user reviews and expert recommendations for reliable options.

- Make informed decisions based on budget and performance goals.

By thoughtfully upgrading your winter gear, you can create a more efficient and reliable operation, ensuring that you are prepared to tackle the toughest weather challenges.

Safety Precautions During Operation

Ensuring a secure environment while handling equipment is paramount for effective performance and user protection. Adopting essential safety measures can significantly reduce the risk of accidents and injuries.

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Conduct a thorough inspection of the machine before use to identify any potential hazards.

- Familiarize yourself with the operating manual and follow all manufacturer instructions.

- Ensure the work area is clear of obstacles and hazards that could interfere with safe operation.

Regular maintenance is critical to prevent equipment failure and ensure smooth functioning. By adhering to safety protocols, operators can maximize efficiency while minimizing risks.

- Keep hands and loose clothing away from moving parts.

- Never operate the machinery under the influence of alcohol or drugs.

- In case of emergency, know how to shut down the machine quickly.

By prioritizing safety, operators can create a reliable environment for themselves and others involved in the operation.

Customer Reviews of John Deere Parts

This section provides insights into user experiences with various components designed for outdoor machinery. Reviews often highlight quality, durability, and overall satisfaction, helping potential buyers make informed decisions.

Quality and Durability

- Many users praise the robustness of the components.

- Several reviews mention long-lasting performance under tough conditions.

- Common feedback points to minimal wear and tear over extended use.

Overall Satisfaction

- Customers frequently express contentment with the ease of installation.

- Support from customer service is often highlighted as a positive aspect.

- Many users recommend these components for their reliability and effectiveness.