In the world of outdoor machinery, comprehending the intricate relationships between various elements is essential for optimal performance and longevity. This section aims to provide clarity on the essential components that make up your machine, ensuring you can navigate its functionalities with ease.

Identifying key features is crucial for troubleshooting and maintenance. By familiarizing yourself with the different segments, users can ensure that their equipment operates smoothly and efficiently, reducing the risk of costly repairs.

Additionally, a comprehensive overview of these components can enhance your ability to make informed decisions regarding upgrades or replacements. Understanding how each part interacts ultimately leads to a more effective and rewarding experience in lawn care.

Understanding Scag Windstorm Components

In the realm of outdoor machinery, comprehending the various elements that contribute to performance is essential for effective maintenance and operation. Each component plays a pivotal role in ensuring that the equipment functions optimally and reliably. By familiarizing oneself with these essential features, operators can enhance their efficiency and prolong the lifespan of their tools.

Key elements include the engine, which serves as the powerhouse, driving all operations. The blades are crucial for achieving the desired results in landscaping, while the frame provides structural integrity and support. Understanding how these parts interact allows users to diagnose issues promptly and perform necessary repairs.

Moreover, attention to the control systems can greatly improve usability. Recognizing the significance of each function enables smoother handling and greater precision in various tasks. By delving into the intricacies of these components, users can make informed decisions about maintenance and upgrades, ultimately achieving peak performance.

Key Parts of the Windstorm Model

This section explores essential components that contribute to the overall functionality and efficiency of this specific machine. Each element plays a crucial role in ensuring optimal performance and reliability in various tasks.

| Component | Description |

|---|---|

| Blade Assembly | Designed for effective cutting and mulching, this component ensures precision in operation. |

| Engine | The powerhouse that drives the entire mechanism, offering robust performance for demanding tasks. |

| Chassis | The framework that supports all other elements, providing stability and durability during use. |

| Control System | Facilitates user interaction, allowing for easy adjustments and settings tailored to specific needs. |

| Wheels | Enables mobility across various terrains, enhancing the versatility of the machine. |

Importance of Regular Maintenance

Routine care is essential for ensuring the longevity and efficiency of any mechanical equipment. By adhering to a consistent maintenance schedule, users can prevent unexpected breakdowns and costly repairs. This proactive approach enhances performance and can significantly extend the life of the machinery.

Benefits of Preventive Care

Preventive maintenance not only reduces the likelihood of malfunctions but also improves safety for operators. By identifying potential issues early, one can avoid dangerous situations and ensure smooth operation.

Cost-Effectiveness

Investing time in regular upkeep ultimately leads to financial savings. Reducing the frequency of major repairs and increasing the efficiency of equipment allows users to maximize their investment over time.

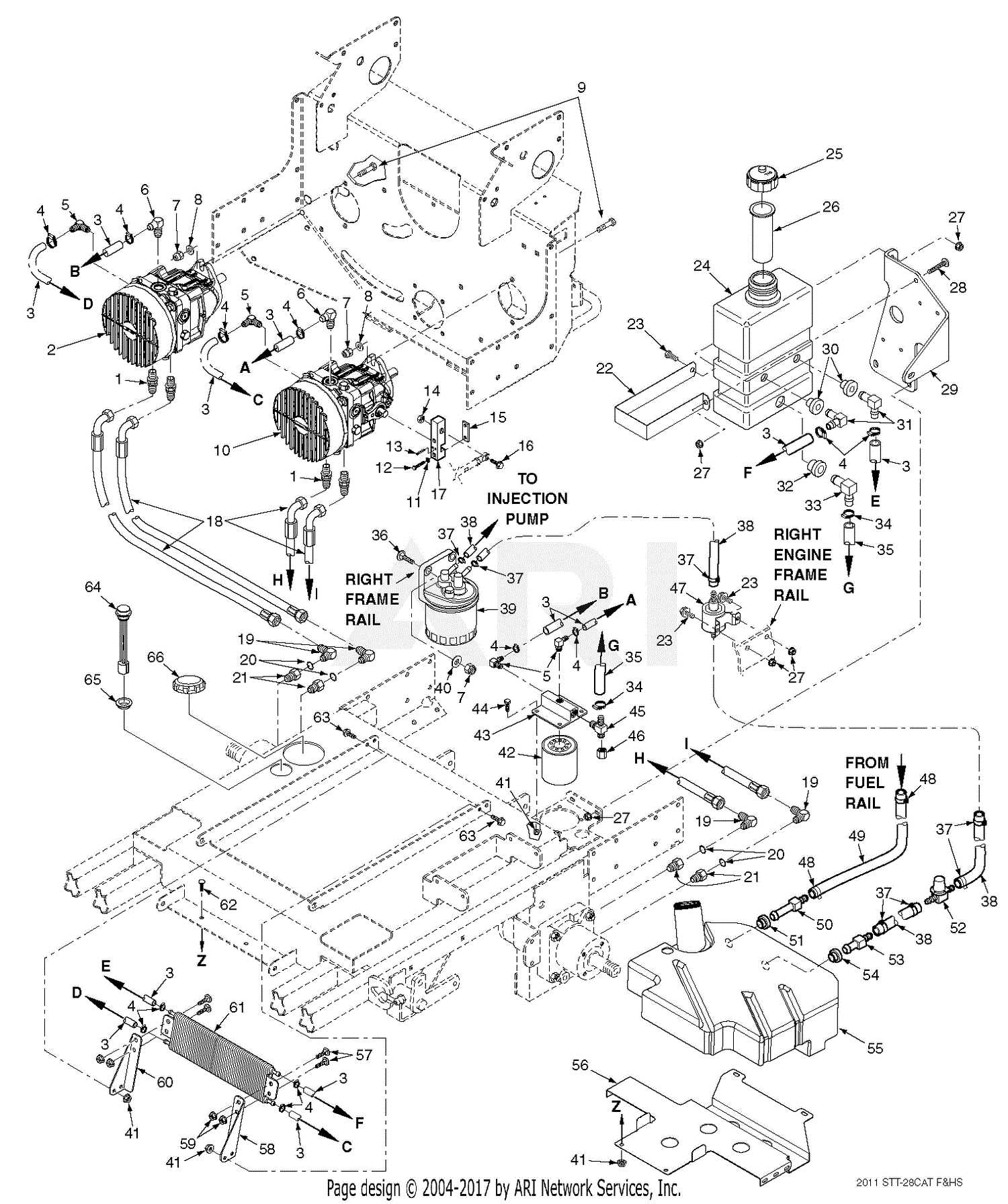

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations provide a comprehensive overview of components and their relationships within a complex system. By familiarizing yourself with the layout and symbols used, you can enhance your ability to identify parts and troubleshoot issues more efficiently.

Familiarize Yourself with the Layout: Typically, these visuals are organized in a way that mirrors the assembly of the equipment. Take note of how various elements are grouped together, which often indicates their functional relationships. Pay attention to the flow of information, as it often guides you through the assembly or disassembly process.

Decipher Symbols and Labels: Most illustrations use specific symbols and notations to represent different components. It’s crucial to understand what each symbol stands for to avoid confusion. Refer to the accompanying legend or key that explains these markings in detail, ensuring you grasp the meaning behind each representation.

Refer to Numerical References: Many technical visuals include reference numbers next to components. These numbers usually correspond to a list or catalog that provides detailed descriptions and specifications. This correlation allows for easier ordering and replacement of necessary items.

Practice Patience and Precision: When navigating these illustrations, take your time. Carefully analyze each section, and cross-reference with manuals or guides when needed. Developing this skill will make you more adept at understanding complex systems, ultimately leading to more successful repairs and maintenance tasks.

Common Issues with Windstorm Units

Equipment designed for handling intense outdoor conditions often encounters specific challenges that can impact performance and longevity. Identifying and addressing these common problems is essential for maintaining efficiency and ensuring reliable operation over time.

Mechanical Failures

One of the primary concerns is mechanical breakdowns, which can arise from wear and tear or inadequate maintenance. Frequent inspections and timely repairs can significantly mitigate these issues, enhancing the unit’s durability.

Electrical Problems

Another frequent complication involves electrical malfunctions, which may stem from faulty wiring or component failure. Proper diagnostics and regular checks of electrical systems are crucial for preventing unexpected downtime and ensuring optimal functionality.

Upgrading Scag Windstorm Equipment

Enhancing your outdoor machinery can lead to improved performance and efficiency. With the right modifications and upgrades, you can significantly increase the capabilities of your equipment, making it more versatile and suited to various tasks.

Benefits of Upgrading

- Enhanced performance in challenging conditions

- Improved fuel efficiency

- Increased durability and longevity

- Better user experience with modern features

Key Areas for Improvement

- Engine: Consider upgrading to a more powerful engine for greater productivity.

- Attachments: Explore additional accessories that can enhance functionality.

- Control Systems: Modernize control interfaces for better handling and responsiveness.

- Safety Features: Incorporate the latest safety technologies to protect users and equipment.

Investing in these upgrades can lead to a more effective and enjoyable operation, ensuring that your machinery meets your evolving needs in the field.

Where to Find Replacement Parts

When the time comes to source components for your outdoor equipment, knowing where to look can make all the difference. There are various avenues available that can help you locate the exact items you need to restore functionality and efficiency.

Online Retailers

The internet offers a wealth of options for purchasing necessary components. Here are some recommended platforms:

- Specialty Websites: These often provide a comprehensive selection of items tailored specifically for your equipment.

- Marketplaces: Large online marketplaces host numerous sellers and may offer competitive prices.

- Manufacturer’s Official Site: Visiting the official website can ensure authenticity and availability of original components.

Local Suppliers

In addition to online options, local shops can be invaluable resources. Consider the following:

- Authorized Dealers: They typically carry a range of items and can assist in finding the right ones for your machinery.

- Hardware Stores: Some general stores may stock common components or can order them for you.

- Repair Shops: Professionals may have insights into where to source specific components or may even sell them directly.

Utilizing these resources will help you efficiently find what you need to keep your equipment running smoothly.

Safety Tips for Operation

Ensuring safety during the use of outdoor equipment is crucial for both the operator and those nearby. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. This section highlights essential precautions to take before, during, and after operating machinery.

Pre-Operational Safety Measures

- Read the user manual thoroughly to understand the equipment’s features and safety warnings.

- Inspect the machinery before use to identify any potential issues, such as loose parts or leaks.

- Wear appropriate personal protective equipment, including gloves, goggles, and hearing protection.

- Ensure that the work area is clear of obstacles and bystanders to prevent accidents.

- Check the weather conditions to avoid operating during adverse weather, which could impair visibility or control.

Operational Safety Practices

- Maintain a firm grip on the controls and stay alert while operating.

- Keep hands and feet away from moving parts to prevent injuries.

- Be cautious when working on slopes or uneven terrain to avoid loss of balance.

- Use the equipment as intended; do not override safety features or modifications.

- Take regular breaks to stay focused and prevent fatigue.

By following these safety guidelines, operators can enhance their safety and that of others while effectively using outdoor machinery.

Comparing Models and Features

When exploring various models within a specific category of outdoor equipment, it’s essential to evaluate the diverse functionalities and specifications they offer. Each unit is designed with particular applications in mind, resulting in unique strengths and capabilities. This comparison not only aids in understanding the distinctions but also helps users make informed decisions based on their specific needs.

Performance is often a key factor in these evaluations. Different models may vary in engine power, speed, and overall efficiency, which can significantly impact their usability in various environments. Understanding these aspects allows potential buyers to select the model that aligns best with their operational requirements.

Additionally, features such as ease of maintenance, user-friendliness, and versatility should be taken into consideration. Some models might offer advanced technological integrations or ergonomic designs that enhance user experience, while others may focus on durability and robustness for heavy-duty tasks.

Ultimately, a thorough comparison highlights not just the individual merits of each model but also the potential trade-offs involved. By analyzing these elements, users can confidently choose equipment that best fits their expectations and operational demands.