Understanding the configuration of various elements in any machine is crucial for ensuring smooth operation and longevity. Knowing where specific elements are located and how they interact allows for quicker and more accurate troubleshooting. This knowledge is vital, especially when dealing with complex equipment that requires regular upkeep.

In this section, we will delve into the structural arrangement of key mechanical and functional elements. By familiarizing yourself with their layout, you’ll be better prepared to handle routine maintenance, identify potential issues, and improve overall performance. A clear understanding of the spatial relationships between these elements is essential for anyone looking to maintain or repair equipment effectively.

Whether you’re conducting preventative maintenance or addressing specific challenges, a well-organized overview of these elements will make the process significantly easier. With this guide, you’ll be able to navigate the intricacies of mechanical systems with confidence and precision.

Key Components of This Model

This section covers the most important elements that contribute to the overall performance and functionality of the machine. These parts are crucial for ensuring smooth operation, durability, and reliability. Understanding their roles will help in maintaining and troubleshooting the equipment efficiently.

Engine and Transmission

The core of this machine is driven by a high-powered engine, paired with a responsive transmission system. Together, they provide the necessary force to handle tough tasks with ease. The engine ensures consistent power output, while the transmission allows smooth speed transitions, contributing to both precision and strength.

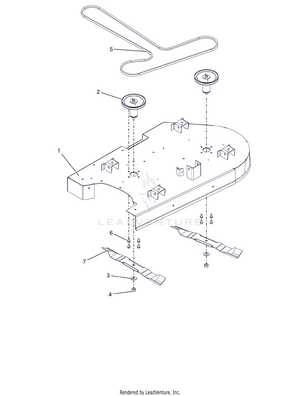

Cutting System

The cutting mechanism is another key feature, designed for efficiency and accuracy. It incorporates a robust deck that supports high-performance blades, capable of delivering clean and even cuts across various terrains. The deck height adjustment system allows users to tailor the cutting height to meet different needs, enhancing versatility and control.

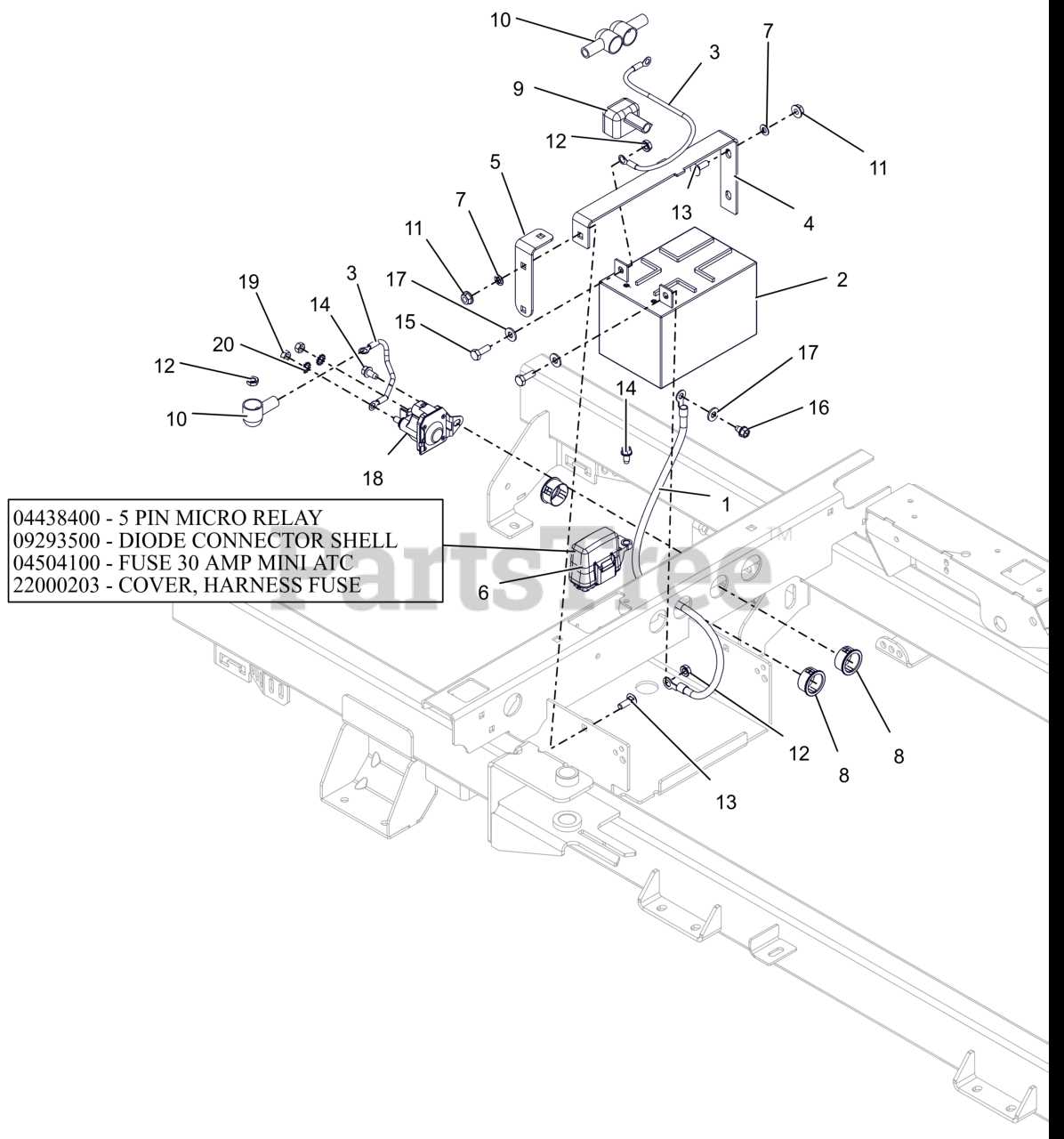

Identifying Essential Mechanical Parts

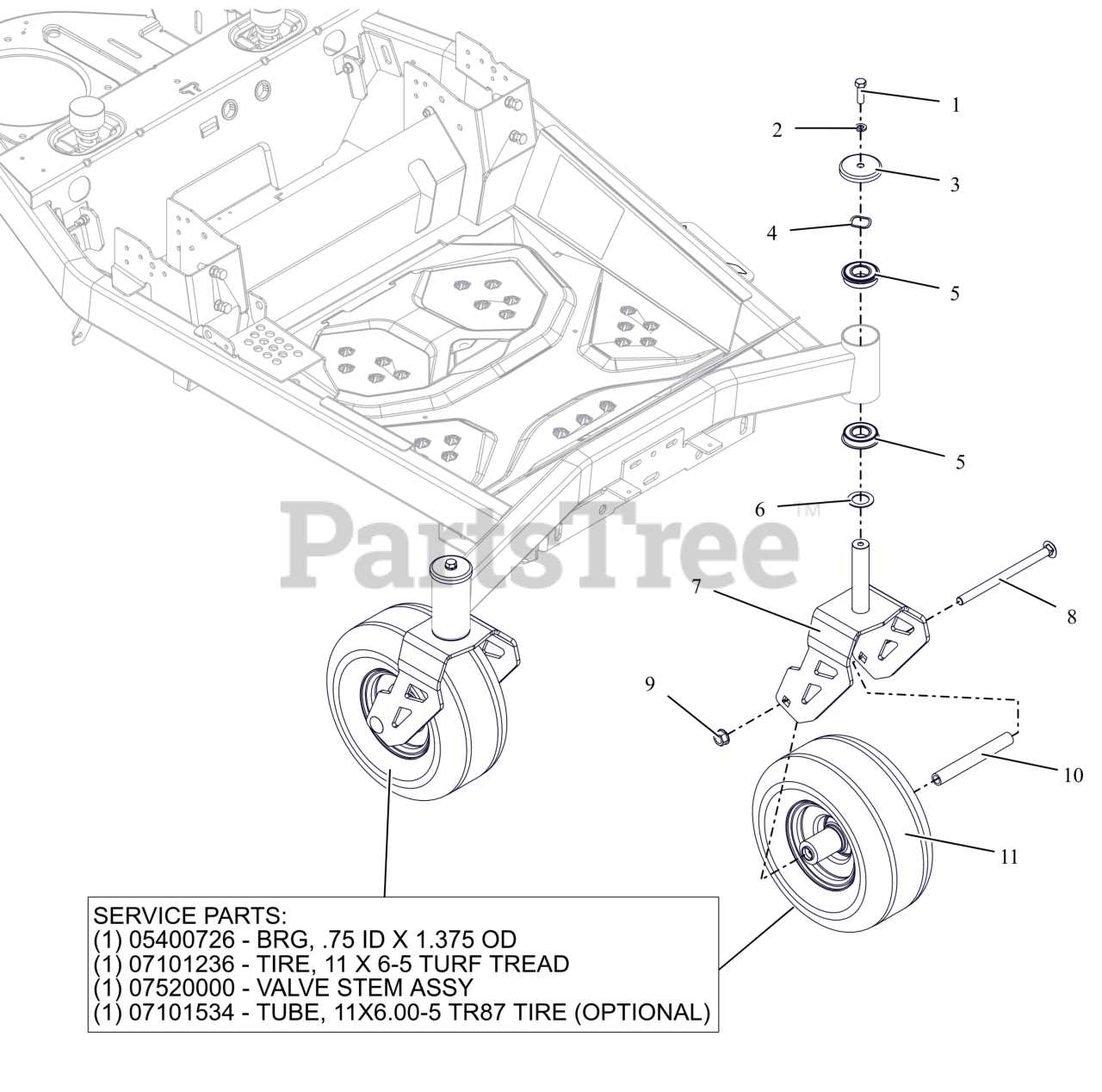

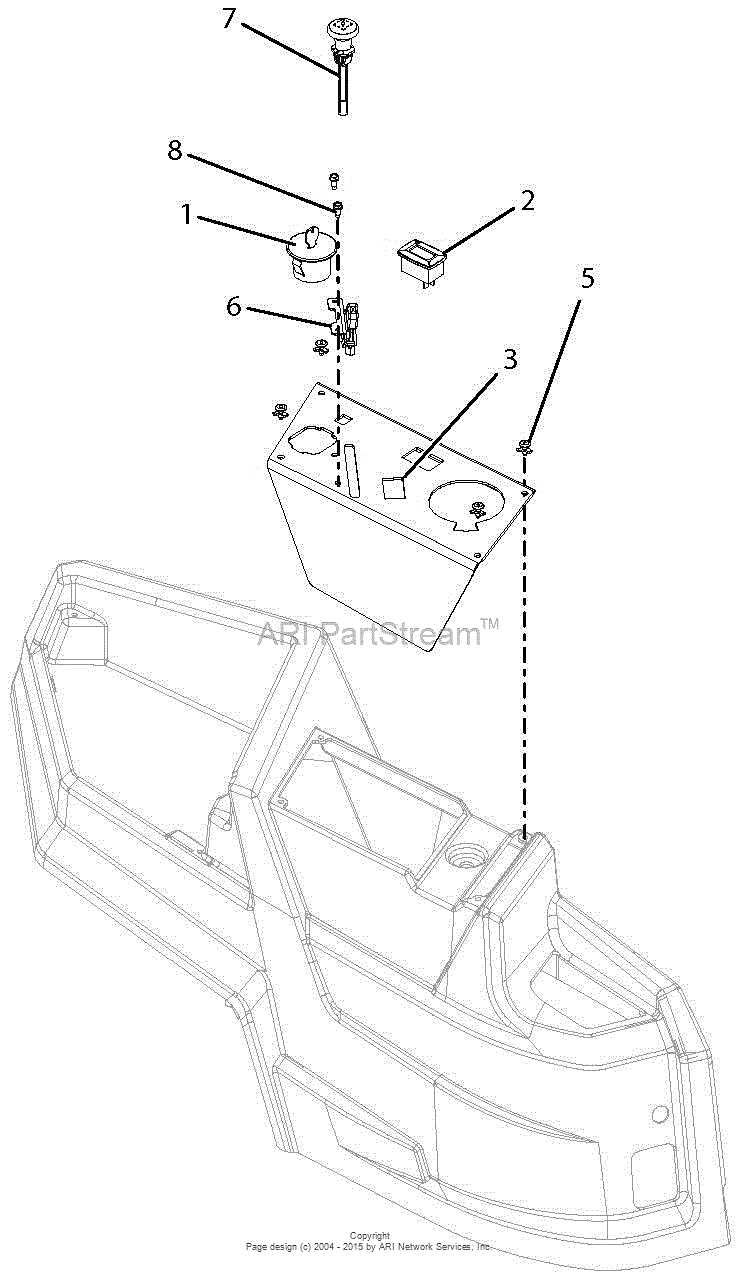

Understanding the core components that make up the mechanical structure is crucial for maintaining functionality and ensuring optimal performance. These elements are vital for both the operation and durability of the equipment, requiring regular inspection and, when necessary, replacement.

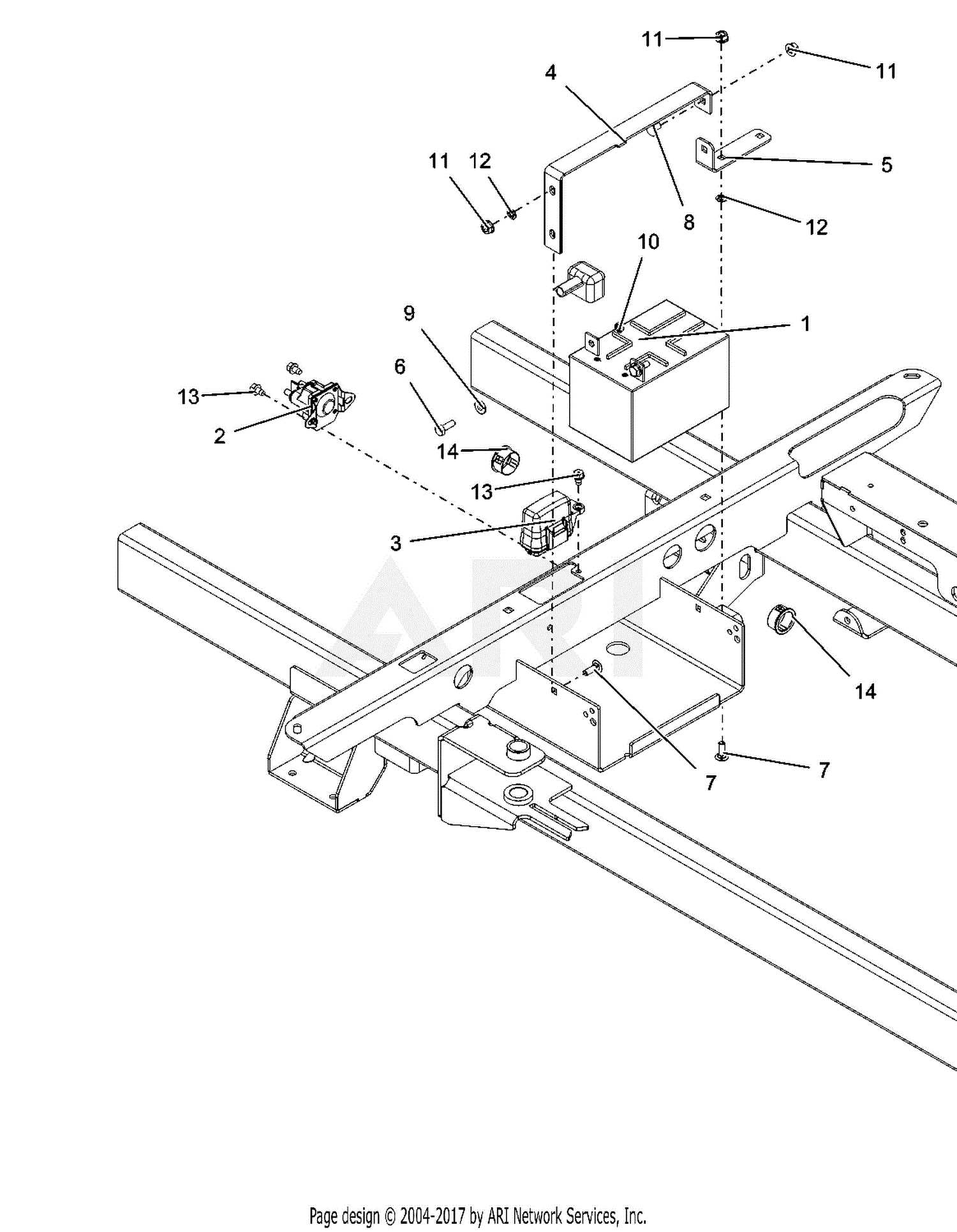

Key Structural Elements

The primary elements of the framework ensure stability and effective movement. Some of the critical items include assemblies responsible for movement control, attachments for proper alignment, and supportive hardware securing everything in place. These items should be checked frequently to prevent any operational disruption.

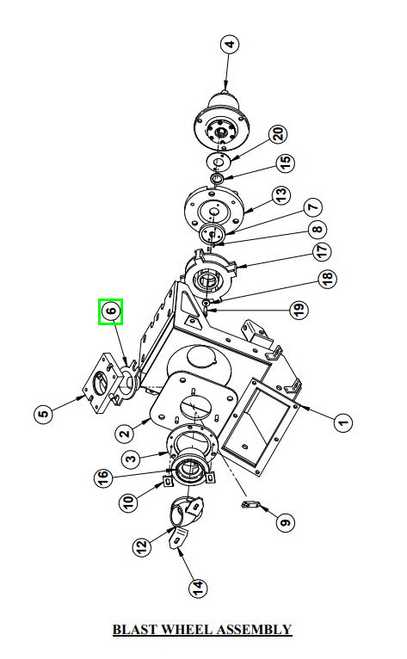

Operational Components

For smooth performance, several operational elements are in constant motion. These include moving parts responsible for speed and direction control, as well as those regulating load distribution. Proper lubrication and maintenance are essential to prolong their lifespan and avoid unnecessary wear.

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Chassis | Provides structural support and

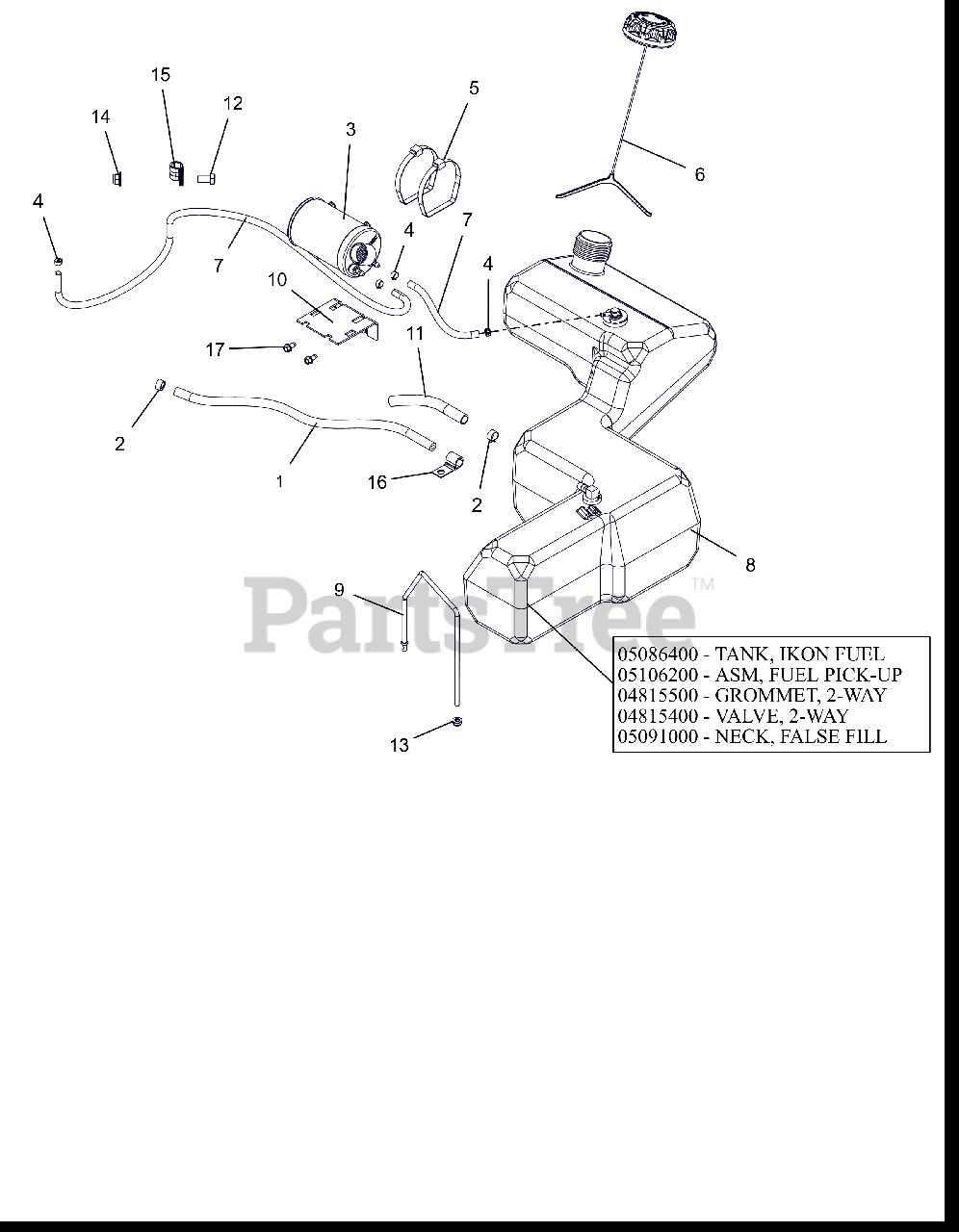

Engine System Overview and MaintenanceThe engine system plays a crucial role in ensuring the efficient operation of your outdoor machinery. Proper upkeep of the engine components is essential for maintaining optimal performance and extending the lifespan of the equipment. In this section, we will explore the fundamental aspects of engine maintenance, helping you understand the key areas to focus on for a smooth-running system.

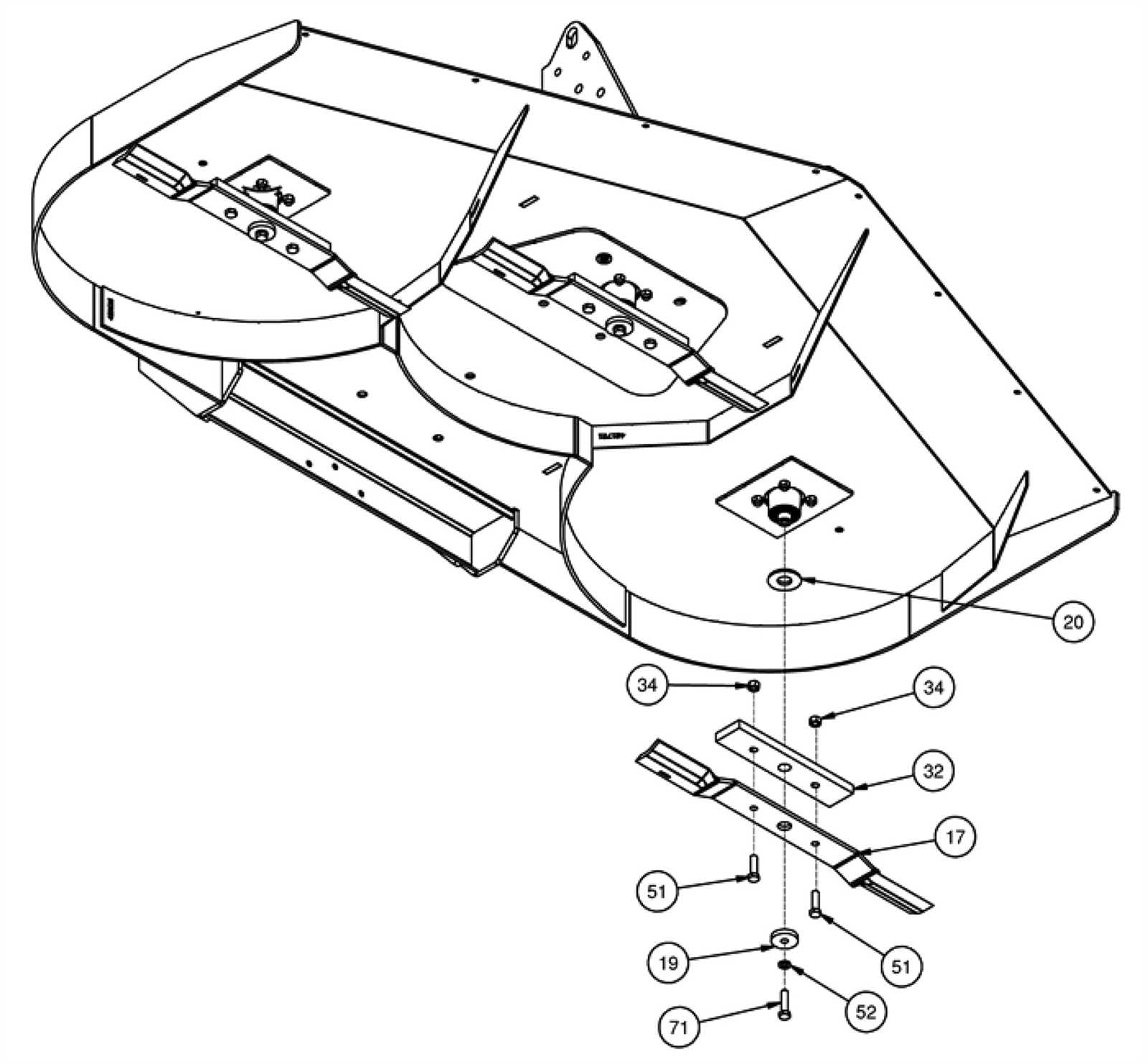

Regular maintenance of the engine components not only improves reliability but also ensures the machinery operates with maximum efficiency. By following these key steps, you can help your equipment run smoothly and avoid costly repairs down the line. Cutting Deck Assembly Breakdown

The cutting system in a riding lawn mower involves a well-coordinated structure designed for efficient grass trimming. Understanding the individual components and how they interact is essential for maintenance and repair. In this section, we will explore the elements that make up the entire cutting mechanism, detailing their functions and how they work together to ensure smooth operation. At the core of this system lies the platform that houses the blades, belts, and spindles, all of which are crucial to achieving precise cuts. Each of these elements plays a specific role in the overall performance, from guiding the blades’ movement to distributing power from the engine. By examining these individual components, we can gain insight into the critical aspects of ensuring durability and peak efficiency. Steering and Control Mechanism

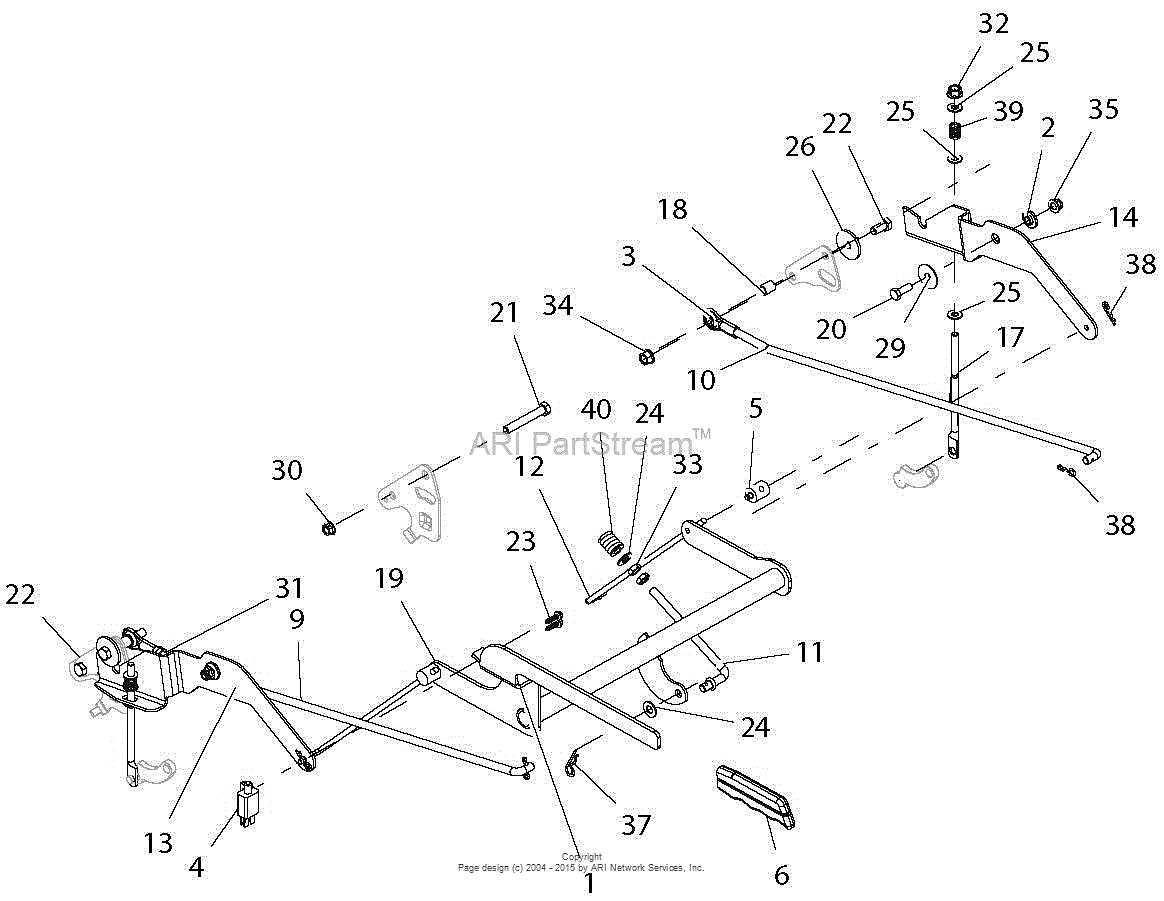

The steering and control system is an essential part of any modern lawn care machine, allowing the operator to smoothly maneuver through various terrains. The mechanism is designed to provide both precision and ease of use, ensuring that direction and speed can be managed efficiently for optimal performance. Proper functionality of this system ensures not only safe operation but also contributes to the overall durability of the equipment. Main Components Overview

The steering mechanism includes various interconnected components that work together to deliver a smooth turning experience. Each part plays a role in maintaining the stability of the machine while allowing for seamless transitions between movements. Below is a general breakdown of the major elements involved in the system:

|