In the world of compact machinery, comprehending the intricacies of each component is essential for optimal performance and longevity. Whether you are a seasoned operator or a newcomer, familiarizing yourself with the specific elements that make up your equipment can significantly enhance your maintenance and repair efforts. This section aims to shed light on the essential parts that ensure your machine runs smoothly.

Every piece plays a role in the overall functionality of your vehicle, contributing to its efficiency and effectiveness in various tasks. From the engine to the hydraulic systems, understanding how each element interacts with others is crucial for troubleshooting issues and performing upgrades. A well-informed operator can not only prevent potential breakdowns but also maximize the capabilities of their machinery.

In this discussion, we will delve into the intricate layout of these components, providing insights that empower users to make informed decisions regarding repairs and replacements. With the right knowledge at your fingertips, you can approach maintenance with confidence, ensuring that your equipment remains reliable for years to come.

Understanding Kubota BX23 Components

When working with compact utility machines, it’s essential to gain a solid understanding of the key elements that ensure their performance. These machines consist of a variety of components that work together to deliver powerful functionality for tasks like digging, lifting, and hauling. Each part, no matter how small, plays a crucial role in maintaining the efficiency and reliability of the entire system.

Key Elements of a Compact Tractor

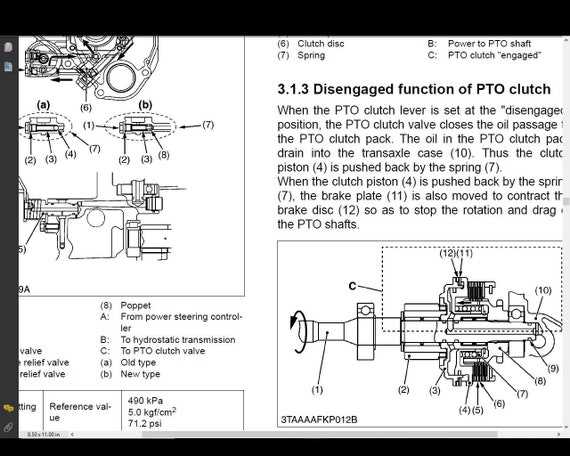

The system of a compact tractor includes numerous parts designed for specific tasks. The engine and transmission are fundamental, providing the power and control needed for movement and operation. The hydraulics system supports attachments such as backhoes, loaders, and mowers, while the steering and suspension components guarantee smooth handling on rough terrains. Additionally, safety mechanisms and electrical systems ensure the machine operates reliably without compromising user safety.

Categories of Components

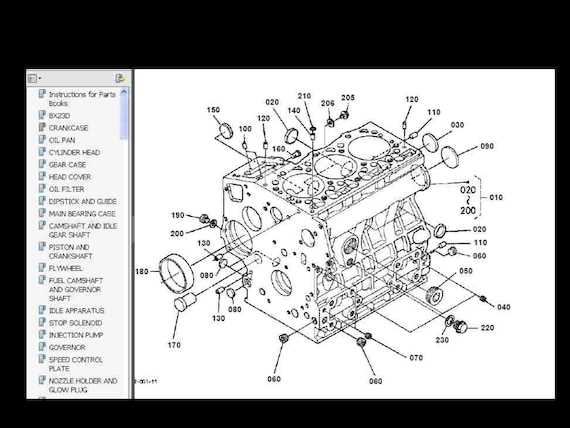

- Engine and Powertrain: These parts include the engine, transmission, and other critical systems responsible for powering the machine.

- Hydraulics: Hydraulic systems are essential for controlling attachments and other equipment that require fluid-based pressure to operate.

- Steering and Suspension: Components like the steering wheel, linkages, and suspension help in maneuvering and stabilizing the tractor on uneven ground.

- Electrical System: This includes wiring, sensors, and batteries that support the operation of the tractor’s electrical features.

- Frame and Chassis: The structural frame provides support for all components, ensuring the machine remains stable and durable under pressure.

Understanding how these parts interact and function together is key to ensuring your machine operates smoothly and effectively. Regular maintenance and familiarity with the essential components will not only improve performance but also extend the lifespan of your equipment.

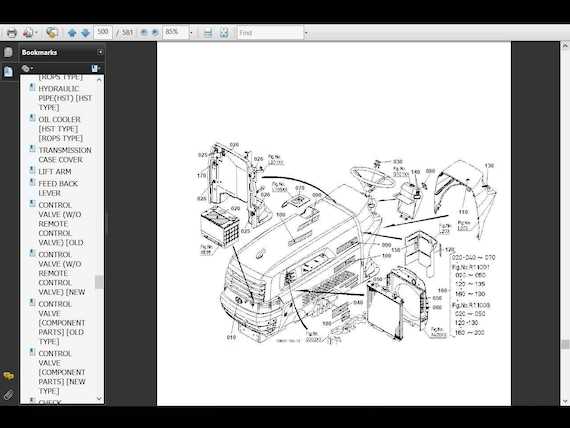

Importance of a Detailed Parts Diagram

Understanding the intricacies of machinery requires a comprehensive visual reference. Such references facilitate efficient maintenance, troubleshooting, and repairs, ensuring that operators can swiftly identify components and their functions.

- Enhances clarity for users unfamiliar with the equipment.

- Streamlines the process of ordering replacements.

- Aids in understanding assembly and disassembly procedures.

- Reduces downtime by allowing quick identification of issues.

Ultimately, having access to a thorough visual guide fosters confidence in handling equipment, leading to better performance and longevity.

How to Use Kubota BX23 Diagrams

Understanding the layout and structure of machinery is crucial for efficient maintenance and repair. Visual guides that outline components and their connections can significantly ease the process of identifying parts and troubleshooting issues. These resources are especially useful when you’re working on mechanical equipment that requires precision and knowledge of each individual part’s function and placement.

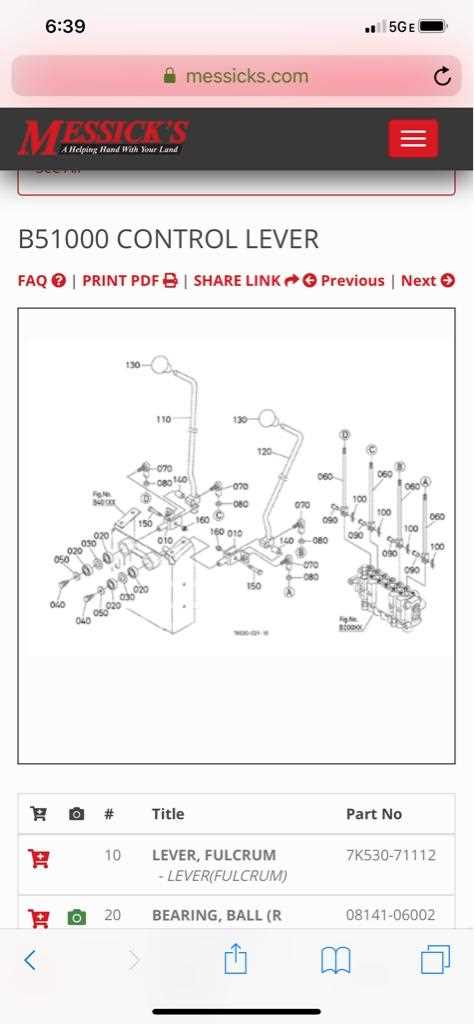

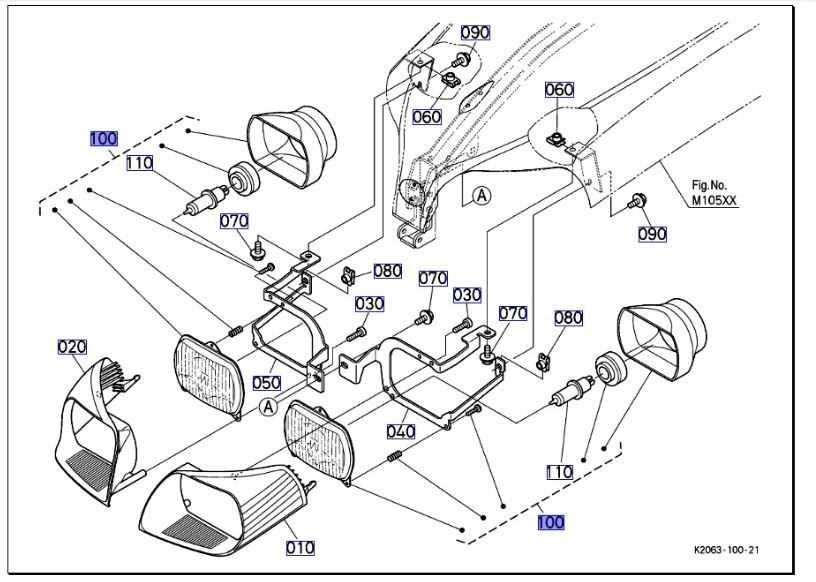

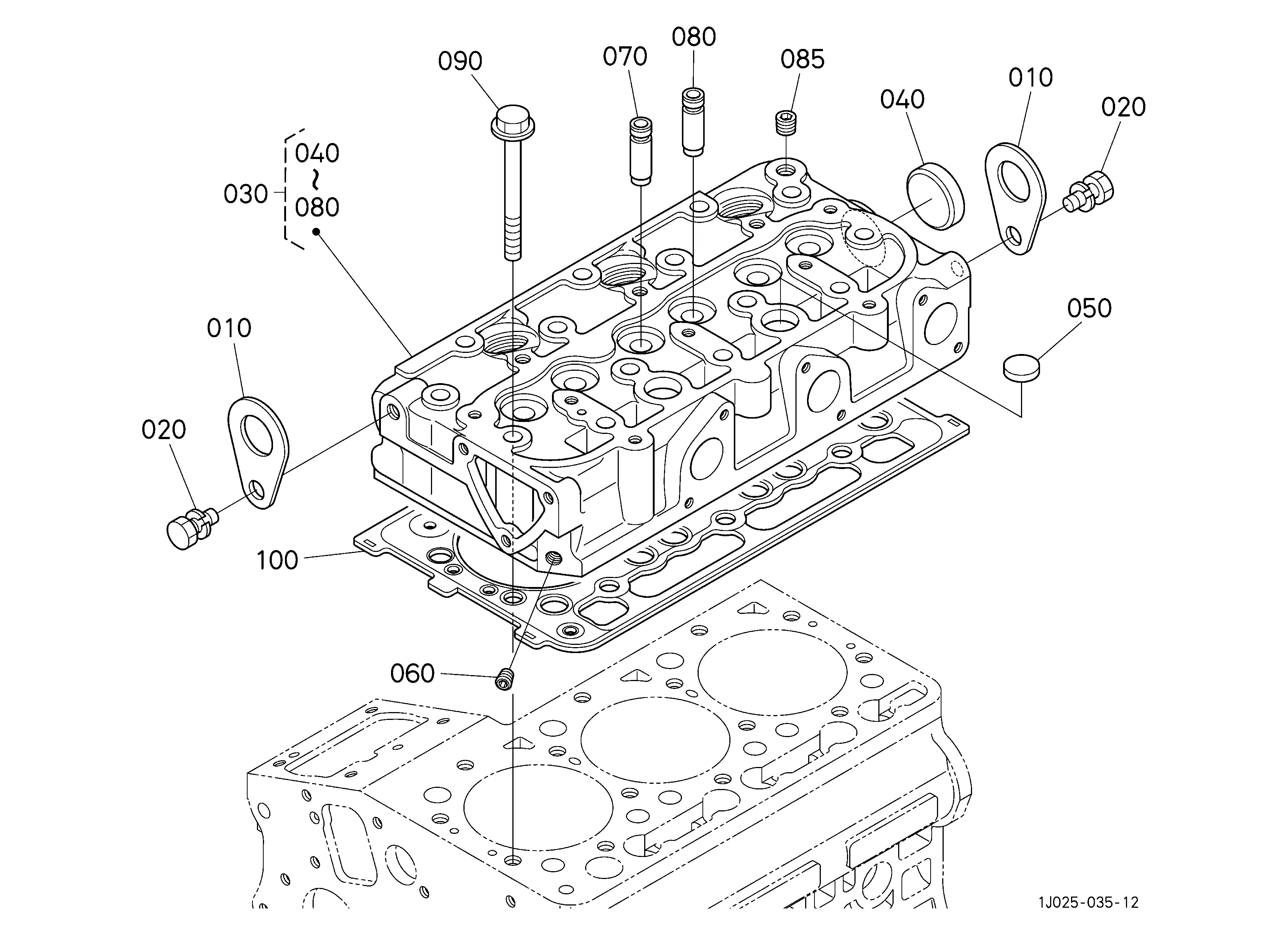

Identifying Components and Connections

The first step in using these visual aids is to carefully study the different components and their relationships within the system. By focusing on the illustrations, you can locate specific sections and understand how each element interacts with others. This can help you quickly pinpoint where an issue might arise, whether it’s a wear-and-tear problem or a more complex malfunction.

Guidelines for Efficient Troubleshooting

Once you’ve familiarized yourself with the key components, troubleshooting becomes more straightforward. Pay attention to part numbers and reference the diagrams when ordering replacements. These guides not only help with assembly and disassembly but also provide valuable insights into routine maintenance. Regularly consulting these resources can extend the longevity of your equipment by preventing unnecessary damage and ensuring that each part functions optimally.

Common Issues and Replacement Parts

Every machine, regardless of its purpose or complexity, is prone to certain challenges over time. Regular wear and tear, combined with environmental factors, can lead to malfunctioning or degraded components. Understanding these common issues and knowing how to address them can significantly extend the lifespan of your equipment. In many cases, timely repairs and replacements are essential to avoid more costly damage or system failures.

Frequent Problems

One of the most prevalent concerns involves engine overheating, which can result from inadequate cooling, clogged air filters, or insufficient fluid levels. Another common issue is with the hydraulic system, where leaks or pressure loss can hinder performance and lead to complete failure if not addressed promptly. Additionally, worn-out belts and pulleys often cause operational disruptions, affecting the efficiency of movement and power transmission.

Replacement Solutions

To resolve these issues, replacement of certain components is inevitable. For overheating, it is critical to replace damaged cooling systems or clogged filters. For the hydraulic system, new seals or hose replacements can restore pressure and functionality. Replacing worn belts and pulleys ensures smooth operation and prevents further damage to surrounding systems. Regular maintenance and timely part replacements can make a significant difference in maintaining the overall performance of the machinery.

Locating Kubota BX23 Part Numbers

When working with machinery or equipment, identifying the correct components is crucial for maintenance, repair, or upgrades. Understanding how to find the specific identification codes for each element ensures the right replacements are made, preventing compatibility issues. The process can be straightforward if you know where to look and what tools are available to assist in your search.

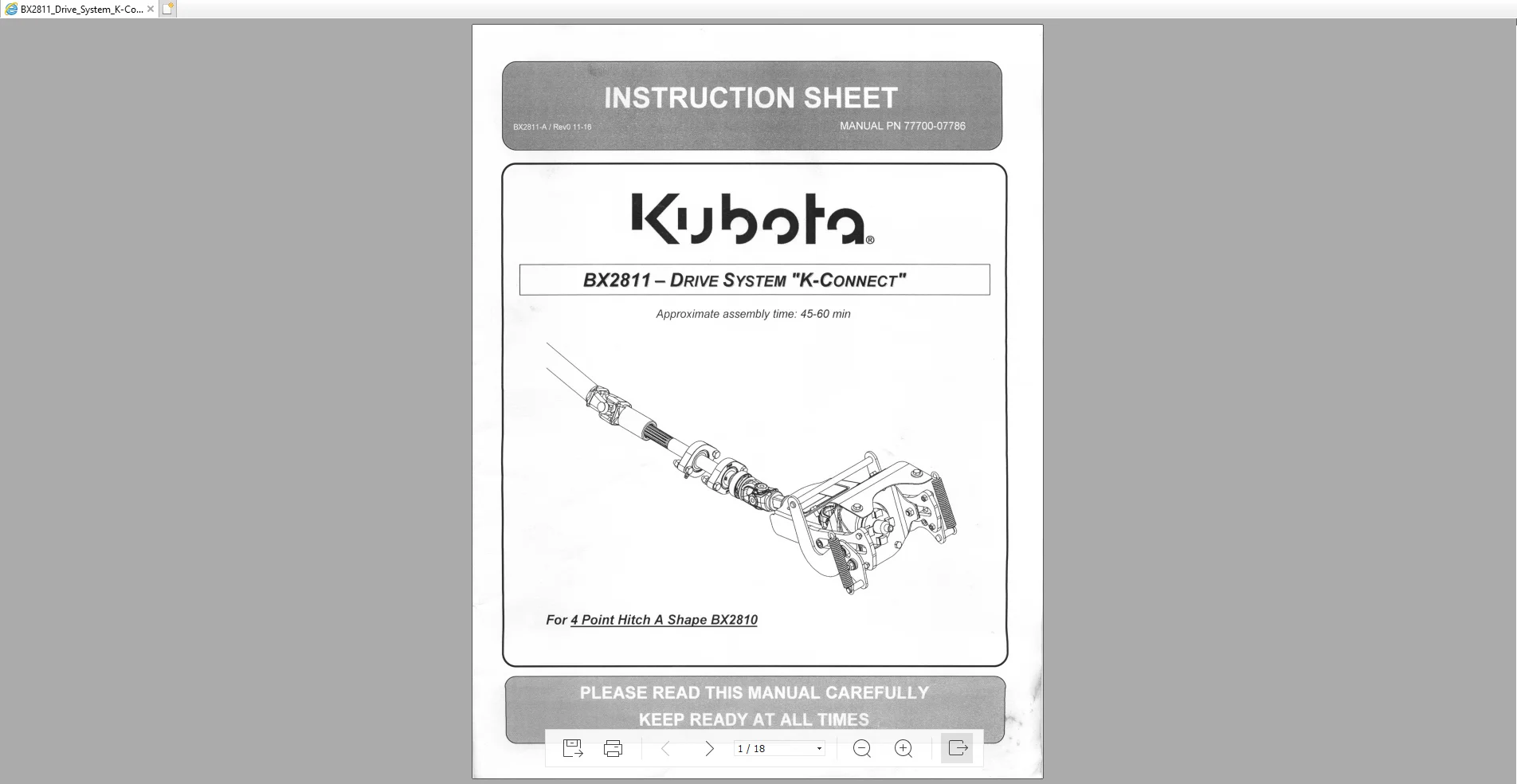

Manuals and Documentation are your first reliable resources. These often provide a comprehensive list of all required items and their corresponding numbers. Most manufacturers include these details in user guides or service books, making it easy for owners to find the correct identifiers when needed.

Online Databases and official websites can also offer detailed search functions. Many companies maintain digital archives where you can look up numbers by category or function. These platforms usually allow users to search by model or category, ensuring faster and more accurate results.

If you’re still uncertain about the numbers you’ve found, it may be helpful to consult dealers and repair shops that specialize in specific equipment. These experts often have extensive catalogs and are knowledgeable about finding the proper codes based on wear patterns, serial numbers, or part descriptions.

Lastly, online forums and community groups can be invaluable resources. Enthusiasts and professionals often share tips and part numbers based on their experiences, which can help you make an informed decision when ordering replacements.

Assembly and Disassembly Insights

Understanding the nuances of assembling and disassembling machinery components is essential for effective maintenance and repair. This process not only ensures optimal performance but also prolongs the lifespan of the equipment. Proper techniques and knowledge of the components involved can significantly reduce the risk of damage and enhance safety during the procedure.

Best Practices for Assembly

When putting together machinery parts, following systematic practices can lead to better outcomes. Start by organizing all necessary tools and components, ensuring everything is within reach. Referencing a reliable guide can provide clarity on the order of assembly, preventing common mistakes. It’s crucial to check for compatibility among parts to avoid misalignment or malfunctions.

Key Considerations for Disassembly

Disassembling machinery requires careful attention to detail. Begin by documenting the arrangement of components, which will aid in reassembly. Use appropriate tools to avoid stripping screws or damaging fragile parts. Take special care to handle any electrical connections safely, disconnecting power sources as needed to prevent accidents.

| Step | Action | Notes |

|---|---|---|

| 1 | Gather tools | Ensure all required tools are available. |

| 2 | Organize parts | Arrange components systematically for easy access. |

| 3 | Refer to guide | Follow instructions to maintain order. |

| 4 | Document arrangement | Take notes for easier reassembly. |

| 5 | Disconnect power | Ensure safety by removing power sources. |

Maintenance Tips for BX23 Parts

Regular upkeep is essential for the longevity and efficiency of your machinery. Proper care not only enhances performance but also prevents costly repairs. By following a few straightforward practices, you can ensure that your equipment remains in excellent working condition.

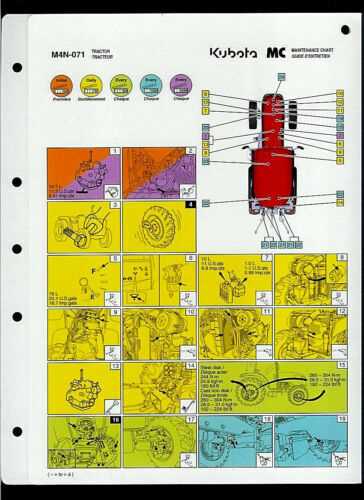

1. Routine Inspections: Conduct frequent checks of all components. Look for signs of wear, leaks, or loose fittings. Early detection of issues can save time and resources in the long run.

2. Cleanliness Matters: Keep all surfaces clean and free from dirt and debris. This is particularly important for moving parts, as buildup can lead to friction and eventual failure. Regular cleaning helps maintain optimal functionality.

3. Lubrication: Ensure that all necessary areas are adequately lubricated according to the manufacturer’s recommendations. Proper lubrication minimizes wear and tear and contributes to smoother operation.

4. Replace Worn Components: Timely replacement of damaged or worn components is crucial. Ignoring this can lead to more significant issues and increased downtime. Always refer to the guidelines for replacement intervals.

5. Store Properly: When not in use, store your equipment in a dry, sheltered area. Exposure to harsh weather conditions can lead to corrosion and other forms of deterioration.

6. Follow Guidelines: Adhere to the maintenance schedule outlined in the owner’s manual. This includes fluid changes, filter replacements, and any specific procedures relevant to your machinery.

By implementing these maintenance tips, you can enhance the reliability and performance of your equipment, ensuring that it operates efficiently for years to come.

Where to Buy Kubota BX23 Parts

When it comes to maintaining your compact utility machine, sourcing high-quality components is essential. Whether you’re tackling regular maintenance or need a replacement for a specific malfunctioning piece, finding the right retailer is key. The marketplace for these vital items is extensive, offering both online and local options to cater to your needs. Understanding where to look can help you secure the best deals and ensure compatibility with your equipment.

There are several reliable sources for obtaining the necessary components. Local dealerships provide personalized service and expert advice, while online marketplaces offer convenience and often a wider selection. Below is a comparison of different purchasing options, helping you make an informed decision.

| Source | Advantages | Disadvantages |

|---|---|---|

| Authorized Dealerships | Expert advice, genuine parts, warranty coverage | Higher prices, limited stock |

| Online Retailers | Wide variety, competitive pricing, convenient shopping | Potential for counterfeit items, shipping delays |

| Aftermarket Suppliers | Affordable options, good availability | Quality may vary, compatibility concerns |

| Local Repair Shops | Quick access, often know the machine well | Limited selection, higher markups |

Depending on your priority–whether it’s saving time, ensuring product authenticity, or keeping costs low–these options can provide the solution you need. Always ensure you are buying from a reputable source to avoid issues with installation or performance down the line.

Benefits of Regular Parts Inspection

Maintaining machinery in optimal condition requires consistent checking of key components. This practice helps identify wear and tear before it leads to major failures, ensuring smooth operation and extending the lifespan of the equipment. Regular inspection prevents costly breakdowns and enhances overall efficiency.

Prevention of Unexpected Failures: By regularly examining critical components, potential issues can be detected early, reducing the risk of sudden malfunctions. This proactive approach allows for timely repairs, preventing unexpected downtime that could disrupt work schedules.

Cost Savings: Routine checks help identify minor damages before they escalate into expensive repairs. Fixing small problems early is far less costly than addressing larger, more complex issues that arise from neglect.

Improved Safety: Ensuring that all parts are functioning properly enhances safety for operators. Worn or damaged components can compromise the stability or performance of machinery, creating hazardous conditions. Regular inspections help mitigate these risks.

Optimized Performance: Keeping components in peak condition ensures that the machinery operates at its best, maximizing fuel efficiency, power, and reliability. Consistent performance also contributes to better productivity and smoother workflow.

Long-Term Durability: Regular inspections help to preserve the overall integrity of the equipment. Proper maintenance contributes to the longevity of all essential parts, ensuring that the machine remains reliable and effective throughout its operational life.