When it comes to maintaining and optimizing your outdoor equipment, having a clear understanding of the various components and their assembly is crucial. This guide provides an overview of the essential mechanisms and configurations, helping you navigate through the setup and upkeep of your machinery effectively.

Whether you are an experienced user or just beginning, knowing the proper arrangement and specifications of each element can significantly enhance the efficiency and longevity of your device. In this guide, we explore how the different parts interact and work together, ensuring smooth operation throughout the season.

Detailed illustrations and explanations allow users to gain deeper insights into the internal workings of their equipment. By familiarizing yourself with this information, you will be better equipped to identify any necessary replacements, perform routine maintenance, and keep your machinery running at its

Understanding the John Deere 44 Snowblower

The equipment designed for winter maintenance is essential for efficiently managing snow accumulation. This specific model is built for reliable and consistent performance, ensuring that users can clear their paths and driveways effectively, even in challenging weather conditions. Its structure and mechanics are tailored to handle heavy snowfall, providing a durable and user-friendly solution for both residential and commercial use.

Key Features:

This model is equipped with a powerful engine that delivers optimal force for removing large amounts of snow. Its adjustable components allow for flexibility, adapting to various terrains and user preferences. The robust design minimizes the risk of clogging and enhances the efficiency of each clearing session, ensuring thorough snow removal in every pass.

Maintenance Tips:

Regular maintenance is crucial for the longevity of the equipment. Checking the belts, blades, and mechanical systems before each season can prevent potential issues. Proper storage during off-seasons, as well as periodic inspections, can extend the life of the machine, keeping it in top working condition when needed most.

Components of the 44in Snowblower

This section provides an overview of the main elements that make up the machine designed for clearing pathways during snowy conditions. The equipment is constructed using various parts that work together to ensure efficient performance and durability.

Main Assembly Units

The equipment is built with several key assemblies that form the core of its functionality. These sections interact to provide smooth operation and effective snow removal.

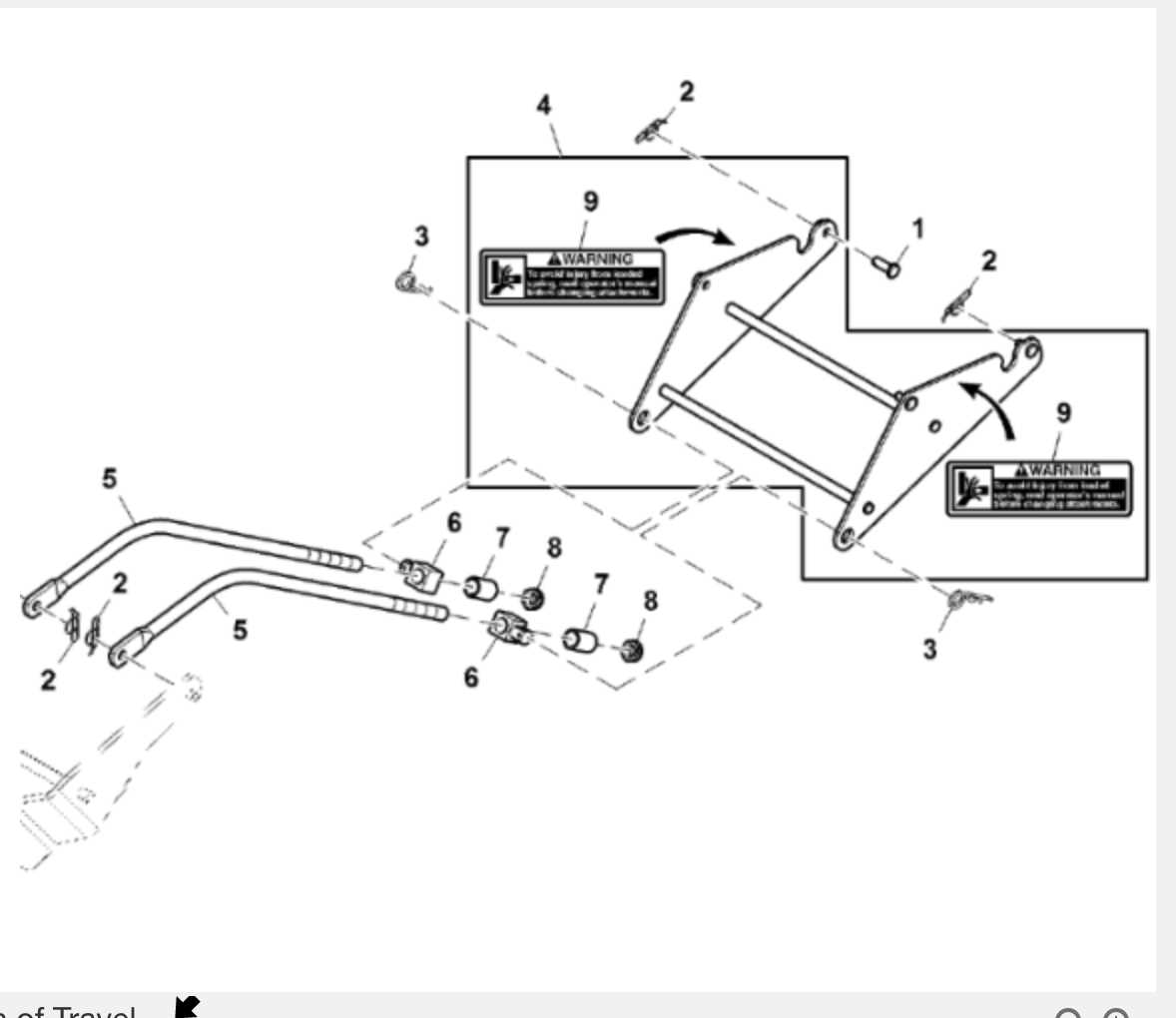

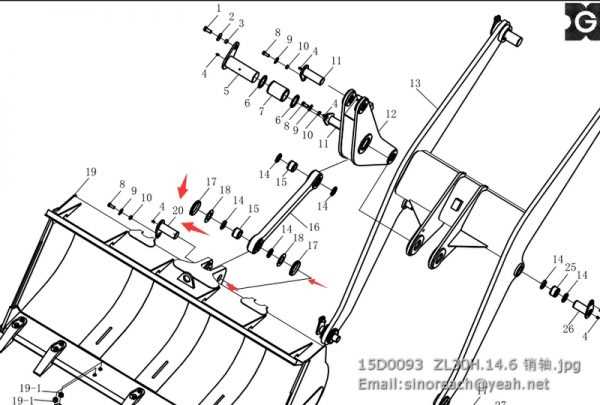

- Auger Assembly – Responsible for gathering and processing accumulated snow, moving it efficiently through the system.

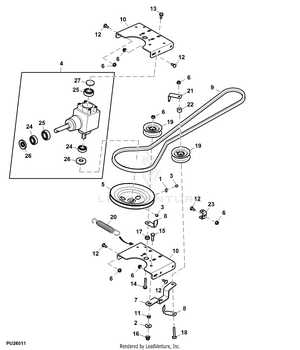

- Drive Mechanism – Powers the rotation of the blades, ensuring consistent movement and performance.

- Discharge Chute – Directs the flow of snow away from the path, allowing precise control of the discharge angle.

Additional Components

In addition to the main assemblies, the equipment also includes various smaller parts that support its overall function.

- Skid Shoes – These help to maintain stability and adjust the height for optimal clearing.

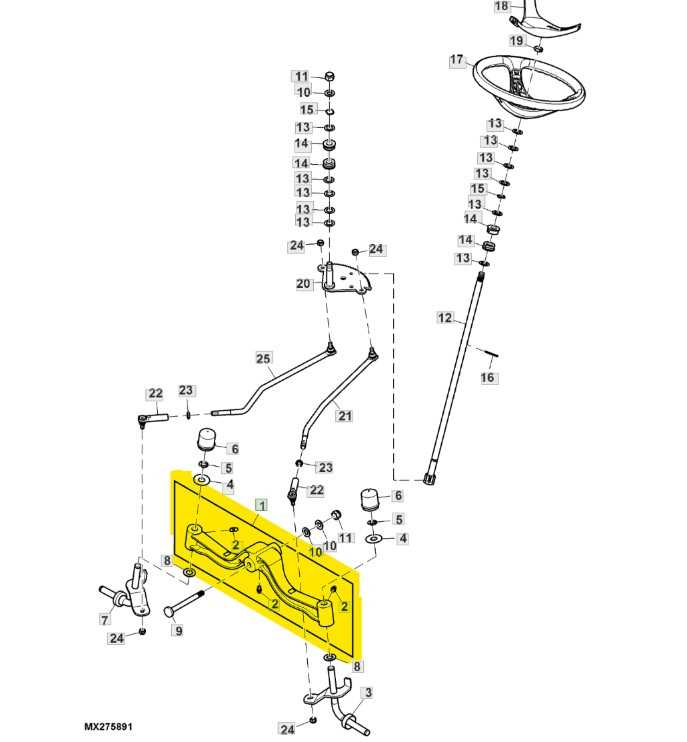

- Control Levers – Allow the operator to manage the speed, direction, and chute orientation easily.

- Consult the user manual to find the specific codes and descriptions associated with each component.

- Check for model numbers or identification tags directly on the equipment to cross-reference them with the manufacturer’s documentation.

- Measure the size and dimensions of the item you need to replace. Comparing these measurements with the specifications in the catalog can confirm accuracy.

- Inspect online databases or digital guides provided by the manufacturer. These resources often include visual references and updated part listings.

- If you encounter difficulties, contact customer support for professional assistance in identifying the appropriate replacements based on your equipment’s serial number.

- Ensure the fuel tank is filled with clean, fresh fuel.

- Check the spark plug for damage or wear, and replace it if necessary.

- Inspect the air filter for clogs and clean or replace it if it’s dirty.

- Verify that all cables and connections are secure.

- Tools: Screwdriver, wrench, and pliers.

- Components: Main body, attachment parts, and fasteners.

- Read the Manual: Before starting, thoroughly review the manufacturer’s instructions. Understanding the specifications and requirements can save time and prevent mistakes.

- Gather Tools: Ensure you have all necessary tools readily available. Having the right equipment on hand minimizes interruptions and allows for a smoother installation process.

- Inspect Components: Before installation, check all components for any visible damage. If you notice any defects, replace them to avoid complications later.

- Follow a Step-by-Step Approach: Work methodically through each step of the installation. Avoid skipping steps to ensure that nothing is overlooked.

- Secure Connections: Make sure that all connections are tight and secure. Loose fittings can lead to operational failures or safety hazards.

- Test Functionality: After installation, test the system to confirm everything is functioning as expected. Address any issues immediately to prevent further complications.

- Keep Records: Document the installation process, including any changes made. Keeping a record can be helpful for future reference or maintenance.

- Engine Performance: Upgrading the engine can provide more power and better fuel efficiency.

- Auger Design: A more efficient auger can cut through snow more effectively, reducing clogging and increasing clearing speed.

- Transmission System: Improving the transmission can offer smoother operation and better control over speed and maneuverability.

- Attachment Options: Adding specialized attachments can increase versatility, making it easier to handle different types of snow and ice.

- Check and change the oil regularly to keep the engine running smoothly.

- Inspect belts and cables for wear and replace them as needed.

- Sharpen or replace the cutting edges to ensure effective snow removal.

- Clean the equipment thoroughly after each use to prevent rust and buildup.

How to Identify Replacement Parts

Understanding how to recognize the correct components for maintenance is crucial to keep your equipment functioning smoothly. Proper identification ensures compatibility and efficiency, helping avoid issues during installation or operation. Below are steps to effectively determine the right components for your needs.

By following these steps, you can ensure that you choo

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure the longevity and efficiency of your equipment during harsh winter months. Consistent maintenance not only enhances performance but also prevents costly repairs and prolongs the machine’s life.

Inspecting and Cleaning Components

Thoroughly inspect the various components before each use. Remove any debris, such as leaves or ice, that may hinder operation. Pay attention to moving parts, ensuring they are clean and free from obstructions to maintain smooth functionality.

Lubrication and Adjustment

Proper lubrication is vital to reduce friction and wear on the system. Regularly apply suitable lubricants to the bearings and pivot points. Check and adjust belts, chains, and cables to guarantee they are tensioned correctly, ensuring reliable operation.

| Maintenance Task | Frequency |

|---|