Maintaining outdoor machinery designed for winter conditions is crucial for optimal performance. Knowing how each component interacts can significantly enhance efficiency and longevity. This section aims to provide a detailed look at the essential elements of your winter clearing apparatus, enabling better upkeep and repair.

Familiarizing yourself with the various components will not only help in troubleshooting issues but also aid in efficient operation. Visual aids can be particularly beneficial, offering a clear perspective on the layout and function of each section. This knowledge is essential for anyone looking to ensure their equipment remains in top condition throughout the season.

By exploring the intricate design and functionality of the machinery, users can gain valuable insights into proper maintenance practices. Understanding how each piece contributes to overall performance will empower you to tackle any challenges that arise during the winter months. Let’s delve into the specifics to maximize the effectiveness of your clearing device.

Understanding John Deere 44 Snowblower

This section provides insights into a specific model designed for winter maintenance tasks. It highlights the essential components and their functions, facilitating a comprehensive understanding of how this equipment operates effectively in clearing snow and ice. A thorough grasp of its construction enhances user experience and ensures optimal performance during challenging weather conditions.

Recognizing the various elements involved is crucial for both operation and maintenance. Each component plays a vital role, contributing to the overall efficiency and reliability of the machine. Familiarity with these features aids in troubleshooting and can prolong the lifespan of the equipment.

For anyone looking to enhance their knowledge of this winter tool, understanding its configuration and functionality is the first step toward effective usage. Comprehensive knowledge empowers users to tackle winter challenges with confidence.

Key Components of the Snow Removal Equipment

Understanding the essential elements of your winter clearing tool is crucial for optimal performance and maintenance. Each component plays a specific role, contributing to the overall efficiency and effectiveness during use. Here, we delve into the primary elements that make up this machinery.

Essential Elements

- Auger: This rotating blade is responsible for breaking up and gathering the snow.

- Impeller: The fan-like mechanism that propels the collected snow out of the chute.

- Chassis: The frame that provides structural support and houses other components.

- Control Panel: The interface that allows the operator to adjust settings and operate the equipment.

- Skid Shoes: These adjustable pieces determine the height at which the machine clears the surface.

Additional Features

- Engine: Powers the entire system and determines the unit’s capabilities.

- Transmission: Transfers power from the engine to the wheels, allowing for movement.

- Chute: Directs the flow of snow and can often be adjusted for better precision.

- Headlights: Enhance visibility during low-light conditions for safer operation.

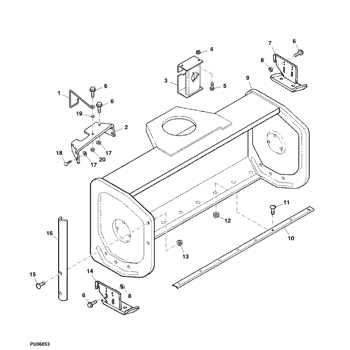

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and function of machinery. They provide clarity, ensuring users can identify each element, facilitating repairs and maintenance effectively.

Enhanced Understanding

Comprehension of the intricate relationships between different elements is vital for anyone working with equipment. These visuals simplify complex structures, making it easier to grasp how each piece interacts within the larger system.

Efficient Repairs

When it comes to fixing issues, having access to these representations allows for quicker identification of faults. Timely maintenance not only saves time but also prevents further damage, ultimately extending the lifespan of the equipment.

Common Replacement Parts Overview

Understanding the essential components of your equipment is crucial for ensuring its efficient operation. Regular maintenance often involves the replacement of specific elements that may wear out over time. Familiarizing yourself with these components can help you maintain optimal performance and extend the lifespan of your machinery.

Essential Components

Several key items are commonly replaced to keep the system running smoothly. These include belts, which are vital for transferring power; shear pins, which protect against damage during operation; and impellers, responsible for moving materials effectively. Regularly checking and replacing these components can prevent more significant issues down the line.

Maintenance Tips

To maximize the efficiency of your machinery, it’s important to follow a routine maintenance schedule. Inspect components regularly for signs of wear and tear. Keeping replacement parts on hand can also save time during emergency repairs. Proper maintenance not only ensures peak performance but also enhances safety during operation.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for efficient maintenance and repair tasks. These visuals provide a detailed representation of components, making it easier to identify and locate necessary items for service or replacement.

Key Elements to Look For

- Labels: Often include part names or numbers.

- Connections: Show how different elements interact.

- Legend: Explains symbols or color coding used in the visual.

Steps to Interpret the Visual

- Start by reviewing the legend to understand any symbols.

- Identify the main components, focusing on their arrangement.

- Match labels with your inventory to locate what you need.

Identifying Compatible Components

Understanding the essential elements for machinery maintenance is crucial for ensuring optimal performance and longevity. Compatibility among various components can significantly enhance efficiency and reduce operational issues.

- Research the specifications of each component.

- Check compatibility with the main unit model.

- Consult user manuals for guidance.

It’s beneficial to keep a record of compatible items to simplify future replacements. This can save time and reduce frustration when troubleshooting equipment.

- Identify the manufacturer’s recommended components.

- Look for aftermarket alternatives with positive reviews.

- Verify dimensions and connections before purchasing.

Taking these steps will ensure that you are equipped with the ultimate knowledge for maintaining your machinery effectively.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life of your outdoor equipment. By implementing a few straightforward practices, you can significantly enhance its performance and durability. Proper attention not only prevents issues but also optimizes functionality throughout its use.

Here are some key maintenance tips to consider:

| Task | Frequency | Benefits |

|---|---|---|

| Check Oil Levels | Before each use | Ensures smooth operation |

| Inspect Belts | Monthly | Prevents breakdowns |

| Clean Air Filter | Every season | Improves engine efficiency |

| Sharpen Blades | As needed | Enhances cutting performance |

| Store Properly | Off-season | Protects from weather damage |

Where to Purchase Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Various avenues exist for acquiring these essential items, each offering unique advantages depending on your specific needs and preferences.

Authorized Dealers: One of the most reliable sources is authorized dealerships, which typically carry a comprehensive selection of genuine items. Shopping at these locations ensures you receive high-quality products specifically designed for your machinery.

Online Retailers: The internet provides a plethora of online marketplaces that specialize in equipment components. Websites such as Amazon or specialized e-commerce sites often feature competitive pricing and convenient home delivery options, making them a popular choice.

Local Hardware Stores: Don’t overlook your neighborhood hardware shop. Many local stores stock common items, and their staff can offer valuable advice and assistance in finding what you need.

Salvage Yards: For those seeking budget-friendly alternatives, salvage yards can be an excellent option. These locations often have used items in good condition, providing an economical solution for those willing to search.

Forums and Community Groups: Engaging with online communities and forums can also yield beneficial information. Members often share recommendations and may even sell or trade components they no longer need.

Each of these sources presents distinct opportunities to secure the necessary components for your machinery. By exploring multiple avenues, you can ensure you find the best fit for your requirements.

Troubleshooting Common Issues

Addressing frequent challenges with outdoor clearing equipment is essential for maintaining its efficiency and longevity. Identifying the root of problems can enhance performance and prevent further complications. Here are some common issues and solutions to consider.

Engine Problems

- Hard Starting: Check the fuel level and ensure the ignition system is functioning properly. Inspect the battery and connections for any corrosion.

- Stalling: Clean the air filter and spark plug. Ensure that fuel is reaching the engine adequately.

Operational Difficulties

- Ineffective Clearing: Ensure the blades are sharp and free of debris. Adjust the chute for optimal snow discharge.

- Unusual Noises: Listen for any grinding or rattling sounds that may indicate worn or damaged components. Check for loose fasteners or foreign objects.