In the realm of outdoor equipment, comprehending the various elements that contribute to optimal performance is essential. Each component plays a pivotal role in ensuring that the device functions smoothly and efficiently. By familiarizing yourself with these intricacies, you can enhance your maintenance skills and prolong the lifespan of your machinery.

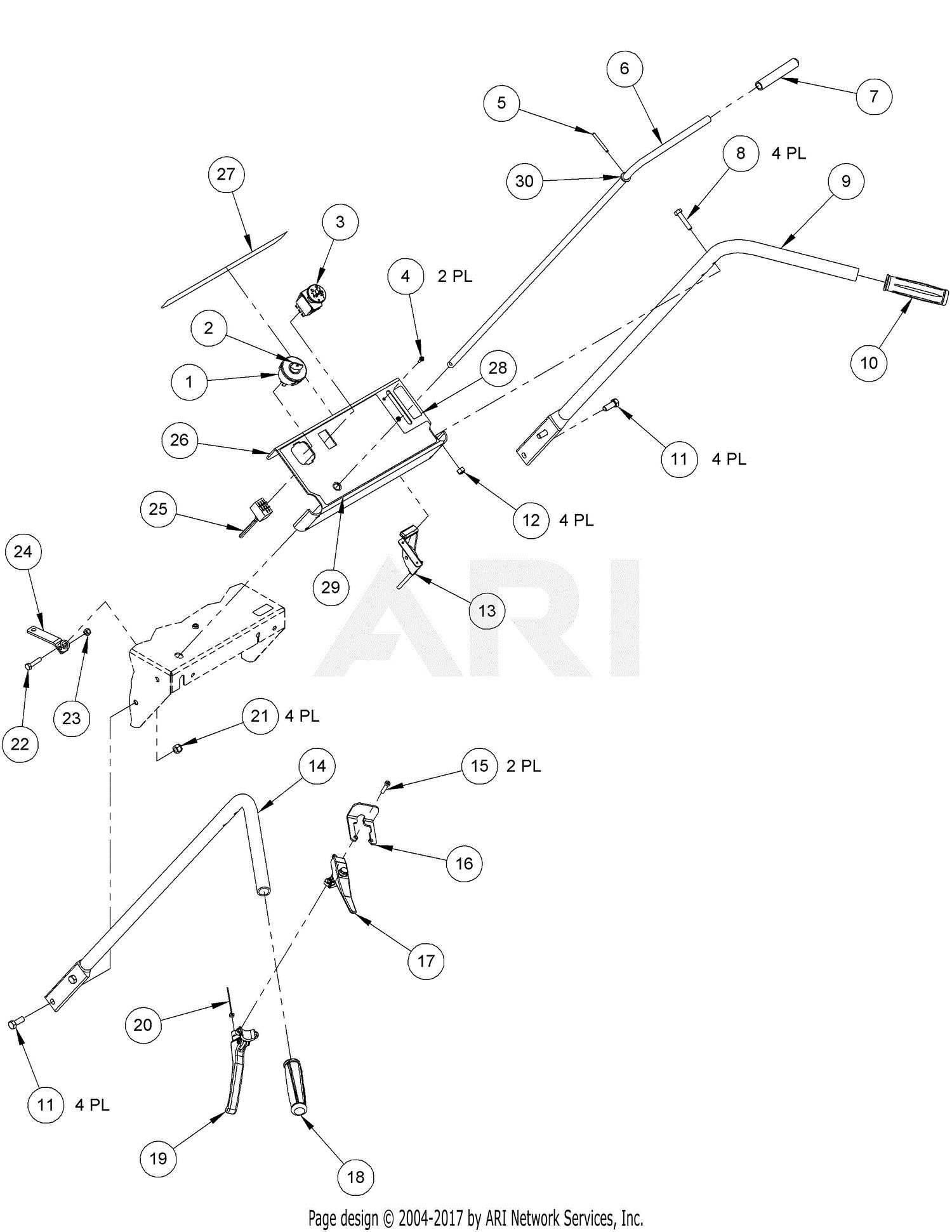

Visual representations serve as valuable tools for users seeking clarity about their equipment’s configuration. These illustrations not only simplify the identification of individual elements but also facilitate troubleshooting and repair tasks. Engaging with these resources allows operators to delve into the inner workings of their devices, paving the way for informed decision-making.

Ultimately, having a comprehensive understanding of your machine’s structure empowers you to tackle any issues that may arise. This knowledge fosters a proactive approach to maintenance, ensuring that your outdoor equipment remains reliable and effective throughout its usage.

Understanding Dr Chipper Parts

This section aims to provide a comprehensive overview of the essential components that contribute to the functionality and efficiency of the Dr. Chipper machine. By familiarizing yourself with these elements, you can enhance your understanding of how the equipment operates and the maintenance required for optimal performance.

Key Components

- Motor: Powers the machinery for efficient processing.

- Feeder: Guides material into the machine smoothly.

- Blades: Crucial for cutting and shredding material.

- Chassis: The frame that supports all other components.

- Discharge chute: Directs processed material for collection.

Maintenance Tips

- Regularly inspect the motor for wear and tear.

- Keep the blades sharp for optimal performance.

- Check the feeder for blockages to ensure smooth operation.

- Lubricate moving parts to prevent rust and ensure longevity.

Importance of Accurate Diagrams

Accurate visual representations play a crucial role in understanding complex systems and components. They serve as essential tools that facilitate clear communication among users, designers, and technicians. By providing detailed illustrations, these visuals help in the seamless execution of tasks, ensuring that everyone involved has a shared understanding of the elements at hand.

Clarity is one of the primary benefits of precise visuals. When information is presented in an organized manner, it minimizes confusion and enhances the ability to grasp intricate details. This is especially important in technical fields where even minor misunderstandings can lead to significant errors or delays.

Moreover, efficiency is greatly improved through the use of well-crafted illustrations. Users can quickly identify and locate specific components, which streamlines processes and reduces the time spent searching for information. This efficiency not only aids in day-to-day operations but also contributes to overall productivity in various environments.

Additionally, accurate visuals serve as valuable references for training and troubleshooting. New users can rely on these guides to familiarize themselves with the system, while experienced technicians can consult them to diagnose issues effectively. This aspect underscores the importance of having high-quality illustrations that are both comprehensive and easy to interpret.

In conclusion, the significance of precise visual aids cannot be overstated. They enhance understanding, boost efficiency, and provide vital support for learning and problem-solving. As such, investing time and resources into creating accurate representations is essential for any field reliant on technical information.

Common Components in Dr Chipper

Understanding the essential elements that make up Dr Chipper’s functionality is crucial for effective maintenance and operation. These components work in harmony to ensure optimal performance, durability, and efficiency, making it easier for users to achieve their desired outcomes.

Key Elements

Each component plays a vital role in the overall system. Here are some of the main elements that contribute to its successful operation:

| Component | Description |

|---|---|

| Engine | Provides the necessary power for operation, ensuring smooth and efficient performance. |

| Feed Mechanism | Facilitates the intake of material, ensuring a steady flow into the processing chamber. |

| Cutting Blade | Designed to effectively shred and reduce the size of the input material for easier handling. |

| Discharge Chute | Directs the processed material away from the machine, allowing for efficient collection. |

Maintenance Considerations

Regular inspection and upkeep of these components are essential for maintaining performance and extending the lifespan of the unit. Proper care ensures that each element functions optimally, minimizing the risk of unexpected failures and enhancing overall productivity.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining the efficiency and longevity of your equipment. Over time, various components may experience fatigue, leading to diminished performance or even failure. Understanding these indicators allows for timely interventions, ultimately saving time and resources.

Visual Inspection is the first step in identifying issues. Look for any obvious signs such as cracks, rust, or uneven surfaces. These physical markers often indicate that a part may be nearing the end of its useful life.

Performance Monitoring can also reveal underlying problems. If the machinery is not operating at its usual capacity, it may suggest that certain elements are worn out. Listen for unusual noises or vibrations, which can be telltale signs of internal issues.

Regular Maintenance is essential for preventing significant wear. Establishing a routine check-up schedule helps in catching minor issues before they escalate. Keeping a log of inspections can also assist in tracking the condition over time.

In conclusion, being vigilant about the signs of deterioration will enable you to maintain optimal functionality and avoid unexpected breakdowns. Awareness and proactive measures are key to ensuring the continued success of your equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of your equipment. By following a systematic approach to maintenance, you can enhance performance and reduce the likelihood of costly repairs. Here are some practical suggestions to keep your machinery in optimal condition.

Routine Inspections

- Check for wear and tear on critical components regularly.

- Look for signs of rust or corrosion, especially in metal parts.

- Ensure that all connections are secure and free of debris.

Cleaning and Lubrication

- Clean the exterior to prevent the buildup of dirt and grime.

- Lubricate moving parts to reduce friction and wear.

- Use appropriate cleaning agents that won’t damage surfaces.

Adopting these maintenance practices will significantly contribute to the reliability and efficiency of your machinery, allowing it to perform at its best for years to come.

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to assemble or repair machinery. Familiarizing yourself with these illustrations helps identify individual elements and their relationships within the whole system.

Here are some key strategies to effectively interpret these visuals:

- Familiarize with Symbols: Each illustration uses specific icons or symbols to represent different components. Learning these can expedite your understanding.

- Identify Key Sections: Most visuals are divided into sections that highlight specific areas of the equipment. Focus on one section at a time to avoid confusion.

- Follow the Legend: Many illustrations include a legend or key that explains what each symbol means. Refer to it frequently for clarity.

Additionally, pay attention to any accompanying notes or annotations that provide important context or installation instructions. This extra information can often clarify how components interact.

By using these techniques, you’ll gain the confidence needed to navigate through complex visual guides effectively.

Repairing vs. Replacing Parts

When it comes to addressing issues in machinery, the choice between fixing components and substituting them can significantly impact both performance and cost. Each approach has its own set of advantages and disadvantages, making it crucial to evaluate the situation carefully.

- Repairing:

- Cost-effective for minor issues.

- Can extend the lifespan of existing components.

- Often quicker to implement.

- Replacing:

- Provides a fresh start with optimal functionality.

- May enhance efficiency and reduce future repairs.

- Can be more reliable if the damage is extensive.

Ultimately, the decision should be based on the severity of the problem, the long-term benefits, and available resources. An informed choice can lead to better performance and reliability in the long run.

Finding Quality Replacement Parts

Ensuring the longevity and efficiency of your equipment hinges on sourcing high-quality components. The right items not only restore functionality but also enhance overall performance.

- Research reputable suppliers known for their reliability.

- Look for customer reviews and ratings to gauge satisfaction.

- Consider warranties offered on the products.

- Examine the materials used for durability and compatibility.

When seeking alternatives, prioritize those that meet industry standards to achieve the best results. Here are a few tips:

- Verify compatibility with your specific model.

- Compare prices among different vendors for the best deal.

- Consult professionals for recommendations.

By following these guidelines, you can confidently navigate the process of acquiring reliable components that will serve your needs effectively.

DIY vs. Professional Service

When it comes to maintenance and repair tasks, individuals often face a choice between tackling the job themselves or hiring an expert. Each option comes with its own set of advantages and challenges, influencing the decision-making process based on various factors.

Choosing to go the DIY route can be appealing for several reasons:

- Cost Savings: Doing the work yourself can significantly reduce expenses associated with labor.

- Personal Satisfaction: Completing a project independently can provide a sense of accomplishment.

- Flexibility: You can work at your own pace and schedule the task according to your convenience.

However, DIY may also present some drawbacks:

- Lack of Expertise: Without the necessary skills, mistakes may occur, leading to further complications.

- Time-Consuming: The process can take longer than anticipated, especially for those without experience.

- Limited Access to Tools: Certain jobs may require specialized equipment that you might not have.

On the other hand, opting for professional assistance has its own merits:

- Expertise: Professionals possess the knowledge and experience to handle tasks efficiently and correctly.

- Guaranteed Results: Many services offer warranties, ensuring peace of mind regarding the quality of work.

- Time Efficiency: Experts can often complete the job more quickly than an inexperienced individual.

Nevertheless, relying on a service can come with its challenges:

- Higher Costs: Professional fees can add up, impacting your budget.

- Scheduling Conflicts: Coordinating availability can sometimes be a hassle.

- Less Personal Involvement: You may miss out on the satisfaction of completing the task yourself.

Ultimately, the decision between a DIY approach and hiring a professional hinges on individual preferences, skills, and the complexity of the task at hand.