Exploring the intricacies of mechanical systems can be both enlightening and essential for maintenance. Knowledge of how each element interacts within the larger assembly not only aids in troubleshooting but also enhances overall efficiency. This section delves into the various components, providing clarity on their arrangement and functionality.

Accurate comprehension of individual parts is vital for anyone looking to ensure optimal performance. By examining detailed layouts, one can identify potential issues before they escalate, leading to better longevity of the machinery. The visual representation of these elements serves as a valuable reference for both novice and experienced users alike.

In this exploration, readers will find useful insights that can guide repairs and replacements, ultimately fostering a more profound understanding of the equipment. Equipped with this knowledge, users can approach their maintenance tasks with confidence and skill, transforming challenges into manageable solutions.

Understanding Onan 5500 Generators

This section delves into the intricate workings and components of a specific power supply system designed for versatility and reliability. By examining the essential elements and their functions, one can appreciate the engineering behind this unit and how it meets various energy needs in different settings.

Key Components and Their Functions

The core elements of this power source play a vital role in its overall performance. Each component, from the fuel system to the electrical output mechanisms, is engineered to ensure optimal functionality. Understanding how these parts interact helps in troubleshooting and maintenance, enhancing the longevity and efficiency of the unit.

Maintenance and Care Tips

Importance of Parts Diagrams

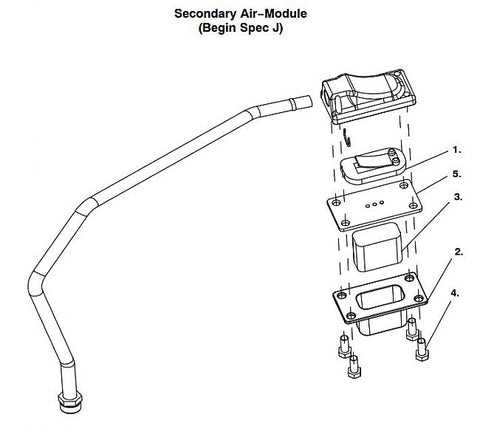

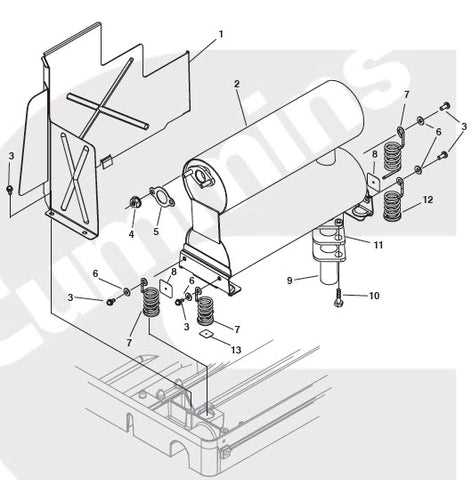

Visual representations of component layouts play a crucial role in maintenance and repair processes. They provide users with clear insights into the structure and function of various elements, ensuring efficient troubleshooting and assembly. Understanding these illustrations is vital for anyone involved in equipment care.

These representations serve multiple purposes, including:

| Benefit | Description |

|---|---|

| Enhanced Understanding | They clarify complex assemblies, making it easier for users to grasp how components interact. |

| Streamlined Maintenance | Visuals allow for quick identification of worn or faulty parts, facilitating timely repairs. |

| Efficient Reassembly | They guide users during the reassembly process, reducing the risk of errors. |

| Training Resource | Such illustrations can serve as valuable training tools for new technicians. |

In conclusion, familiarity with these visual guides is essential for effective equipment management, ultimately leading to improved performance and longevity.

Common Issues with Onan 5500 Generators

Many users encounter various challenges when operating their portable power sources. Understanding these common problems can help in troubleshooting and maintaining optimal performance. Below are some frequently reported issues along with potential causes and solutions.

Electrical Problems

- Start Failure: Often caused by a dead battery, faulty ignition switch, or wiring issues.

- Voltage Fluctuations: May result from a malfunctioning voltage regulator or loose connections.

- Overheating: Commonly linked to blocked air vents or insufficient oil levels.

Mechanical Issues

- Noisy Operation: Can indicate worn bearings or loose components.

- Fuel Leaks: Usually arise from damaged fuel lines or loose fittings.

- Difficulty in Starting: Often related to dirty filters or a clogged carburetor.

Regular maintenance and timely intervention can significantly reduce the frequency of these issues and enhance the reliability of the equipment.

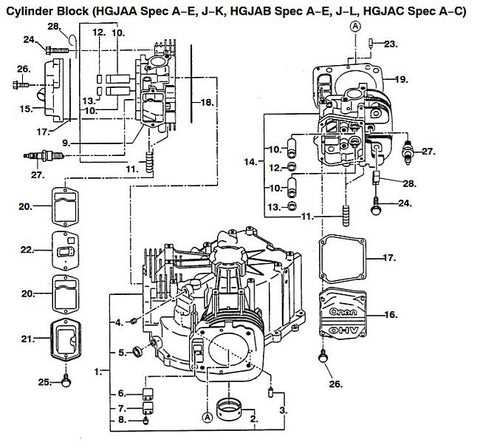

How to Read Parts Diagrams

Understanding schematic illustrations is crucial for efficient maintenance and repair tasks. These visual guides represent components and their relationships, providing insights into the assembly and functionality of a system. By familiarizing yourself with these representations, you can easily identify elements and troubleshoot issues more effectively.

To begin, look for a legend or key that explains the symbols used in the illustration. This will help you decode the representation of various elements. Typically, components are depicted in a simplified manner, allowing for quick recognition. Pay attention to the labels and numbers, as they often correspond to specific parts in a list, facilitating accurate identification and ordering.

Next, observe the connections between different parts. Lines often indicate how components interact, showing pathways for energy or materials. Understanding these connections can provide insights into the overall functionality and help pinpoint potential failure points. Additionally, look for grouping of components that may serve similar functions or belong to the same assembly.

Finally, take note of any notes or annotations on the illustration. These can offer valuable information regarding assembly order, torque specifications, or maintenance tips. By following these guidelines, you can enhance your ability to read and utilize schematic illustrations effectively, leading to better repair outcomes and a deeper understanding of the system.

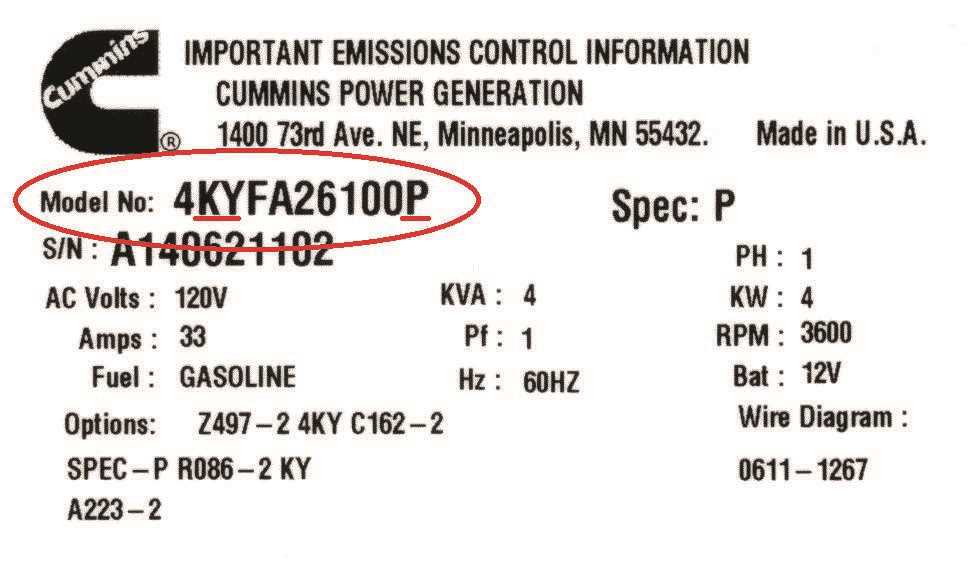

Essential Components of the Generator

Understanding the fundamental elements that contribute to the operation of a power supply unit is crucial for effective maintenance and troubleshooting. Each component plays a vital role in ensuring that the system functions smoothly and efficiently, providing reliable energy output when needed.

The engine serves as the heart of the unit, converting fuel into mechanical energy. Its efficiency directly impacts the overall performance and longevity of the equipment. Coupled with the engine is the alternator, which transforms the mechanical energy into electrical energy, making it accessible for various applications.

An integral part of this assembly is the control panel, which monitors and manages the operation of the entire system. It provides essential information regarding power output and alerts users to any potential issues. Additionally, a robust cooling system is essential to prevent overheating, ensuring optimal performance during prolonged use.

Fuel systems, including tanks and filters, are crucial for the delivery of energy resources, while the exhaust system facilitates the safe expulsion of gases produced during operation. Finally, proper wiring and connections are necessary for the seamless transmission of electricity to the desired locations, highlighting the importance of each component in maintaining functionality and safety.

Where to Find Replacement Parts

Locating the right components for your equipment can be crucial for its optimal performance. Various resources are available to assist in sourcing these essential items. Understanding where to search can save both time and money while ensuring that your machine continues to operate efficiently.

One of the most reliable sources for obtaining new components is through authorized dealers. These establishments often carry a comprehensive selection of items that meet manufacturer specifications. Additionally, they provide expert advice and support, making them a great option for those seeking quality replacements.

Another valuable avenue to explore is online marketplaces. Numerous websites specialize in aftermarket and OEM options, allowing you to compare prices and find what suits your budget. User reviews and ratings can also guide you in choosing reputable sellers, ensuring you receive quality merchandise.

Local repair shops can be an excellent resource as well. Many technicians maintain a stock of commonly needed components or can assist in placing special orders. Establishing a relationship with a trusted mechanic can lead to valuable insights and recommendations for sourcing parts effectively.

Lastly, forums and online communities dedicated to your specific equipment type often provide tips and leads on where to find hard-to-get components. Engaging with fellow users can lead to shared experiences and suggestions that enhance your search efforts.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention to detail. By implementing a consistent maintenance routine, you can significantly extend the lifespan of your machinery while enhancing its efficiency.

Here are some essential tips to consider:

- Regular Cleaning: Dust and debris can accumulate over time, leading to inefficiencies. Clean the exterior and accessible components frequently.

- Check Fluid Levels: Regularly inspect and replenish necessary fluids, including oil, coolant, and fuel. Maintaining appropriate levels helps prevent overheating and mechanical failures.

- Inspect Filters: Replace air and fuel filters at recommended intervals to ensure optimal airflow and fuel delivery, reducing strain on the system.

- Battery Maintenance: Keep terminals clean and ensure the battery is securely mounted. Check the charge regularly to avoid unexpected power loss.

- Run Regular Tests: Periodically operate the unit under load to confirm that all components are functioning correctly and efficiently.

By following these guidelines, you can help ensure that your equipment remains reliable and performs at its best for years to come.

DIY Repairs and Troubleshooting

When facing issues with your machinery, understanding how to conduct repairs and troubleshoot effectively can save both time and money. This section explores common problems you might encounter and provides guidance on resolving them without professional assistance.

Identifying Common Issues

Before diving into repairs, it’s essential to pinpoint the source of the malfunction. Look for signs such as unusual noises, performance drops, or erratic behavior. These symptoms can often guide you toward the ultimate solution. Create a checklist to systematically evaluate each component.

Basic Repair Techniques

Once you’ve identified the problem, you can delve into basic repair techniques. Ensure you have the necessary tools on hand, and consult any available manuals or online resources for step-by-step instructions. Taking a methodical approach will enhance your confidence and efficiency in resolving the issue.

Upgrading Your Generator System

Enhancing your power supply setup can significantly improve efficiency, reliability, and overall performance. By implementing strategic upgrades, you can ensure that your energy source meets your evolving needs and maintains optimal functionality.

When considering enhancements, focus on the following aspects:

- Power Output: Assess the current output capacity and determine if an increase is necessary. This may involve upgrading the engine or adding additional units.

- Fuel Efficiency: Explore options for improving fuel consumption, such as advanced fuel management systems or alternative fuel sources.

- Control Systems: Implement modern control panels that provide real-time monitoring and automation features, allowing for seamless operation and diagnostics.

Moreover, think about the following components that can be upgraded:

- Battery Systems: Opt for higher capacity batteries or advanced technologies that enhance charging speed and longevity.

- Cooling Mechanisms: Improve cooling systems to prevent overheating and extend the lifespan of critical components.

- Noise Reduction: Consider soundproofing options to minimize operational noise, enhancing user comfort and compliance with regulations.

Incorporating these upgrades not only boosts performance but also ensures a more sustainable and efficient energy solution for your needs.