Exploring the intricate arrangement of various components within a refrigeration unit is essential for effective maintenance and repair. A clear overview of the internal structure aids in diagnosing issues and enhancing functionality. This guide provides insights into the critical elements and their relationships, contributing to a better understanding of how each part works together.

By delving into the configuration of essential features, users can gain valuable knowledge that empowers them to troubleshoot problems efficiently. Recognizing the role of each segment not only facilitates repairs but also promotes longevity and optimal performance. Understanding the layout ensures that users are well-prepared for any maintenance challenges that may arise.

This examination serves as a foundational resource for anyone seeking to familiarize themselves with the inner workings of refrigeration units. By grasping the relationships between various components, users can navigate the complexities of their appliance with confidence.

Overview of Samsung RF266AEPN Components

This section provides a comprehensive understanding of the essential elements that comprise a modern refrigeration unit. Each component plays a crucial role in ensuring optimal performance, energy efficiency, and user convenience. A thorough exploration of these elements reveals how they work in unison to maintain the ideal storage environment for food and beverages.

Key Functional Parts

The primary components include the cooling system, which regulates temperature, and the compressor, which circulates refrigerant throughout the unit. Additionally, the thermostat plays a pivotal role in monitoring and controlling the internal temperature, while the evaporator coils facilitate heat exchange. Each part is engineered to operate seamlessly, contributing to the overall functionality of the appliance.

Design and Construction Elements

The structure of the appliance incorporates various materials and technologies designed for durability and efficiency. Insulation materials enhance energy conservation, while the exterior finish offers aesthetic appeal and protection. Understanding the design choices made in these units highlights the balance between functionality and user experience.

Understanding the Layout of Interior Parts

The organization of internal components plays a crucial role in the overall functionality and efficiency of household appliances. A well-structured arrangement ensures that each element operates harmoniously, contributing to the device’s performance and user convenience. Understanding how these components fit together can enhance maintenance practices and troubleshooting efforts.

Typically, the interior space is designed to optimize both storage and airflow, allowing for effective cooling and accessibility. Various sections may include compartments for food storage, areas for temperature regulation, and mechanisms for ice production. Each part’s location is intentional, aimed at maximizing usability and energy efficiency.

Additionally, the layout facilitates easy access to essential features, such as control panels and lighting, which enhance user interaction. Recognizing the significance of this organization can empower users to make informed decisions regarding care and maintenance, ensuring longevity and optimal operation of the appliance.

Key Features of the Cooling System

The efficiency and performance of a refrigeration unit largely depend on its cooling mechanism. This critical component plays a vital role in maintaining optimal temperature conditions for food preservation. Understanding its key attributes helps in recognizing how these systems operate to enhance freshness and energy efficiency.

Advanced Temperature Management

One of the standout characteristics is the advanced temperature management technology. This system ensures a consistent cooling environment by utilizing precise sensors that monitor temperature fluctuations. Dynamic airflow is employed to distribute cold air evenly, preventing hotspots and maintaining uniform conditions throughout the storage compartments.

Energy Efficiency

Another significant feature is its focus on energy efficiency. The innovative cooling technology minimizes energy consumption while maximizing cooling output. The design often includes eco-friendly refrigerants that not only comply with environmental regulations but also contribute to reducing operational costs. This dual focus on performance and sustainability makes the cooling system a smart choice for modern households.

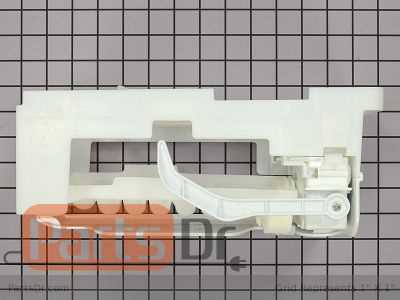

Common Issues with Door Mechanism

The functionality of any appliance heavily relies on its access points. Problems with these components can lead to significant inconveniences and may affect the overall performance. Understanding frequent challenges associated with the entry framework is crucial for efficient operation and maintenance.

Inadequate Sealing

One prevalent concern is insufficient sealing. If the gasket or sealing material becomes worn or damaged, it can allow air to escape or enter. This not only affects temperature regulation but may also lead to increased energy consumption. Regular inspection and replacement of worn seals can enhance efficiency and prolong the appliance’s lifespan.

Misalignment Issues

Another common problem is misalignment. Over time, the door may not close properly due to improper installation or wear and tear on the hinges. Misalignment can result in gaps that compromise the internal climate, leading to inconsistent cooling. Adjusting or realigning the door can often resolve these issues and ensure a secure closure.

Role of Electronic Control Board

The electronic control board serves as the brain of modern refrigeration units, orchestrating various functions to ensure optimal performance and efficiency. This crucial component manages the operation of the cooling system, monitors temperature settings, and communicates with other parts of the appliance.

Functions of the Control Board include regulating the compressor’s operation, adjusting fan speeds, and activating defrost cycles when necessary. By processing information from temperature sensors, it makes real-time decisions to maintain the desired climate within the storage compartment.

Moreover, the electronic control board enhances energy efficiency by optimizing power consumption. It can detect anomalies and adjust operations accordingly, thus preventing excessive energy usage and prolonging the lifespan of the appliance. Regular maintenance and prompt replacement of a faulty control board are essential to ensure the longevity and functionality of the cooling unit.

How the Ice Maker Functions

The mechanism responsible for producing frozen water is a remarkable assembly of components working in harmony. It converts liquid into ice through a series of well-coordinated processes, ensuring that the supply remains consistent and meets user demands.

Basic Operation Principles

The operation of the freezing unit can be broken down into several key phases:

- Water Supply: The system receives water from a connected source, typically through a dedicated line.

- Freezing Cycle: The liquid is transferred to a mold where it is subjected to low temperatures, causing it to freeze.

- Harvesting Ice: Once the ice reaches a certain thickness, it is released from the mold, often facilitated by warming the base slightly.

- Storage: The formed ice is then directed into a designated storage compartment until needed.

Control Mechanisms

To maintain efficiency and prevent issues, the unit incorporates various control elements:

- Thermostat: Monitors temperature levels to initiate the freezing process.

- Timer: Regulates the duration of each cycle, ensuring optimal ice formation without excessive energy consumption.

- Sensor: Detects the presence of ice in the storage area, signaling when to produce more.

Maintenance Tips for Longer Lifespan

To ensure that your appliance remains functional and efficient over time, regular upkeep is essential. Simple maintenance tasks can significantly extend the life of the unit and enhance its performance. By implementing a few practical tips, you can minimize wear and tear and avoid costly repairs.

Regular Cleaning: Keeping the exterior and interior clean is crucial. Wipe down surfaces with a mild detergent to prevent buildup of dirt and grime. Pay special attention to door seals, as they can accumulate debris that affects energy efficiency.

Check Temperature Settings: Ensure that the temperature is set appropriately to prevent overworking the compressor. The ideal range for refrigeration is typically between 35°F and 38°F, while freezers should be around 0°F.

Inspect Door Seals: Regularly examine the seals for any signs of damage or wear. If they are not sealing properly, it can lead to temperature fluctuations and increased energy consumption. Replace them if necessary to maintain efficiency.

Defrost Regularly: If the model is not frost-free, periodic defrosting is necessary to prevent ice buildup. This can help improve cooling performance and energy efficiency.

Vacuum Coils: Dust and debris can accumulate on the condenser coils, hindering heat dissipation. Vacuuming the coils at least twice a year can help maintain optimal performance.

Schedule Professional Maintenance: Consider having a technician perform an annual inspection. They can identify potential issues before they become major problems and ensure that all components are functioning correctly.

By following these maintenance recommendations, you can enhance the longevity of your unit, ensuring it continues to operate smoothly for years to come.

Identifying Vital Water Filtration Elements

Understanding the essential components involved in water purification systems is crucial for maintaining optimal performance and ensuring safe drinking water. These elements play a significant role in removing impurities and enhancing the overall quality of the water. Knowledge of their functions and configurations can aid in troubleshooting and replacement when necessary.

Key Components of Water Filtration Systems

Among the primary components are filters designed to capture particles, contaminants, and sediments. These elements vary in type and effectiveness, depending on the filtration technology employed, such as activated carbon or reverse osmosis. Regular inspection and timely replacement of these filters are essential for sustaining the efficiency of the entire purification process.

Maintenance and Replacement Considerations

To ensure the longevity and effectiveness of the filtration system, it is important to adhere to recommended maintenance schedules. Monitoring flow rates and observing changes in taste or odor can provide valuable insights into the health of the components. Familiarity with these elements allows users to promptly address issues, thereby enhancing the quality of their water supply.

Replacement Guide for Broken Shelves

When a shelf within your cooling unit is damaged, it can disrupt the organization of your food items and beverages. This guide provides essential steps to help you efficiently replace broken shelves, ensuring your appliance functions optimally and remains aesthetically pleasing.

Before proceeding with the replacement, gather the necessary tools and materials. You will typically need a measuring tape, a screwdriver, and a replacement shelf compatible with your appliance. It’s crucial to choose a shelf that matches the dimensions and design of your current setup for proper fit and support.

Follow these steps to replace the broken shelf:

| Step | Action |

|---|---|

| 1 | Remove all items from the damaged shelf to prevent further accidents. |

| 2 | Locate and unscrew any brackets or supports holding the broken shelf in place. |

| 3 | Carefully slide the damaged shelf out of the unit. |

| 4 | Insert the new shelf into the designated area, ensuring it sits securely. |

| 5 | Reattach any brackets or supports to stabilize the new shelf. |

| 6 | Replace items onto the new shelf, distributing weight evenly for optimal support. |

Regular maintenance and timely replacement of damaged shelves can prolong the lifespan of your appliance. Always consult your user manual for specific instructions and compatibility when selecting replacement parts.