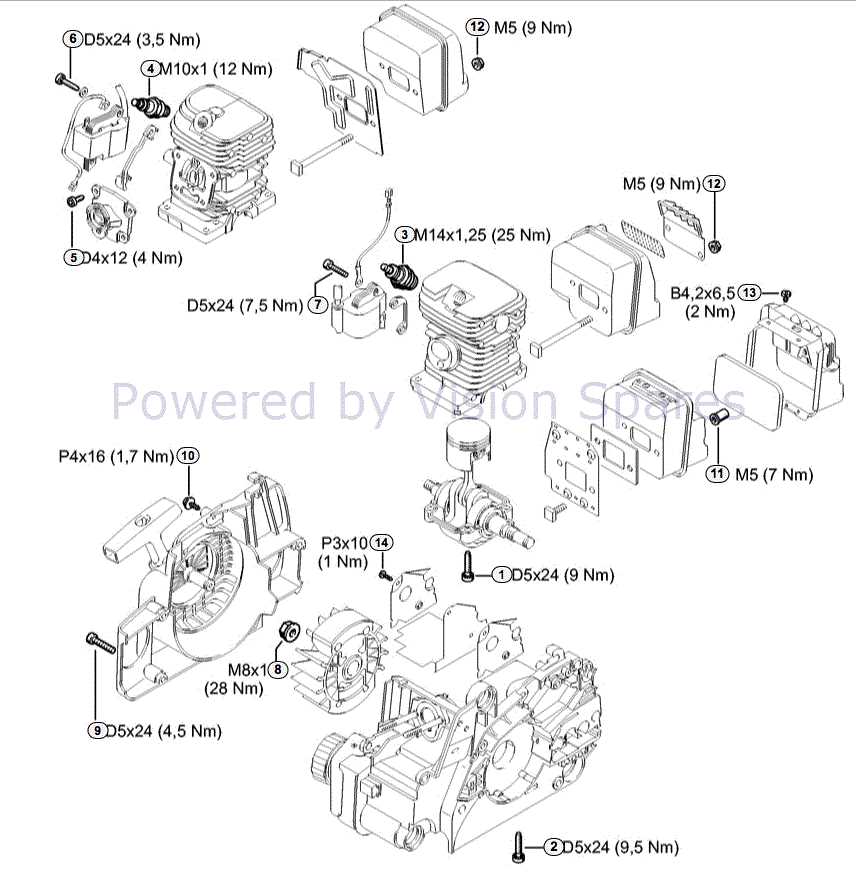

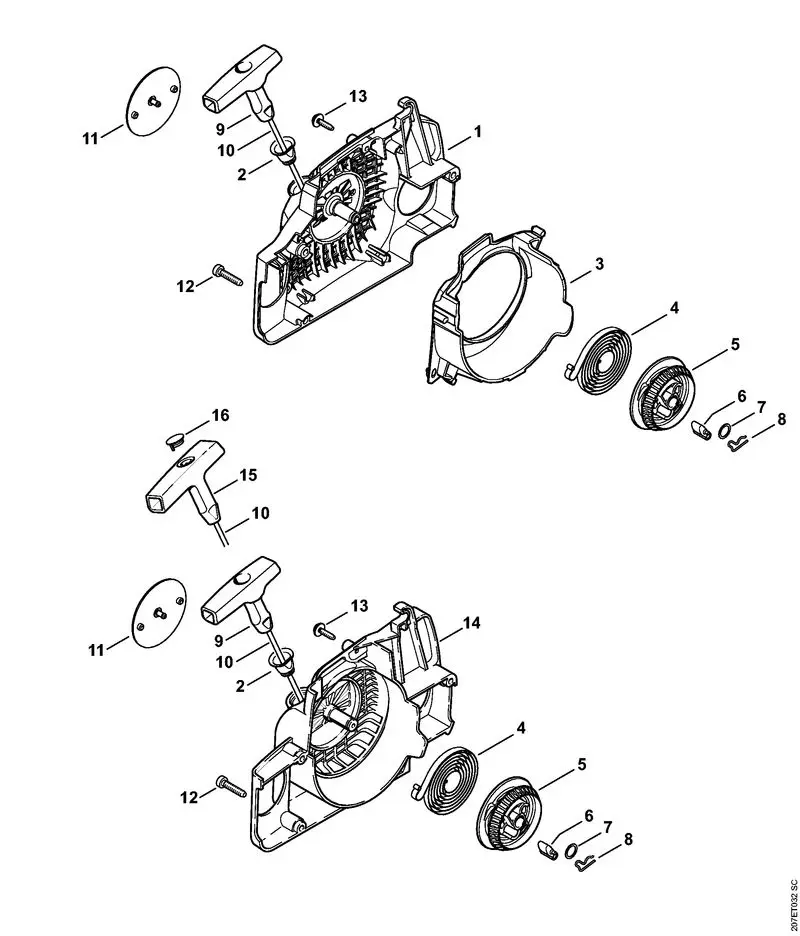

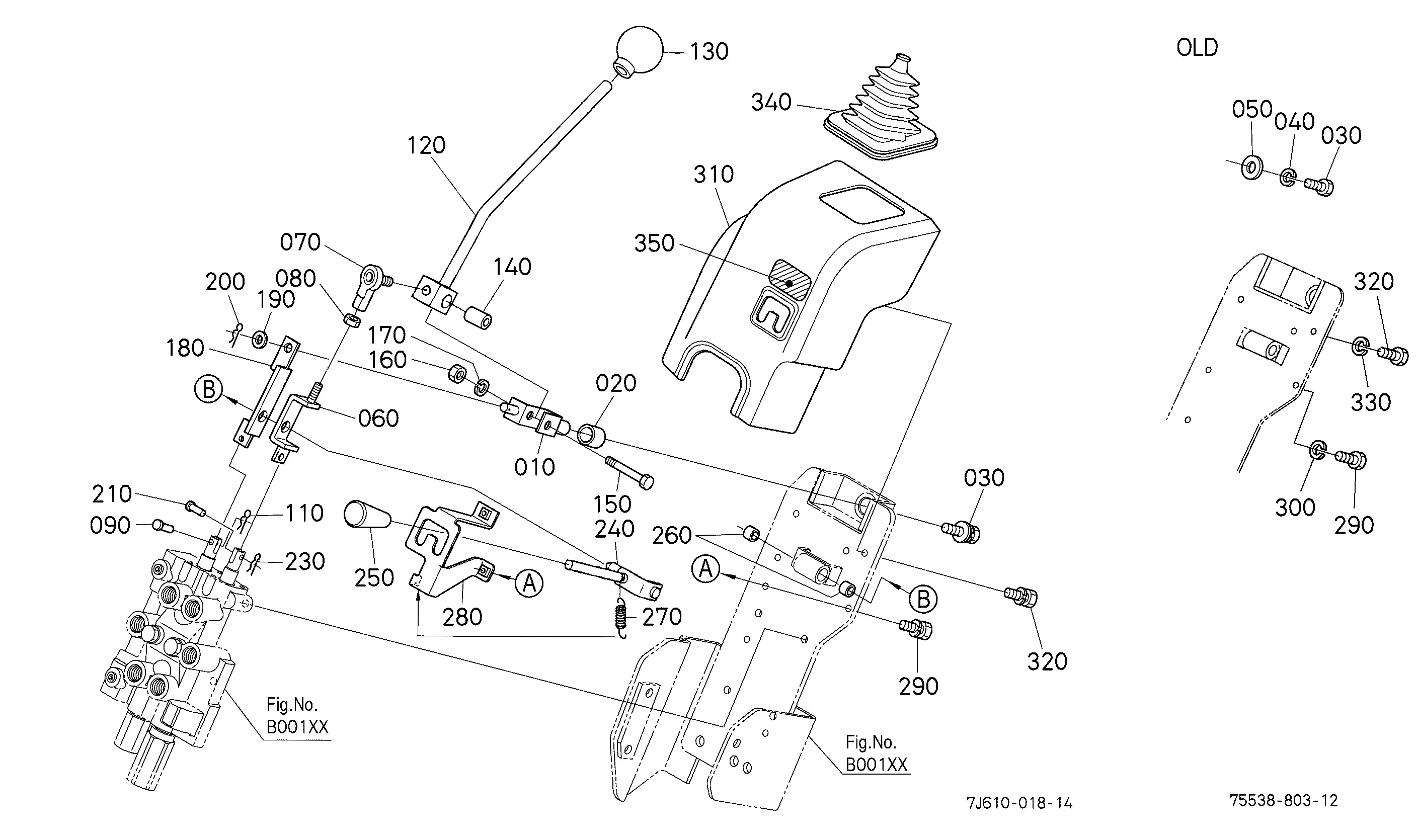

When maintaining or repairing your cutting tool, having a clear visual representation of its various elements is crucial. A detailed illustration can enhance your understanding of how each section interacts, allowing for more effective troubleshooting and assembly. Whether you are an experienced user or a newcomer, familiarity with your machine’s structure can significantly improve its performance and longevity.

In this resource, you will find a comprehensive guide that provides insights into the specific components of your equipment. By examining the layout of the internal and external parts, you can identify potential issues and understand the proper methods for disassembly and reassembly. This knowledge not only simplifies maintenance tasks but also empowers you to tackle repairs with confidence.

With the right visual aids at your disposal, you can ensure that your cutting tool operates at its best. This guide serves as a valuable reference, facilitating easier access to information about your device’s intricacies. Explore the connections and functionalities of each component to make informed decisions about repairs and upgrades.

Overview of Stihl MS170 Chainsaw

This powerful cutting tool is designed for both homeowners and professionals, offering a blend of performance and ease of use. Its compact size and lightweight construction make it an ideal choice for various tasks, from trimming branches to cutting firewood.

Key features include:

- Efficient engine for reliable power.

- User-friendly design for comfortable handling.

- Quick-start mechanism to minimize downtime.

- Durable components that ensure longevity.

Whether you are a seasoned user or a beginner, this chainsaw is built to handle a range of applications with precision and efficiency.

Important specifications to consider:

- Engine displacement: Provides a balance of power and fuel efficiency.

- Bar length: Versatile options for different cutting needs.

- Weight: Lightweight design for reduced fatigue during extended use.

- Safety features: Essential for safe operation.

This cutting tool stands out in the market due to its reliability and ease of maintenance, making it a valuable addition to any toolkit.

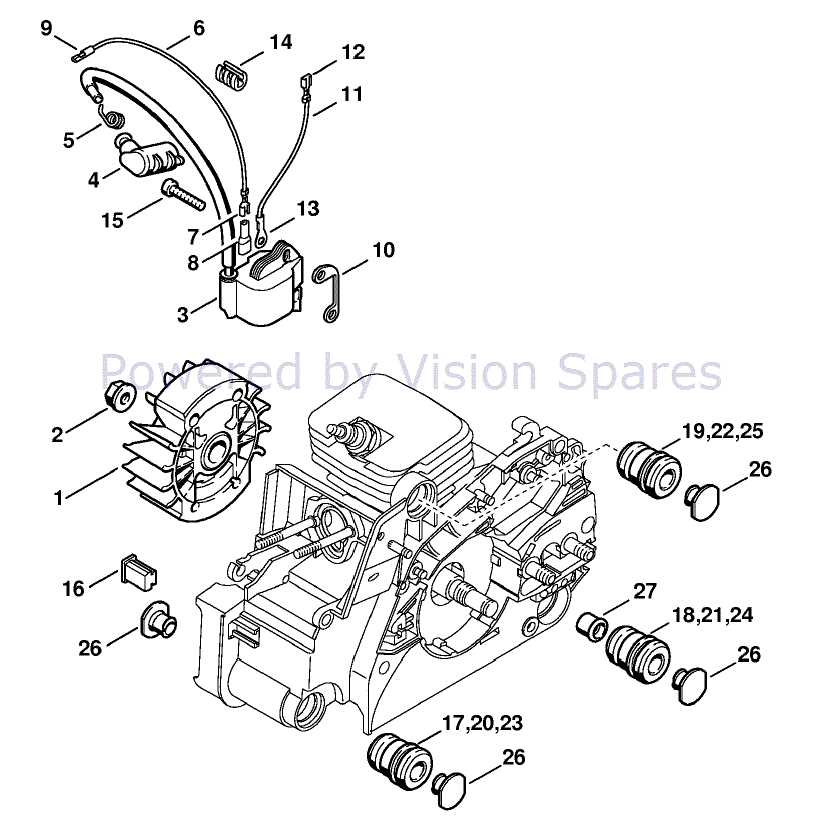

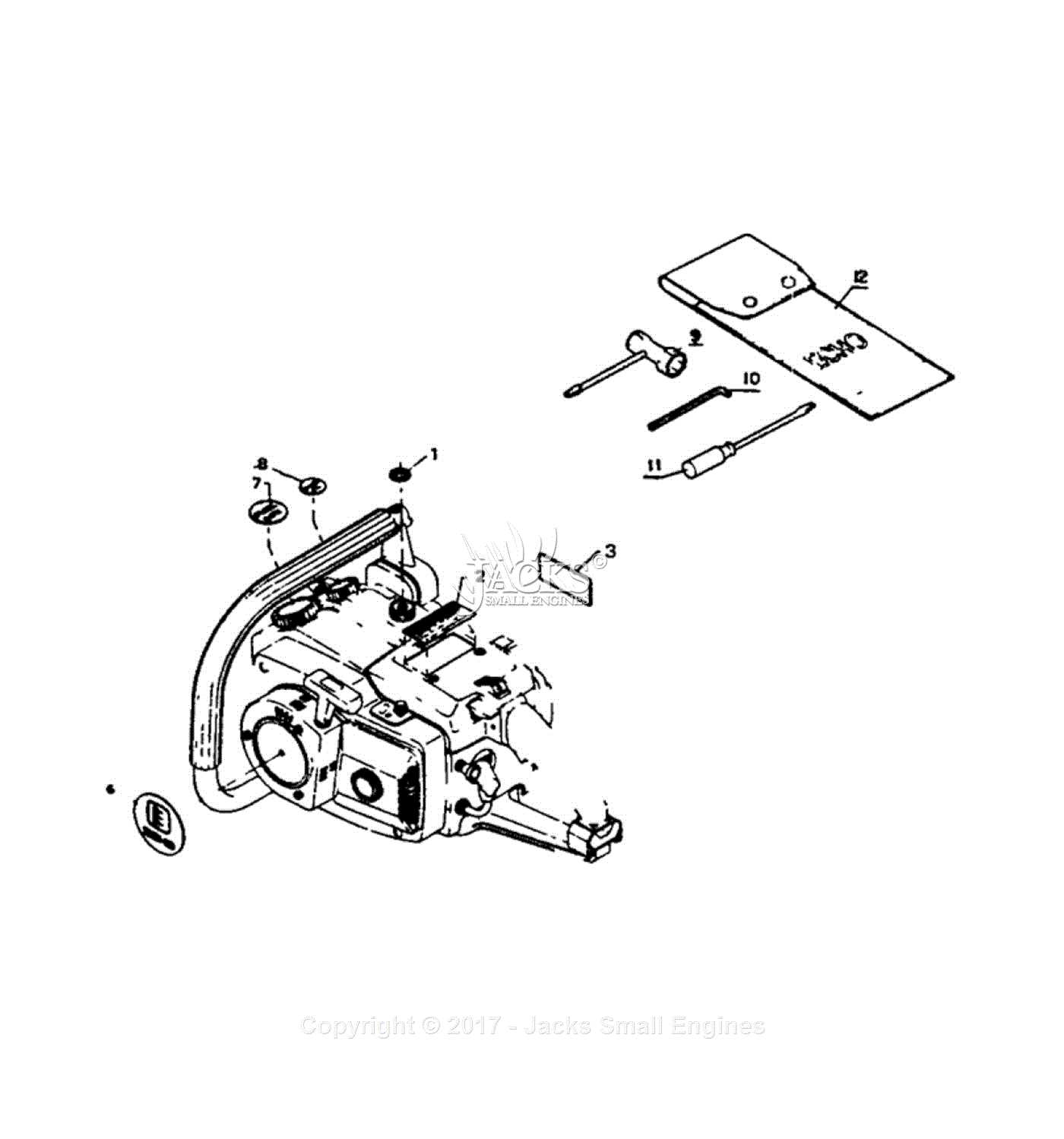

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations of these elements provide clarity and guidance, ensuring that users can easily identify and access the necessary pieces for various tasks. This resource is invaluable for both novice and experienced users, as it fosters a deeper comprehension of the equipment’s structure and function.

Enhanced Maintenance Efficiency

When users can quickly reference a visual guide, they are better equipped to perform maintenance tasks. Clear illustrations eliminate confusion about the placement and function of individual components, reducing the time spent troubleshooting issues. As a result, the likelihood of errors decreases, leading to more effective repairs and a longer lifespan for the equipment.

Facilitating Parts Replacement

Accurate visuals play a crucial role in the replacement process. By providing a clear view of how parts fit together, these guides ensure that users can select the correct components without guesswork. This precision not only speeds up the replacement but also minimizes the risk of purchasing incorrect items, saving both time and money.

In summary, visual aids are vital tools that support effective maintenance and efficient repairs. They empower users with the knowledge needed to manage their equipment responsibly and effectively.

How to Access PDF Files

Accessing digital documents can enhance your experience when seeking specific information or instructions. Various methods can be employed to locate and retrieve these files, ensuring you can efficiently find the content you need.

- Search Engines: Utilize popular search platforms to enter relevant keywords related to the documents you wish to find.

- Official Websites: Visit the official sites of manufacturers or organizations, where such files are often available for download.

- Document Sharing Platforms: Explore websites dedicated to hosting various types of files, allowing users to upload and share their documents.

- Email Attachments: Check your email for attachments that may contain the files you are looking for, sent by colleagues or friends.

Once you locate the desired documents, downloading and accessing them is straightforward:

- Click on the link or button provided for the download.

- Select the location on your device where you want to save the file.

- Open the downloaded document using compatible software or apps.

By following these steps, you can easily find and access the necessary digital resources for your projects or inquiries.

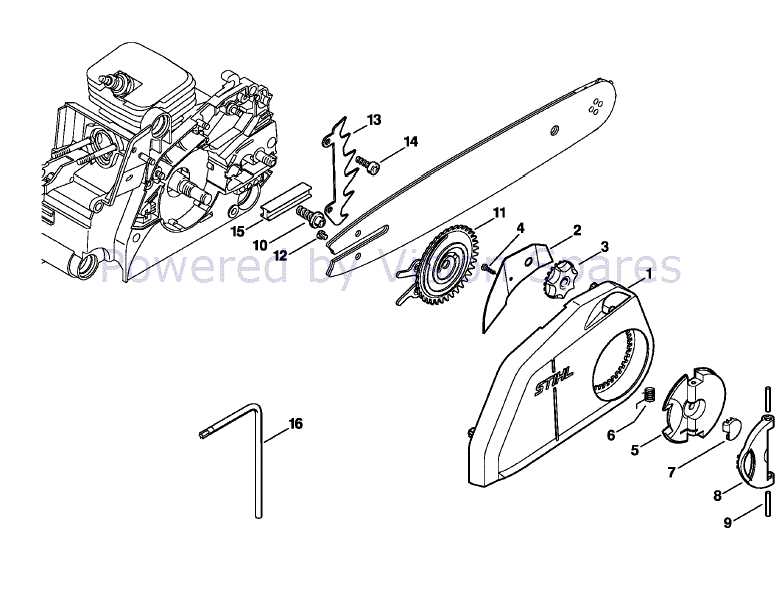

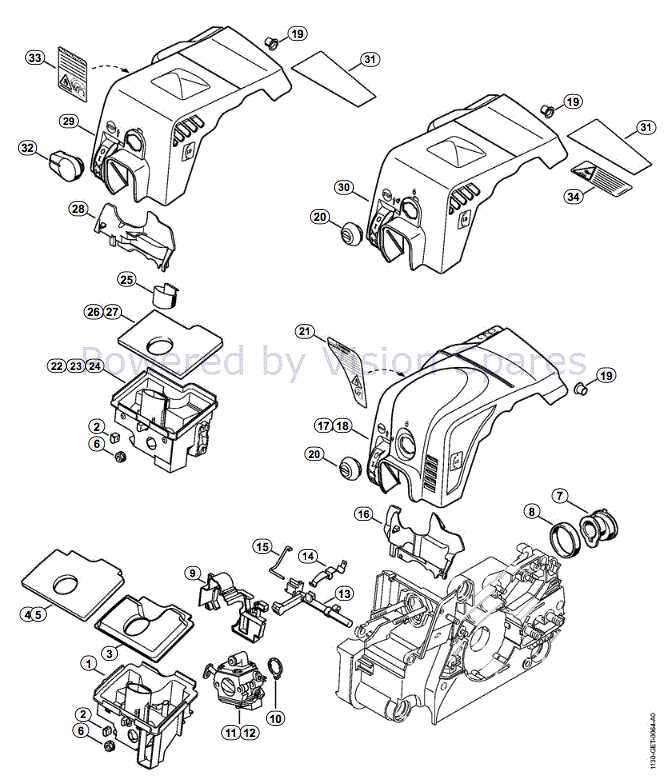

Key Components of the MS170

Understanding the essential elements of a chainsaw can significantly enhance its performance and longevity. Each part plays a crucial role in the overall functionality, ensuring smooth operation and efficiency during use. Below are the primary components that contribute to the effective functioning of this tool.

- Engine: The power source that drives the chainsaw, providing the necessary energy to cut through various materials.

- Guide Bar: A metal bar that supports and guides the cutting chain, determining the depth and type of cut.

- Cutting Chain: Equipped with sharp teeth, this component revolves around the guide bar and performs the actual cutting action.

- Air Filter: Prevents dirt and debris from entering the engine, maintaining optimal performance and prolonging its life.

- Fuel System: Comprising the fuel tank and lines, this system supplies the necessary fuel to the engine.

- Chain Brake: A safety feature that stops the chain quickly in the event of kickback, protecting the operator.

- Handle: Provides a grip for maneuverability and control during operation, ensuring user comfort.

Each of these components works in harmony, allowing the tool to operate efficiently and safely, making it essential to understand their functions for proper maintenance and troubleshooting.

Common Repairs for MS170 Models

When maintaining a chainsaw, certain issues tend to arise more frequently than others. Understanding these common repairs can help users keep their equipment in optimal condition and extend its lifespan. Below are typical problems encountered and their solutions.

Frequent Issues

- Fuel System Clogs

- Chain Tension Adjustments

- Starting Difficulties

- Bar and Chain Wear

Repair Solutions

- Fuel System Clogs: Ensure the fuel lines and filter are clean. Regularly replacing the fuel can prevent build-up.

- Chain Tension Adjustments: Regularly check the chain tension. Use the adjustment screw to ensure the chain fits snugly against the guide bar without being overly tight.

- Starting Difficulties: Check the spark plug for wear and replace if necessary. Ensure the air filter is clean and unobstructed.

- Bar and Chain Wear: Inspect the guide bar for damage. Regularly lubricate the chain and replace it when signs of wear are evident.

By addressing these common concerns promptly, users can maintain their equipment’s performance and reliability, ensuring safe and efficient operation.

Tips for Maintenance and Care

Proper upkeep of your equipment is essential for its longevity and optimal performance. Regular attention to maintenance can prevent breakdowns and ensure that your tool operates smoothly, enhancing efficiency during use. By implementing a few straightforward practices, you can significantly extend the lifespan of your machinery and keep it in top-notch condition.

Routine Inspection

Conducting frequent checks is crucial. Look for signs of wear or damage that might compromise functionality. Here are some key areas to inspect:

| Component | What to Check | Recommended Action |

|---|---|---|

| Chain | Sharpness and tension | Sharpen or adjust as needed |

| Air Filter | Clogging or dirt buildup | Clean or replace regularly |

| Fuel System | Leaks or contamination | Inspect and clean thoroughly |

Cleaning and Lubrication

Regular cleaning is vital to maintain performance. Remove debris and buildup after each use. Additionally, appropriate lubrication of moving parts reduces friction and wear, ensuring efficient operation. Follow manufacturer guidelines for suitable lubricants and application frequency.

Understanding Replacement Parts Options

When it comes to maintaining your equipment, knowing your options for substituting components is crucial. The market offers a variety of alternatives that can meet your needs, whether you’re looking for OEM selections or aftermarket choices. Each type has its advantages and considerations, making it essential to understand what is available.

Here are some key options to consider:

- OEM Components: These are original items made by the manufacturer. They guarantee compatibility and quality, often ensuring that your equipment performs at its best.

- Aftermarket Alternatives: Produced by third-party companies, these components can provide cost savings. However, the quality may vary, so it’s important to choose reputable brands.

- Refurbished Items: Pre-owned parts that have been restored to working condition. This option can be economical, but it’s vital to assess their reliability.

- Universal Parts: These components are designed to fit a range of models. They offer flexibility but may require modifications for perfect compatibility.

When selecting replacements, consider the following factors:

- Compatibility: Ensure that the component matches your equipment’s specifications.

- Quality: Research the materials and manufacturing processes to gauge durability.

- Cost: Compare prices across different sources to find the best deal without sacrificing quality.

- Warranty: Check if the item comes with a guarantee, providing peace of mind for your purchase.

By understanding these replacement options, you can make informed decisions that enhance the performance and longevity of your machinery.

Where to Find Genuine Stihl Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Whether you’re looking for replacements or upgrades, knowing where to find reliable sources can save you time and money.

Here are some trusted options for obtaining genuine components:

| Source | Description |

|---|---|

| Authorized Dealers | These retailers specialize in outdoor machinery and carry a comprehensive selection of original components, ensuring quality and compatibility. |

| Official Website | The manufacturer’s site often provides a catalog of products and a list of authorized dealers, making it easy to find what you need. |

| Local Repair Shops | Many service centers offer genuine components and can provide expert advice on installation and maintenance. |

| Online Marketplaces | Reputable e-commerce platforms may offer a wide range of original components, but it’s essential to verify the seller’s credibility. |

By exploring these avenues, you can ensure that you are acquiring the right components for your equipment, leading to improved performance and reliability.

FAQs About MS170 Parts and Diagrams

This section addresses common inquiries regarding the components and visual aids related to a specific model of chainsaw. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity of the equipment.

| Question | Answer |

|---|---|

| Where can I find detailed images of the components? | Detailed visuals can typically be accessed through the manufacturer’s official website or authorized dealers. |

| What should I do if a specific piece needs replacement? | Identify the component and check compatibility with your model before purchasing a new one. |

| How can I ensure I am getting genuine components? | Always purchase from certified retailers or directly from the manufacturer to guarantee authenticity. |

| Is there a maintenance guide available for this model? | Yes, many resources provide maintenance instructions that can help you care for your chainsaw effectively. |

| Can I repair my equipment myself? | With the right tools and resources, many users can successfully perform their own repairs. |