In the realm of winter equipment, understanding the intricate assembly of machinery is crucial for optimal performance. This section aims to explore the various elements that contribute to efficient snow removal, ensuring your equipment functions seamlessly when it matters most.

Every machine consists of numerous integral components, each playing a vital role in overall operation. Familiarity with these elements not only enhances maintenance efforts but also allows operators to tackle challenges with confidence.

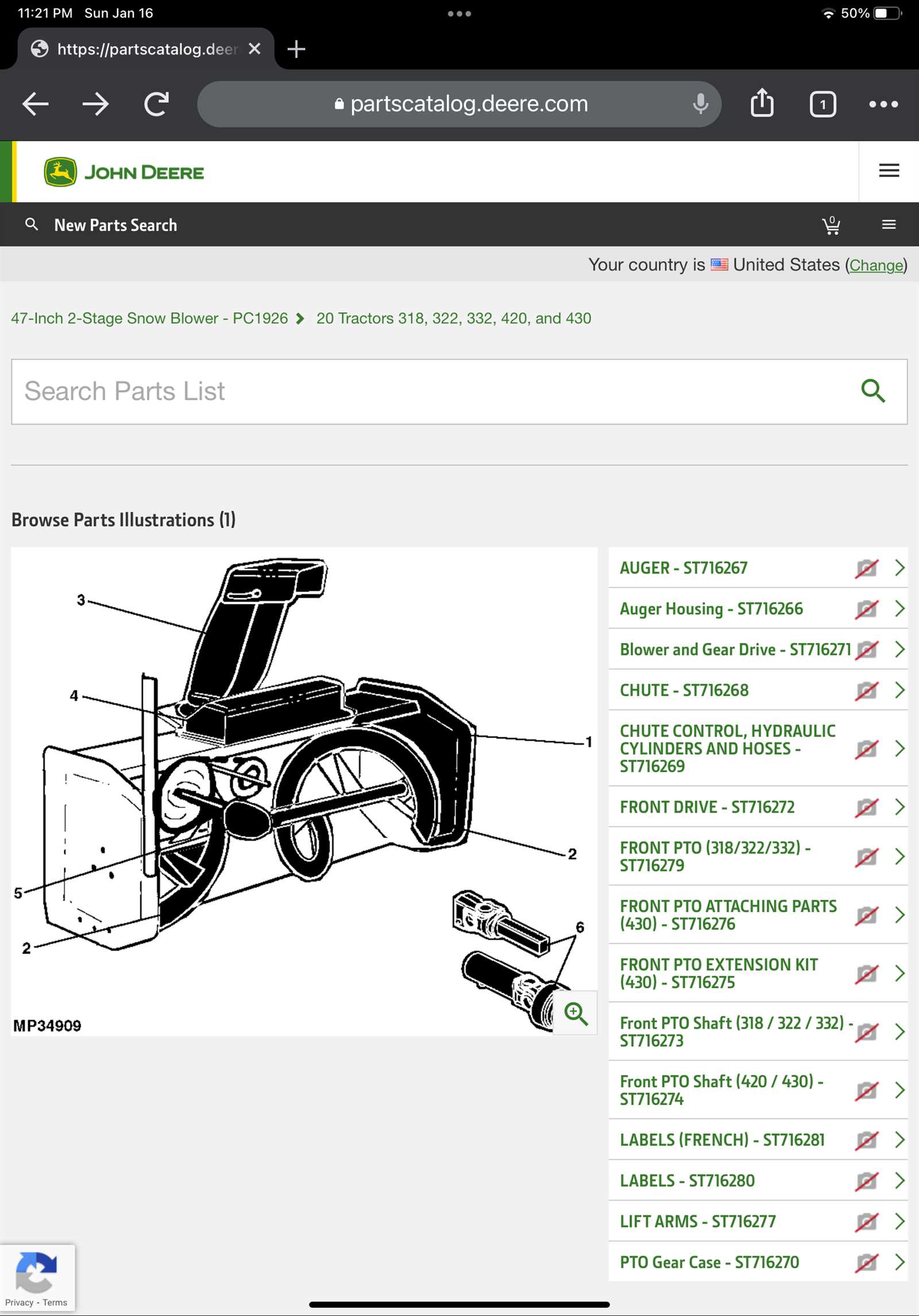

By examining the visual representation of these components, users can effectively identify parts, facilitating repairs and upgrades. This guide serves as a valuable resource for anyone looking to enhance their winter readiness through informed decision-making.

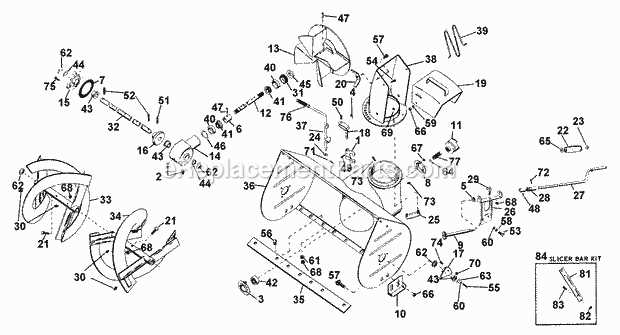

Understanding the 47-Inch John Deere Snowblower

The 47-inch model designed for winter tasks offers an efficient solution for managing heavy snowfall. Its robust construction and user-friendly features make it a popular choice for homeowners seeking to clear driveways and pathways with ease. Understanding its components and functionality is essential for optimal performance and maintenance.

This equipment is engineered to handle various snow conditions, providing reliable operation even in challenging weather. Key features include adjustable chute controls and a powerful auger system, allowing users to direct snow precisely where needed. Familiarity with its design will enhance both usability and longevity.

Regular inspection and upkeep of the unit’s mechanisms are vital for maintaining its effectiveness. By knowing how each part contributes to overall operation, users can troubleshoot issues more efficiently. This understanding not only ensures smoother operation but also prolongs the life of the machinery.

In summary, grasping the intricacies of this winter tool equips operators to maximize its capabilities and address any challenges that may arise during use. Investing time in understanding its design will pay dividends in performance and satisfaction during the snowy months.

Key Features of the Snow Removal Model

This model stands out due to its innovative design and efficiency in tackling winter challenges. It integrates advanced technology with user-friendly elements, making it an essential tool for clearing heavy snowfall. Below are some of the notable characteristics that enhance its performance and usability.

- Powerful Engine: Equipped with a robust motor that delivers high performance, ensuring effective snow displacement even in severe conditions.

- Adjustable Chute: The chute can be easily adjusted to control the direction of snow discharge, providing flexibility based on the user’s needs.

- Durable Construction: Made from high-quality materials, this equipment is designed to withstand harsh winter environments, ensuring longevity and reliability.

- Easy Maneuverability: Features a lightweight design and ergonomic handles, allowing for effortless navigation through tight spaces and heavy drifts.

- Enhanced Safety Features: Incorporates safety mechanisms to prevent accidents, providing peace of mind during operation.

These features collectively contribute to an efficient and effective solution for managing snow, making the model a preferred choice for homeowners and professionals alike.

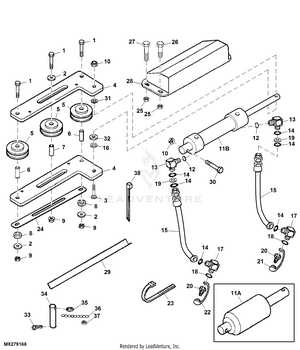

Essential Parts for Maintenance and Repair

Understanding the crucial components of your equipment is vital for effective upkeep and repair. Regular attention to these elements ensures optimal performance and longevity, allowing you to tackle winter challenges with confidence.

| Component | Description | Function |

|---|---|---|

| Auger | Spiral blade designed to gather and move snow. | Essential for efficient snow removal. |

| Drive Belt | Flexible loop transmitting power from the engine. | Crucial for operational functionality. |

| Skids | Supportive elements that guide the machine’s height. | Maintain clearance and prevent damage to surfaces. |

| Shear Pins | Breakable connectors that protect the machinery. | Prevent damage during heavy loads. |

| Chute | Directed channel for snow discharge. | Controls where snow is thrown. |

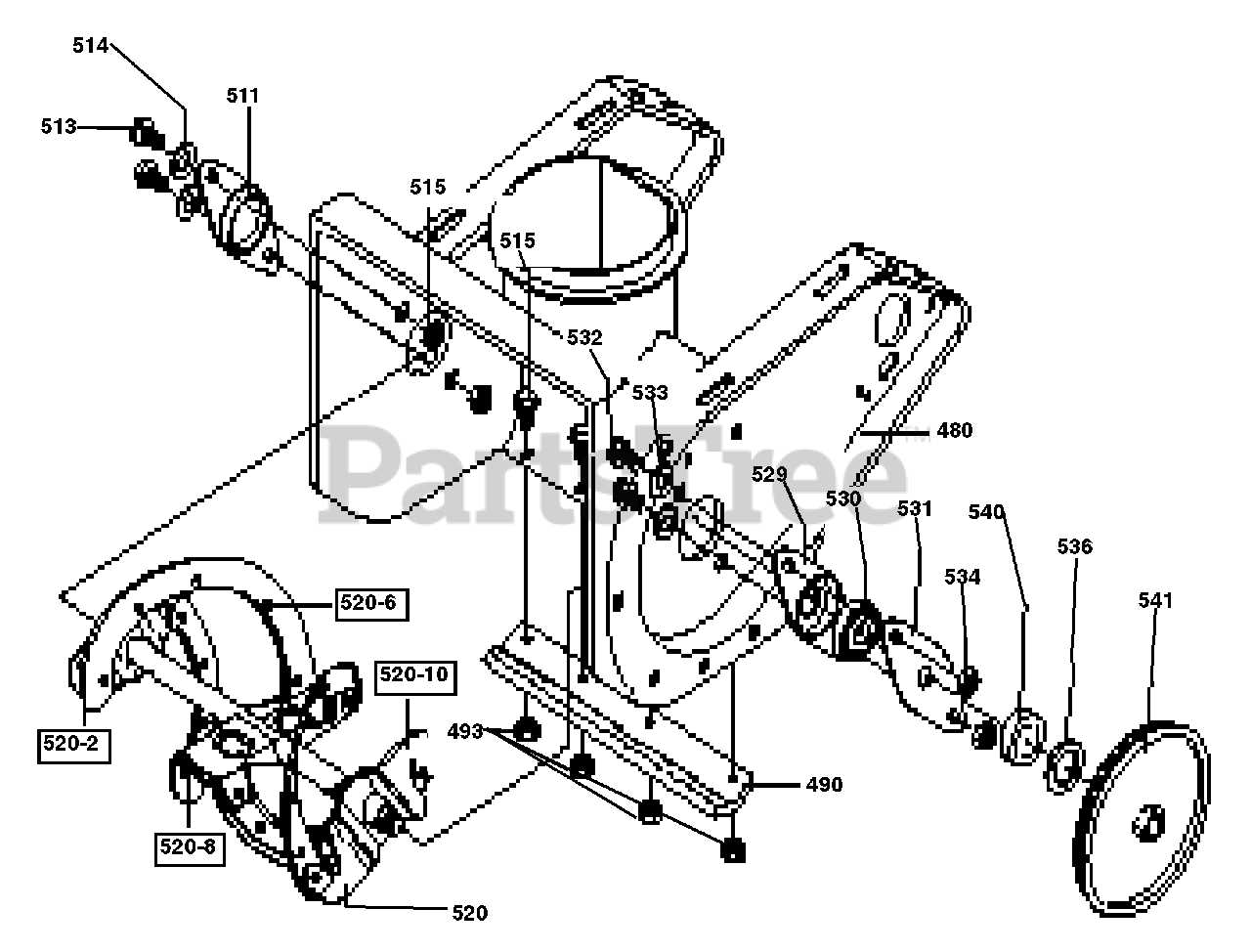

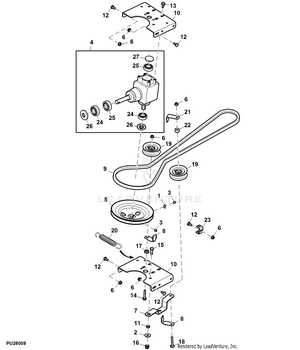

How to Interpret Parts Diagrams Effectively

Understanding visual representations of components can significantly enhance your ability to perform maintenance and repairs. These illustrations serve as a crucial tool for identifying individual elements and their relationships within a complex system.

To effectively navigate these visuals, consider the following steps:

- Familiarize yourself with the key or legend that explains symbols and colors.

- Identify the main assembly and its subcomponents for better context.

- Pay attention to part numbers for accurate ordering and replacement.

- Look for any notes or annotations that provide additional details.

By following these guidelines, you can delve deeper into understanding the structure and functionality of the equipment, ensuring you make informed decisions during repairs.

Common Issues and Troubleshooting Tips

Understanding frequent challenges and solutions can significantly enhance the efficiency of your outdoor equipment during winter. Identifying the root cause of a problem is crucial for timely repairs and optimal performance.

Here are some typical issues you might encounter:

- Ineffective Operation: Equipment may fail to clear effectively, resulting in leftover snow or ice.

- Engine Difficulties: Problems starting or running smoothly can hinder performance.

- Blockages: Snow buildup can obstruct the chute or auger, causing inefficiency.

- Uneven Discharge: Irregular snow ejection can lead to frustration and requires immediate attention.

To address these issues, consider the following troubleshooting tips:

- Check Fuel Quality: Ensure you are using fresh fuel and appropriate oil for optimal engine performance.

- Inspect Belts and Cables: Look for wear and tear on belts and cables that could affect operation.

- Clear Blockages: Regularly inspect and remove snow buildup from the chute and auger.

- Test Controls: Make sure all controls are functioning properly to avoid operational delays.

By proactively addressing these common issues, you can maintain the effectiveness of your equipment and ensure a smoother winter experience.

Where to Find Replacement Components

Locating essential components for your equipment can be a straightforward process if you know where to look. Various sources are available, ensuring you can maintain optimal performance and functionality.

- Authorized Dealers: Start by visiting official dealers that specialize in your brand. They typically offer genuine components and can provide expert advice.

- Online Retailers: Many e-commerce platforms cater to your needs. Search for specialized websites that focus on outdoor equipment to find a wide selection.

- Local Repair Shops: Consider reaching out to nearby repair services. They often have spare parts on hand or can order them for you.

- Manufacturer’s Website: Check the manufacturer’s official website. They may have a dedicated section for replacement components, including specifications and ordering options.

Before making a purchase, ensure that the components are compatible with your equipment. This will help avoid issues and ensure longevity.

Tips for Optimal Snowblowing Performance

Achieving peak efficiency during winter clearing tasks requires careful attention to technique and equipment maintenance. Proper preparation and smart practices can significantly enhance performance and make the job easier.

| Tip | Description |

|---|---|

| Regular Maintenance | Ensure all components are well-lubricated and free of debris to prevent malfunctions. |

| Adjusting Settings | Customize height and angle settings for different types of surfaces to optimize clearing. |

| Clear Pathways | Remove obstacles and large objects from the area to avoid damaging the equipment. |

| Proper Speed | Maintain a steady pace; moving too fast can lead to incomplete clearing and inefficient use of energy. |

| Safety First | Wear appropriate footwear and gear to prevent accidents and ensure stability on slippery surfaces. |

Safety Guidelines for Snowblower Operation

Operating a machine designed for clearing snow can present various hazards. To ensure a safe experience, it is crucial to adhere to specific precautions. Understanding and following these guidelines will help prevent accidents and injuries while maintaining the effectiveness of the equipment.

Pre-Operation Checks

Before starting the equipment, perform a thorough inspection to ensure everything is in proper working condition. This includes checking fuel levels, examining for any leaks, and ensuring all parts are securely attached. Regular maintenance is essential for optimal performance.

Operational Safety Measures

While in use, it is important to follow safety practices to protect yourself and others. Maintain a safe distance from bystanders and avoid operating the machine in enclosed spaces. Always wear appropriate protective gear, such as gloves and goggles, to minimize risks associated with flying debris and cold exposure.

| Safety Tip | Description |

|---|---|

| Stay Alert | Keep your focus on the task to avoid distractions that could lead to accidents. |

| Clear Obstacles | Remove any potential hazards from the area before beginning to ensure smooth operation. |

| Use Caution on Slopes | Be extra careful when working on inclines to maintain balance and control. |

| Shut Down Properly | Turn off the machine and allow it to cool down before performing any maintenance. |

Comparing Other John Deere Models

This section explores the various models from the renowned manufacturer, focusing on their unique features and capabilities. By examining alternatives, users can make informed decisions based on their specific needs and preferences.

| Model | Engine Power | Width | Weight | Best For |

|---|---|---|---|---|

| Model A | 10 HP | 42 inches | 200 lbs | Residential Use |

| Model B | 12 HP | 46 inches | 220 lbs | Light Commercial |

| Model C | 15 HP | 50 inches | 250 lbs | Heavy-Duty Tasks |

| Model D | 18 HP | 54 inches | 280 lbs | Professional Use |

Each variant serves distinct purposes, allowing users to select the best match for their requirements. Consideration of power, size, and weight will enhance operational efficiency and performance.