The efficient operation of outdoor machinery is crucial for tackling seasonal challenges. Familiarity with the various elements that contribute to a machine’s functionality can significantly enhance performance and reliability. This section aims to provide a comprehensive overview of the essential components of a specific type of equipment, ensuring users can navigate their maintenance and repairs with confidence.

Identifying the individual pieces and their respective roles is vital for anyone looking to optimize their machinery’s performance. Each component works in harmony to achieve the desired outcomes, making it essential for operators to understand their functions. By gaining insight into these elements, users can make informed decisions when it comes to repairs, replacements, or upgrades.

Exploring the layout of these components not only aids in troubleshooting but also fosters a deeper connection with the machinery. A clear understanding of how each part interacts can lead to more efficient operation and maintenance practices. Whether you are a novice or a seasoned operator, familiarizing yourself with these intricacies can enhance your overall experience with the equipment.

Overview of John Deere 826 Snowblower

This section provides a comprehensive insight into a specific model of snow removal equipment known for its efficiency and robust performance. It serves as a reliable solution for managing winter weather challenges, ensuring that users can maintain clear pathways and driveways during heavy snowfall. The machine is engineered for durability and effectiveness, making it a popular choice among homeowners and professionals alike.

Key Features

Designed to handle a variety of snow conditions, this equipment boasts a range of features that enhance its functionality. These attributes not only improve performance but also contribute to user convenience. From adjustable speeds to powerful auger systems, each element is meticulously crafted to deliver optimal results.

Maintenance Recommendations

To ensure longevity and reliability, regular maintenance is essential. Users are advised to follow a structured maintenance routine that includes inspections, cleaning, and timely replacements of wear components. Adhering to these practices will keep the equipment in peak operating condition throughout its service life.

| Feature | Description |

|---|---|

| Engine Power | Robust engine delivering high performance |

| Clearing Width | Generous width for efficient snow removal |

| Weight | Heavy-duty construction for stability |

| Speed Settings | Multiple settings for various snow conditions |

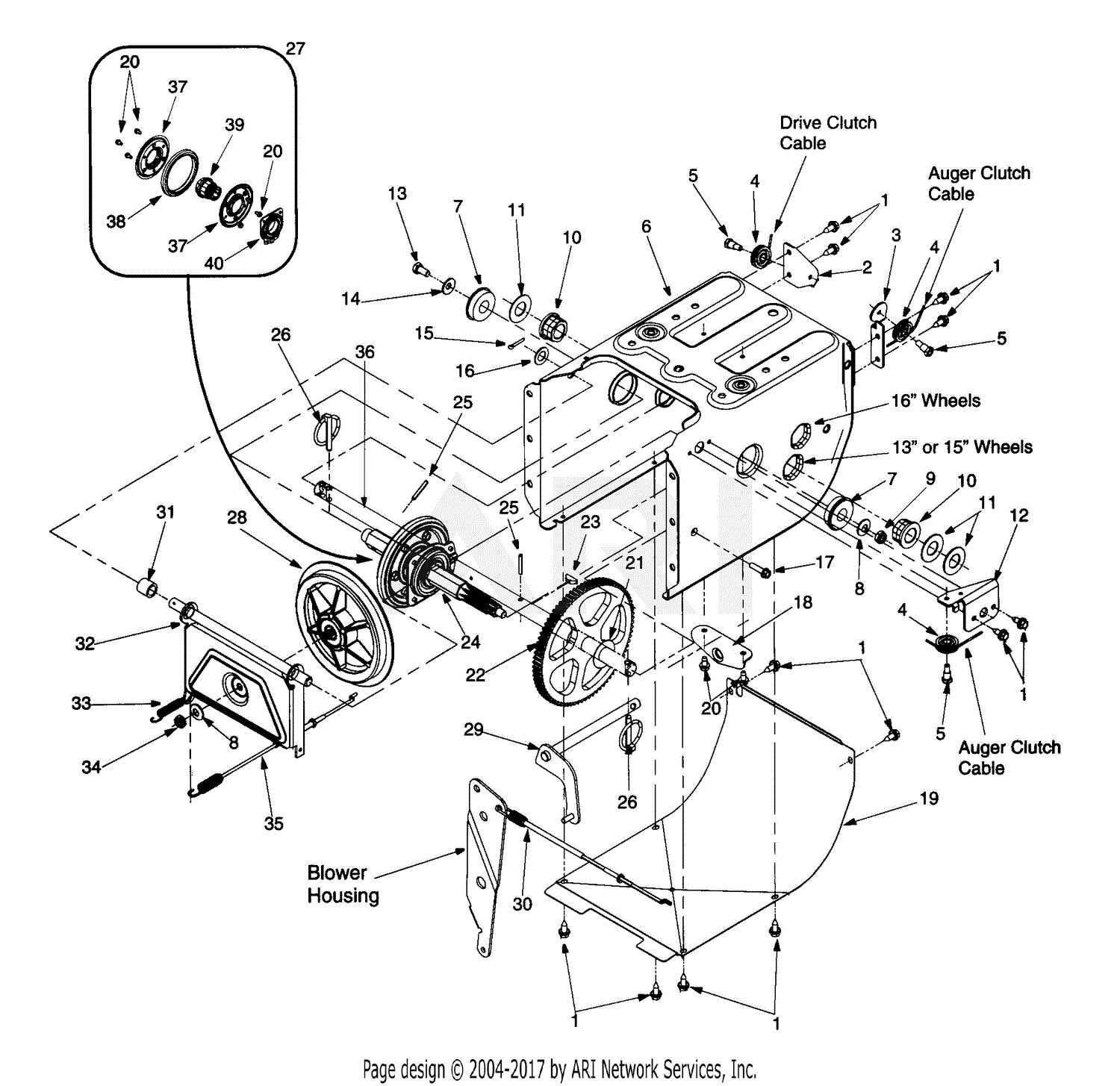

Key Components of Snowblower Assembly

Understanding the essential elements of a snow-clearing machine is crucial for efficient operation and maintenance. These components work together to ensure optimal performance during winter conditions, allowing for effective removal of snow and ice from driveways and pathways.

Engine serves as the heart of the machine, providing the necessary power to drive various mechanisms. This component is responsible for converting fuel into kinetic energy, enabling the device to function effectively.

Auger plays a vital role in gathering and moving snow toward the discharge chute. Its design often features sharp edges or blades that facilitate the breaking up of packed snow, ensuring a smooth clearing process.

Chassis provides structural integrity and houses the components securely. It must be sturdy enough to withstand harsh conditions while allowing for easy maneuverability during operation.

Discharge Chute directs the expelled snow away from the cleared area, helping to prevent re-accumulation. The adjustable feature of this component allows operators to control the distance and angle of the snow being thrown.

Controls are essential for the operator to manage the machine’s speed and direction. Ergonomically designed controls enhance user experience, providing convenience during extended use.

Regular inspection and maintenance of these components can significantly extend the lifespan of the equipment and improve its effectiveness in clearing snow. Familiarity with the assembly’s key parts aids in troubleshooting and repairs, ensuring that the machinery remains in peak condition.

Understanding the Parts Breakdown

Grasping the intricacies of an equipment assembly can significantly enhance maintenance and repair efficiency. Familiarity with each component’s function and interrelation not only streamlines troubleshooting but also aids in proper servicing. This knowledge empowers users to identify potential issues before they escalate.

Within this assembly, each segment plays a vital role, contributing to the overall performance and reliability of the machine. Recognizing the significance of these elements helps users appreciate their contribution to seamless operation. By understanding the various functions, one can ensure that each part is adequately maintained, leading to improved longevity and effectiveness.

Moreover, possessing a comprehensive view of the assembly allows for informed decisions regarding replacements or upgrades. Knowledge of available components can lead to better choices that enhance functionality and efficiency. Ultimately, a well-rounded understanding of these critical elements fosters confidence in managing equipment and addressing challenges as they arise.

Identifying Replacement Parts Efficiently

When it comes to maintaining outdoor machinery, recognizing suitable components is crucial for optimal performance. Efficiently pinpointing the necessary items not only ensures smooth operation but also prolongs the lifespan of the equipment. By adopting a systematic approach, users can easily navigate the selection process.

Here are several strategies to help identify required components effectively:

- Consult the User Manual: Always refer to the accompanying documentation, as it provides detailed information about specifications and compatible items.

- Use Online Resources: Many websites offer comprehensive catalogs and guides. Take advantage of search filters to narrow down options based on specific needs.

- Contact Professionals: Reach out to experts or local dealers. They can offer valuable insights and recommendations tailored to your specific equipment.

Additionally, utilizing diagrams can significantly aid in visualizing where each component fits within the machinery. Having a clear understanding of the assembly can streamline the process of finding replacements.

By applying these techniques, users can ensure that they select the right components, enhancing the efficiency and longevity of their outdoor equipment.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your equipment operates efficiently throughout the winter months. Adopting a proactive approach to maintenance can significantly enhance functionality and longevity. This section will outline key practices that contribute to the effective performance of your machinery.

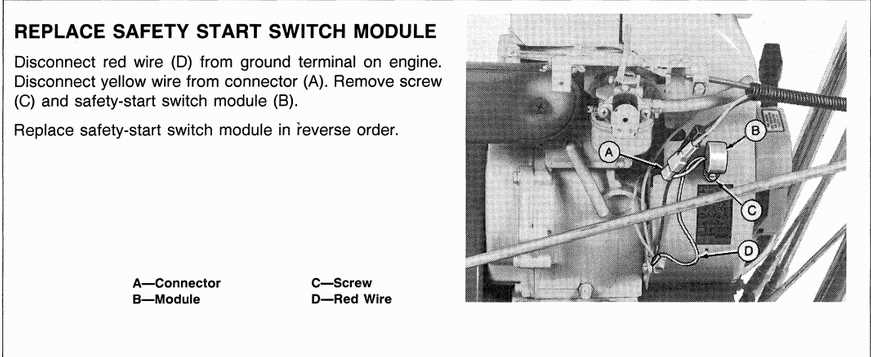

Inspect Components Regularly: Routine checks of the key elements are vital to identify wear and tear before they escalate into serious issues. Look for signs of damage or deterioration in belts, chains, and other crucial components.

Keep Clean and Free of Debris: Maintaining a clean work environment is crucial for optimal operation. After each use, clear any accumulated snow and ice, as well as any debris that may impede performance. This practice not only helps in maintaining efficiency but also prevents rust and corrosion.

Lubrication is Key: Regularly lubricate moving parts to reduce friction and wear. Ensure that all grease points are adequately serviced to facilitate smooth operation and prevent overheating.

Follow Seasonal Preparations: Before the onset of winter, perform a thorough inspection and service. This should include checking fluid levels, replacing filters, and ensuring that all systems are functioning correctly. Being well-prepared can make a significant difference in performance during peak usage times.

Store Properly: After the season, proper storage is critical. Keep the equipment in a dry, sheltered location to protect it from the elements. Use covers to prevent dust accumulation and check periodically for any signs of moisture or pests.

Common Issues and Troubleshooting Techniques

Understanding potential challenges that can arise with outdoor power equipment is essential for effective maintenance. By familiarizing yourself with typical problems and their corresponding solutions, you can ensure smoother operation and prolong the lifespan of your machinery.

Here are some frequent issues and their troubleshooting methods:

- Difficulty Starting:

- Check the fuel level and quality; stale fuel can cause starting problems.

- Inspect the spark plug for wear or damage, and replace if necessary.

- Examine the battery connections and charge status to ensure proper power supply.

- Ineffective Clearing:

- Inspect the blades for sharpness; dull blades can impede performance.

- Ensure there are no obstructions in the intake area or discharge chute.

- Check the drive belts for wear and proper tension, as loose or damaged belts can affect operation.

- Unusual Noises:

- Listen for grinding or rattling sounds, which may indicate loose or damaged components.

- Examine the auger and impeller for any foreign objects that could cause noise.

- Ensure all bolts and screws are tightened to prevent vibrations that can lead to further damage.

By addressing these common issues promptly, you can maintain optimal functionality and ensure a hassle-free experience during operation.

Exploring Compatibility with Other Models

When considering machinery for winter maintenance, understanding the interchangeability of components can significantly enhance functionality and efficiency. Many operators seek options that allow for greater flexibility and adaptability, ensuring that their equipment can be optimized for varying conditions and tasks.

Key Factors in Compatibility

Several elements contribute to the compatibility of equipment across different models:

- Design Specifications: Evaluate the dimensions and layout of components to ensure they align with existing machinery.

- Functionality: Assess whether the parts perform similar tasks and meet the operational requirements of different devices.

- Manufacturer Recommendations: Consult guidelines provided by manufacturers regarding compatible models and components.

Benefits of Compatibility

Exploring compatible models offers numerous advantages, including:

- Increased availability of replacement parts, reducing downtime.

- Cost savings through the use of interchangeable components.

- Enhanced performance by utilizing advanced features from other designs.

By understanding these factors, operators can make informed decisions about enhancing their equipment’s capabilities while ensuring reliable performance throughout the winter season.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for ensuring optimal performance and longevity. Whether you are maintaining an outdoor tool or replacing a crucial element, it is vital to seek out trusted sources that provide high-quality alternatives. Various avenues are available to ensure that you receive genuine materials suited for your machine.

Authorized Dealers are often the best option for acquiring reliable items. These vendors have direct access to the manufacturer’s inventory and can guarantee that what you purchase meets the required specifications. Additionally, many dealers offer knowledgeable staff who can assist you in identifying the correct components for your particular model.

Another viable source is the manufacturer’s website. Here, you can find comprehensive catalogs and online shops where you can browse and order the required materials. Many websites also provide useful resources, including installation guides and troubleshooting tips, which can be beneficial when working on your equipment.

Online Marketplaces can also be a good place to search for genuine components. Look for reputable sellers with positive reviews and verified listings to avoid counterfeit products. Always check the seller’s return policy and warranty options before making a purchase to ensure you are protected.

Lastly, local repair shops often have access to authentic items or can help you order them. These establishments can offer personalized service and expertise that can be valuable in finding exactly what you need for your maintenance or repair tasks.

Upgrading Your Snowblower for Efficiency

Enhancing your winter clearing machine can significantly boost its performance and effectiveness. By implementing specific modifications and utilizing advanced components, you can ensure smoother operation and quicker results during the cold months. This guide focuses on practical upgrades that can transform your equipment into a more reliable ally against snow accumulation.

Improving Power and Performance

One of the most impactful ways to elevate the efficiency of your device is by upgrading the engine. Consider a higher horsepower engine for increased torque, enabling better handling of heavy snowfall. Additionally, installing a performance-enhancing air intake system can improve airflow, resulting in optimal combustion and increased power output.

Enhancing Maneuverability

Upgrading the wheels and tracks can vastly improve maneuverability on icy surfaces. Opt for larger, all-terrain tires or high-traction tracks to gain better grip and stability. Moreover, adding a snow thrower attachment designed for your specific model can enhance the clearing capabilities, allowing for faster and more efficient snow removal.

By investing in these upgrades, you can maximize the efficiency of your equipment, making winter tasks less daunting and more manageable.