The efficiency of your winter equipment hinges on a comprehensive understanding of its various components. This intricate machinery operates through a series of interconnected elements that work harmoniously to tackle the challenges of snow and ice. Familiarity with these parts not only enhances your operational proficiency but also empowers you to make informed decisions regarding maintenance and repairs.

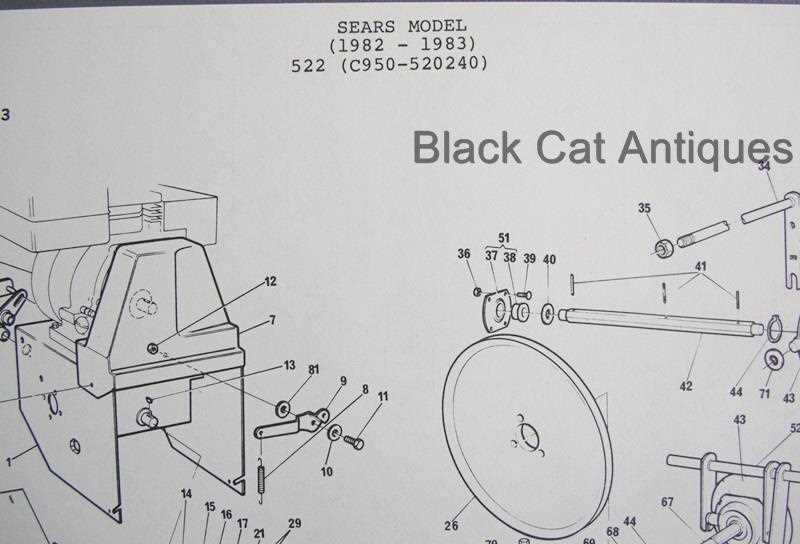

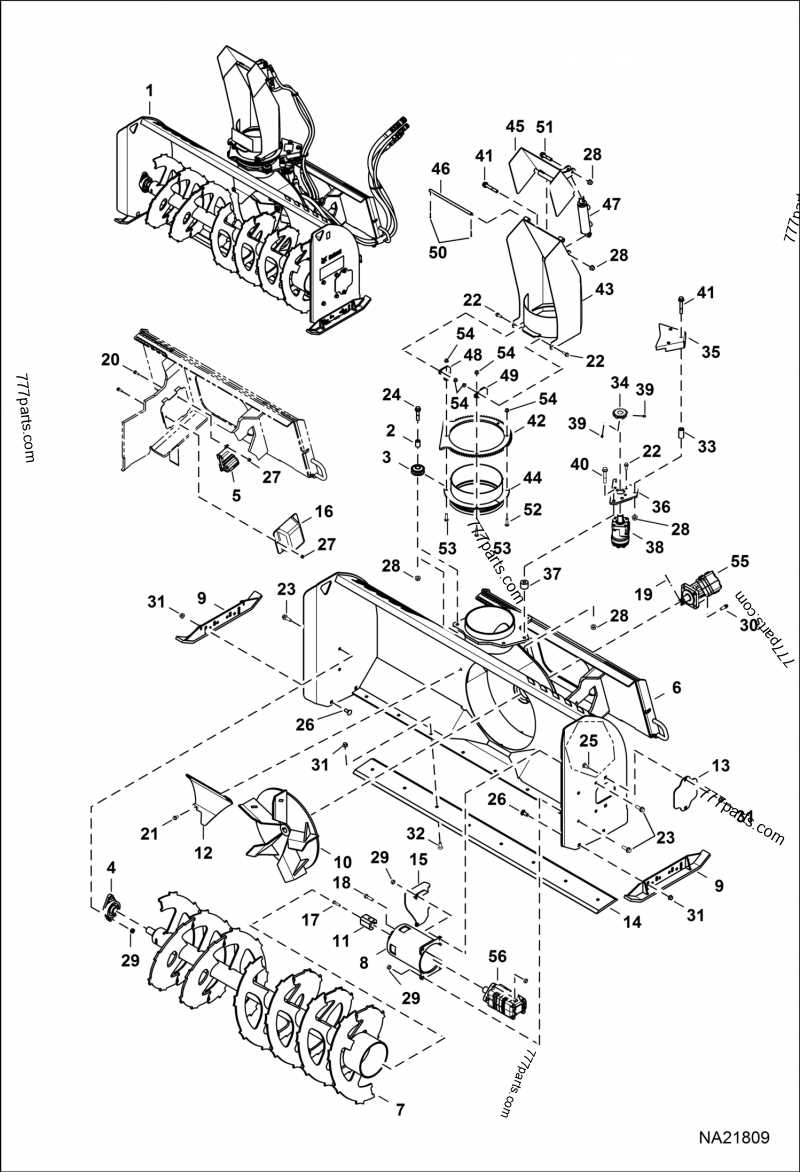

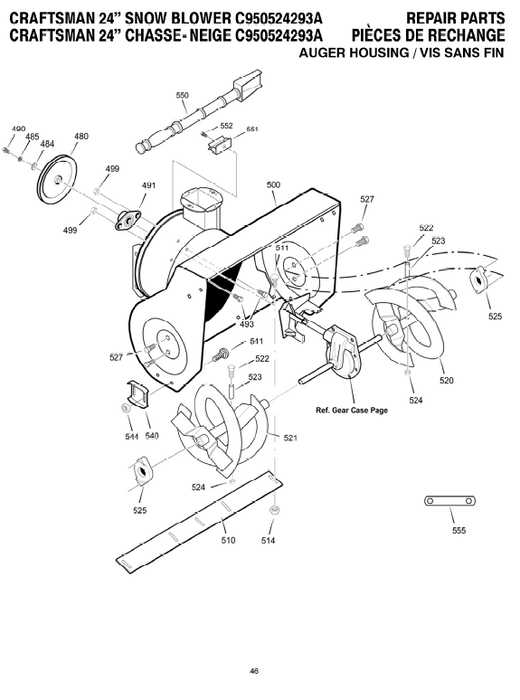

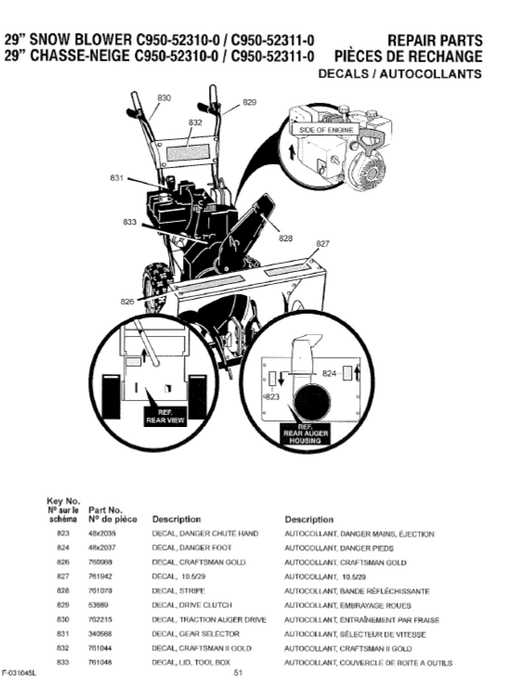

When faced with malfunctions, a visual representation of the essential elements becomes invaluable. It allows users to identify issues quickly and understand how each segment contributes to overall functionality. By delving into the specific roles and arrangements of these elements, you can ensure optimal performance during harsh weather conditions.

Ultimately, possessing a clear overview of this machinery’s anatomy will lead to improved care and longevity. As you navigate through the details, you’ll gain insights that elevate your expertise, making winter challenges more manageable and less daunting.

Understanding Snowblower Components

Gaining insight into the essential elements of a snow-clearing machine is crucial for effective maintenance and operation. Each component plays a vital role in ensuring efficiency and durability during winter challenges.

Key Elements to Explore

- Engine: The powerhouse driving the entire unit.

- Auger: Responsible for breaking up and moving the snow.

- Chute: Directs the cleared snow to the desired location.

- Skids: Help adjust the height and protect the surface beneath.

- Gearbox: Transmits power to various components.

Maintenance Tips

- Regularly check the engine oil levels.

- Inspect the auger for wear and tear.

- Clear any debris from the chute to ensure proper function.

- Lubricate moving parts to avoid rust and improve performance.

Types of Snowblower Designs

When it comes to clearing snow, various designs cater to different needs and preferences. Each configuration is engineered to optimize performance based on factors such as terrain, snowfall volume, and user convenience. Understanding these distinctions can help users select the most suitable equipment for their specific situations.

Single-Stage Models

Single-stage machines are typically compact and lightweight, making them ideal for residential use, particularly on driveways and sidewalks. These models utilize a single auger that collects snow and discharges it through a chute. They are particularly effective for light to moderate snowfall and can easily maneuver in tight spaces.

Two-Stage Models

In contrast, two-stage configurations are designed for heavier snowfall and larger areas. They feature an auger that first gathers the snow and then a separate impeller that propels it out through the chute. This design allows for efficient handling of thicker snow and ice, making it suitable for commercial applications or homeowners in regions with significant winter weather.

Understanding the nuances between these designs is essential for selecting the right machine, ensuring efficiency and effectiveness in snow management. Whether one opts for a compact solution or a robust option, the right choice can make winter maintenance significantly easier.

Key Parts in Snowblower Operation

Understanding the essential components that facilitate efficient operation is crucial for optimal performance during winter tasks. Each element plays a specific role in ensuring smooth functioning, enabling users to tackle heavy snowfall effectively.

The engine serves as the powerhouse, providing the necessary energy to drive the entire machine. Coupled with this, the auger is responsible for gathering and breaking up the accumulated snow, ensuring it is efficiently moved towards the discharge chute. The impeller then propels the snow out, directing it away from the path being cleared.

Additionally, the controls are vital for maneuverability, allowing users to adjust speed and direction seamlessly. The skid shoes and scraper blade help maintain proper contact with the ground, ensuring optimal clearance and preventing damage to surfaces below.

Finally, the chassis provides structural support, housing all components and contributing to the overall stability and durability of the equipment. By delving into these elements, one can appreciate the intricate design that leads to effective snow management.

Common Snowblower Maintenance Tips

Regular upkeep is essential for ensuring optimal performance during winter months. By focusing on a few key practices, you can extend the lifespan of your equipment and enhance its efficiency. Below are some effective strategies to keep your machine running smoothly.

Routine Inspections

Perform regular checks on your equipment to identify any potential issues. Look for signs of wear, including cracks or loose components. Addressing these problems early can prevent larger, costlier repairs.

Proper Lubrication

Ensure all moving parts are well-lubricated to minimize friction and prevent overheating. Use the recommended oil types and follow the manufacturer’s guidelines for application. Consistent lubrication can significantly improve operational efficiency and reduce wear over time.

Diagnosing Snowblower Issues

Identifying problems with your winter machinery requires a systematic approach. Understanding the symptoms and their potential causes can help you effectively troubleshoot and restore functionality. This guide will outline common issues and how to address them.

Common Symptoms

Many users encounter issues such as poor performance or strange noises. No operation might suggest electrical failures, while inconsistent clearing could point to blockages or mechanical wear. Observing these symptoms closely will aid in narrowing down the source of the trouble.

Troubleshooting Steps

Start by examining the power source and ensuring connections are secure. If mechanical components are the concern, delve into the belt system and augers for signs of wear or damage. Consulting a detailed layout can provide the ultimate clarity on the specific components that need attention.

Essential Tools for Repairs

When tackling any machinery maintenance, having the right equipment at your disposal is crucial. The effectiveness and efficiency of your repairs can be greatly enhanced by using specific tools designed for various tasks, ensuring a smoother workflow and better results.

Basic Hand Tools

Wrenches and screwdrivers are indispensable for loosening and tightening bolts or screws. A well-organized toolbox with these essentials will allow for quick adjustments and repairs, saving both time and effort.

Specialized Equipment

For more intricate repairs, consider investing in torque wrenches and pliers. These tools enable precise handling and manipulation of components, ensuring that each part is fitted correctly for optimal performance.

Replacing Worn-Out Snowblower Parts

Over time, certain components of your outdoor equipment may experience wear and tear, affecting performance and efficiency. Regular maintenance and timely replacement of these elements can significantly enhance functionality and extend the lifespan of the machine. Understanding when and how to replace these critical components is essential for optimal operation during winter months.

Identifying Signs of Wear

Recognizing the indicators of deterioration is crucial. Look for unusual noises, reduced performance, or visible damage on parts. Regular inspections can help catch these issues early, preventing further complications.

Replacement Process Overview

When it comes to swapping out damaged components, following a systematic approach is vital. Start by consulting the manufacturer’s guidelines and ensure you have the right tools at hand. Below is a simple overview of the steps involved:

| Step | Description |

|---|---|

| 1 | Turn off the equipment and disconnect any power source. |

| 2 | Remove any housing or covers to access the required components. |

| 3 | Carefully detach the worn-out elements, noting their arrangement. |

| 4 | Install the new components, ensuring a secure fit. |

| 5 | Replace any covers and reconnect the power source before testing. |

Regularly addressing issues related to worn elements not only improves performance but also ensures safer operation, allowing you to tackle the challenges of winter with confidence.

Safety Precautions for Snowblower Use

Operating winter machinery can pose various hazards, making it essential to prioritize safety to prevent injuries and ensure efficient operation. Understanding the necessary precautions can greatly reduce risks associated with these powerful tools.

- Always read the manufacturer’s instructions thoroughly before use.

- Inspect the equipment for any damage or wear before each operation.

- Wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Ensure that all guards and safety devices are in place and functional.

While operating the machine, adhere to the following guidelines:

- Start the equipment in an open area to avoid carbon monoxide buildup.

- Keep hands and feet away from moving parts at all times.

- Never attempt to clear clogs while the engine is running.

- Be mindful of your surroundings, especially when working near others or pets.

After use, follow these recommendations:

- Allow the machinery to cool down before storing it.

- Clean the equipment thoroughly to prevent rust and damage.

- Store the unit in a dry, secure location, away from children and pets.

By following these precautions, operators can ensure a safer experience while effectively managing winter conditions.

Where to Find Replacement Parts

Maintaining outdoor equipment can be challenging, especially when components wear out and require replacement. Fortunately, there are several avenues to explore when searching for new pieces to restore functionality. Knowing where to look can save both time and effort in the repair process.

Online Retailers: Numerous e-commerce platforms specialize in offering a wide range of replacement components. These sites often feature detailed descriptions and customer reviews, helping you make informed decisions. A simple search can yield multiple options, from OEM to aftermarket alternatives.

Local Hardware Stores: Many community hardware shops stock essential items for various outdoor machinery. Visiting a nearby store allows you to consult knowledgeable staff who can assist in identifying the right components and might even suggest compatible options.

Manufacturer Websites: If you have a specific brand in mind, checking the official website can be beneficial. Manufacturers typically provide catalogs or search functions to help locate exact replacements. This approach ensures compatibility and often offers warranties on new items.

Salvage Yards: For those seeking budget-friendly solutions, salvage yards can be a treasure trove. These locations may have used components in good condition. It’s worth visiting to find what you need at a fraction of the cost of new items.

Forums and Community Groups: Engaging with online communities dedicated to equipment maintenance can yield valuable insights. Fellow enthusiasts often share recommendations on where to find reliable sources for new and used components, along with tips on installation and care.

By utilizing these resources, you can efficiently locate the necessary items to keep your outdoor equipment running smoothly, ensuring it remains an essential asset for years to come.