The effective operation of a 44 unit attachment relies on a clear understanding of its various components. Each element plays a crucial role in ensuring that the attachment functions optimally, especially in challenging weather conditions. Familiarity with the arrangement and interaction of these components can significantly enhance the performance and longevity of the equipment.

In this section, we will explore the essential elements of the 44 unit attachment, focusing on how they contribute to its overall efficiency. By examining the layout and function of each component, users can better appreciate the design and engineering that goes into creating reliable tools for outdoor maintenance. Knowing these details can aid in maintenance and troubleshooting, allowing for a smoother experience when using the attachment.

Furthermore, recognizing the specific roles of each component will empower users to make informed decisions regarding repairs or upgrades. This knowledge not only facilitates effective operation but also enhances safety during usage. A comprehensive understanding of the attachment’s structure can lead to improved results in various tasks, making it a valuable asset for anyone involved in outdoor work.

This section aims to provide a comprehensive overview of the various components that make up the 44 model of the snow-clearing machine. Understanding these elements is essential for maintenance and repairs, ensuring optimal performance during winter operations.

Key Components of the Snow-Clearing Equipment

Below are the primary elements that contribute to the functionality of the snow-clearing unit:

- Auger: Responsible for gathering and moving snow.

- Impeller: Helps to discharge snow away from the machine.

- Chassis: The main frame that supports other components.

- Skids: Adjustable pieces that control the height of the equipment above the ground.

- Gearbox: Facilitates the transfer of power from the engine to the working parts.

Maintenance Tips for Optimal Performance

To ensure longevity and efficiency, consider the following maintenance practices:

- Regularly inspect and clean the auger and impeller to prevent blockages.

- Check the oil levels and change as needed.

- Examine belts and cables for wear and replace them when necessary.

- Lubricate moving parts to reduce friction and wear.

- Store the machine in a dry place to prevent rust and corrosion.

Key Components of the Snow Clearing Machine

Understanding the essential elements of a snow clearing device is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance during winter conditions. Familiarizing oneself with these parts can enhance both the efficiency and longevity of the equipment.

Primary Elements

The primary components include the cutting mechanism, which is responsible for breaking through the accumulated snow, and the propulsion system that enables movement across various terrains. These elements work in harmony to deliver powerful performance in challenging weather.

Supporting Features

Additional features, such as the control mechanisms and chute adjustments, contribute to user convenience and operational effectiveness. Proper understanding of these functionalities allows operators to make necessary adjustments for improved handling and maneuverability in adverse conditions.

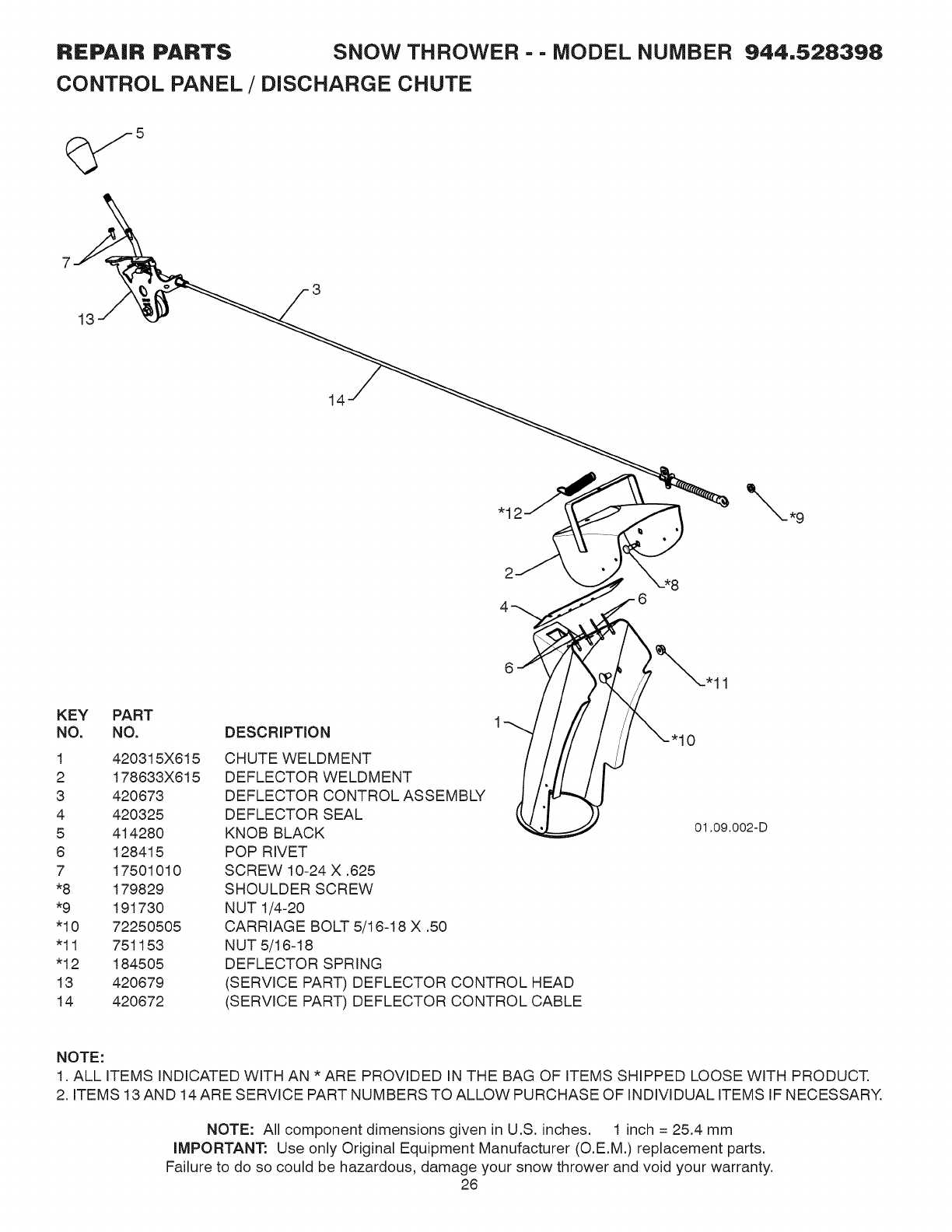

How to Read the Parts Diagram

Understanding the layout of components can greatly enhance your ability to identify and select the necessary items for maintenance or repair tasks. This section will guide you through the essential steps to effectively interpret these visual representations, ensuring you can navigate them with confidence.

To begin, familiarize yourself with the various symbols and labels used in the illustration. Each element is typically marked with a reference number that corresponds to a list, making it easier to find specific components. It’s crucial to recognize the organization of the image, as it often categorizes items by function or location.

| Reference Number | Description | Quantity |

|---|---|---|

| 1 | Auger Assembly | 1 |

| 2 | Drive Belt | 2 |

| 3 | Chassis Cover | 1 |

| 4 | Impeller | 1 |

By paying close attention to the details in the representation, you can ensure that you have a clear understanding of what each item is and how it fits into the overall assembly. This knowledge not only streamlines your repair process but also helps in maintaining the efficiency of the entire system.

Common Issues and Solutions

When operating outdoor machinery designed for clearing snow, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their corresponding solutions can help maintain optimal functionality and prolong the lifespan of the equipment.

| Issue | Description | Solution |

|---|---|---|

| Insufficient Clearing | The machine may struggle to clear snow effectively, leaving behind unprocessed areas. | Check the blade height and adjust as necessary. Ensure the chute is not clogged. |

| Engine Starting Problems | The engine may fail to start or run inconsistently. | Inspect the fuel supply, replace the spark plug, and clean the air filter. |

| Vibration Issues | Excessive vibration during operation can indicate mechanical problems. | Examine all bolts and fasteners for tightness, and check for any worn-out components. |

| Drive Malfunction | The unit may not move or respond correctly to controls. | Inspect the drive belt for wear, and adjust or replace as needed. |

Maintenance Tips for Optimal Performance

Ensuring that your equipment operates efficiently requires regular upkeep and attention. By following a few essential guidelines, you can enhance its functionality and longevity, making your tasks more manageable and effective.

Regular Inspection

Conducting periodic evaluations is crucial for identifying potential issues before they escalate. Here are some areas to focus on:

- Check for wear and tear on moving components.

- Inspect belts and cables for signs of damage.

- Ensure all connections are secure and free from rust.

Proper Cleaning

Maintaining cleanliness is vital for optimal performance. Accumulated debris can hinder functionality. Consider these steps:

- Remove any build-up of dirt or snow after each use.

- Clean the exterior surfaces to prevent corrosion.

- Ensure air vents are clear to allow proper airflow.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its functionality and longevity. Several avenues exist for sourcing these essential items, each offering unique advantages. Understanding where to look can streamline the process and ensure you obtain high-quality replacements without unnecessary delays.

Authorized Dealers

One of the most reliable sources for acquiring components is through authorized dealers. These establishments typically carry an extensive inventory of original items, ensuring compatibility and performance. Moreover, staff members at these locations are often knowledgeable and can assist with any inquiries regarding installation or maintenance.

Online Retailers

The internet has revolutionized the way consumers shop for replacement components. Numerous online platforms provide a vast selection, often at competitive prices. When purchasing online, it’s crucial to verify the credibility of the seller and to read customer reviews to ensure the quality of the items. Additionally, many websites offer detailed descriptions and specifications, aiding in the selection process.

Benefits of Using OEM Components

When it comes to maintaining and enhancing equipment, the choice of components plays a crucial role in ensuring optimal performance. Utilizing original manufacturer components offers distinct advantages that can significantly impact the longevity and reliability of machinery.

One of the primary benefits of OEM components is their precise compatibility with the equipment. These components are specifically designed to fit seamlessly, minimizing the risk of operational issues that often arise from using generic alternatives. Furthermore, original parts are typically crafted with higher quality materials, leading to improved durability and performance over time.

Another advantage is the assurance of warranty coverage. Many manufacturers provide warranties on their components, which can offer peace of mind and protect against potential repair costs. In addition, using original parts can help maintain the equipment’s resale value, as buyers often prefer machinery that has been serviced with OEM components.

In summary, opting for original manufacturer components not only ensures a perfect fit but also enhances performance, reliability, and value retention. Investing in these quality parts can lead to a more efficient and longer-lasting operation.

Frequently Asked Questions About Snow Removal Equipment

This section addresses common inquiries related to machinery designed for clearing snow. It aims to provide users with essential insights, guiding them in making informed decisions regarding their equipment and maintenance.

What should I consider when choosing snow removal machinery?

When selecting equipment for snow clearing, factors such as the size of your area, the average snowfall, and the machine’s capabilities should be taken into account. Additionally, consider the ease of operation, maintenance requirements, and available features to ensure efficiency and effectiveness.

How do I maintain my snow clearing equipment?

Proper maintenance involves regular inspections, cleaning after use, and addressing any wear or damage promptly. It is essential to check fluid levels, ensure that moving parts are lubricated, and store the machinery in a dry place to prevent rust and deterioration.

Resources for John Deere Owners

Owning equipment from a renowned manufacturer provides access to a wealth of information and support. This section aims to highlight essential resources that enhance the experience for enthusiasts and users of these powerful machines. From maintenance tips to troubleshooting guidance, these tools can significantly improve the ownership journey.

Official Manufacturer Support

Accessing official support is crucial for all owners. The manufacturer’s website offers a comprehensive database of manuals, guides, and specifications. Users can easily locate documentation relevant to their specific model, ensuring proper care and understanding of their equipment.

Online Community Forums

Engaging with online forums provides a platform for owners to connect, share experiences, and seek advice. These communities are invaluable for exchanging tips on upkeep, modifications, and best practices. Participating in discussions can help resolve issues more quickly and foster a sense of camaraderie among fellow users.