Maintaining outdoor machinery is essential for ensuring optimal performance during the winter months. Properly understanding the various components of your equipment can significantly enhance its efficiency and longevity. Familiarizing oneself with the intricacies of each part can lead to better maintenance practices and troubleshooting techniques.

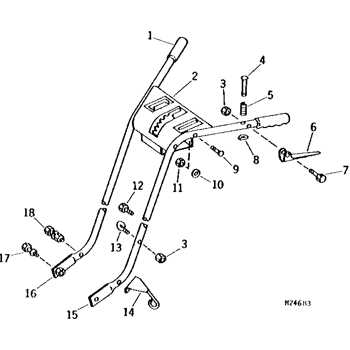

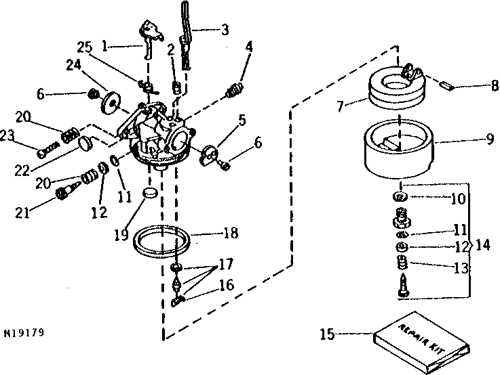

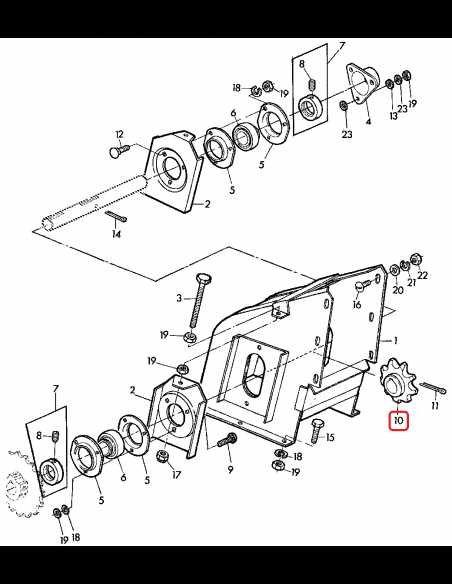

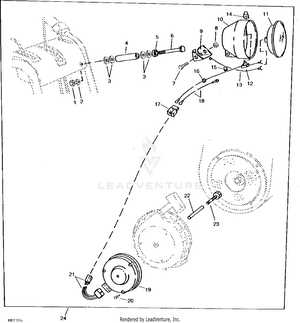

Visual aids serve as invaluable tools in this process, allowing users to quickly identify and understand the functionality of different components. A well-structured visual representation can simplify complex mechanisms and provide clarity on assembly and disassembly. This understanding not only aids in repairs but also fosters a deeper connection with the machinery.

In this guide, we will explore the essential elements that constitute your equipment, emphasizing the importance of knowing each component’s role. By engaging with these visuals, you will empower yourself to tackle any challenges that may arise, ensuring that your machinery remains in top condition throughout its lifespan.

Understanding the John Deere 1032 Snowblower

This section delves into the functionality and components of a renowned winter clearing machine, emphasizing its role in maintaining accessibility during snowy conditions. The mechanism’s design ensures efficiency and reliability, making it an essential tool for many households facing harsh winter weather.

Key Features and Functions

The equipment boasts a powerful motor that provides substantial performance, enabling it to handle heavy accumulations of frost. Its auger system effectively collects and expels snow, while user-friendly controls allow for effortless operation. Additionally, the construction is designed to withstand the rigors of regular use, ensuring durability over time.

Maintenance Tips

Regular upkeep is vital for optimal functionality. Users should routinely inspect the machine for wear and tear, paying particular attention to the blades and belts. Lubrication of moving parts is essential to prevent friction and prolong the lifespan of the equipment. Following the manufacturer’s recommendations will help maintain efficiency and reliability throughout the snowy seasons.

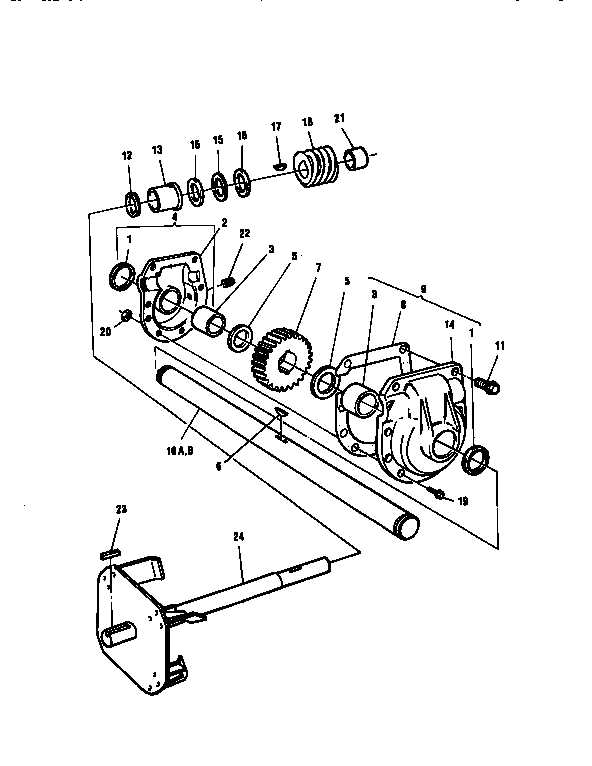

Essential Components of the Snowblower

Understanding the critical elements of a snow-clearing machine is vital for effective operation and maintenance. Each component plays a significant role in ensuring that the equipment functions efficiently, allowing for quick and effective snow removal during winter conditions.

Power Unit: The heart of the machine, responsible for providing the necessary energy to drive all other mechanisms. Its performance directly impacts the overall efficiency of snow clearing.

Auger: This part is crucial for gathering and transporting snow into the discharge chute. The design and material of the auger affect its ability to handle different types of snow.

Discharge Chute: This component directs the expelled snow away from the path being cleared. Adjustable features allow for customized snow throwing angles to suit various environments.

Skid Shoes: Positioned at the base, these elements help control the height at which the machine operates, ensuring optimal contact with the ground while minimizing damage to surfaces beneath.

Drive Mechanism: This assembly enables mobility, allowing the operator to navigate through different terrains effortlessly. It is essential for providing traction and control during operation.

Controls: Intuitive interface components facilitate easy operation, giving the user the ability to adjust settings quickly and efficiently while working in harsh conditions.

By familiarizing oneself with these essential elements, operators can enhance their effectiveness and prolong the lifespan of the equipment during demanding winter months.

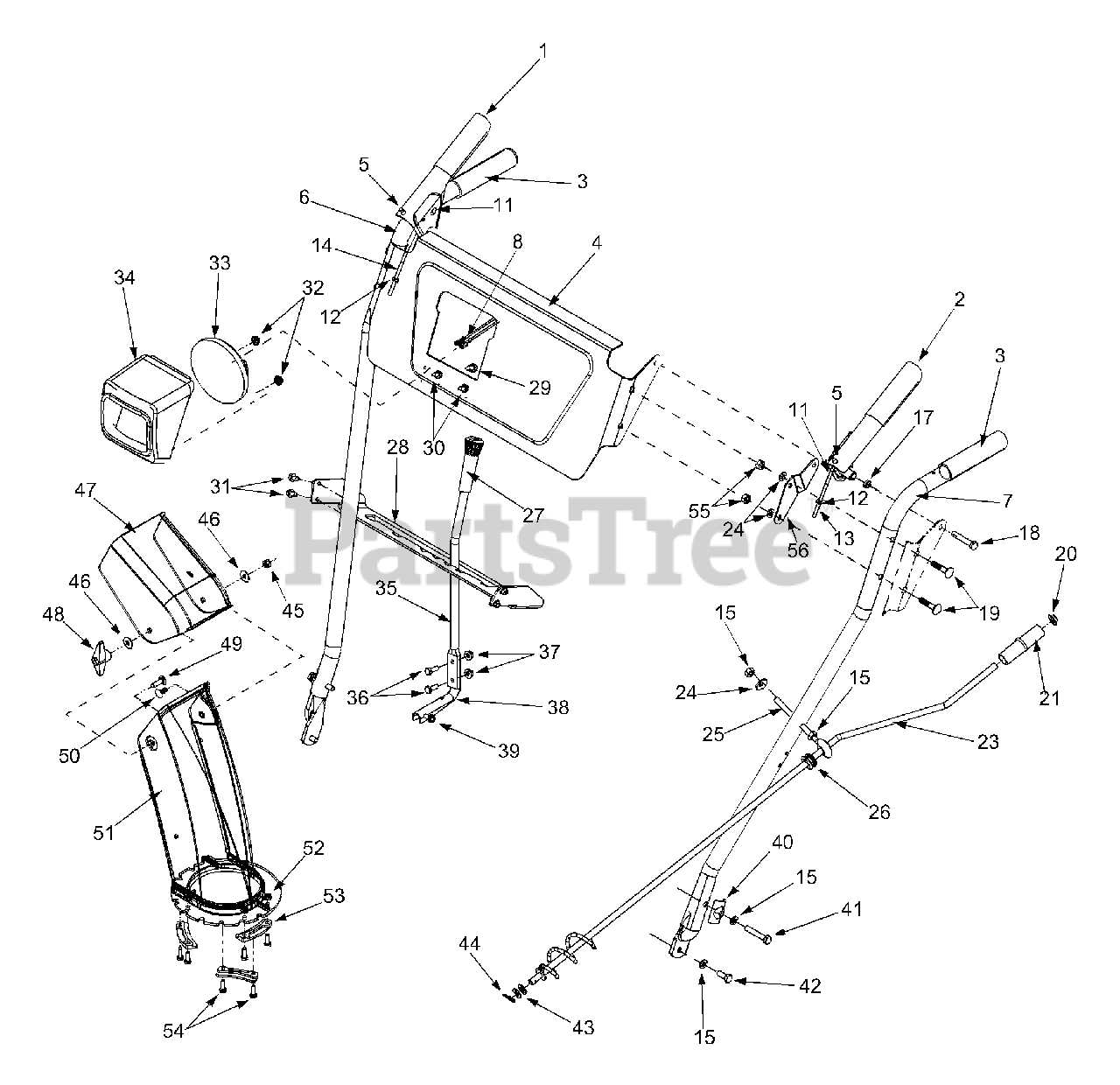

How to Read the Parts Diagram

Understanding an assembly illustration is essential for efficient maintenance and repair of your equipment. These visuals provide a detailed overview of components, helping users identify individual elements and their relationships within the system. By becoming familiar with the layout and symbols used, you can streamline your troubleshooting process and ensure that replacements are accurate.

Begin by examining the legend or key, which often accompanies the illustration. This section explains the symbols and numbering used to represent different components. Familiarizing yourself with these notations is crucial for interpreting the visual correctly. Each part will typically have a corresponding reference number that can be cross-referenced with a list of available replacements.

Next, focus on the arrangement of components. Notice how they are organized and connected, as this reflects their actual placement within the machinery. Pay attention to any notes or highlighted areas, which may indicate specific areas of concern or assembly instructions. This information can be invaluable when troubleshooting or planning a repair.

Lastly, when searching for replacement items, use the reference numbers in conjunction with the manufacturer’s catalog or online resources. This approach ensures that you acquire the correct components needed for your project, ultimately leading to a more effective repair process.

Common Replacement Parts Overview

This section provides an insight into frequently needed components that ensure optimal performance and longevity of your equipment. Understanding these essentials can help in timely maintenance and prevent potential breakdowns. Knowing what to look for can make a significant difference in efficiency and effectiveness during operation.

Key Components

Among the most commonly replaced elements are belts, which play a crucial role in the transfer of power throughout the machinery. Regular inspection is necessary to identify any wear or damage that could impede functionality. Additionally, shear pins are critical for protecting the system from heavy loads and unexpected obstacles, requiring periodic replacement to maintain safety and operational integrity.

Maintenance Essentials

Filters are another vital aspect, as they help maintain the quality of fluids circulating through the system. Keeping these clean and replacing them as needed can greatly enhance performance and prolong the life of the machine. Furthermore, checking and replacing worn-out blades is essential for achieving optimal cutting efficiency, ensuring that the equipment operates smoothly and effectively during use.

Maintenance Tips for Optimal Performance

To ensure efficient operation and longevity of your equipment, regular upkeep is essential. By following a few straightforward practices, you can maximize the performance and reliability of your machine throughout the season.

Regular Inspection

- Check the condition of belts and cables for wear or fraying.

- Inspect the cutting components for damage or dullness, replacing as necessary.

- Examine the fluid levels, ensuring that oil and fuel are adequate and clean.

Seasonal Preparation

- Before the start of each season, conduct a thorough cleaning to remove debris and buildup.

- Sharpen or replace blades to enhance cutting efficiency.

- Lubricate moving parts to reduce friction and wear.

By adhering to these simple maintenance tips, you can keep your equipment functioning optimally, ensuring reliable performance when you need it most.

Where to Find Genuine Parts

When maintaining outdoor equipment, sourcing authentic components is crucial for optimal performance and longevity. Genuine replacements ensure compatibility and reliability, which can significantly impact the efficiency of your machine. Here are some reliable sources for acquiring these essential items.

Authorized Dealers

One of the most trustworthy ways to find authentic replacements is through authorized dealerships. These establishments are equipped with knowledgeable staff and can provide:

- Original equipment manufacturer (OEM) components

- Expert advice on installation and compatibility

- Access to exclusive promotions and warranty options

Online Retailers

The internet offers a wide range of options for obtaining quality replacements. Reputable online retailers often have extensive inventories and can deliver directly to your doorstep. Consider the following:

- Search for websites specializing in outdoor machinery supplies.

- Verify customer reviews and ratings for trustworthiness.

- Ensure that the site provides clear information on return policies.

By utilizing these resources, you can confidently procure the necessary components to keep your equipment running smoothly.

Troubleshooting Common Issues

Encountering difficulties with outdoor equipment can be frustrating, but many issues can be resolved with a systematic approach. Identifying symptoms and understanding potential causes is essential for effective resolution. This guide provides insights into frequent problems and their solutions.

Common Problems and Solutions

- Machine Won’t Start:

- Check the fuel level and ensure that it’s fresh.

- Inspect the spark plug for wear or carbon buildup.

- Examine the ignition system for proper function.

- Insufficient Snow Clearing:

- Verify that the impeller and auger are not clogged.

- Ensure that the blades are sharp and not damaged.

- Adjust the speed settings for optimal performance.

- Unusual Noises:

- Listen for grinding sounds, which may indicate foreign objects caught in the mechanism.

- Check for loose components that could be causing rattling.

- Inspect bearings and belts for wear and tear.

Maintenance Tips

- Regularly clean the equipment after each use to prevent buildup.

- Perform routine checks on fluids and lubricants.

- Store the machine in a dry place to avoid rust and corrosion.

DIY Repairs and Upgrades

Maintaining and enhancing outdoor machinery can significantly improve its efficiency and longevity. By undertaking simple repairs and modifications, you can ensure optimal performance while saving on professional service costs. This section provides guidance on tackling various tasks that not only restore functionality but also introduce valuable upgrades to your equipment.

One effective approach to enhance your machine’s performance is to regularly inspect and replace worn components. Focus on areas that experience the most stress, such as drive belts and augers. Upgrading to higher-quality materials can yield better results and increase durability. Additionally, consider implementing modifications that improve operation efficiency, like adjusting the chute direction or optimizing the height settings for different snow conditions.

Moreover, routine cleaning and lubrication can prevent premature wear and tear. Simple practices such as clearing debris and applying grease to moving parts can lead to smoother operation. Embrace these DIY efforts to cultivate a deeper understanding of your equipment, empowering you to tackle more complex challenges in the future.

Benefits of Using Authentic Components

Utilizing genuine components for machinery maintenance offers numerous advantages that contribute to the longevity and efficiency of the equipment. Authentic items are specifically designed to meet the exact specifications of the original model, ensuring optimal performance and reliability.

One significant benefit is enhanced durability. Genuine components are manufactured using high-quality materials and stringent quality control standards. This results in a longer lifespan and better resistance to wear and tear compared to aftermarket alternatives.

Moreover, using original parts can lead to improved performance. These components are engineered to work seamlessly with the entire system, reducing the likelihood of compatibility issues that can arise from using non-genuine options. As a result, users can expect consistent operation and efficient functioning.

In addition to reliability and performance, utilizing authentic components can also ensure warranty protection. Many manufacturers require the use of original parts for warranty coverage. Choosing genuine components helps maintain the warranty status, safeguarding the investment made in the equipment.

Lastly, sourcing authentic components often provides access to better customer support and technical assistance. Manufacturers typically offer comprehensive support for their original products, which can be invaluable when troubleshooting or seeking guidance on repairs.