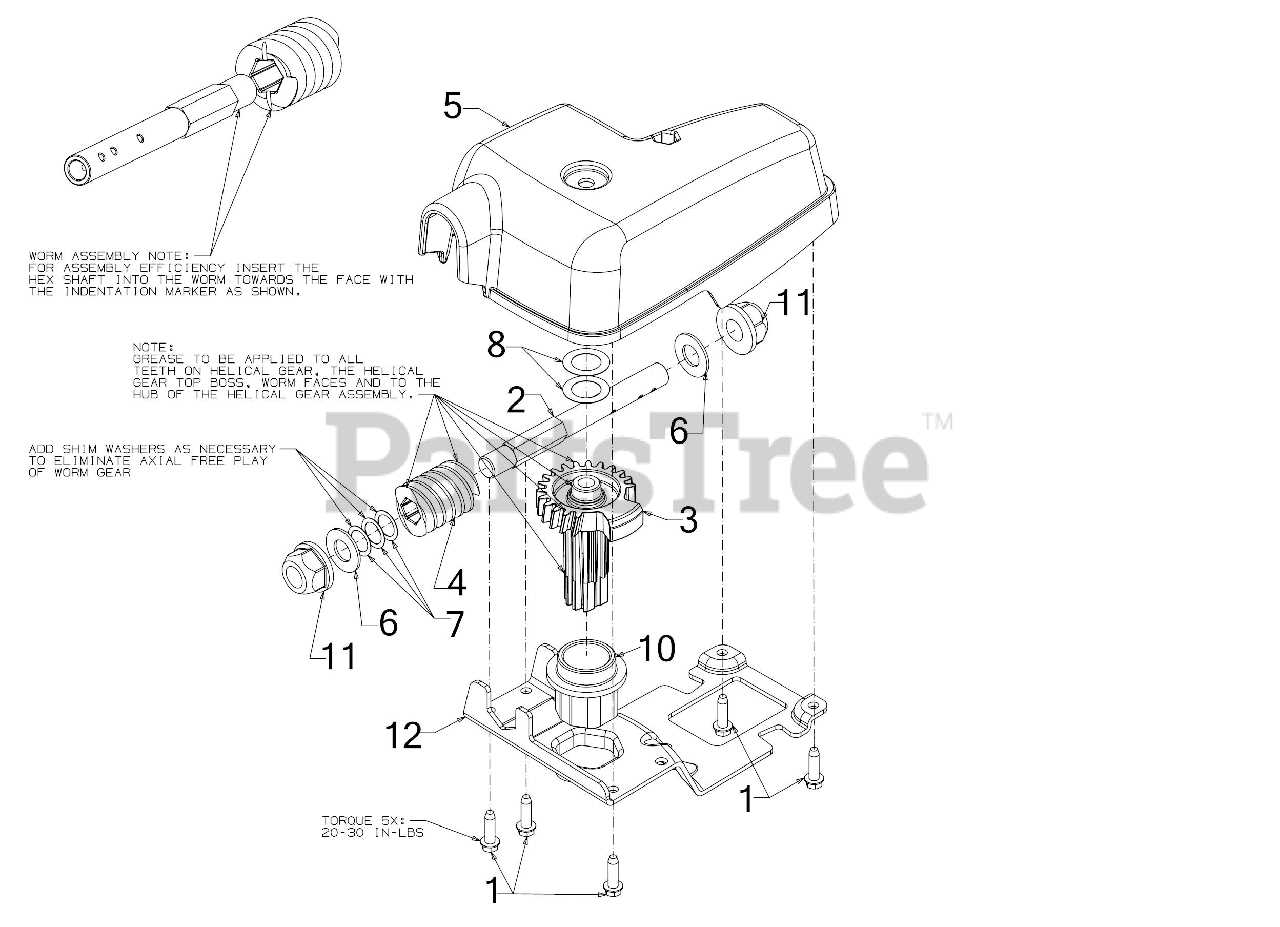

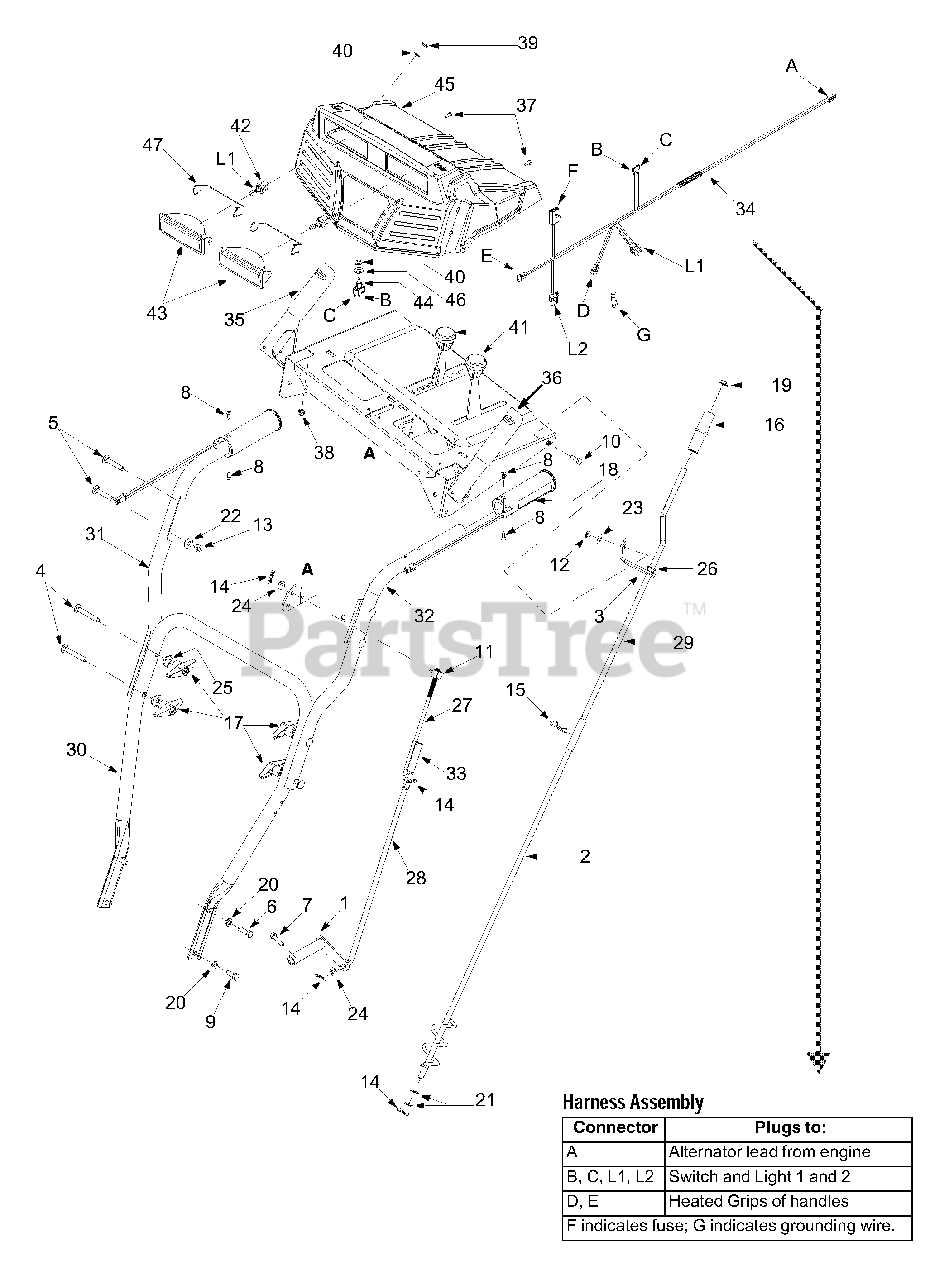

When it comes to maintaining winter equipment, having a clear understanding of its various elements is crucial. This knowledge not only enhances the performance of the machine but also simplifies the process of troubleshooting and repairs. Recognizing the specific functions and arrangements of each component will empower users to address issues promptly and effectively.

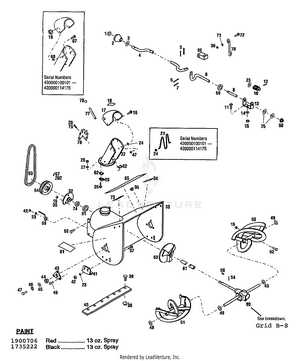

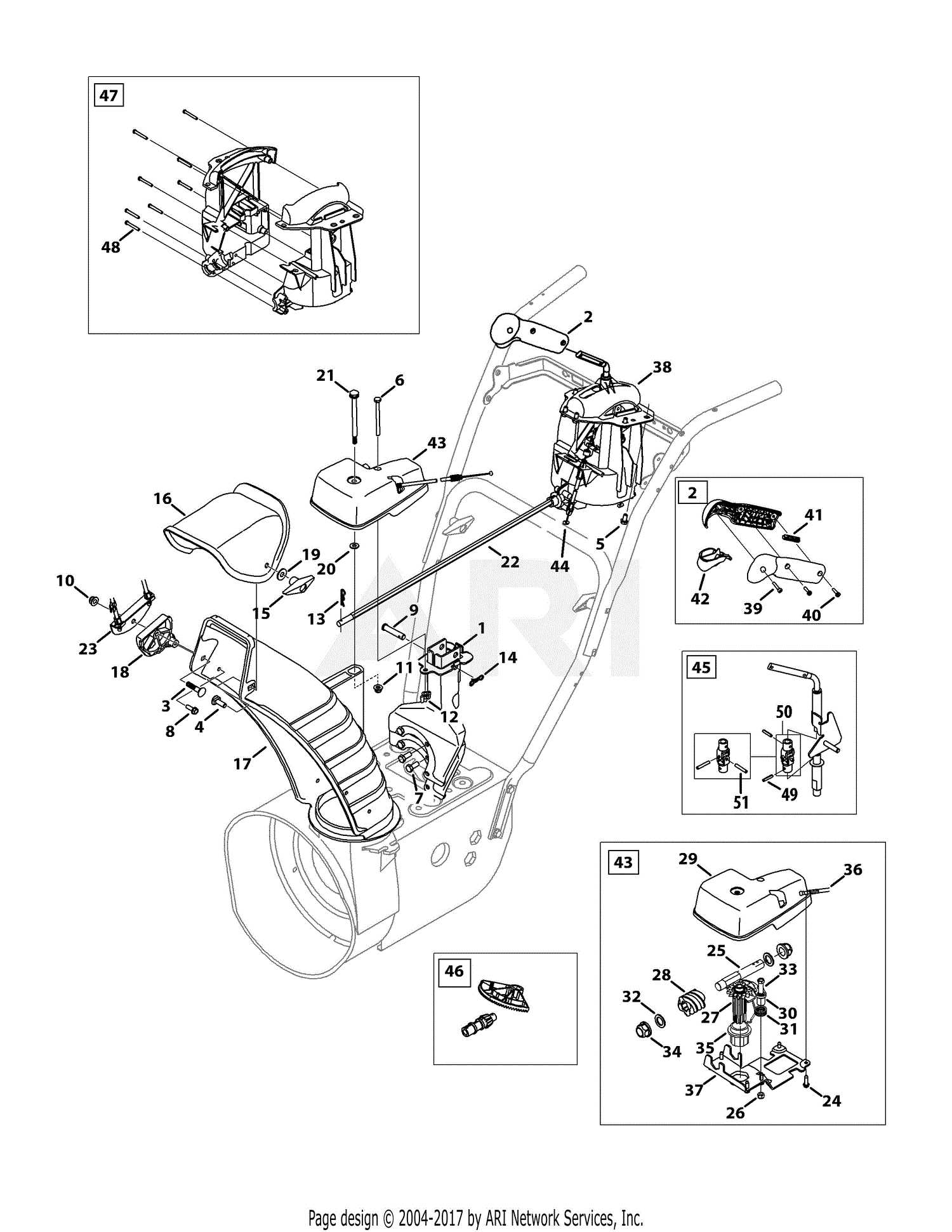

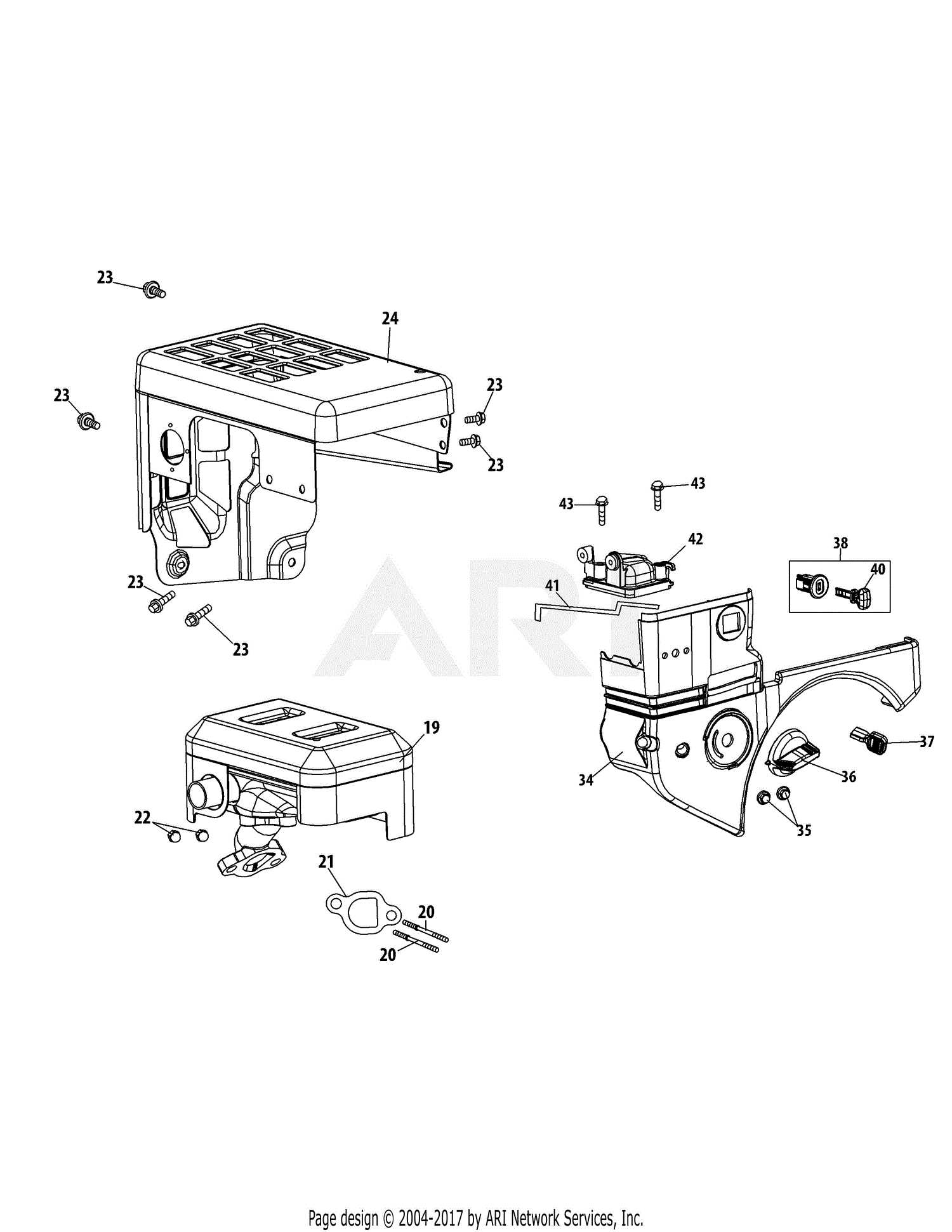

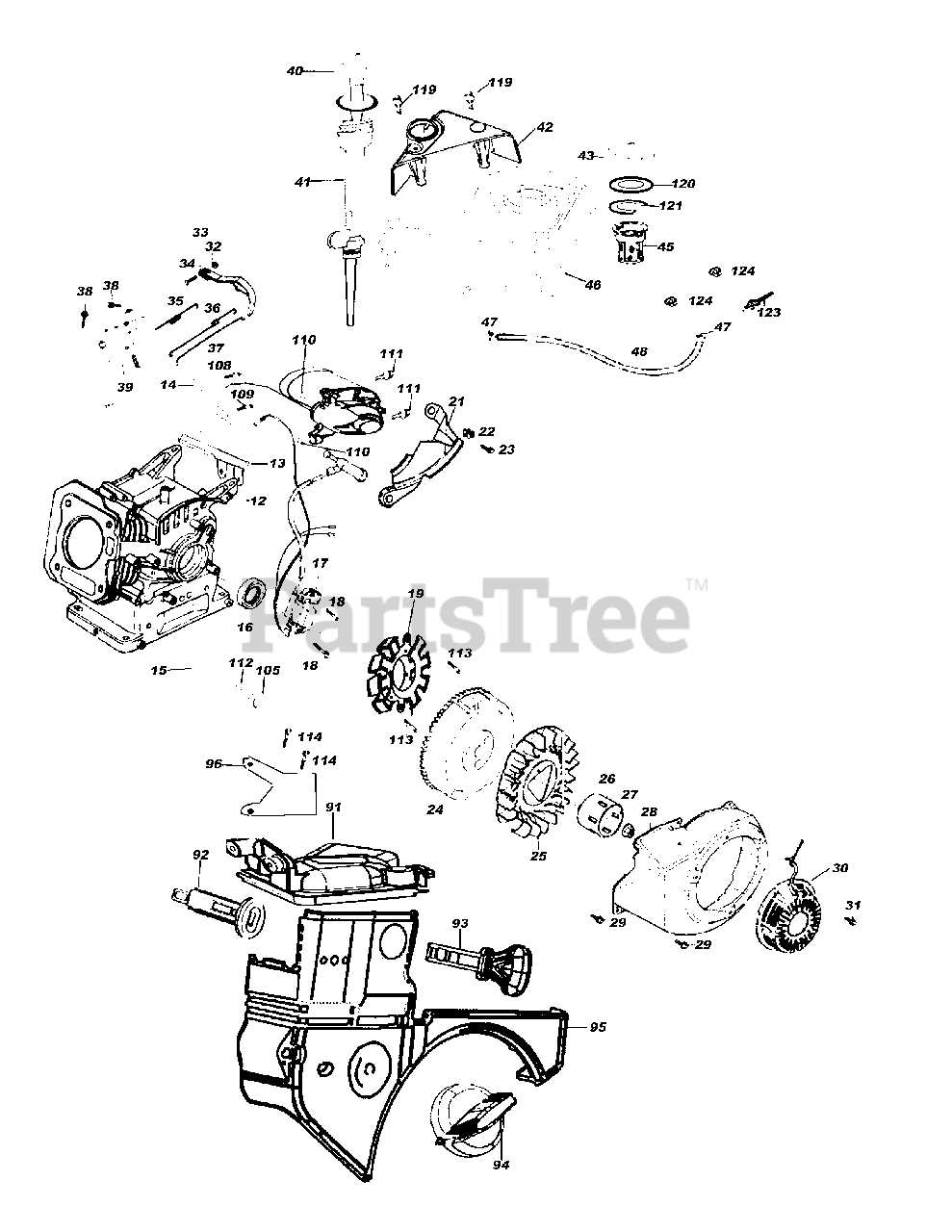

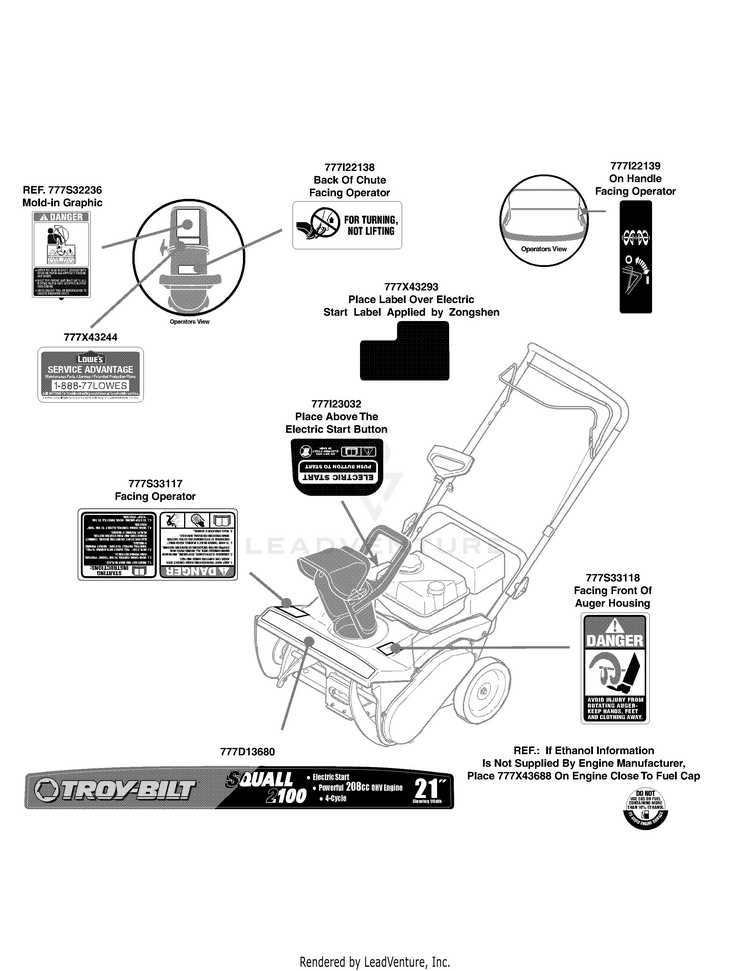

In this section, we will explore a comprehensive visual representation of a well-known model designed for snow removal. This illustration serves as a valuable resource, offering insights into the arrangement and relationship of different mechanisms within the equipment. By familiarizing oneself with these details, operators can ensure that their machine operates at peak efficiency throughout the chilly months.

Whether you are a seasoned professional or a novice user, grasping the intricacies of your equipment can lead to more informed decisions regarding maintenance and upgrades. Thus, investing time in understanding the inner workings will not only extend the lifespan of your device but also improve its overall functionality.

Understanding Snowblower Components

A thorough comprehension of the various elements of a snow-clearing machine is essential for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance, enhancing the user experience while facilitating efficient snow removal. Recognizing the functions and interconnections of these parts can greatly aid in troubleshooting and repairs.

Key components include the engine, which provides the necessary power, and the auger system that gathers and moves the snow. The chute directs the snow, allowing for controlled discharge in the desired location. Additionally, controls and handles ensure ease of maneuverability, while the framework supports the entire assembly. Familiarity with these elements empowers users to make informed decisions regarding repairs, replacements, and enhancements, ultimately leading to a more effective snow management process.

Overview of Troy Bilt Models

This section provides a comprehensive look at various models offered by the brand, highlighting their unique features and specifications. Understanding the different versions available is essential for users seeking optimal performance in winter conditions.

| Model Name | Engine Power | Clearing Width | Weight |

|---|---|---|---|

| Model A | 10 HP | 24 inches | 150 lbs |

| Model B | 12 HP | 30 inches | 170 lbs |

| Model C | 8 HP | 20 inches | 130 lbs |

| Model D | 11 HP | 28 inches | 160 lbs |

Common Parts of Snow Removal Equipment

Understanding the fundamental components of snow clearing machinery is essential for effective maintenance and operation. Each element plays a crucial role in ensuring optimal performance during winter conditions, enabling users to efficiently clear pathways and driveways.

Key elements often found in these machines include:

- Engine: The heart of the equipment, responsible for powering the entire system.

- Auger: A rotating mechanism that collects and propels snow away from the surface.

- Chassis: The framework that houses various components and provides stability during operation.

- Intake Shroud: The part that directs snow into the auger for efficient removal.

- Transmission: Transfers power from the engine to the wheels, enabling movement across various terrains.

Familiarity with these critical elements can enhance the user experience and prolong the lifespan of the equipment.

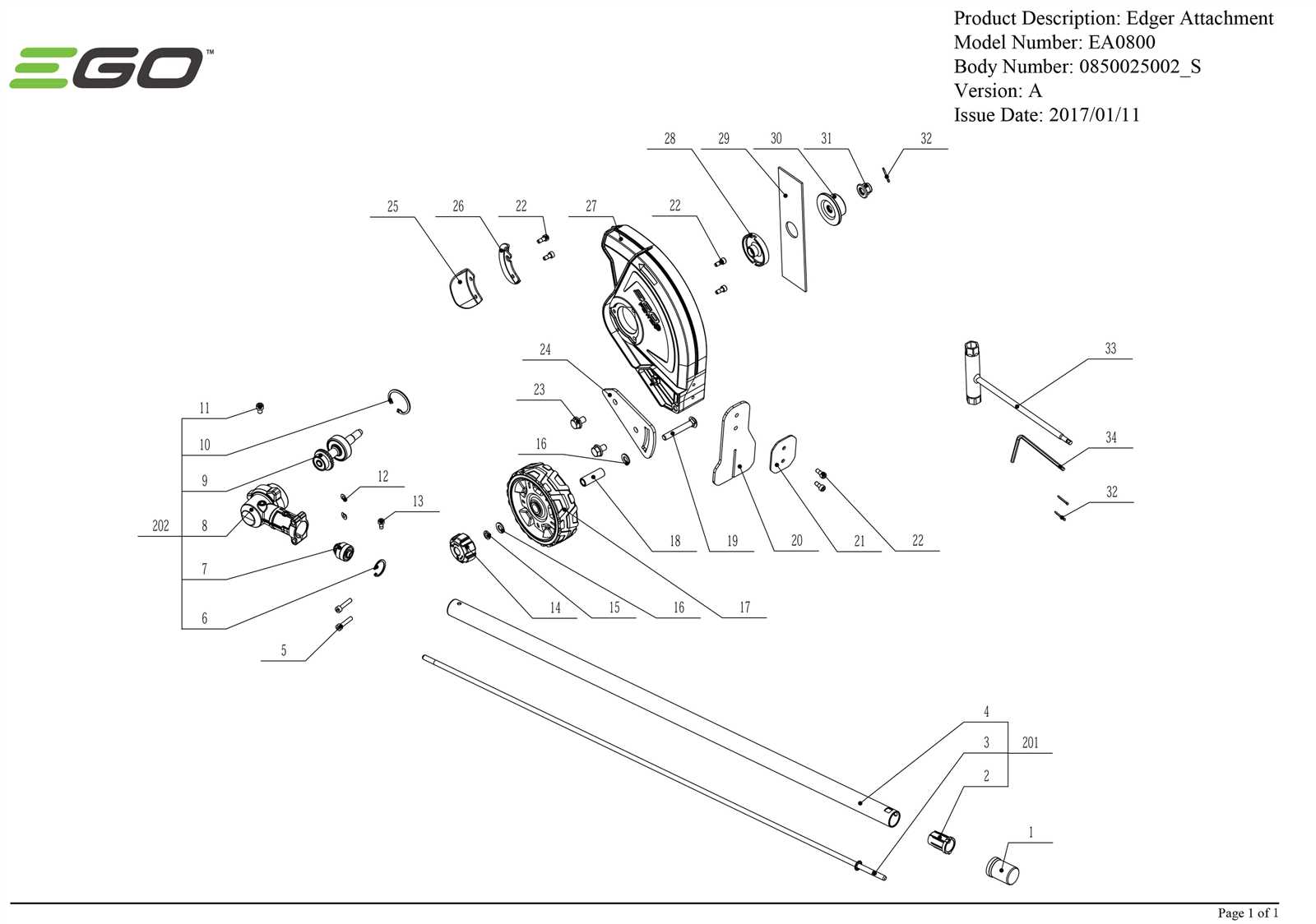

Identifying Replacement Components

Understanding the various elements of a snow clearing machine is essential for effective maintenance and repair. Recognizing the specific components that require replacement can enhance the machine’s performance and longevity. This section aims to guide users in pinpointing these crucial elements to facilitate efficient repairs.

Common Components to Monitor

Regular inspection of the machine should include an assessment of several key components. Notable items to check include the drive belt, which is vital for transmitting power, and the auger assembly, responsible for collecting and throwing snow. Additionally, the shear pins should be examined regularly, as they play a critical role in protecting the auger and gearbox from damage.

Resources for Component Identification

Utilizing online resources and user manuals can significantly aid in identifying necessary components. Various websites provide detailed breakdowns of machine components, helping users locate specific parts efficiently. Furthermore, consulting with local retailers or service centers can provide insights into compatible replacements and ensure proper installation.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor equipment requires regular care and attention. By following a few simple maintenance practices, you can extend the lifespan of your machinery and enhance its performance during use.

Regularly inspect the engine components for any signs of wear or damage. Replace filters and fluids according to the manufacturer’s recommendations to keep the engine running smoothly. Lubricating moving parts is essential to prevent friction and reduce wear over time.

Additionally, cleaning the exterior and removing debris can help maintain optimal airflow and prevent overheating. Store your equipment in a dry and sheltered area to protect it from harsh weather conditions when not in use. These proactive steps will ensure your equipment remains reliable for many seasons to come.

How to Access the Parts Diagram

Gaining access to the schematic representation of components is essential for effective maintenance and repair. This guide will provide you with the necessary steps to locate and utilize these visual aids efficiently.

First, ensure that you have the correct model number of your equipment. This information is crucial as it allows you to find the specific illustration that corresponds to your device. Once you have this, visit the manufacturer’s official website or authorized dealer platform. These sites often have a dedicated section for user manuals and visual references.

After locating the appropriate webpage, navigate to the section where diagrams are available. You may need to enter your model number in a search bar or select it from a list. Once found, you can view or download the schematic for your reference.

Tip: Consider printing the diagram for easy access during maintenance tasks. This way, you can have a physical copy on hand to refer to as you work on your equipment.

Order and Installation Procedures

Ensuring the proper acquisition and setup of components is crucial for maintaining the functionality of your equipment. This section provides a comprehensive overview of the necessary steps for ordering and installing essential elements effectively.

Follow these outlined procedures to streamline the process:

| Step | Description |

|---|---|

| 1 | Identify the required components based on your equipment’s specifications. |

| 2 | Visit authorized retailers or online platforms to place your order. |

| 3 | Receive the items and inspect them for any damage or discrepancies. |

| 4 | Gather the necessary tools and prepare your workspace for installation. |

| 5 | Follow the installation instructions meticulously to ensure proper assembly. |

| 6 | Test the equipment to confirm that all components are functioning correctly. |

Troubleshooting Common Issues

Addressing frequent challenges is essential for maintaining optimal functionality of your equipment. This section outlines typical problems that users may encounter and provides guidance on identifying and resolving these issues effectively.

Performance Problems

Inadequate performance can arise from various factors. Insufficient power may be linked to fuel supply, while a clogged intake can hinder airflow, reducing efficiency. Regularly checking the fuel levels and cleaning the intake area can significantly improve performance.

Operational Difficulties

When the machine fails to start or operate smoothly, it is crucial to inspect the ignition system and battery condition. Corroded connections may impede functionality, while ensuring that all components are properly assembled can prevent operational setbacks. Routine maintenance checks can help in preempting these issues.

Resources for Snowblower Owners

Maintaining a winter machine can be daunting, especially when it comes to finding reliable information and components. Owners can benefit from a variety of sources that provide assistance, tips, and essential information for ensuring their equipment operates smoothly throughout the snowy season.

Online Communities

Joining forums and social media groups can be incredibly beneficial. These platforms allow owners to share experiences, ask questions, and receive advice from fellow users. Popular online communities include:

- Facebook groups dedicated to winter equipment

- Reddit forums focused on maintenance tips

- Manufacturer-specific discussion boards

Instructional Videos

Visual learners can take advantage of numerous video tutorials available online. These resources often cover a range of topics, including maintenance procedures and troubleshooting techniques. Key platforms include:

- YouTube channels featuring expert advice

- Manufacturer websites with instructional content

- DIY home improvement sites